Preparation method of shape memory polyurethane coating solution

A polyurethane coating and polyurethane technology, applied in the field of polyurethane coating preparation, can solve problems such as wrinkles and wear, and achieve the effects of large adjustability, thin coating and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

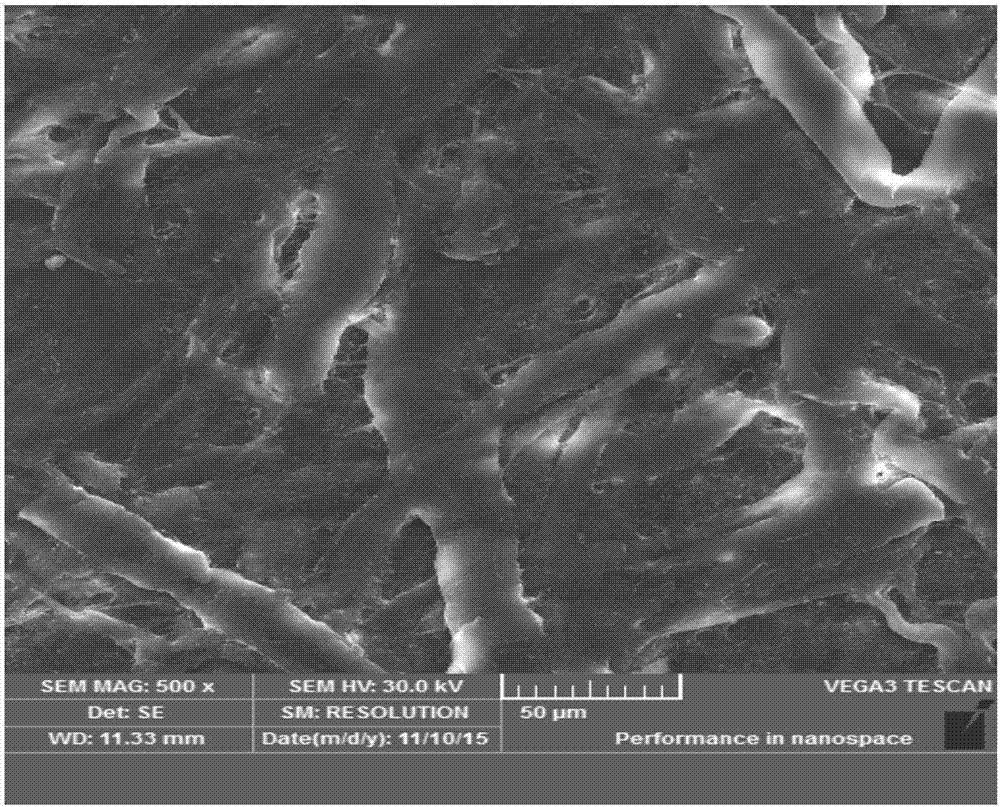

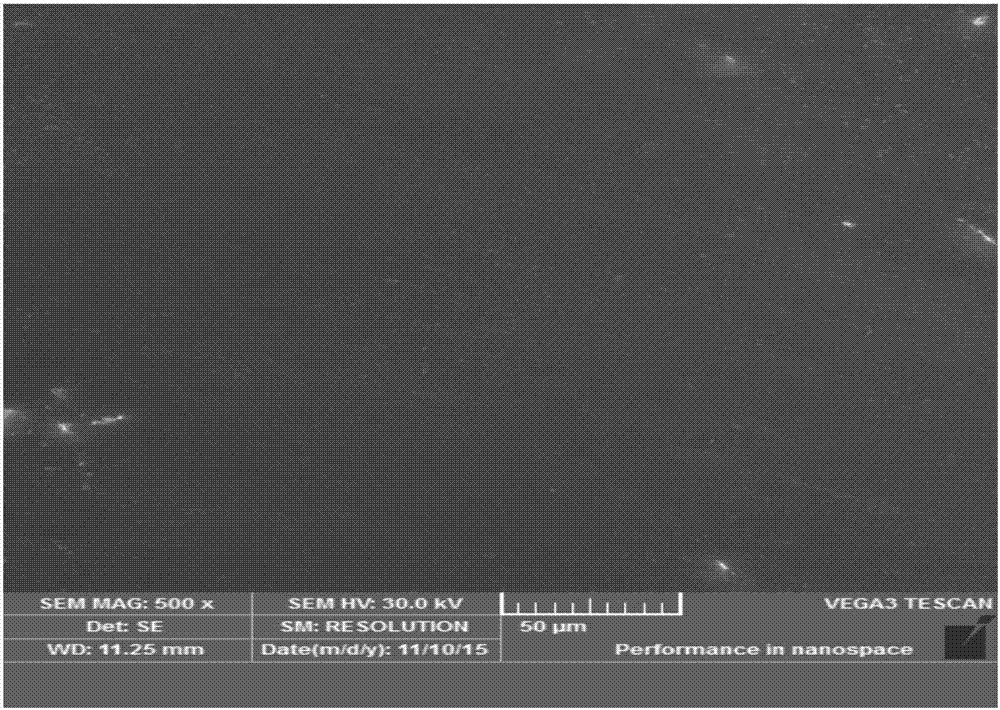

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the preparation method of the shape-memory polyurethane coating solution of this embodiment is implemented according to the following steps:

[0026] 1. Use DMF (N,N-dimethylformamide) Molecular sieves are dried to obtain dry DMF, and liquid PCL (polycaprolactone) is placed in a reaction vessel for vacuum dehydration, and then dry DMF and MDI (diphenylmethane diisocyanate) are added under the condition of argon protection, at 70 Stir and react at ~80°C for 1.5 to 2.5 hours to obtain a prepolymer;

[0027] 2. Add 1,4-BDO (1,4-butanediol) and dry DMF to the prepolymer obtained in step 1, and carry out chain extension reaction at a temperature of 70-80°C to obtain a compound with a solid content of 13 %~18% linear SMPU solution (linear shape memory polyurethane);

[0028] 3. Apply the linear SMPU solution evenly on a glass plate, place it in an oven at 70-100°C for 12-15 hours, and then place it at room temperature for 22-26 hours to obtain shap...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the liquid PCL described in step 1 is obtained by heating and melting solid PCL in a drying oven. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, liquid PCL (polycaprolactone) is placed in a reaction vessel and dehydrated in a vacuum for 1 hour in a water bath at 120° C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com