Poly (p-dioxanone)/polytetrahydrofuran multi-block copolyether ester with shape memory function and preparation method thereof

A technology of polydioxanone and polytetrahydrofuran, which is applied in the field of polydioxanone/polytetrahydrofuran multi-block copolyether ester and its preparation, can solve the problem of non-degradable hard segments, low material toughness, Short chain segments, etc., to achieve good mechanical processing strength, reduce production costs, and broaden the application field

Active Publication Date: 2010-09-01

SICHUAN UNIV

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Jing Xiabin, Chen Xuesi et al. W.S.Wang, X.S.Chen, X.B.Jing, Poly(ε-caprolatone)polyurethane and its shape-memory property, Biomacromolecules 2005, 6, 587-592.W.S.Wang, P.Ping, X.S.Chen, X.B.Jing, Shape memory effect of poly( L-lactide)-based polyurethanes with differenthard segments, Polym.Int.2007, 56, 840-846.) respectively with aliphatic polyester polylactic acid (PLA), polycaprolactone (PCL) or both copolymer PCLA It is a reversible phase, and the physical crosslinking structure formed by the carbamate obtained by the reaction of diisocyanate with 1,4-butanediol or ethylene glycol is a stationary phase (hard segment), and a shape memory material is obtained. g Adjustable in the range of 33-52.5°C, deformation fixation rate (R f ) is 96-99%, the deformation recovery rate (R r ) can reach 92-100%, although the above-mentioned copolymer has good shape fixation rate and shape recovery rate and realizes that the temperature can be adjusted within a certain range, but because its hard segment is not degradable, when the content is low, the chain segment is relatively low. Short, unable to form a stable physical cross-linked structure, thus affecting the shape memory performance, while higher content can meet the requirements of shape memory performance, but can not achieve the purpose of degradation, and the toughness of the material is not high, which greatly limits the Its scope of application

Obviously, it is difficult for this technology to meet the requirements of shape memory, controllable thermal transition temperature, controllable molecular weight, and biodegradability at the same time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

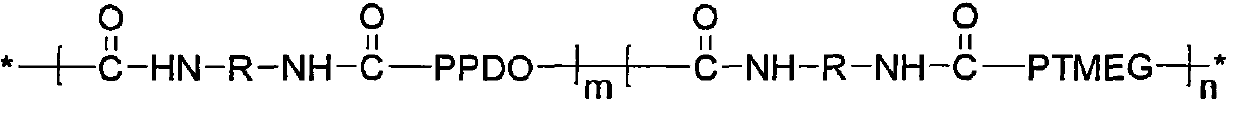

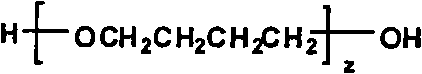

The invention discloses poly (p-dioxanone) / polytetrahydrofuran multi-block copolyether ester with shape memory function. The repetitive structure of the copolyether ester is shown in the specification, the intrinsic viscosity is 0.54-3.5dl / g, the shape fixed rate Rf is 82.6-100% and the shape recovery rate Rr is 84.9-100%. The invention also discloses a preparation method of the multi-block copolyether ester. The multi-block copolyether ester provided by the invention simultaneously has the advantages of shape memory function, controlled thermal transition temperature, controlled molecular weight, biodegradability, etc and has wide application prospect. The preparation method provided by the invention is simple, convenient and mature and has easily controlled process.

Description

technical field The invention belongs to the technical field of preparation of multi-block copolyether esters with shape memory function. Specifically, the present invention relates to a polydioxanone / polytetrahydrofuran multi-block copolyether ester with a shape memory function and a preparation method thereof. The copolyether ester can be used as a medical material, a degradation material, a packaging material with a memory function materials etc. Background technique Shape memory polymer material (Shape Memory Polymer, SMP), as a new type of intelligent material, has attracted worldwide attention due to its unique properties since the 1960s, and related research has also developed rapidly. Shape memory refers to the phenomenon that a product with an initial shape can be restored to its original shape after being deformed and fixed by external stimulus means such as heating. Shape memory polymer materials can be divided into thermal induction type, electric induction ty...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G18/48C08G18/42

Inventor 杨科珂张静静邱志成王玉忠汪秀丽陈思翀

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com