Water stimulation response rubber composite material and preparation method thereof

A stimuli-responsive, composite material technology, applied in the field of water stimuli-responsive rubber composites and their preparation, can solve problems such as temperature tolerance of human body, achieve good shape memory fixation and shape recovery performance, short process flow, and improve utilization value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

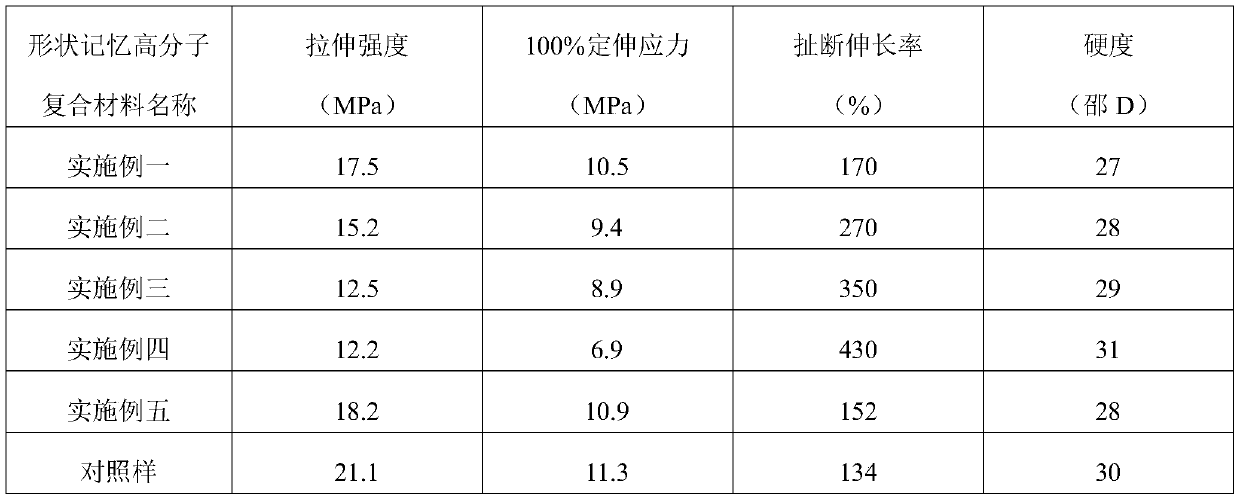

Examples

preparation example Construction

[0026] A kind of preparation method of water stimulus response rubber composite material of the present invention comprises the following steps:

[0027] Mixing process, in the double-roller mill, adjust the roll temperature to 60-80°C, add nitrile rubber and polyethylene oxide, and cover the rolls; after it is completely covered with rolls, add vulcanizing agent and processing aids , left and right thin pass 3-5 times; adjust the roller distance to 1-3mm, and then unload; park for 18-24h, re-smelting, thin pass 3-5 times; adjust the roller distance to 1-3mm, and unload;

[0028] Vulcanization process, the vulcanization temperature is 150-160°C, and the vulcanization time is 5-10min to obtain rubber composite materials.

[0029] Specifically, the vulcanization process is carried out in a high-temperature flat vulcanizer.

[0030] Further, in the mixing process, the wrapping time is 4-10 minutes.

[0031] Preferably, the re-milling temperature in the mixing process is 60-80°C...

Embodiment 1

[0033] A kind of preparation method of water stimulus response rubber composite material of the present invention comprises the following steps:

[0034]1) Weigh the following raw materials in parts by weight in turn: 30 parts of nitrile rubber, 70 parts of polyethylene oxide, 0.8 part of vulcanizing agent DCP, 1 part of processing aid, including 0.3 part of zinc oxide, 0.2 part of antioxidant MB part and 0.5 part of stearic acid;

[0035] 2) Mixing process, in the double-roll mill, adjust the roll temperature to 60°C, add nitrile rubber and polyethylene oxide, and cover the rolls; after it is completely covered with rolls, add vulcanizing agent and processing aids , left and right thin passes 3 times; adjust the roller distance to 1mm, and then unload; park for 18h, re-smelt, thin pass 5 times; adjust the roller distance to 1mm, and unload;

[0036] 3) Vulcanization process, in a high-temperature plate vulcanizer, with a vulcanization temperature of 150°C and a vulcanization...

Embodiment 2

[0038] A kind of preparation method of water stimulus response rubber composite material of the present invention comprises the following steps:

[0039] 1) Weigh the following raw materials in parts by weight in turn: 60 parts of nitrile rubber, 40 parts of polyethylene oxide, and 1.6 parts of vulcanizing agent DCP;

[0040] 2) Mixing process, in the double-roller mill, adjust the roller temperature to 80°C, add nitrile rubber and polyethylene oxide, and cover the rolls; 5 times; adjust the roller distance to 3mm, and then unload; park for 24 hours, re-smelt, thin pass 3 times; adjust the roller distance to 3mm, and unload;

[0041] 3) Vulcanization process, in a high-temperature plate vulcanizer, the vulcanization temperature is 160° C., and the vulcanization time is 5 minutes to obtain rubber composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| 100% modulus stress | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com