Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

a technology of memory polymers and thermoplastic polyurethanes, applied in the field of shape memory polymers, can solve the problems of limiting the types of processing possible, and achieve the effects of excellent shape recovery effect, sharp and tunable transition temperatures, and above the melting point of poss domains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

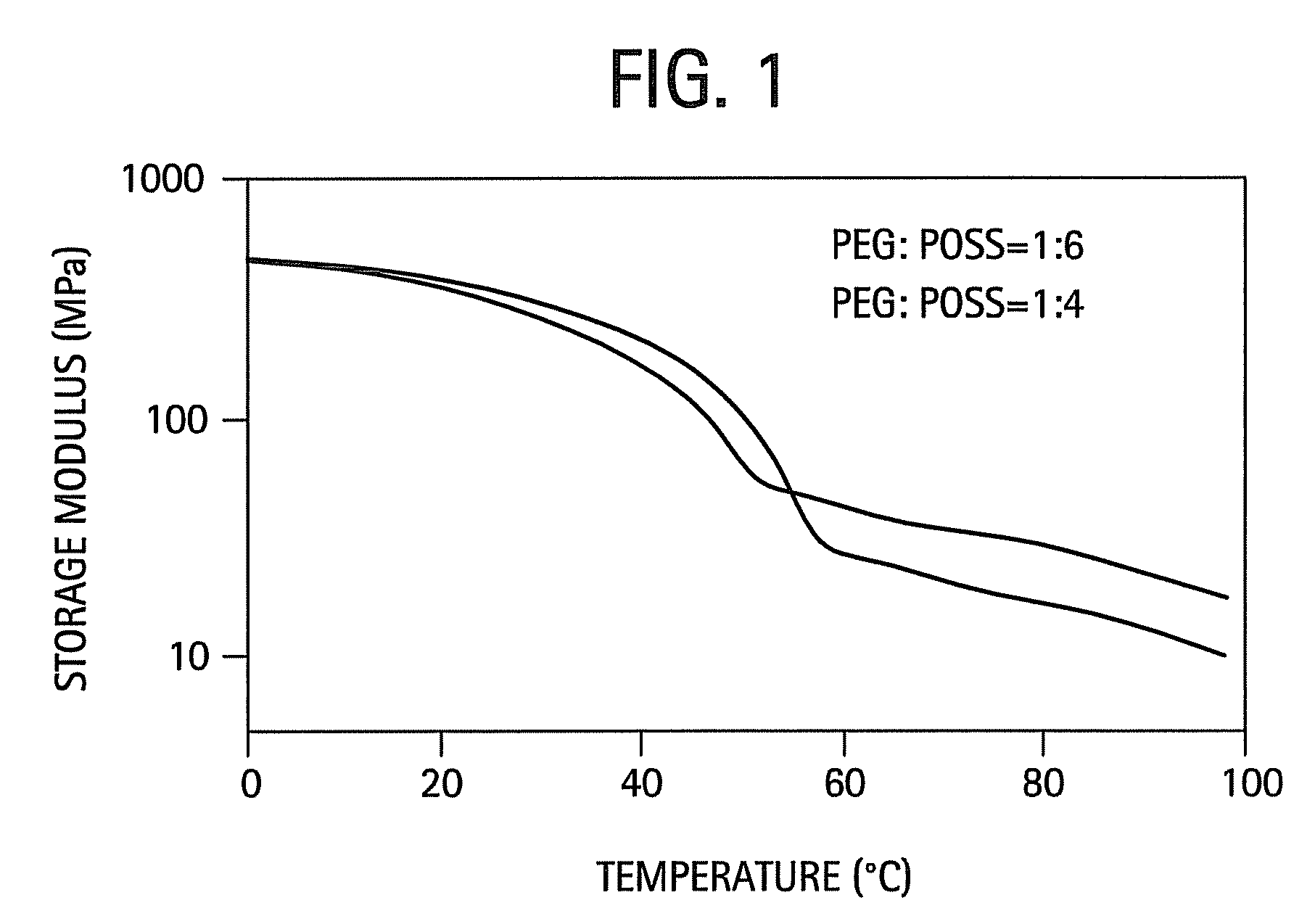

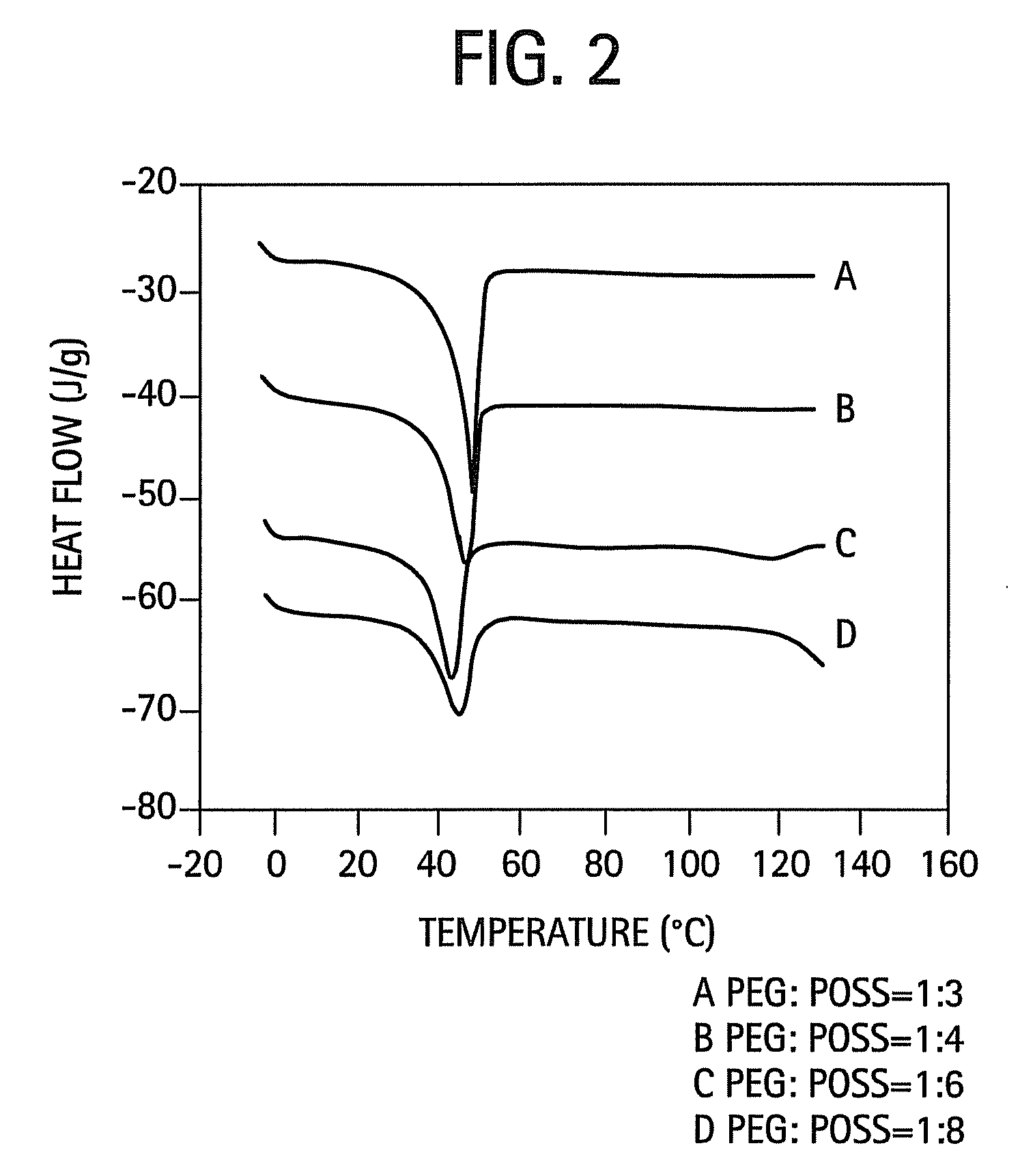

[0041]Thermoplastic polyurethanes with different compositions were synthesized by one-step condensation polymerization using scheme 1 shown above ((A) PEG as the polyol, (B) transcyclohexanediolisobutyl-polyhedral oligosilsesquioxane diol and (C) MDI as the diisocyanate. Toluene was used as solvent and dibutyltin dilaurate was used as catalyst. The reaction was kept at 90° C. under the nitrogen for 2 hours and then cooled down to room temperature and precipitated into hexane. The product was dried thoroughly and dissolved in toluene to make a 10 wt % solution for casting films. The molecular weights and molecular weight distributions of this series of samples obtained from size exclusion chromatography are summarized in Table 1.

TABLE 1Molecular weights and molecular weight distributionsof POSS-based polyurethanes having polyol (PEG)block length of 10000 g / molSampleMn (g / mol)Mw / MnPEG:POSS =47,4001.421:3PEG:POSS =48,8001.441:4PEG:POSS =54,0001.541:6PEG:POSS =49,2001.301:8

[0042]Samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| room temperature | aaaaa | aaaaa |

| cooling rates | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com