Patents

Literature

79results about How to "Large temperature adjustment range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

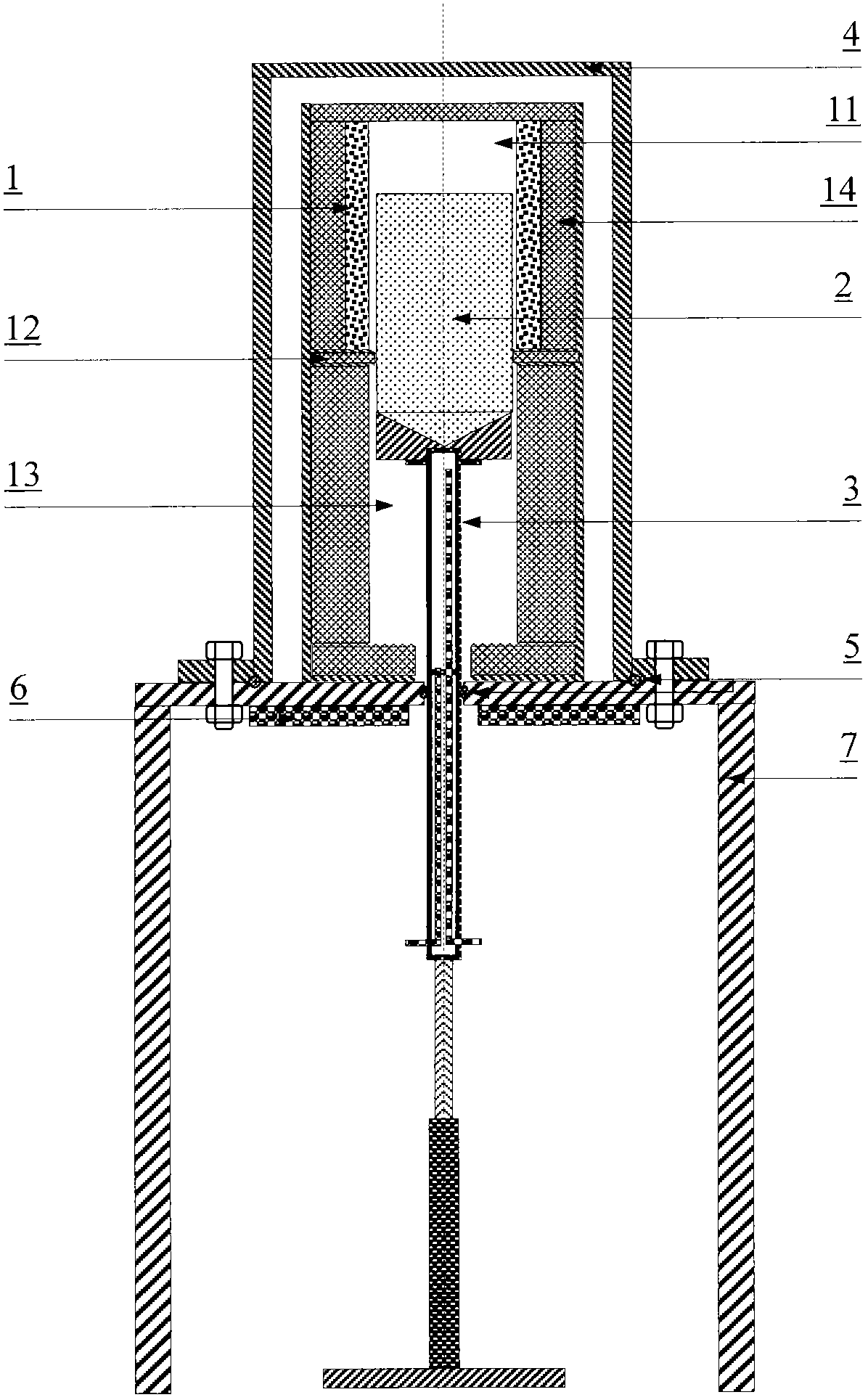

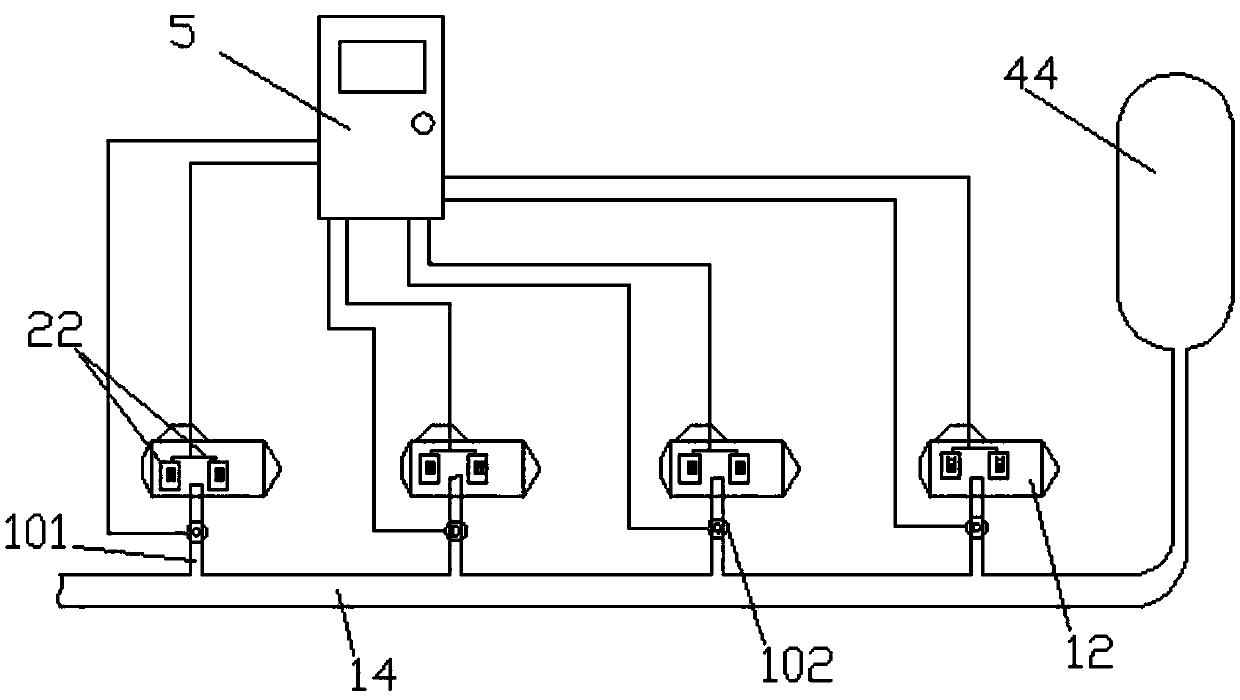

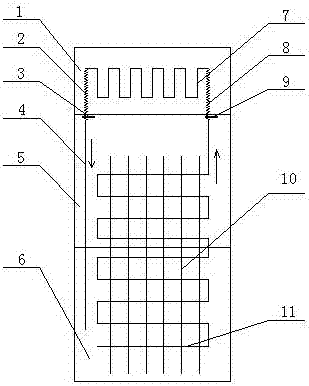

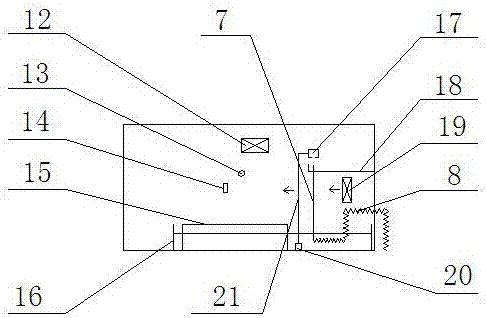

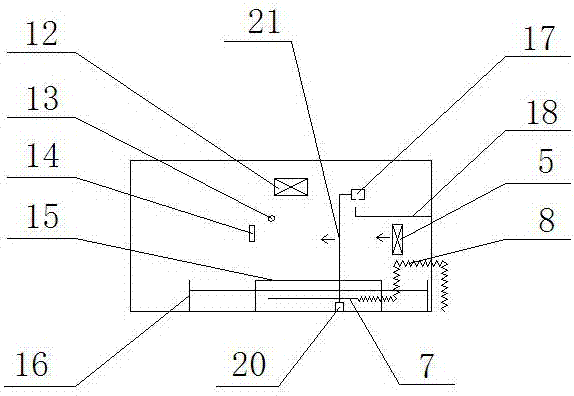

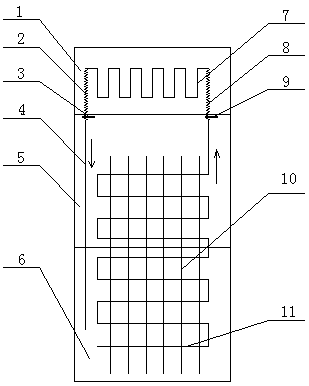

Low-temperature keep-alive transporter for freshwater fishes

ActiveCN102812918ALarge temperature adjustment rangeRealize low temperature preservation transportationPisciculture and aquariaFresh water organismEngineering

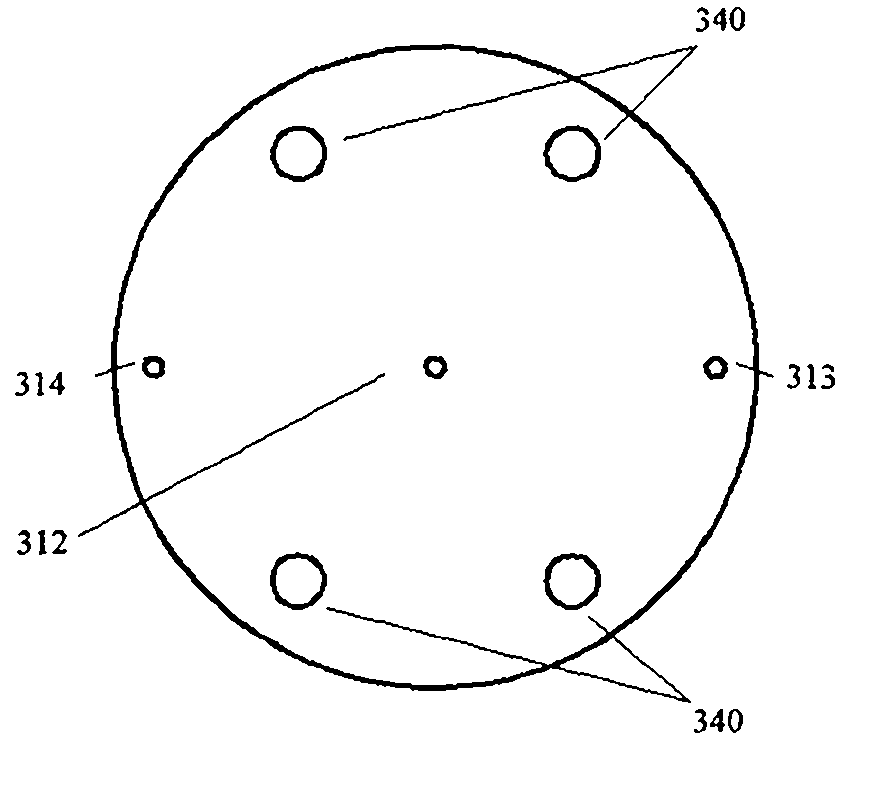

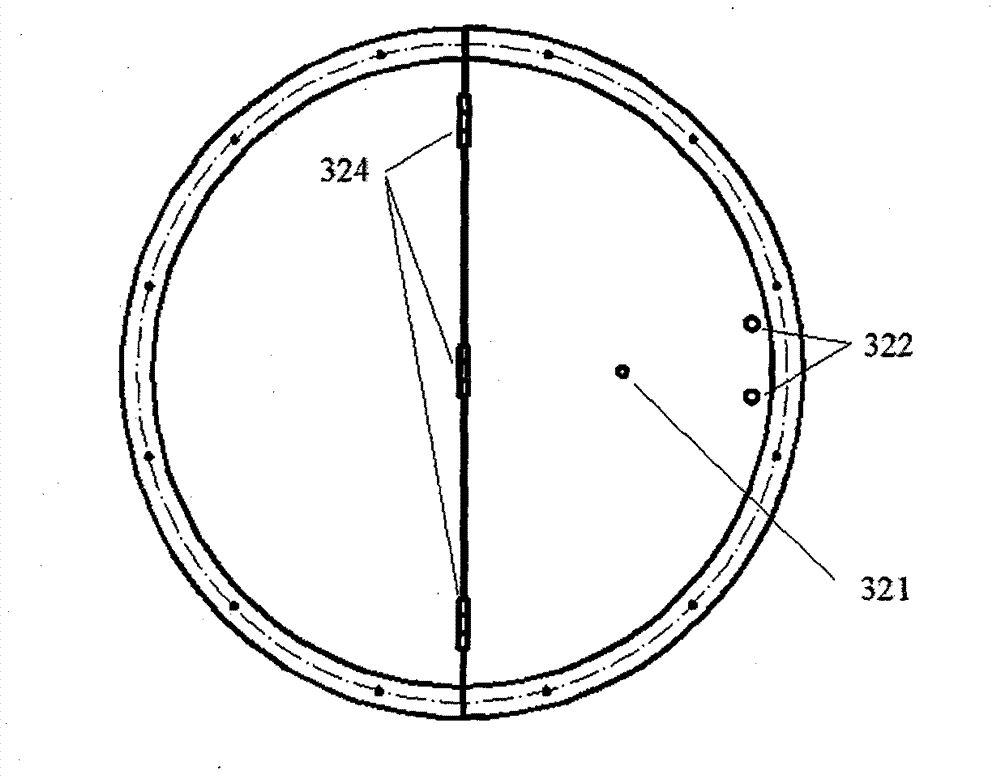

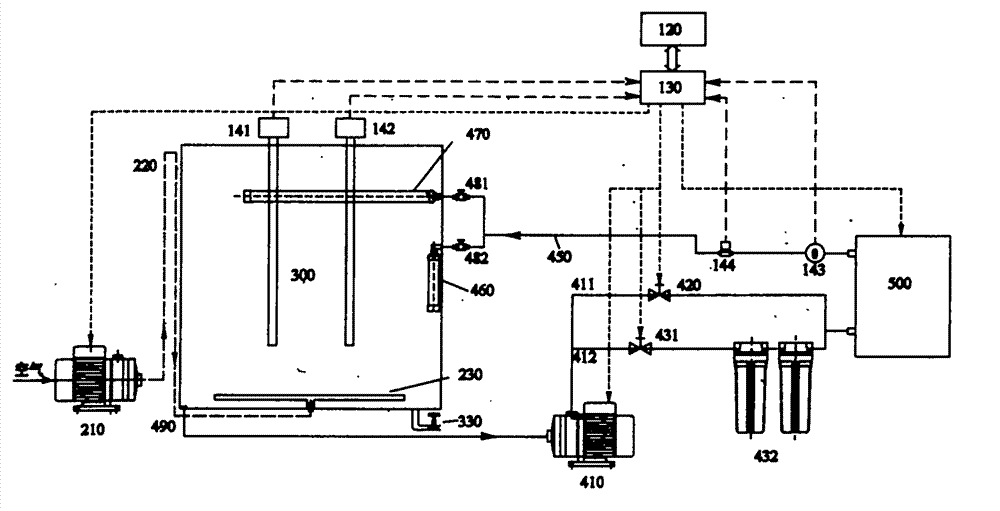

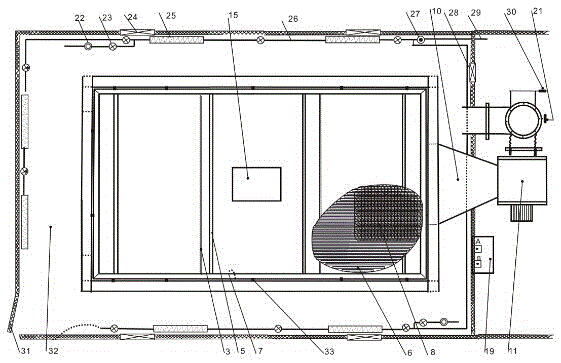

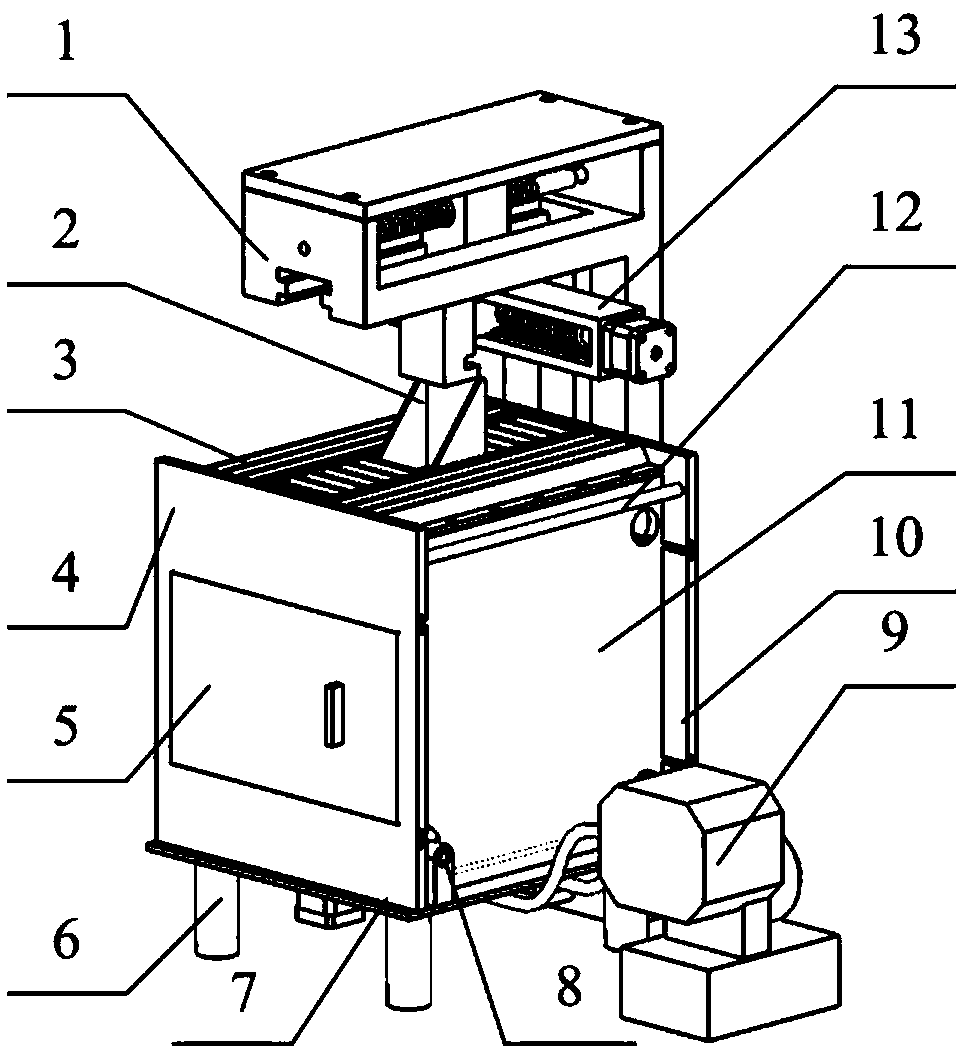

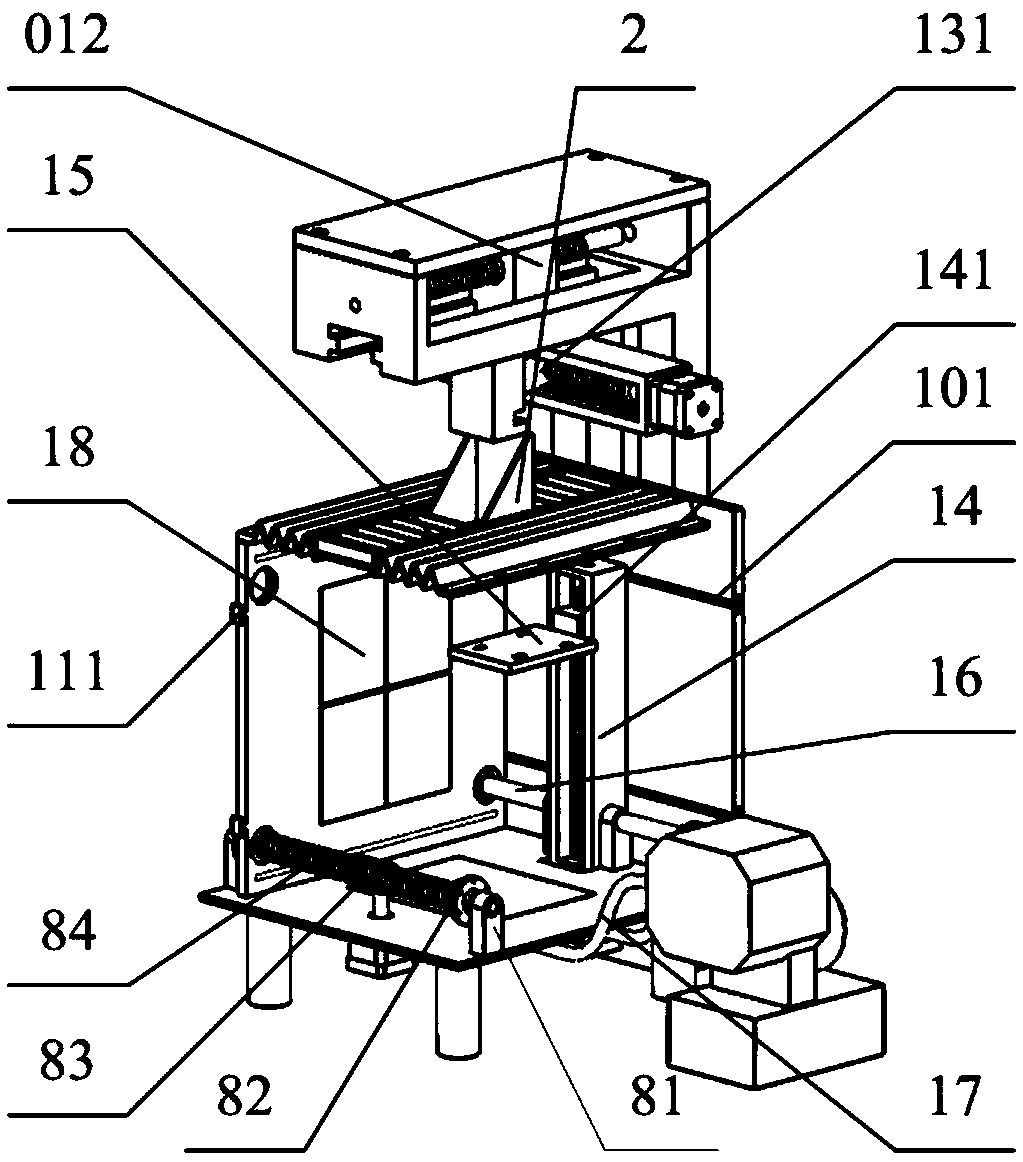

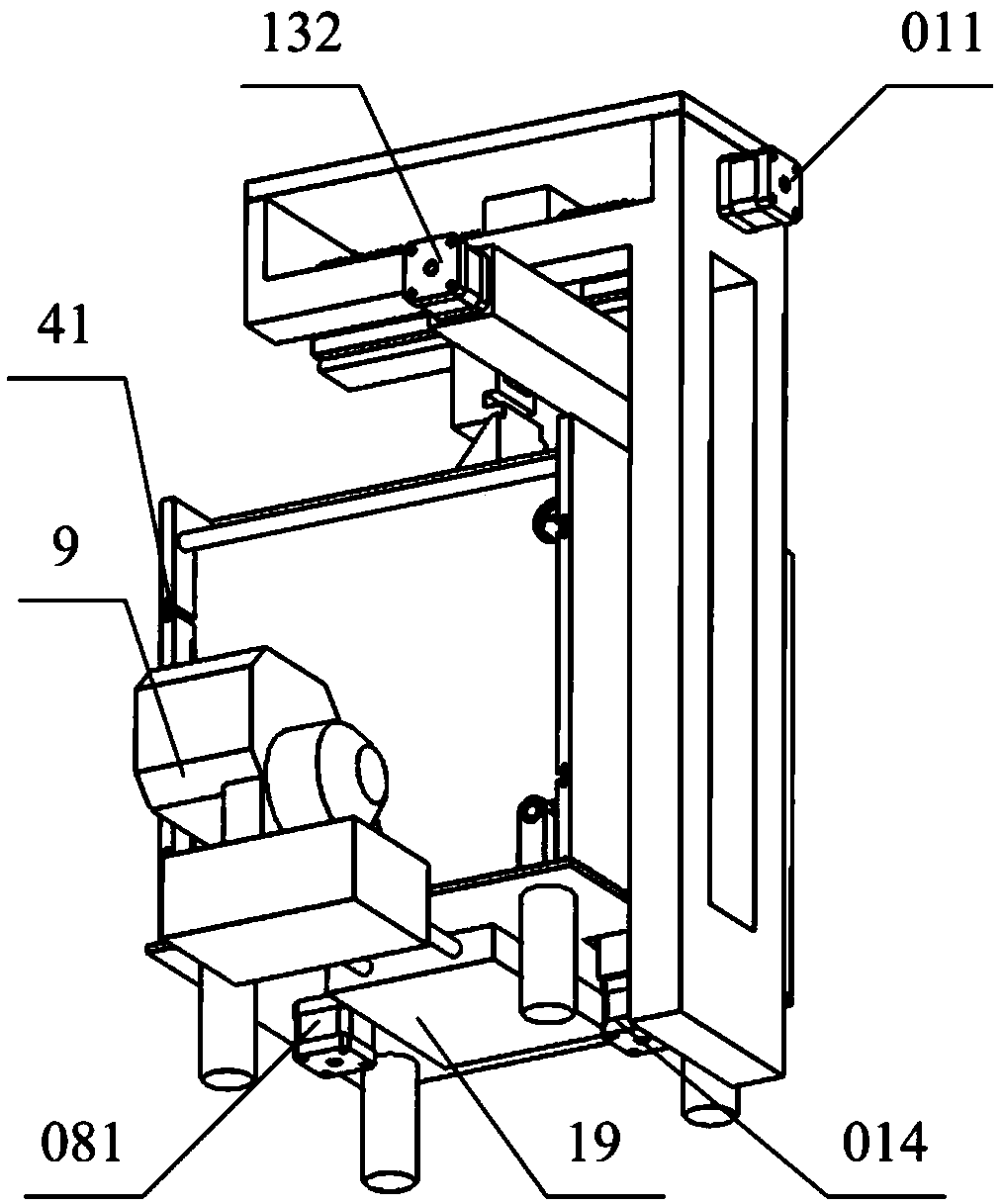

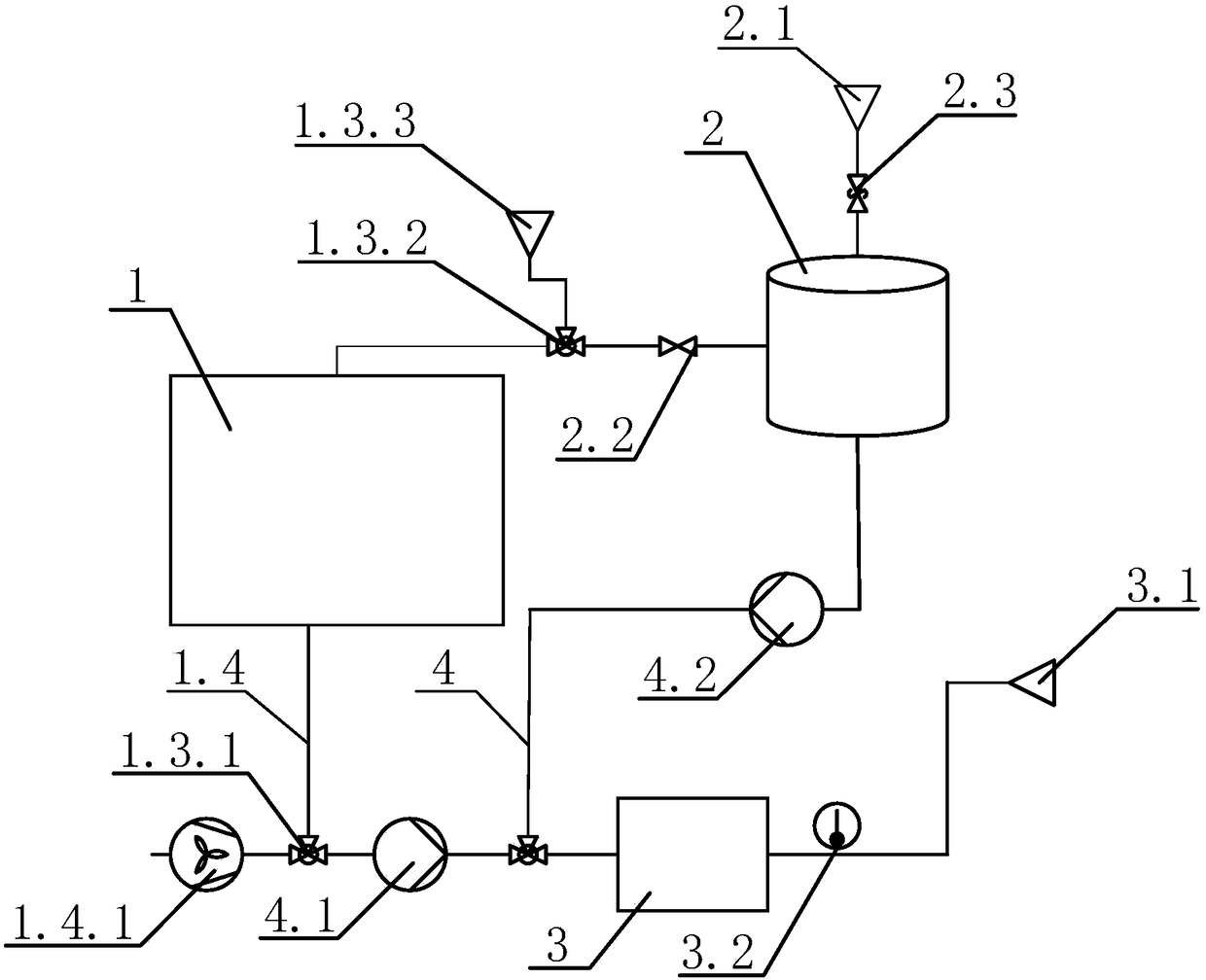

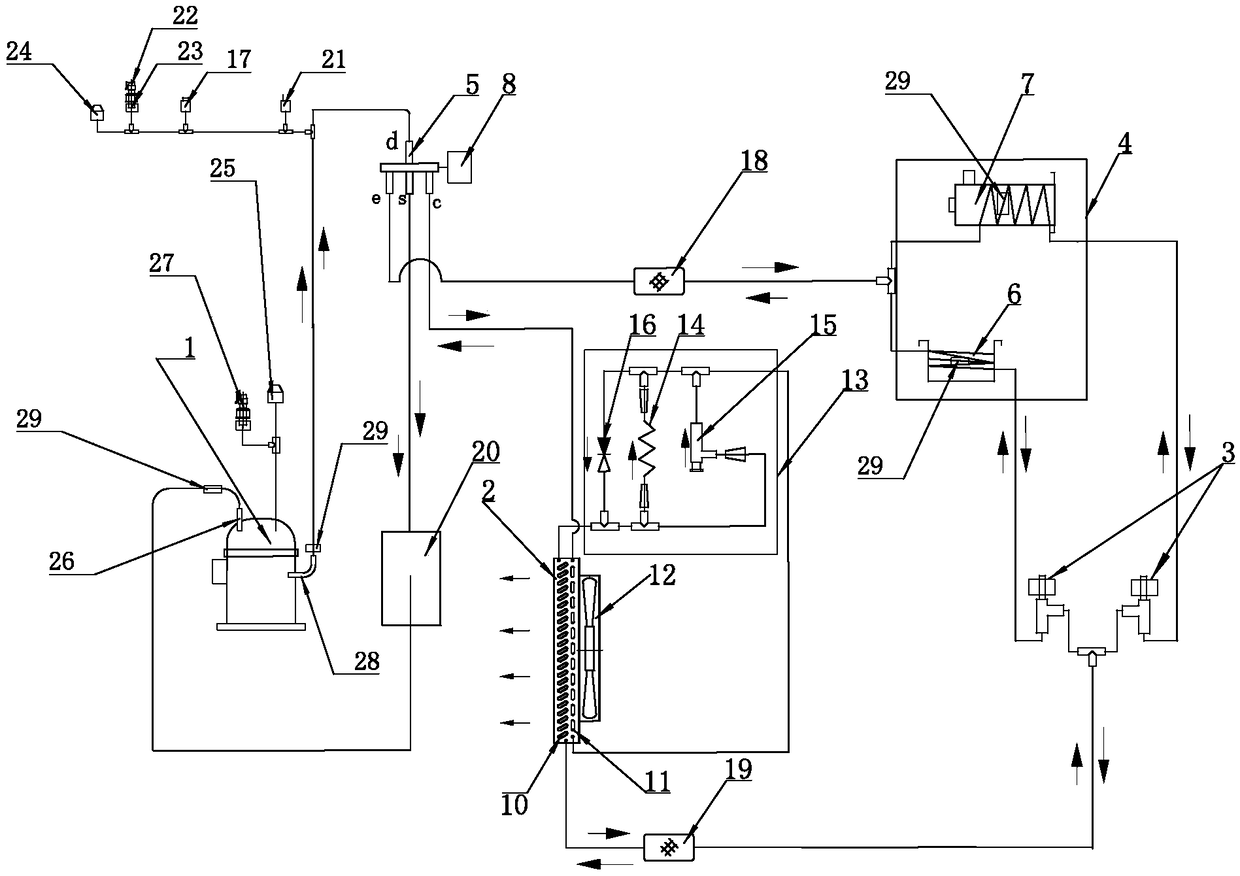

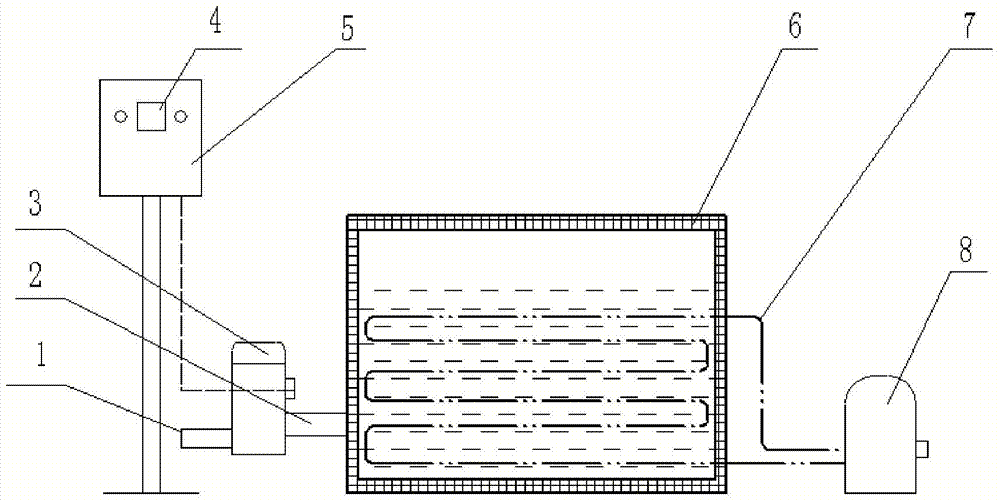

The invention particularly relates to a low-temperature keep-alive transporter for freshwater fishes. The low-temperature keep-alive transporter for freshwater fishes comprises a PLC (programmable logic controller) control system (100), an aeration system (200), a fish box (300), a water circulation system (400), a filter system (430) and a water heating-cooling unit (500). The low-temperature keep-alive transporter for freshwater fishes is capable of automatically monitoring pH, dissolved oxygen and temperature of the water in the live fish transport box and storing and recording the data in the transport process, such as the pH, the dissolved oxygen and the temperature. The low-temperature keep-alive transporter for freshwater fishes is simple and convenient to operate. An operator can click on a touch screen to achieve the whole control process. The low-temperature keep-alive transporter for freshwater fishes can be used for low-temperature keep-alive transport and controlled freezing-point transport. No water needs to be added during the whole transport process. The biological water standard required by the high-density transport of live aquatic products can be guaranteed by the aid of the water circulation and the filter system of the transporter.

Owner:HUAZHONG AGRI UNIV

Shape memory fiber prepared with shape memory polyurethane and its prepn process

InactiveCN1706997AGood shape recoveryLarge temperature adjustment rangeMonocomponent synthetic polymer artificial filamentNatural fiberMelt spinning

The present invention relates to one kind of shape memory fiber prepared with shape memory polyurethane and its preparation process. The shape memory polyurethane is prepared with material including one hydroxyl containing polymer, chain expander, diisocyanate and blocking agent in the molar ratio of 1 to 1-3 to 2.4-4.8 to 0.8-1.6. The preparation process of the shape memory fiber includes the following steps: preparing shape memory polyurethane with excessive isocyanate; adding blocking agent to obtain blocked shape memory polyurethane; and melt spinning to obtain shape memory fiber. The shape memory fiber of the present invention has very wide temperature regulating range, practical elasticity, strength and shape memory performance and comfortable hand feeling, is easy to spin alone or together with synthetic fiber and natural fiber, and may find wide application in clothing, biomedical material and other fields.

Owner:THE HONG KONG POLYTECHNIC UNIV

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

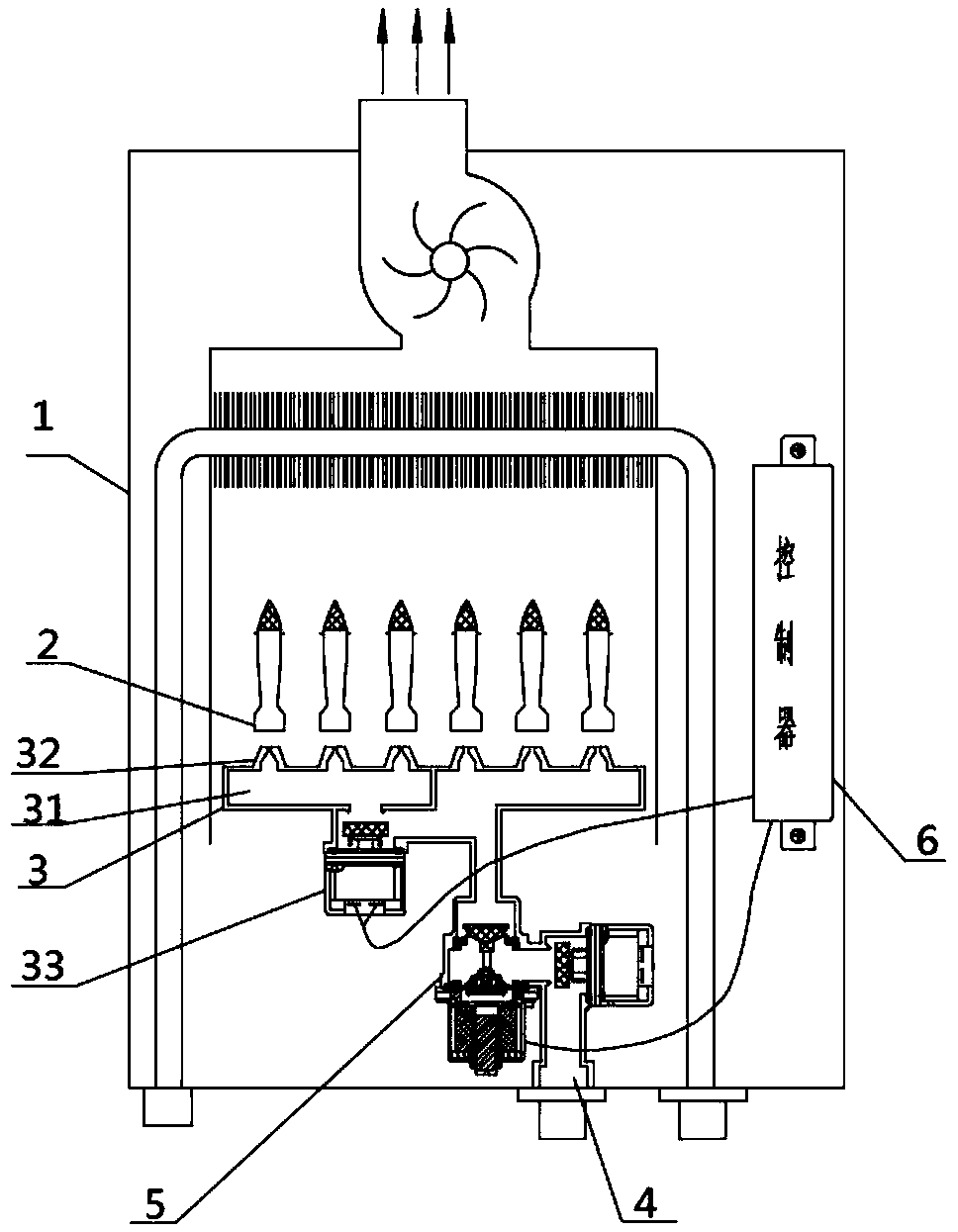

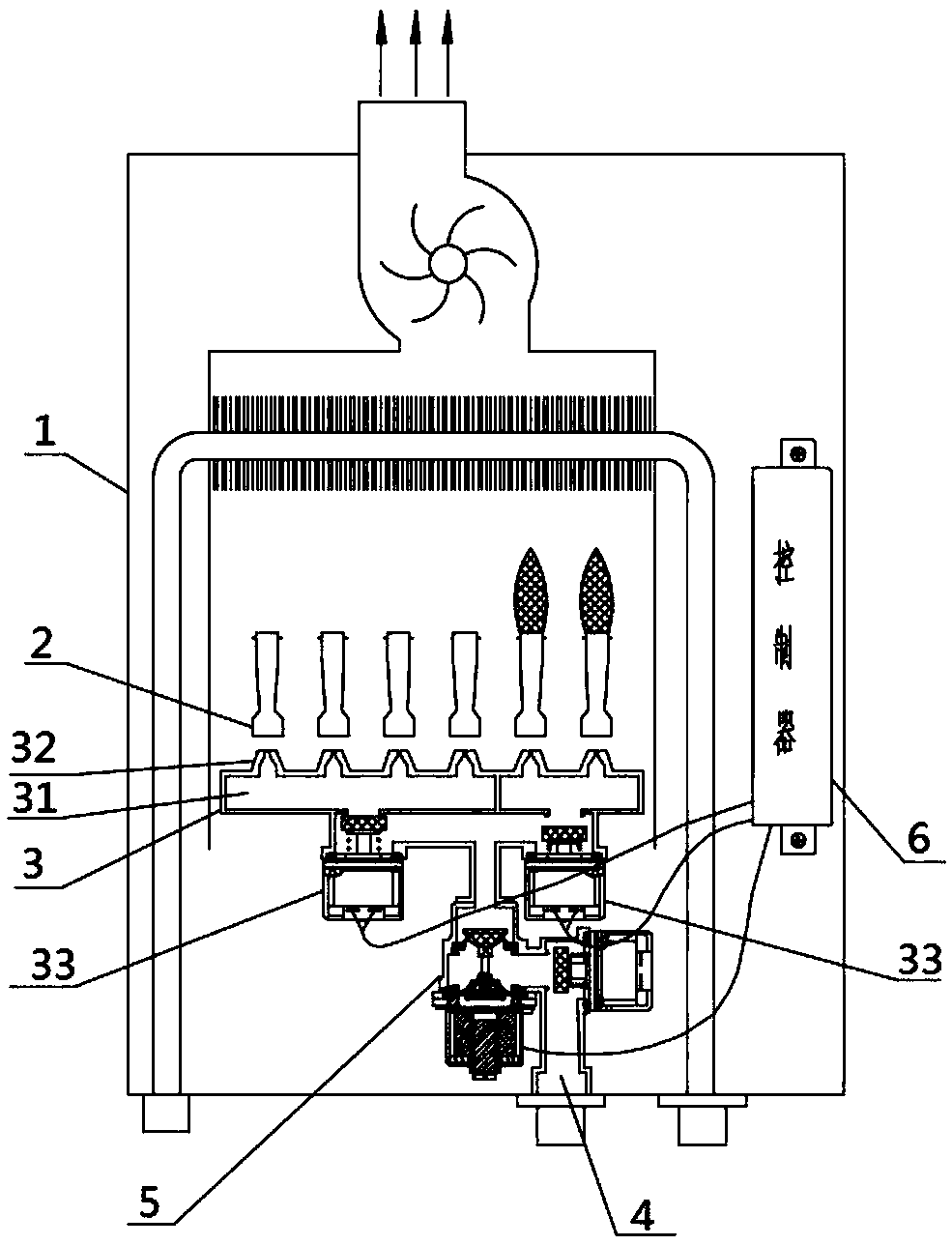

Gas water heater for segmented combustion and control method thereof

ActiveCN110207386AReduce cut-off pressureImprove versatilityFluid heatersEngineeringLoad following power plant

The invention discloses a gas water heater for segmented combustion and a control method thereof. The gas water heater comprises a gas water heater main body, a combustor, a segmentation valve, a gaschannel, a gas proportional valve and a controller; the combustor, the segmentation valve, the gas channel and the controller are all arranged in the gas water heater main body; the gas proportional valve is arranged on the gas channel; the controller is electrically connected with the segmentation valve and the gas proportional valve, and is used for switching fire levels of the gas water heaterand adjusting current sections of the gas proportional valve in any fire level; the switching of the fire levels is realized through the switching control of the segmentation valve by the controller,and a current linkage control mode is adopted to limit different fire levels in different current sections of the gas proportional valve, so that the heat load overlap section between the low fire level and the high fire level is widened; the disconnecting pressure of the water heater can be effectively reduced; and constant-temperature hot water still can be output when the gas supply pressure isinsufficient, so that the bath feeling is improved.

Owner:VATTI CORP LTD

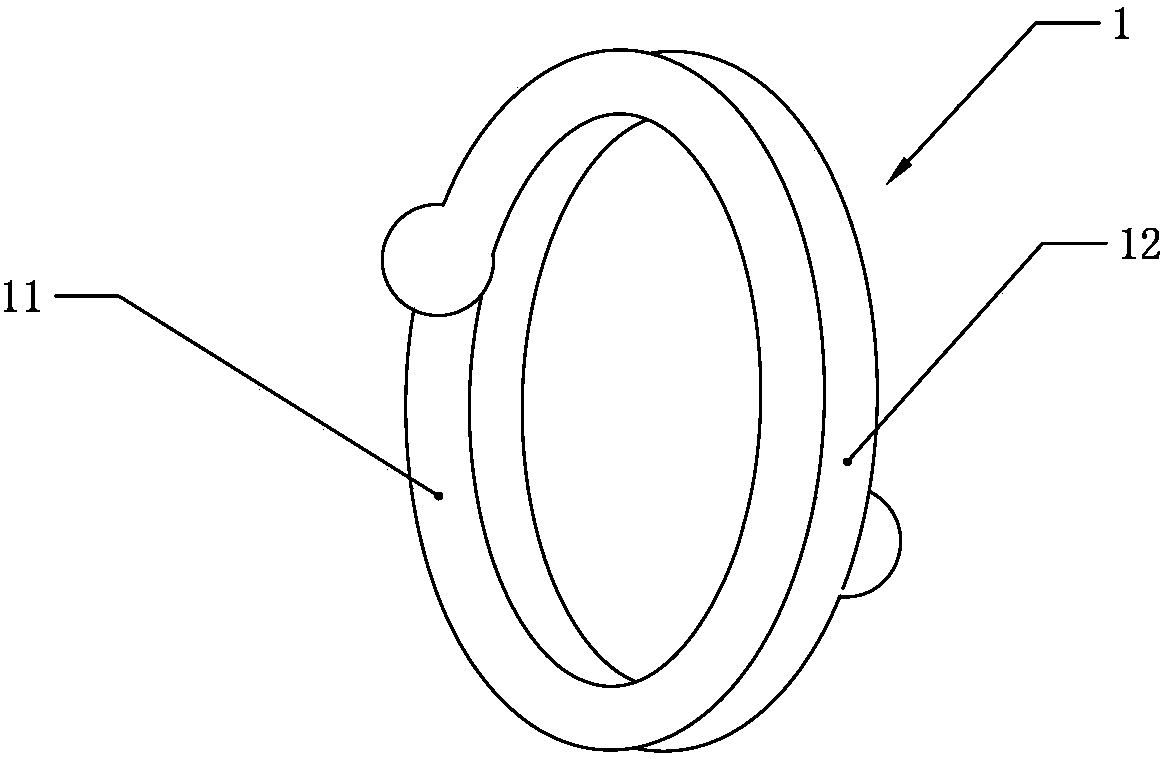

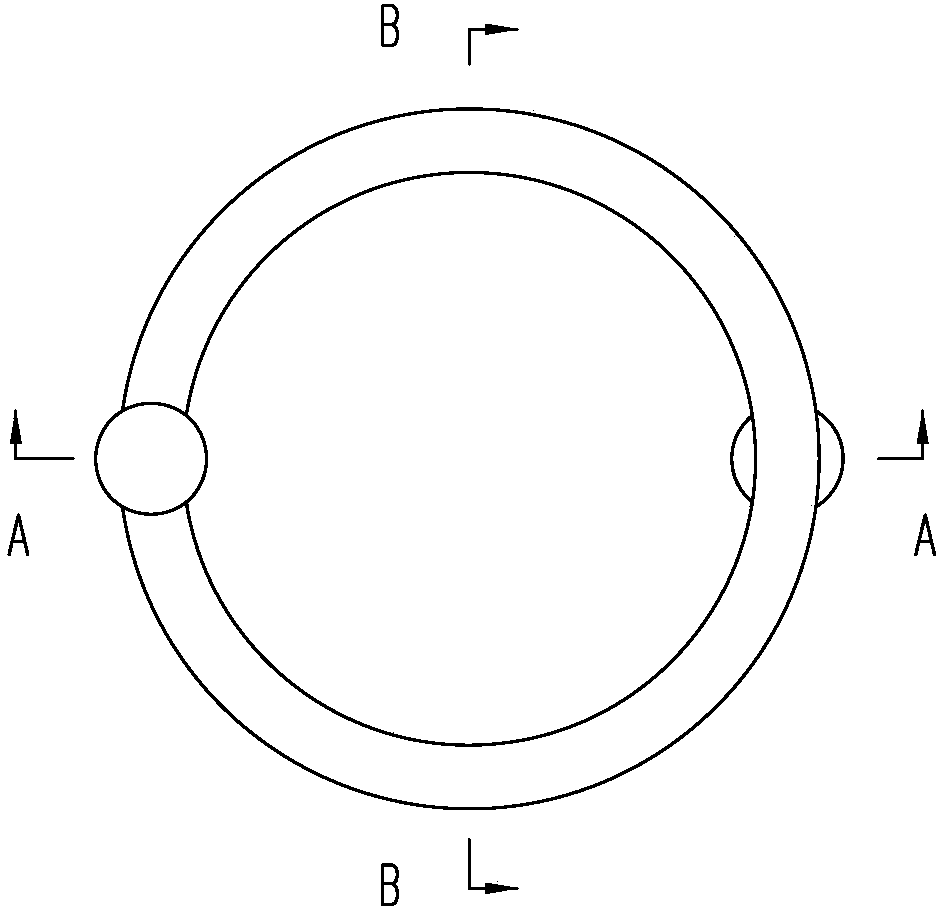

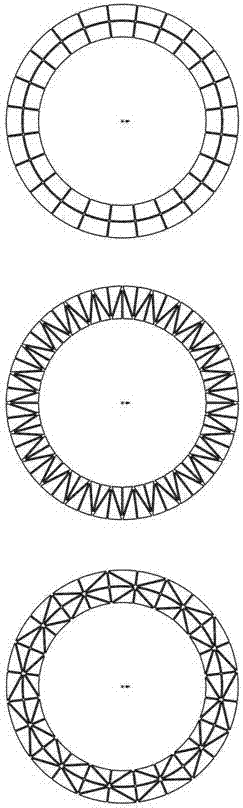

Mercury-based temperature tunable electromagnetic metamaterial and manufacturing method thereof

The invention discloses a mercury-based temperature tunable electromagnetic metamaterial, which comprises a double-ring-shaped glass tube. A mercury column and two mercury balls are encapsulated in the double-ring-shaped glass tube. The mercury balls and the mercury column are encapsulated in the double-ring-shaped glass tube. The double-ring-shaped glass tube comprises a first ring-shaped glass tube and a second ring-shaped glass tube. The structure of the first ring-shaped glass tube and the structure of the second ring-shaped glass tube are the same. The first ring-shaped glass tube is communicated with the second ring-shaped glass tube. The positions of the two mercury balls are symmetrically arranged relative to the circle center of the double-ring-shaped glass tube. The diameter of each mercury ball ranges from 0.8 mm to 1.5 mm. The mercury column is of an arc structure, and the diameter of the mercury column ranges from 0. 05 mm to 0.15 mm. The initial arc length of the mercurycolumn ranges from 20 mm to 22 mm.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

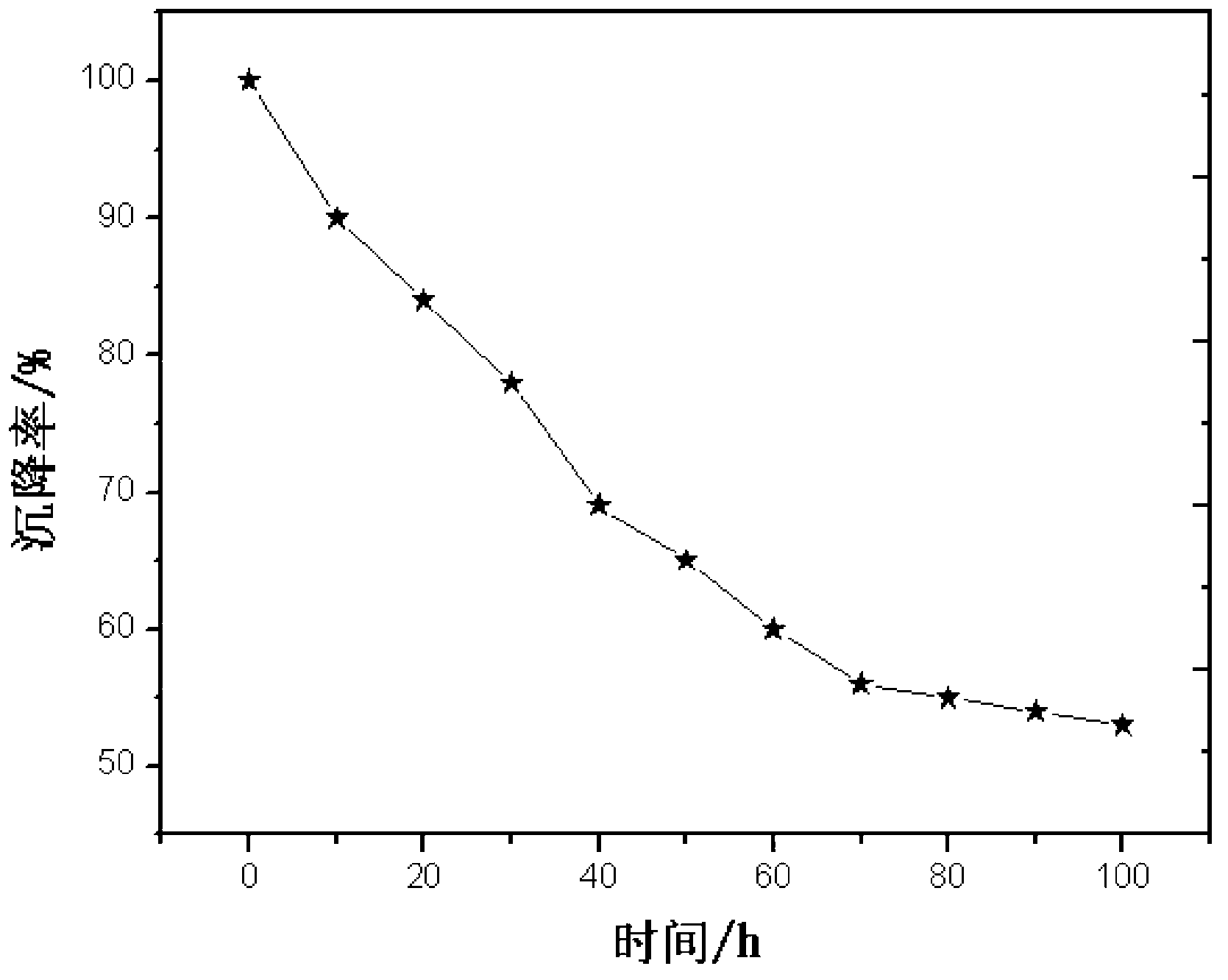

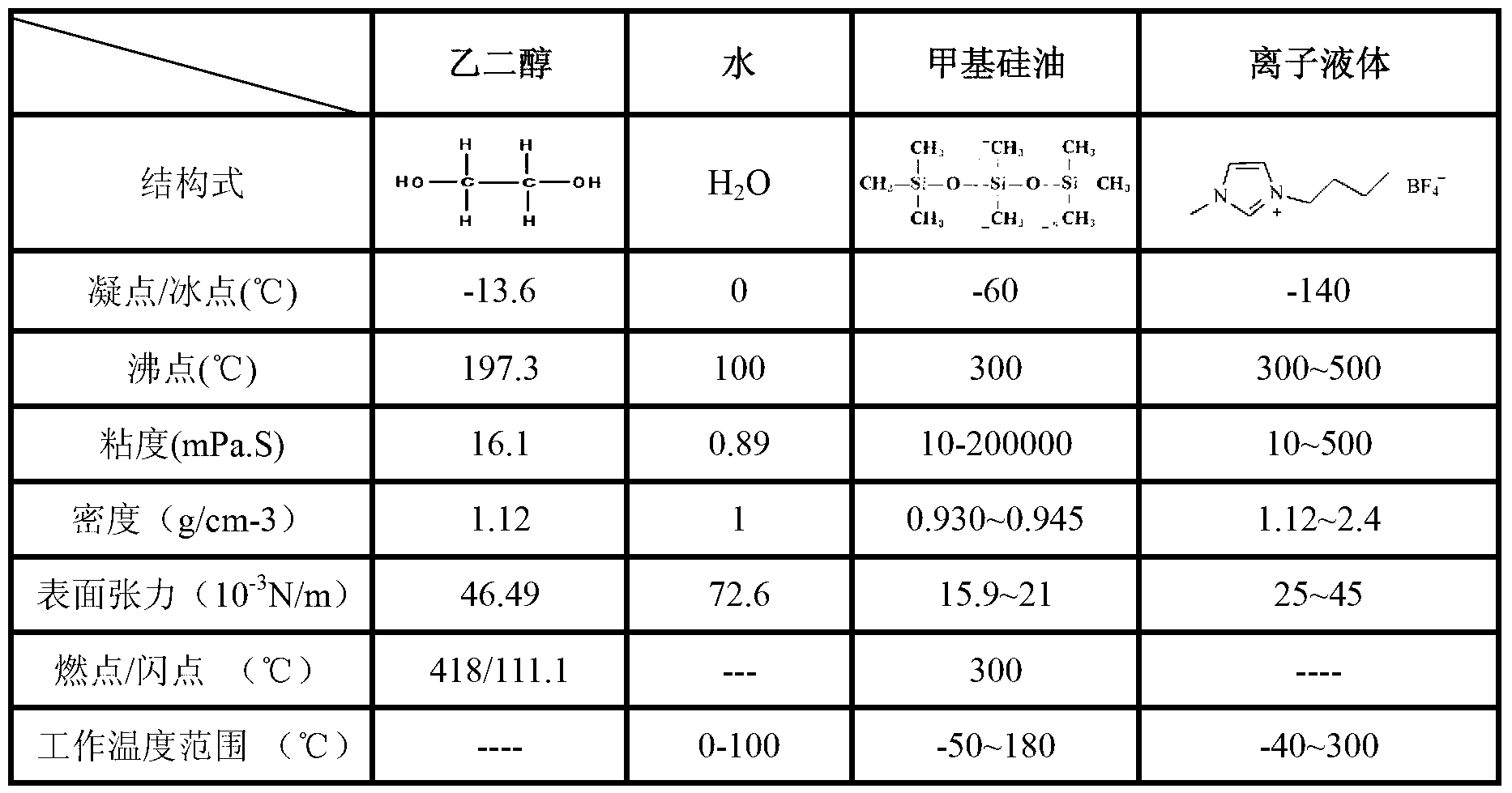

Application of ionic liquid serving as magnetorheological fluid base solution, magnetorheological fluid based on ionic liquid and preparation method thereof

InactiveCN103305324AGood reunion stabilityImprove stabilityLubricant compositionMagnetorheological elastomerOperating temperature

The invention discloses an application of an ionic liquid serving as a magnetorheological fluid base solution, and also discloses magnetorheological fluid based on the ionic liquid, namely an ionic liquid-based magnetorheological fluid. The magnetorheological fluid comprises the base solution, a dispersed phase and addictives, wherein micro or submicro magnetic particles are used as the dispersed phase; the base solution is an ionic liquid and comprises the components in parts by weight: 8-39.5 parts of the base solution, 60-90 parts of the dispersed phase and 0.5-5 parts of the addictives. A method for preparing the magnetorheological fluid based on the ionic liquid comprises the following steps of: firstly, preparing magnetic particles; acquiring the ionic liquid and the maddictives in the mass proportion; adding the addictives into the ionic liquid, and stirring for dissolving in a mixed mode; finally, adding the magnetic particles, stirring and uniformly stirring in a mixed mode to finish the preparation of the magnetorheological fluid. The magnetorheological fluid is high in stability, wide in operating temperature and high in designability, has environment-friendly property, and is suitable for vacuum environment.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

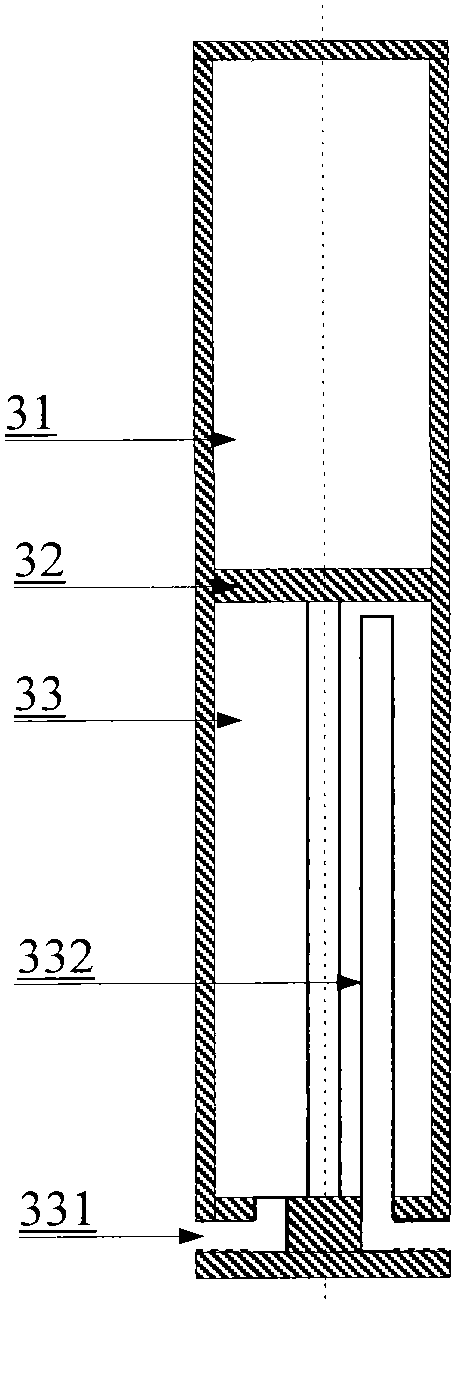

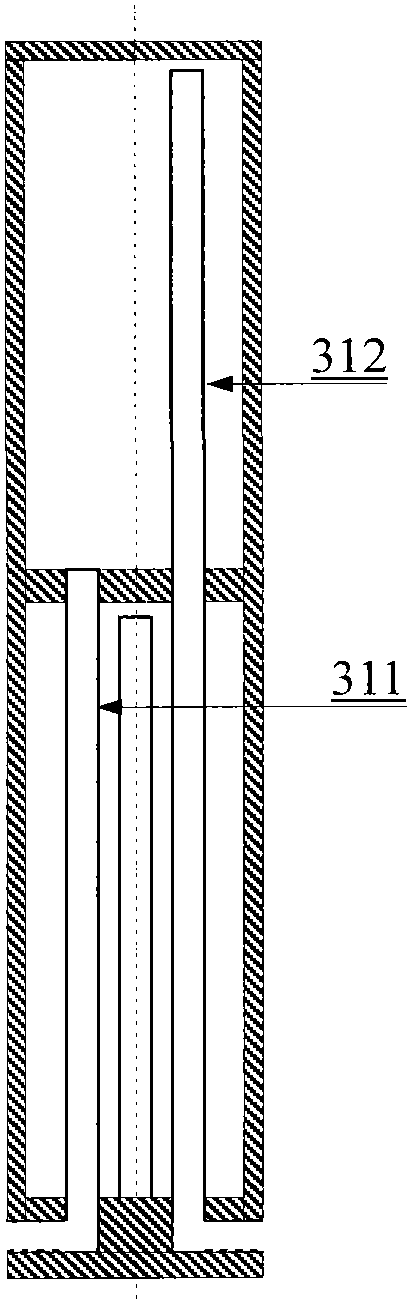

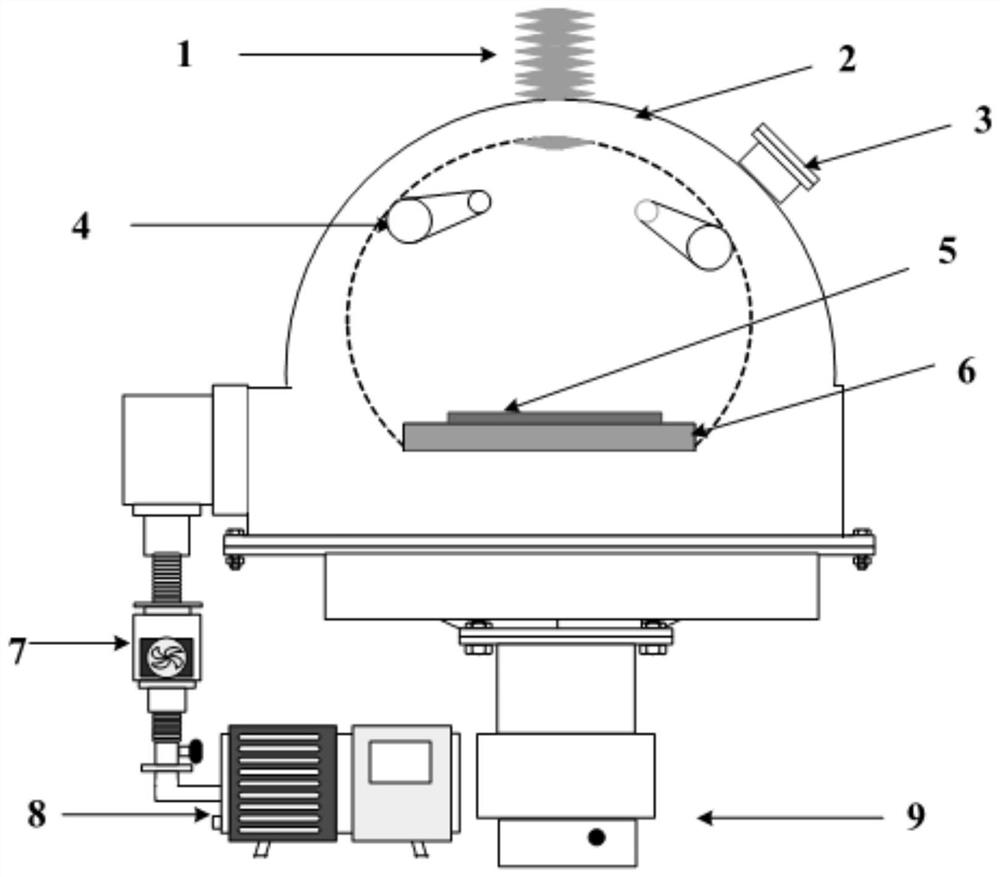

Superconductor cooling structure used for superconductive magnetic suspension micro thrust measurement system

ActiveCN107393676ARapid coolingConsistent temperature changeSuperconducting magnets/coilsMeasurement of vehicle's tractive/propulsive powerIndiumConduction cooling

The invention discloses design of a special superconductor low-temperature cooling structure applied to a superconductive magnetic suspension micro thrust measurement system. The superconductor low-temperature cooling structure comprises a refrigerator, a cooling base, a cooling copper column, a cooling copper ring, a superconductive stator array, an Al<2>O<3> ceramic cover plate, an indium sheet, graphite gaskets, an anti-radiation screen and the like. Specific to the requirements of high cooling efficiency and low eddy current loss of the cooling structure of the measurement system, a dual-path conduction cooling structure with low eddy current effect is designed; according to the cooling structure, the heat conduction gaskets capable of lowering contact heat resistance are arranged on the respective contact surfaces of corresponding parts, and by virtue of setting of the anti-radiation screen, radiation heat flow from the exterior can be isolated; and when the measurement system is in use, the Al<2>O<3> ceramic cover plate and the graphite gaskets with a weak eddy current effect are positioned in a region with severe magnetic field changes, while the cooling base, the cooling copper ring and the cooling copper column with an obvious eddy current effect are isolated from the region, so that the eddy current loss of the conduction cooling structure is suppressed by virtue of the conduction cooling structure layout.

Owner:BEIHANG UNIV

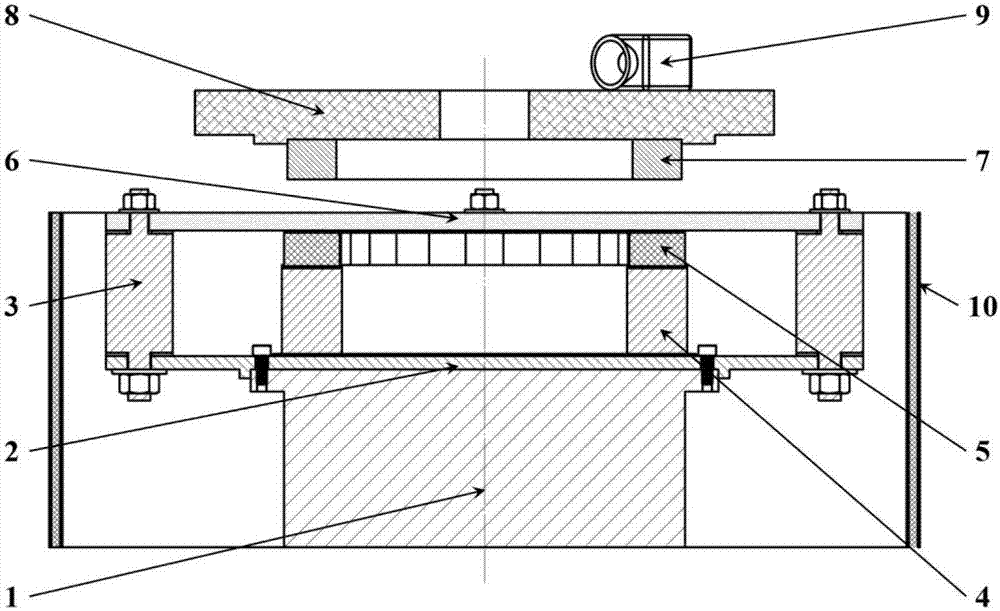

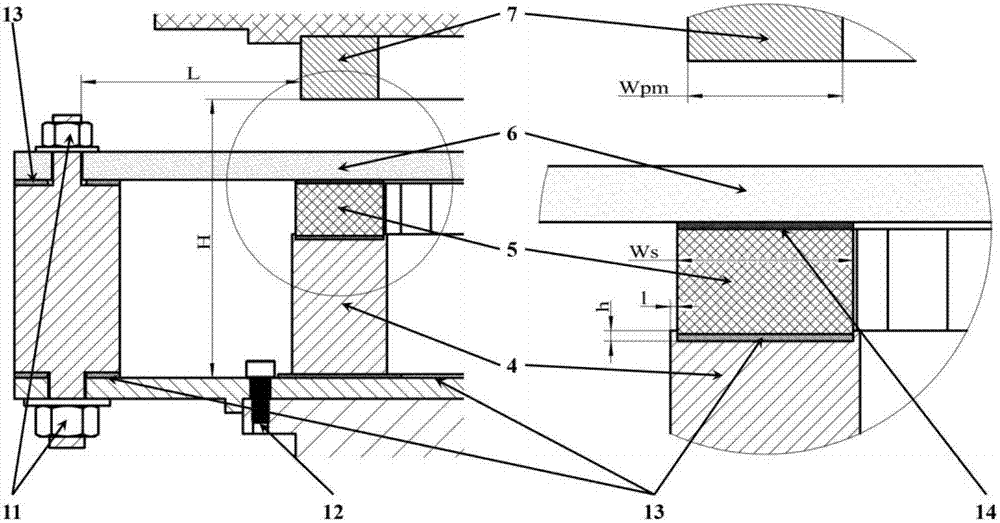

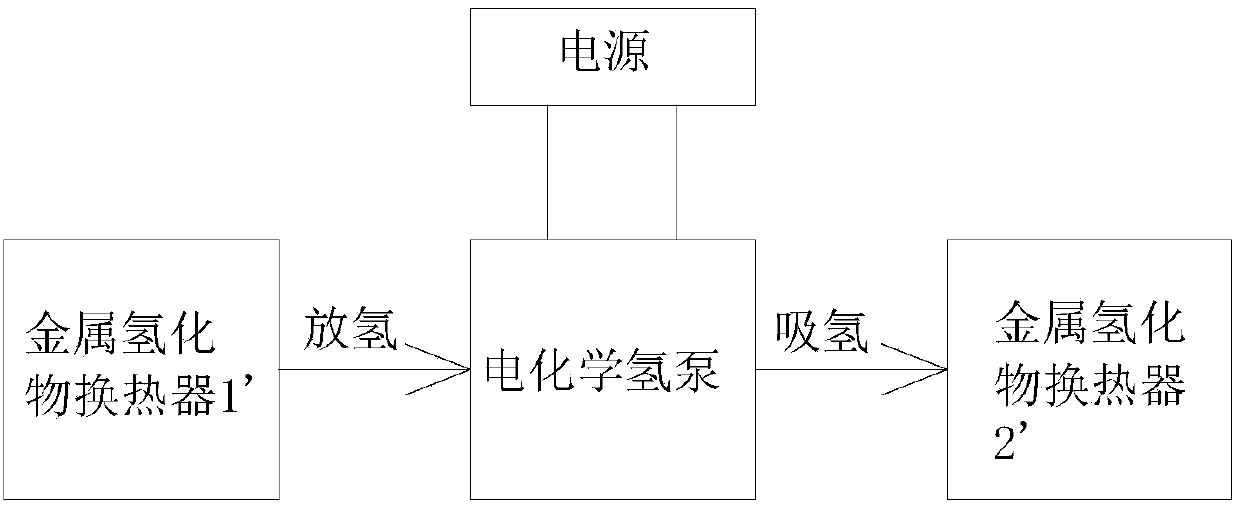

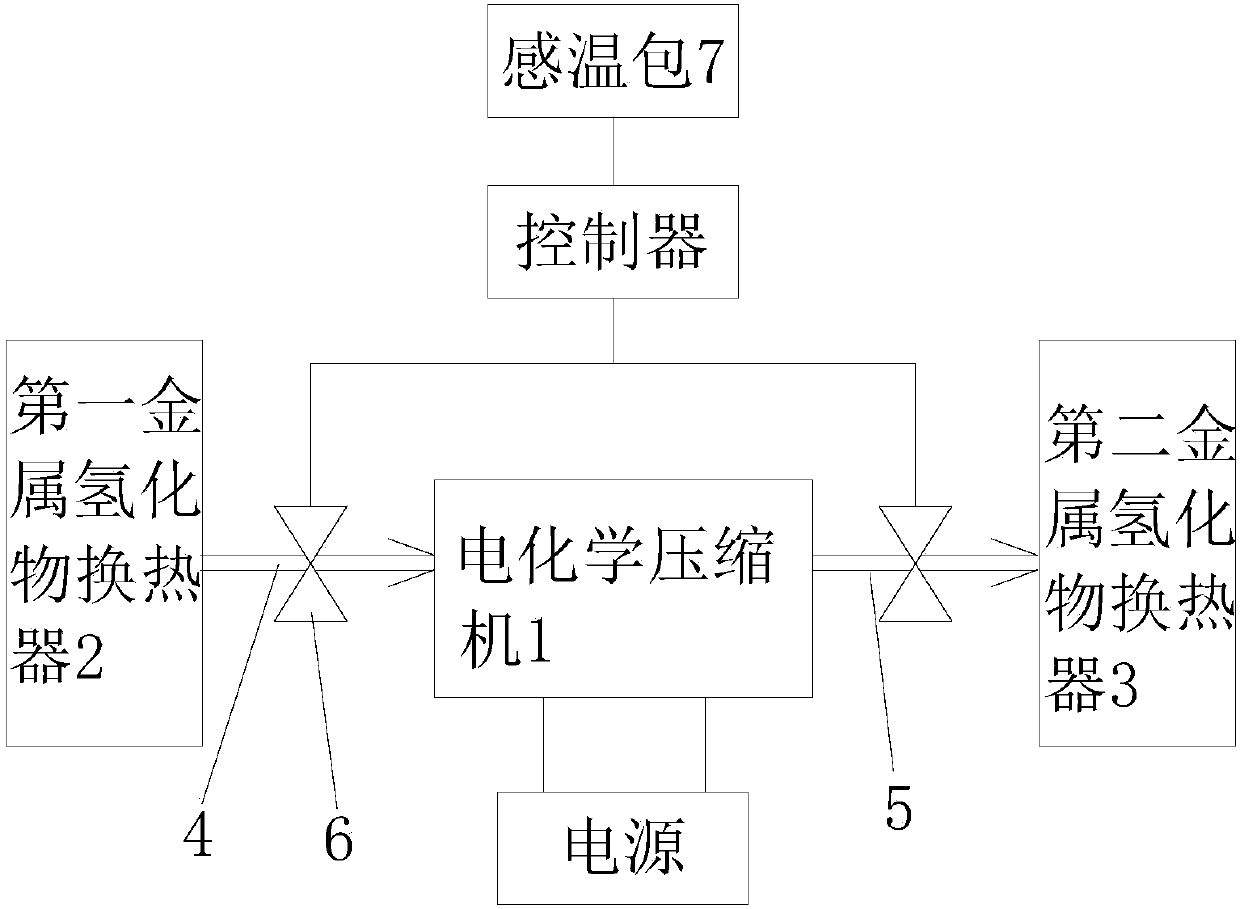

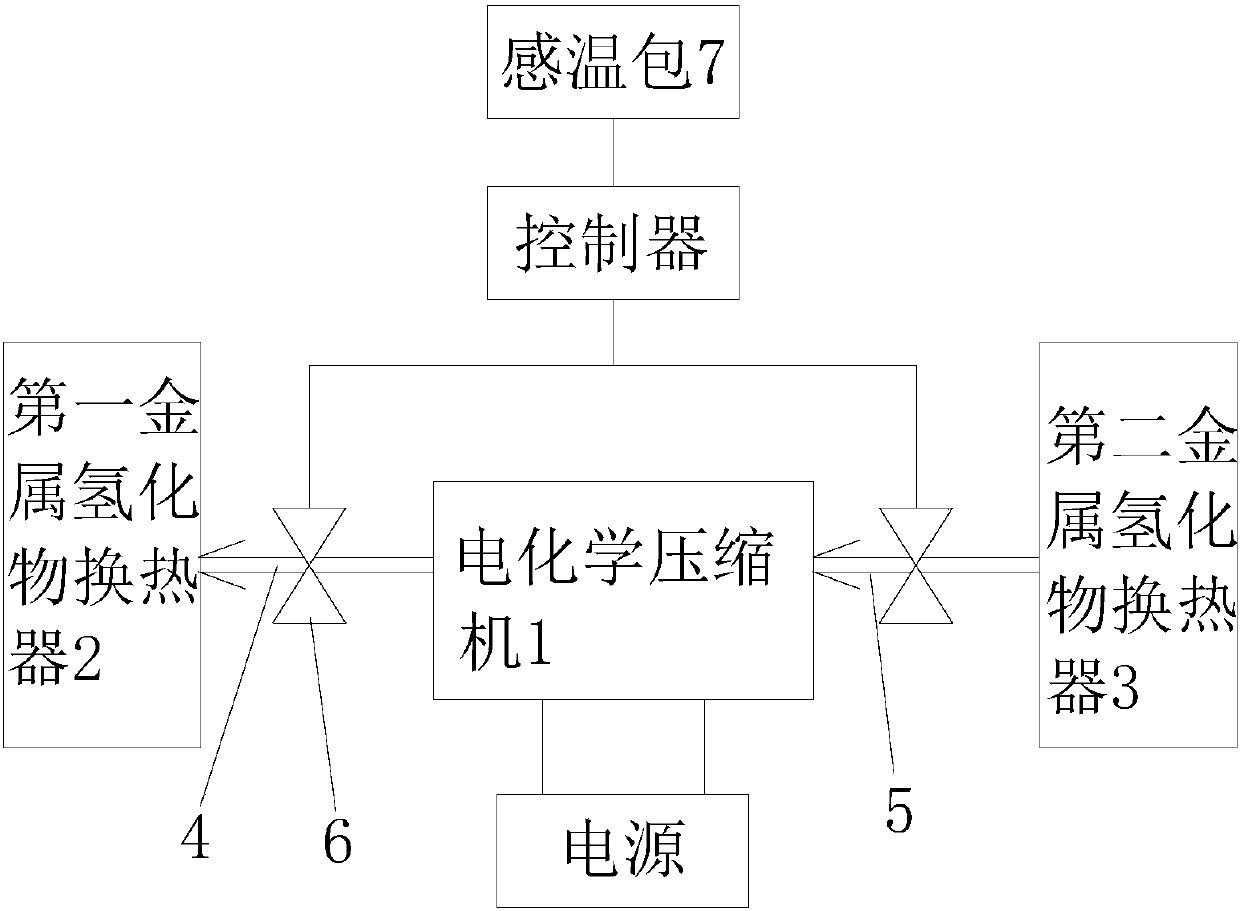

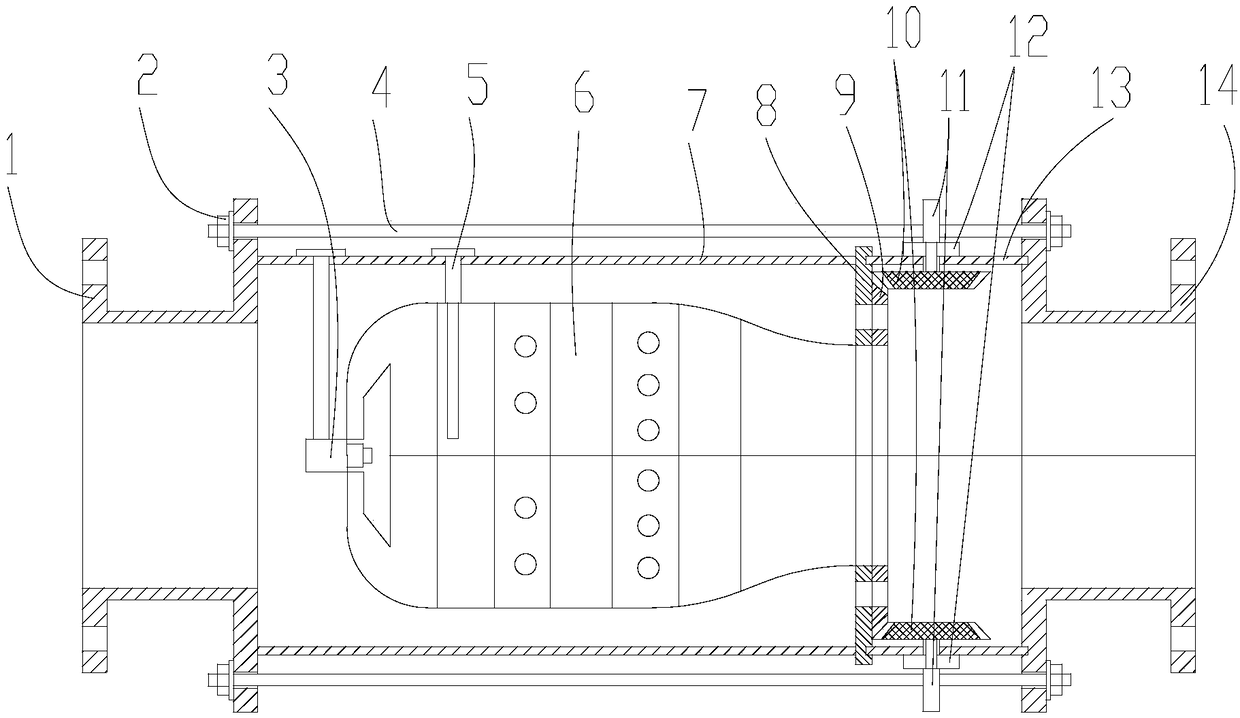

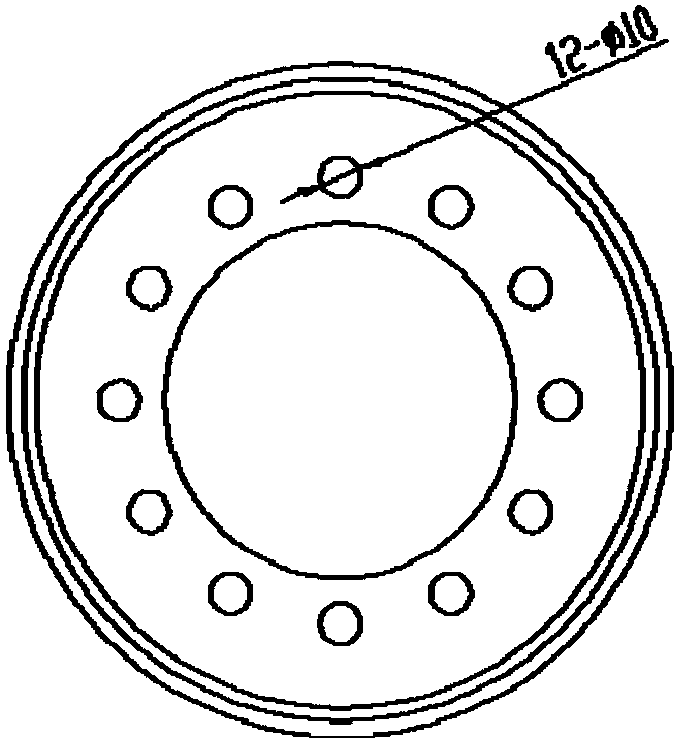

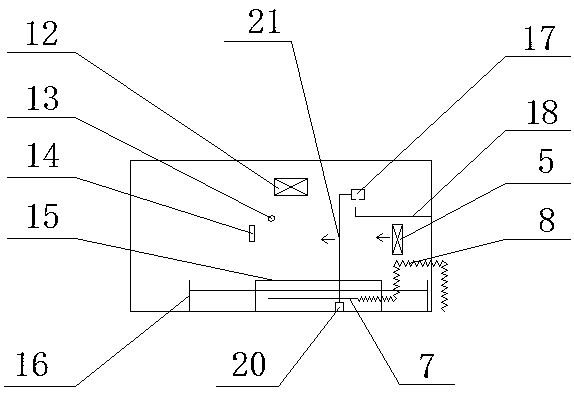

Electrochemical refrigerating system and control method for same

InactiveCN107782012ASatisfy the user experienceMeet the use requirementsRefrigeration safety arrangementControl flowEngineering

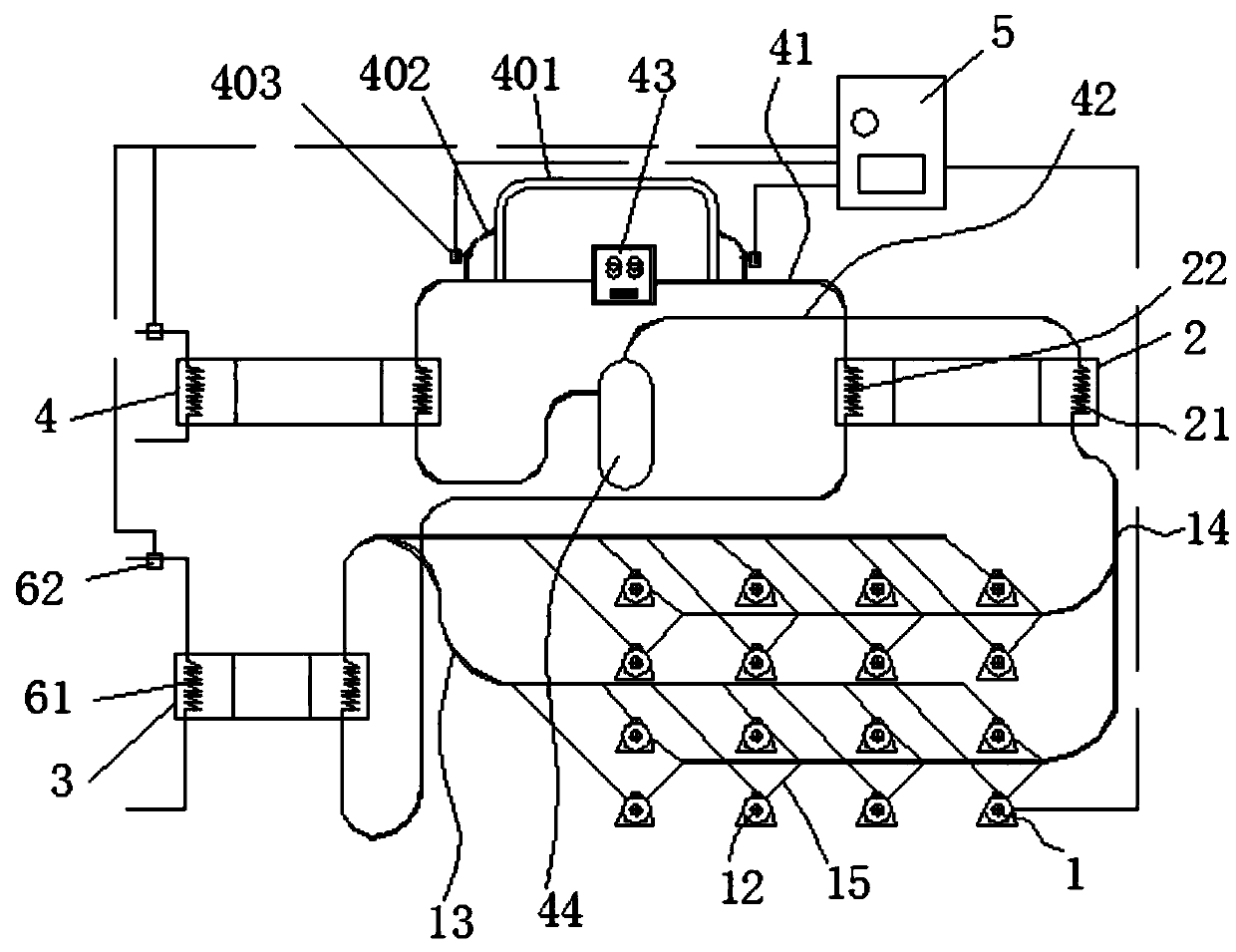

The invention discloses an electrochemical refrigerating system and a control method for the same. The electrochemical refrigerating system comprises an electrochemical compressor (1), a first metal hydride heat exchanger (2) and a second metal hydride heat exchanger (3), wherein the first metal hydride heat exchanger (2) is connected to a first interface end of the electrochemical compressor (1)through a first pipeline (4); the second metal hydride heat exchanger (3) is connected to a second interface end of the electrochemical compressor (1) through a second pipeline (5); and at least one of the first pipeline (4) and the second pipeline (5) is provided with a flow adjusting valve (6) for controlling flow of the pipelines. According to the electrochemical refrigerating system and the control method for the same, the problems that in the prior art, the electrochemical refrigerating temperature is inconvenient to adjust, and the adjustment range is small can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Turbosuperchager test bed combustion chamber with adjustable outlet temperature

ActiveCN108224419AImprove combustion efficiencyLarge temperature adjustment rangeMachine part testingBurnersCold airCombustion chamber

The invention provides a turbosuperchager test bed combustion chamber with the adjustable outlet temperature. The combustion chamber comprises a front flange, a nozzle, an ignition rod, a flame barrel, a casing barrel, a flame barrel flange, a temperature adjusting mechanism, a mixing segment outer barrel and a rear flange; the flame barrel flange is fixedly arranged on the tail of the flame barrel, the flame barrel is sleeved with the casing barrel, one end is connected with the flame barrel flange, the other end makes contact with the front flange, one end of the mixing segment outer barrelis connected with the other side face of the flame barrel flange, and the other end of the mixing segment outer barrel makes contact with the rear flange. The position of the mixing segment outer barrel is provided with the temperature adjusting mechanism. According to the combustion chamber, the adjusting mechanism is added on an outlet of the combustion chamber, cold air is introduced through anadjusting disc, cold air and high temperature gas are mixed, and the temperature adjusting range of the combustion chamber outlet is widened.

Owner:CHINA NORTH ENGINE INST TIANJIN

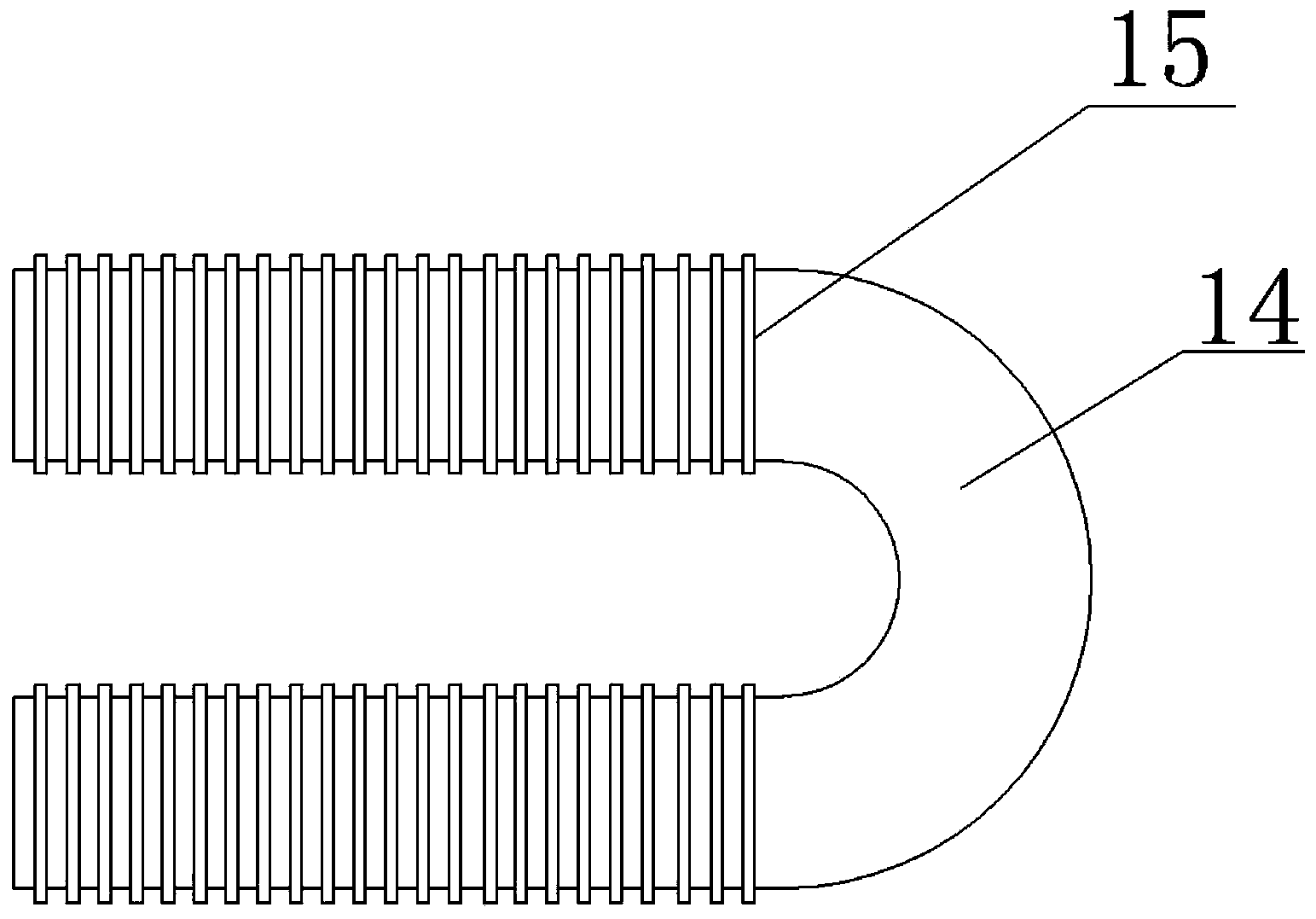

Water-cooled rod and crystal growth furnace using the water-cooled rod

The invention relates to the field of crystal growth equipment, and specifically relates to a water-cooled rod, which utilizes a crucible descending method to grow large-size crystals, and a crystal growth furnace using the water-cooled rod. The provided water-cooled rod comprises an upper water-cooled section and a lower water-cooled section; and the upper water-cooled section and lower water-cooled section are both provided with a water inlet and a water outlet. The invention further provides a crystal growth furnace comprising the water-cooled rod. The thermal field is adjusted through a sectional water-cooled rod, thus the crystallization latent heat can be effectively conducted, and the balance of thermal filed is guaranteed. Beside the invention also provides an enclosed crystal growth furnace comprising the water-cooled rod. The enclosed crystal growth finance completely eliminates the environmental pollution of volatile matters, besides the crucible does not need to be sealed and thus can be used repeatedly, and the heating furnace filament can be prevented from oxidation in a vacuum or aerated state.

Owner:BEIJING HAMAMATSU PHOTON TECH INC

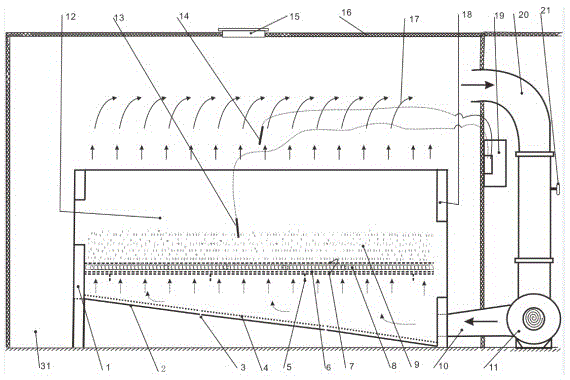

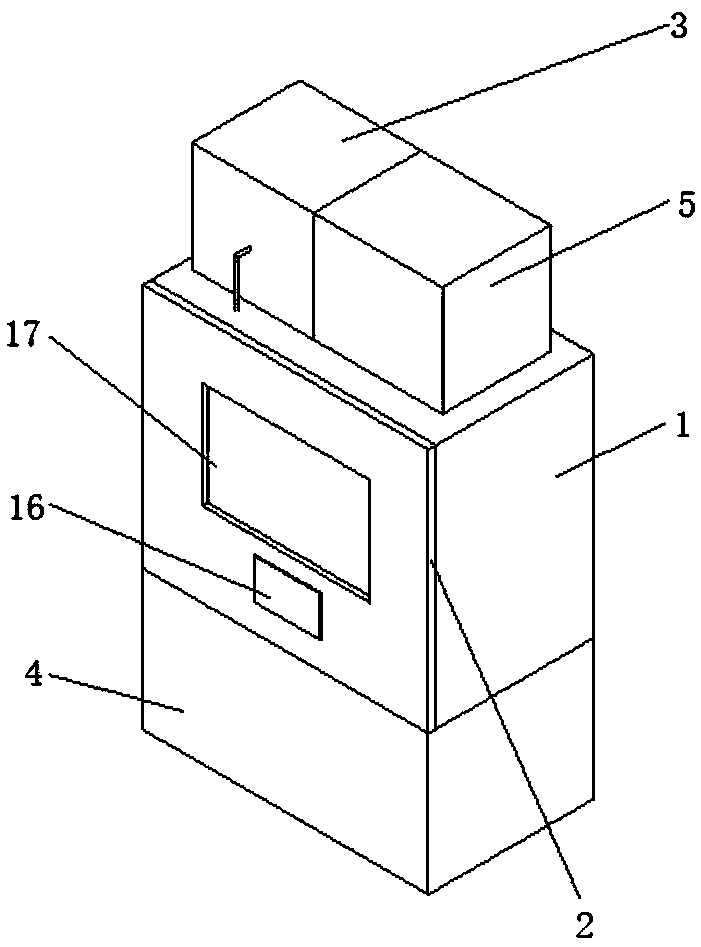

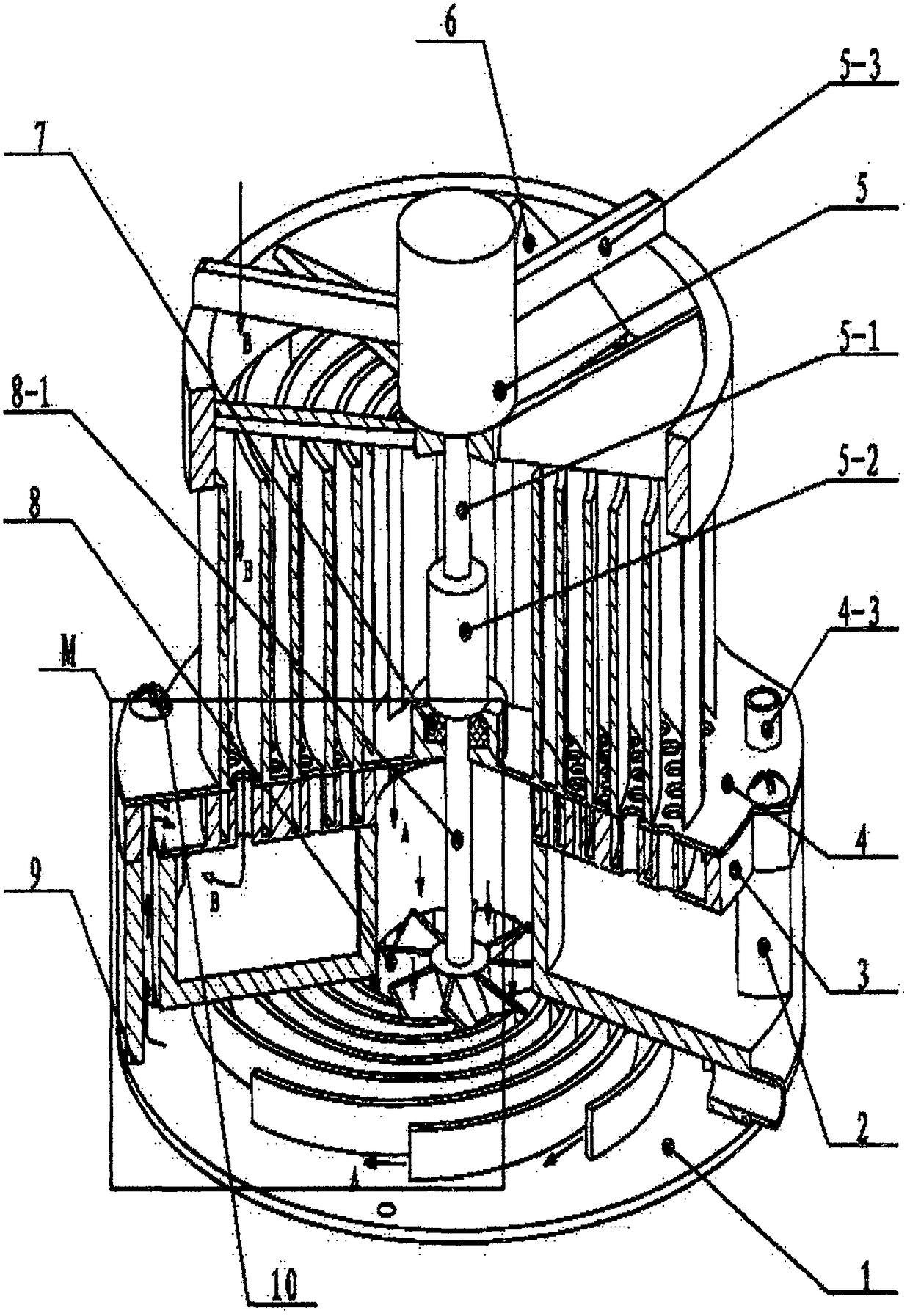

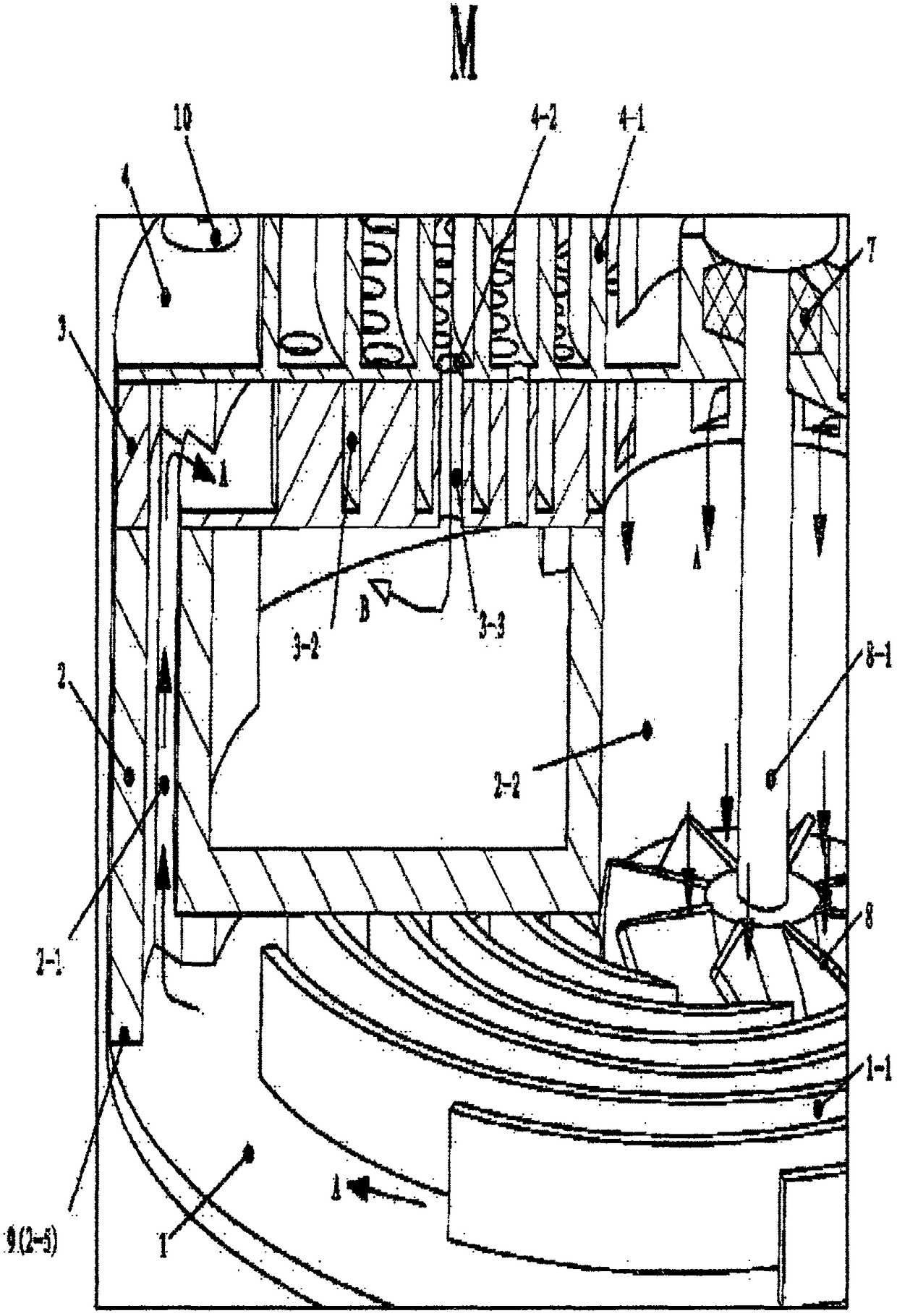

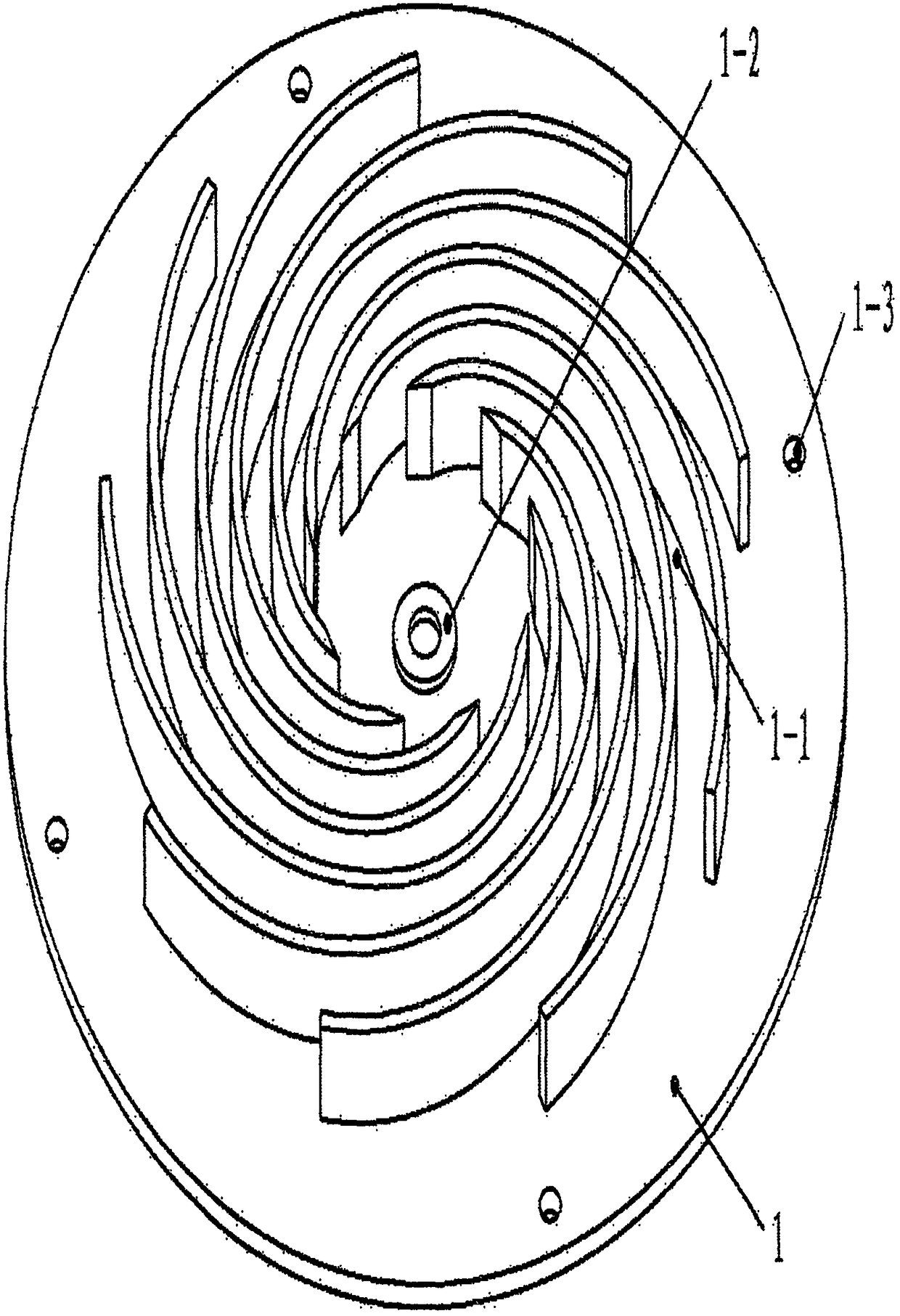

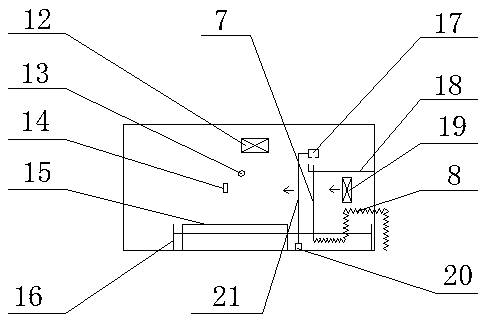

Combined mechanical ventilation fermenting and drying dual-purpose tank

InactiveCN105462813ALarge temperature adjustment rangePrecise temperature controlBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlEngineering

The invention discloses a combined mechanical ventilation fermenting and drying dual-purpose tank. The combined mechanical ventilation fermenting and drying dual-purpose tank comprises a bearing mechanical ventilation device, a temperature regulation automatic control device and an indoor-temperature heating device which are installed in a fermenting and drying chamber. The bearing mechanical ventilation device comprises a ventilation tank and an electric fan, the ventilation tank is formed by two long-side biconvex plates, two wide-side biconvex plates and the like in a combined and spliced mode and is supplied with air through the electric fan. An intelligent temperature regulation instrument in a distribution box of the temperature regulation automatic control device is connected with the electric fan and an electromagnetic steam regulation valve. The indoor-temperature heating device is composed of a central heating introduction air inlet pipe through the electromagnetic steam regulation valve, steam pipelines, steam stop valves, steam heat radiation fins and steam trap valves. The combined mechanical ventilation fermenting and drying dual-purpose tank is simple in structure, reasonable in design, capable of achieving two proposes and saving labor and time, convenient to operate, high in production efficiency, and capable of well achieving the purposes of fermenting and drying yeast materials and bringing great advantages to product transport and the price.

Owner:贵州省轻工业科学研究所

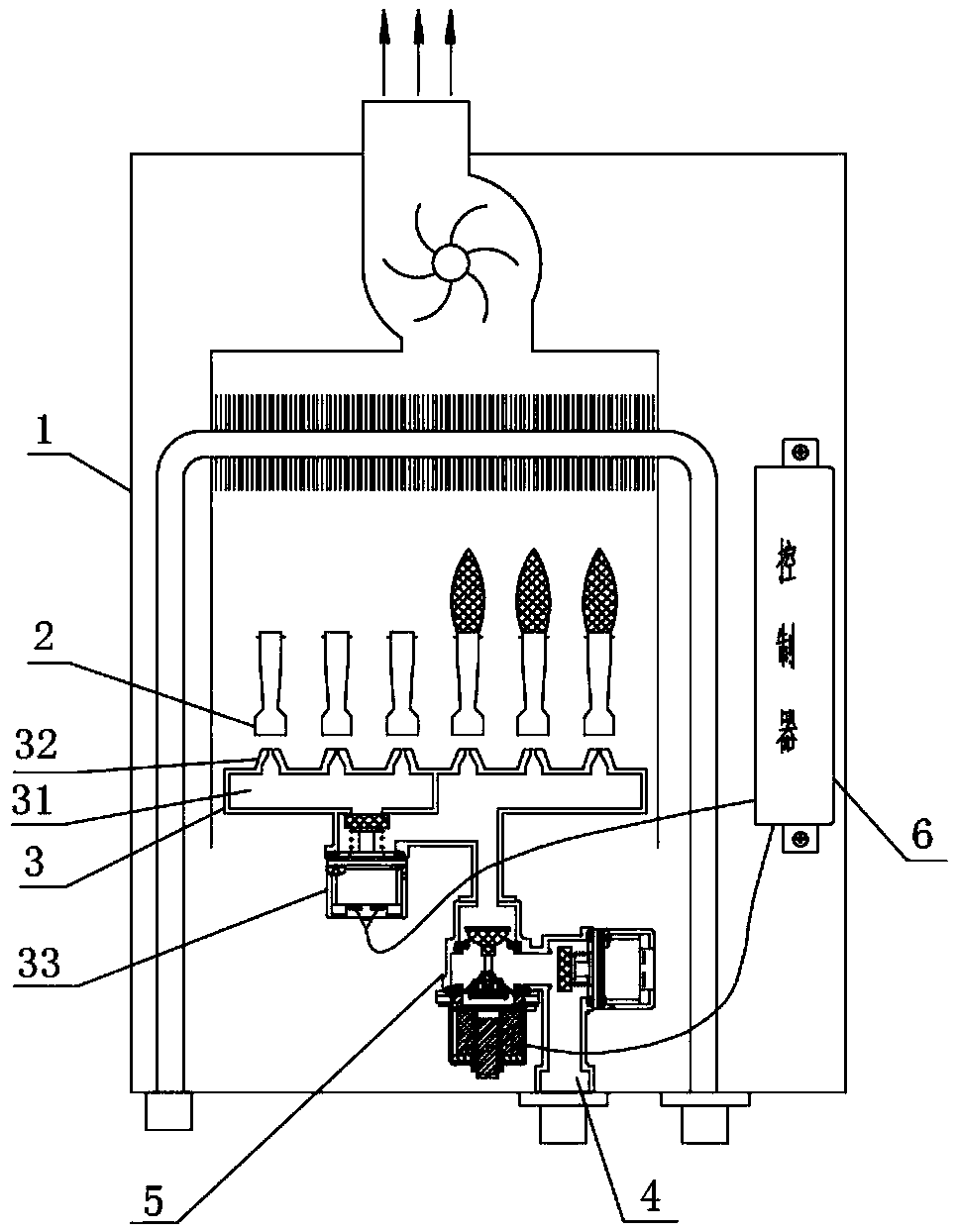

High and low temperature adjustable three-dimensional printing forming equipment

PendingCN109591291AMeet printing needsSave energyBioreactor/fermenter combinationsBiological substance pretreatmentsComputer moduleEngineering

The invention discloses high and low temperature adjustable three-dimensional printing forming equipment. The high and low temperature adjustable three-dimensional printing forming equipment comprisesa base, a forming chamber, an adjusting mechanism, a heating module, a refrigeration module, a forming platform, a printing module and a control module. The forming chamber is composed of a front panel vertically mounted on the base, a rear panel, two side panels and an upper panel covering the front panel. The adjusting mechanism comprises a lead screw parallel to the front panel and a drive part driving the lead screw to rotate, the thread directions of the two ends of the lead screw are different, and the two ends of the lead screw are in threaded fit with the two side panels. The formingplatform is used for containing a printing structure component. The control module is used for controlling work of the heating module and the refrigeration module. According to the high and low temperature adjustable three-dimensional printing forming equipment, through the arrangement of the forming chamber with the forming space capable of changing along with the size of the printing structure component, the heating module and the refrigeration module, the printing requirements of materials of multiple types for the high temperature environment and the low temperature environment can be metat the same time; and compared with existing three-dimensional printing equipment, the high and low temperature adjustable three-dimensional printing forming equipment has the advantages of being highin temperature adjusting efficiency and energy utilization rate, wide in application range, long in service life and the like.

Owner:乐清市智能装备与制造研究院

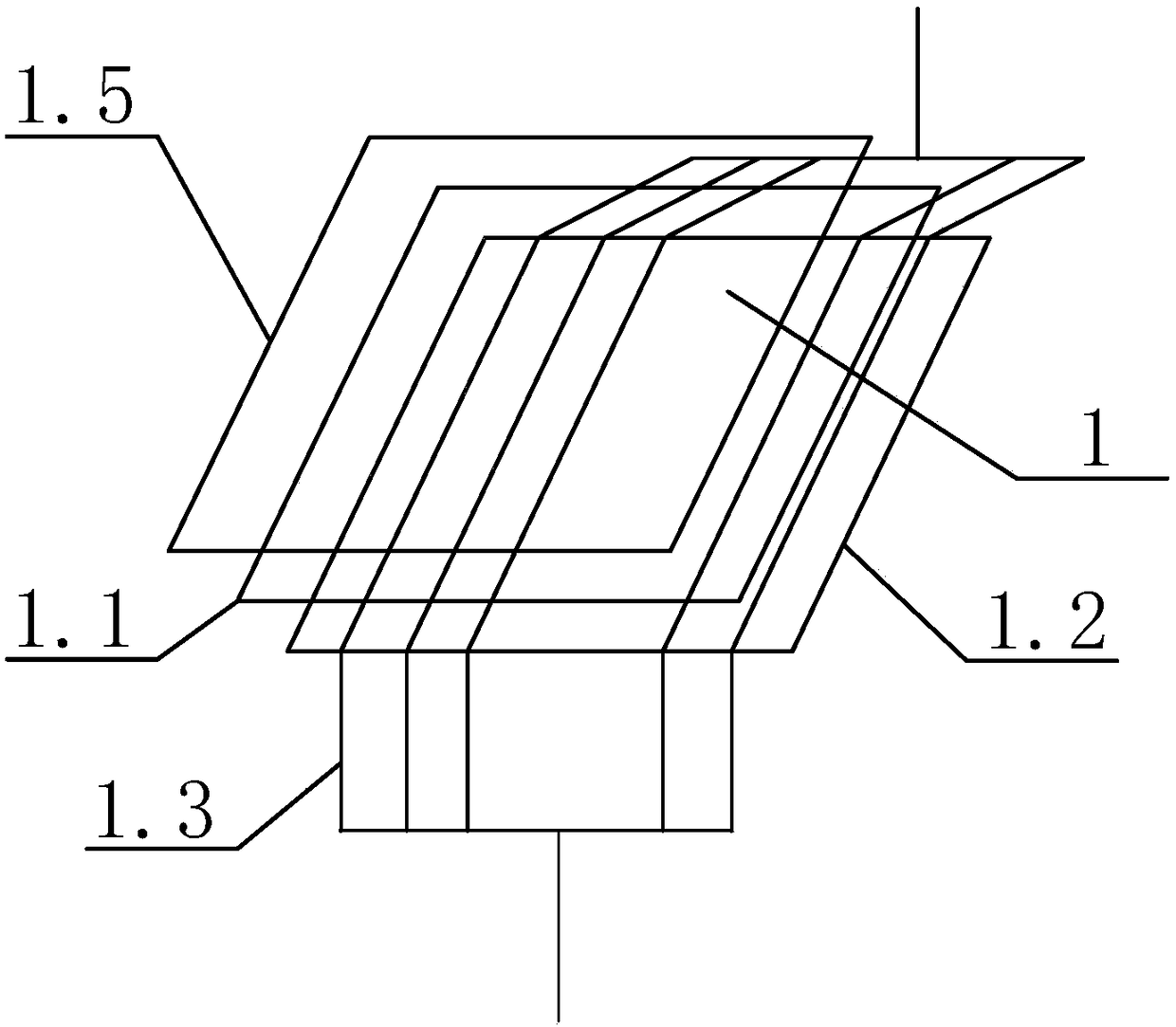

Solar photovoltaic photo-thermal and heat storage type electric boiler combined power supply and heating system

InactiveCN108106025ALarge temperature adjustment rangeHigh degree of automation controlSolar heating energyPhotovoltaicsAutomatic controlWater pipe

The invention discloses a solar photovoltaic photo-thermal and heat storage type electric boiler combined power supply and heating system. The system comprises a solar module, a water storage tank andan electric boiler, wherein the solar module, the water storage tank and the electric boiler communicate with one another through a water pipe; the solar module comprises a solar photovoltaic panel used for solar power generation and a bottom plate arranged below the solar photovoltaic panel, and a heat exchange pipeline and an air duct are arranged between the solar photovoltaic panel and the bottom plate; the water storage tank communicates with an external water source, and the water storage tank communicates with the inlet end of the heat exchange pipeline; and the inlet end of the electric boiler correspondingly communicates with the outlet end of the heat exchange pipeline and the water storage tank, and an external water outlet is formed in the outlet end of the electric boiler. The solar photovoltaic photo-thermal and heat storage type electric boiler combined power supply and heating system has the advantages that the temperature adjusting range is wide, wherein the boiler outlet temperature range is 110-180 DEG C; the automatic control degree is high, and specifically, output power of the electric boiler is dynamically distributed according to solar radiation intensity;and energy gradient utilization is realized, and specifically, through combined utilization of solar energy and the electric boiler, use of electric power during peak is reduced, and the utilization rate of the solar energy is improved.

Owner:国网电力科学研究院武汉能效测评有限公司 +3

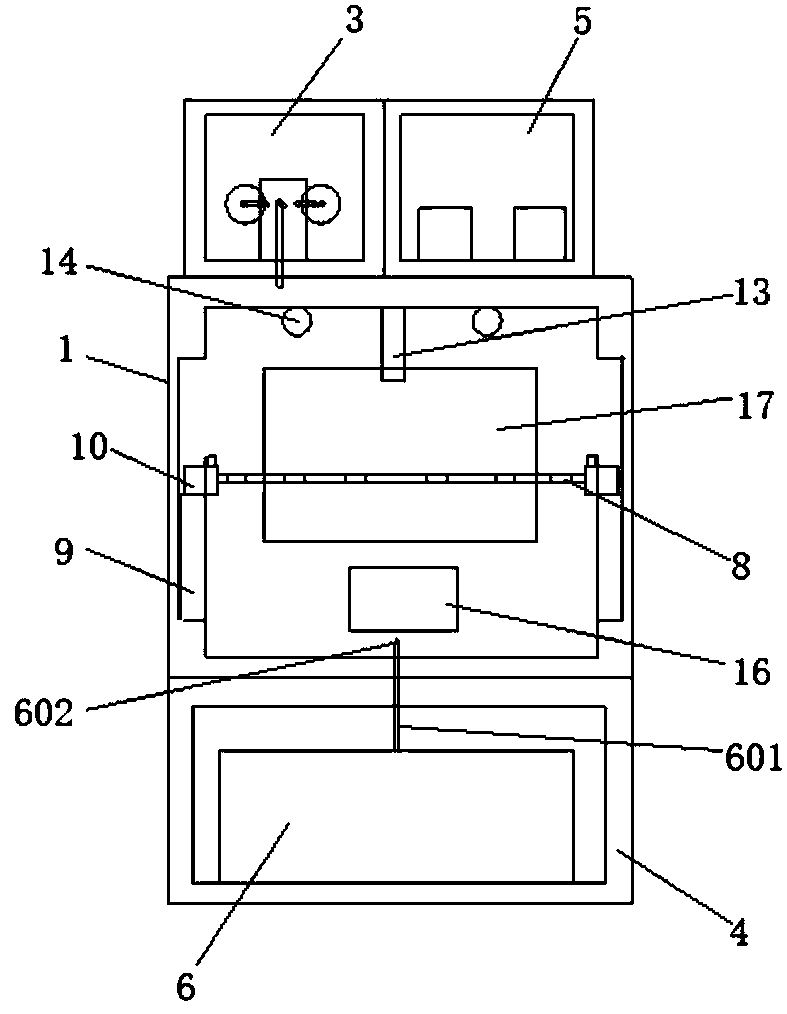

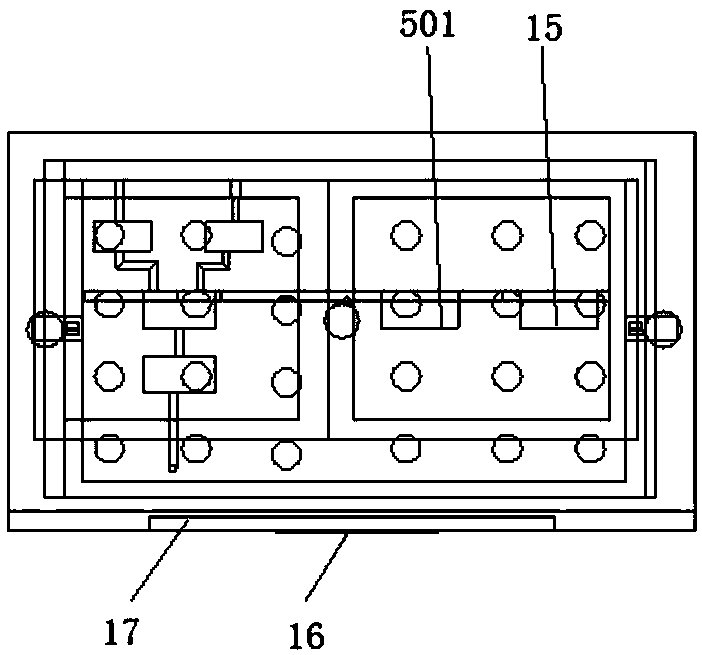

Constant-temperature incubator

PendingCN111088159AMaintain temperatureMaintain humidityBioreactor/fermenter combinationsBiological substance pretreatmentsControl roomIncubator

The invention discloses a constant-temperature incubator. The incubator comprises an incubator body, an incubator door, a temperature adjusting chamber, a humidifying chamber and a control chamber, the incubator door is hinged to the incubator body, the temperature adjusting chamber and the control chamber are arranged at the upper end of the incubator body side by side, and the humidifying chamber is arranged at the lower end of the incubator body; and the side wall and the upper wall of the incubator body are both of a hollow structure and communicate with each other, a plurality of air holes penetrating through the hollow structure are uniformly formed in the inner side wall and the inner top wall of the incubator body, a first air inlet, a second air inlet and an air outlet are formedin the temperature adjusting chamber, the air outlet in the temperature adjusting chamber communicates with the hollow structure of the upper wall of the incubator body through a temperature adjustingpipeline, an air outlet of a humidifier communicates with an inner cavity of the incubator body through a humidifying pipeline, and the end, arranged in the inner cavity of the incubator body, of thehumidifying pipeline is connected to an electromagnetic nozzle. According to the invention, air with required temperature in the incubator body can be accurately controlled, heat in the box body is uniformly distributed, bacteria in the air are prevented from entering the incubator body to damage a culture, and the culture quality and the experiment accuracy are improved.

Owner:上海隽澄生物科技有限公司

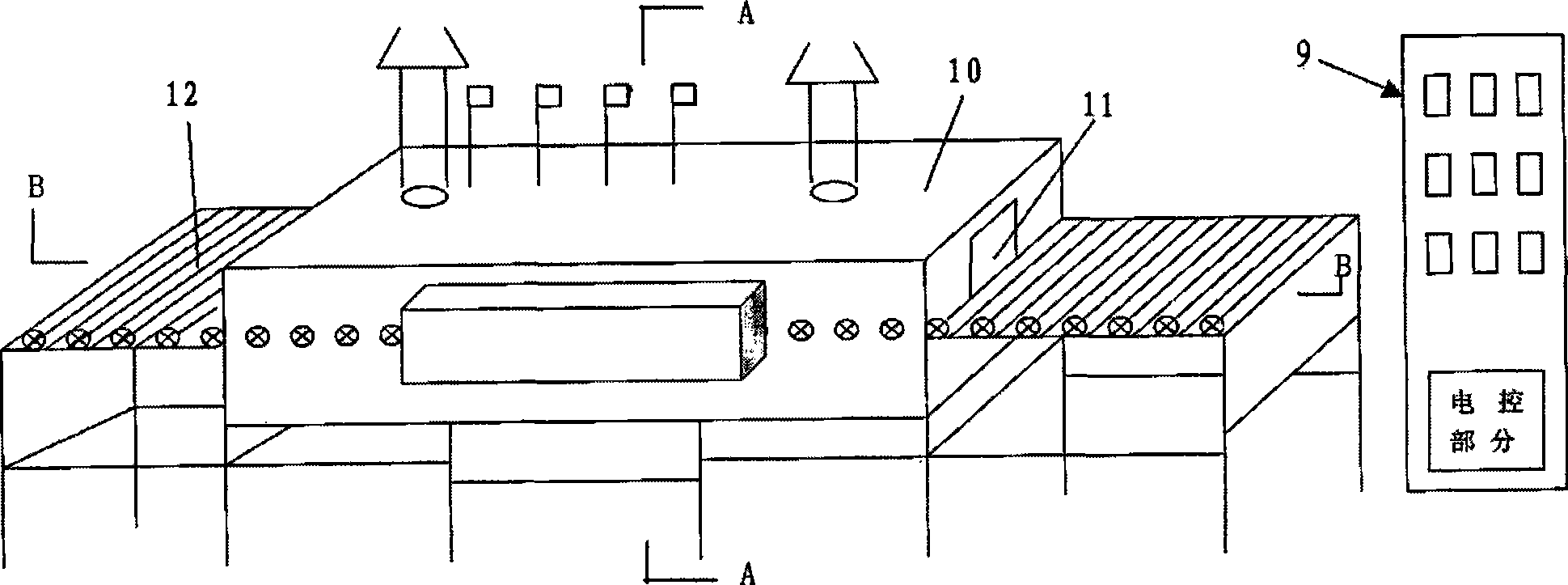

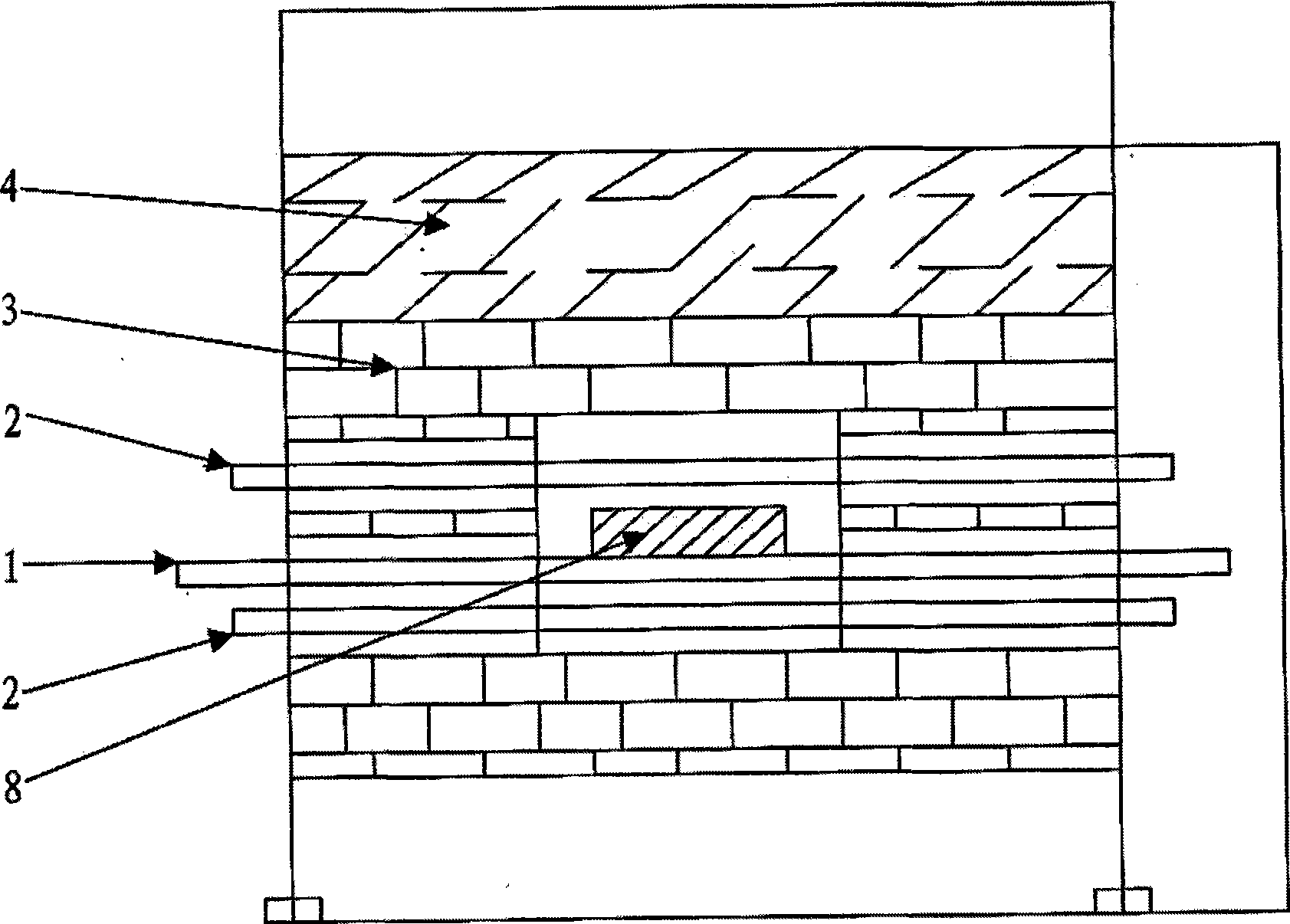

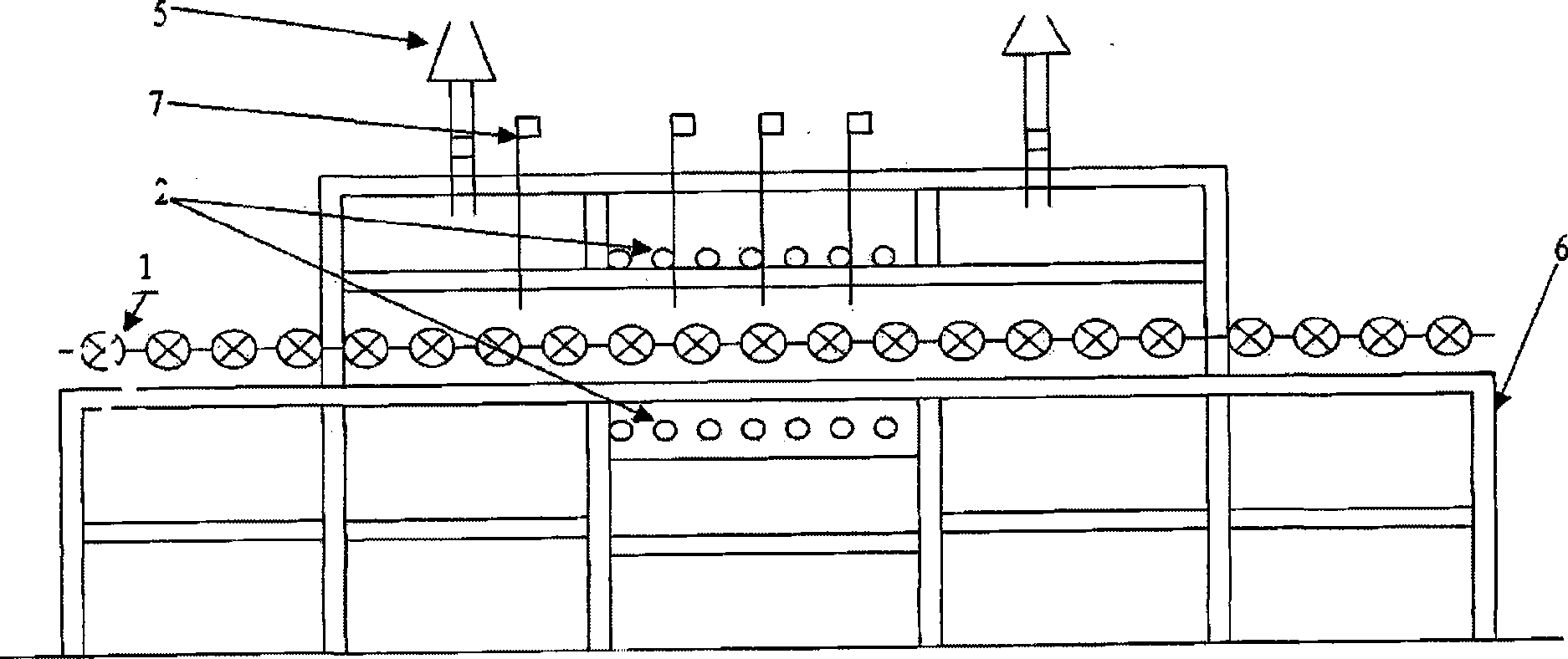

Calcination equipment for producing photocatalyst material

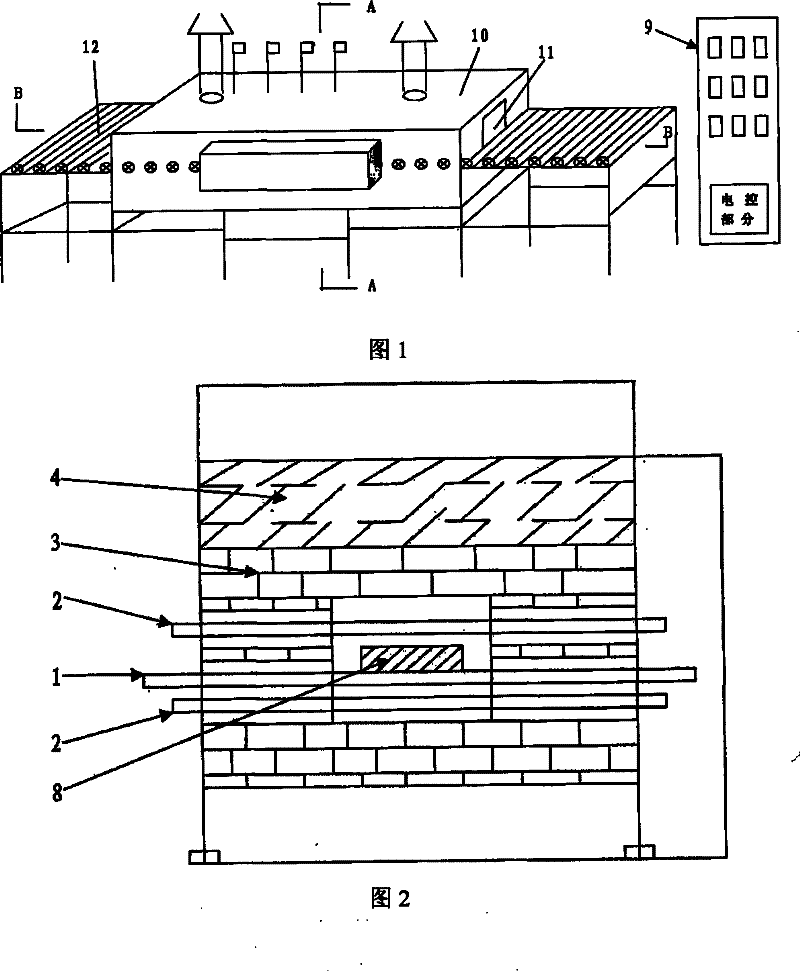

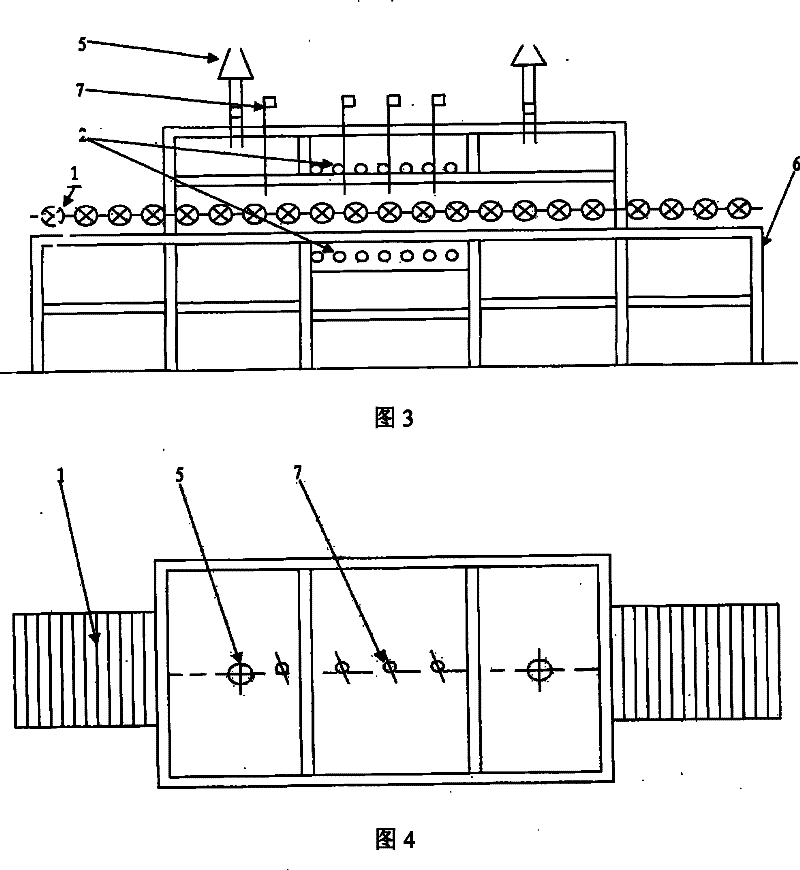

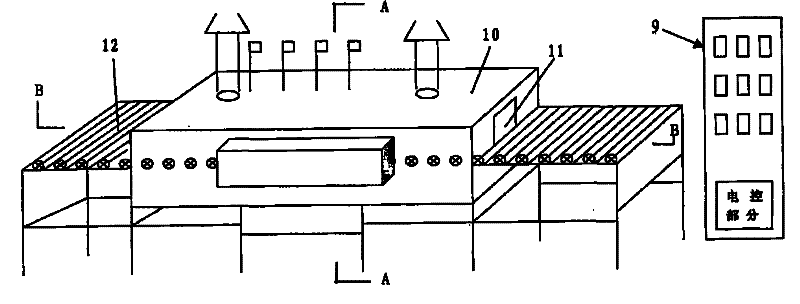

InactiveCN101497050ALarge temperature adjustment rangeReasonable structural designCatalyst activation/preparationFurnace typesBrickBiochemical engineering

The invention relates to calcining equipment for producing a photocatalyst material, which belongs to the technical field of calcinating equipment structures. The calcining equipment for producing the photocatalyst material comprises an equipment support 6, and is characterized in that the upper end surface of the equipment support 6 is provided with a live-roll table 12 spread by evenly distributed live rolls 1; a heater box body 10 is arranged above the equipment support 6; the live-rolls 1 pass through the inside of the heater box body 10; the heater box body 10 is provided with a transmission channel 11 along the direction of the live-rolls 1; the upper side and the lower side of each live-roll 1 inside the heater box body 10 are provided with an electric heating silicon carbide rod 2 used for heating respectively; an insulating brick 3 is arranged on the outer layer of the electric heating silicon carbide rod 2; and an insulating material 4 is arranged on the outmost layer of the heater box body 10. The equipment with arbitrarily adjusted temperature between 100 and 2,000 DEG C is applicable to calcination oxidation for different materials at different temperatures, and has the advantages of reasonable structure design, adjustable operating speed of between 0.01 and 1m / min in continuous running without outage, energy and manpower conservation, high stability and production continuity, product quality and yield improvement and energy consumption reduction.

Owner:莱阳子西莱环保科技有限公司

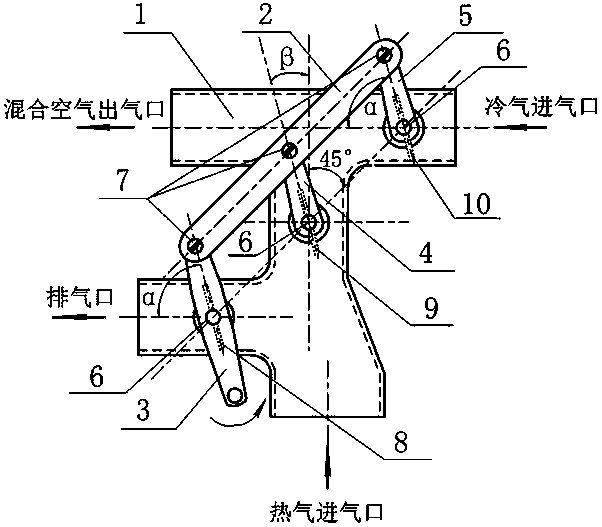

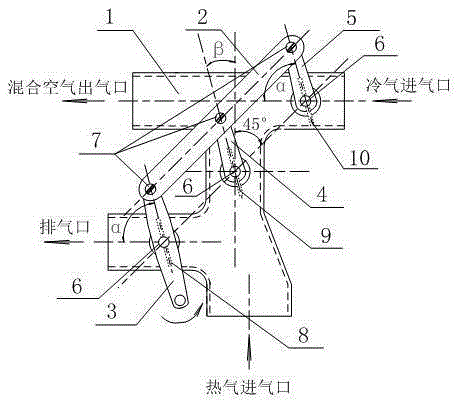

Air mixing and distributing device with temperature adjustment function

ActiveCN104019252AImprove comfortImprove ventilationOperating means/releasing devices for valvesAir-treatment apparatus arrangementsCold airTemperature conditioning

An air mixing and distributing device with a temperature adjustment function comprises a shell, a connection rod, a large rocker arm, a small rocker arm I, a small rocker arm II, rotary shafts, a bolt, a valve piece I, a valve piece II and a valve piece III, wherein the connection rod, the large rocker arm, the small rocker arm I, the small rocker arm II and the rotary shafts on the shell form a parallel rocking shaft connection rod mechanism. When the large rocker arm is shaken, the valve pieces can be controlled to rotate around the rotary shafts in respective pipelines in a linkage mode through the parallel rocking shaft connection rod mechanism. When the included angle alpha of the valve piece I of an air exhaust path and the axis of the pipeline of the air exhaust path and the included angle alpha of the valve piece III of a cold air path and the axis of the pipeline of the cold air path are larger than 10 degrees and smaller than 80 degrees, at the time, the included angle beta of the valve piece II of a hot air path and the axis of the pipeline of the hot air path is equal to 90 degrees minus alpha, cold air and hot air are in a mixed state, and the mixing ratio of the cold air and the hot air can be controlled by controlling the included angle alpha. According to the device, the ventilation capacity of a ventilation system of a plane is improved, the temperature adjustment range is widened, circulation of fresh air in a cabin is improved and environment comfort of the cabin is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

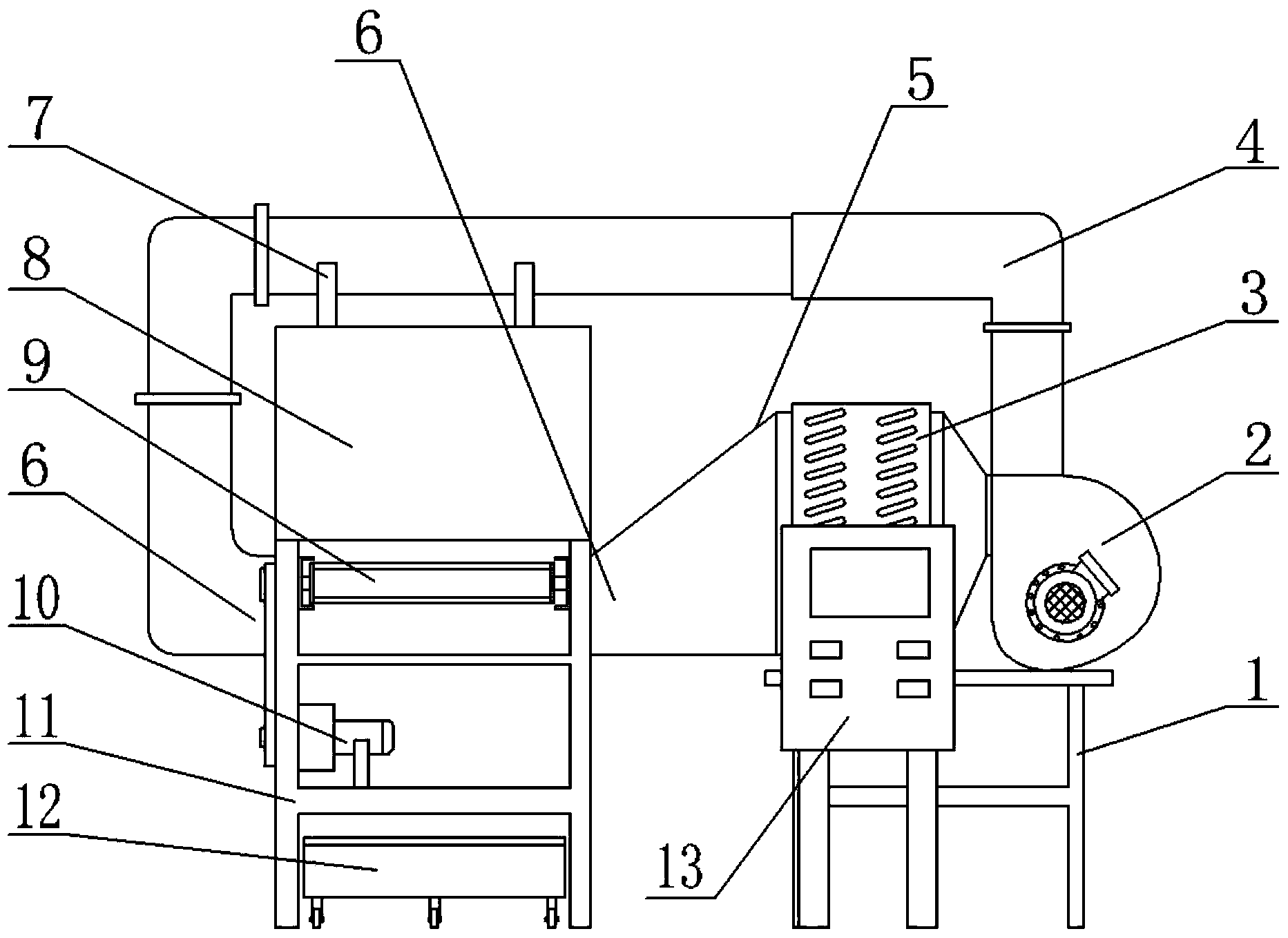

Conduction oil heating dryer

InactiveCN104296514ANo pollution in the processNo effect on healthStorage heatersDrying gas arrangementsEngineeringAir blower

The invention relates to the field of the drying equipment and in particular relates to a conduction oil heating dryer for materials such as food, Chinese herbs and dehydrated vegetables. The conduction oil heating dryer comprises a left support, a right support, a motor, an air blower and a heater, wherein the motor is arranged on the left support, while the air blower and the heater are arranged on the right support; one end of the air blower is connected with a first communicating pipeline, while the other end of the air blower is connected with the heater; one end of the heater is connected with one end of a drying box by use of a second communicating pipeline; a steam outlet is formed in the drying box; the motor is connected with a conveyor belt by use of a chain. The conduction oil heating dryer is environmental friendly and energy-saving; besides, the dryer is provided with double air outlets to supply air so that the efficiency and quality of drying are effectively improved, and the production cost of an enterprise is reduced while the production efficiency of the enterprise is improved.

Owner:NINGGUO RUIGUANTAI EQUIP

Novel refrigeration system for ice cream machine

PendingCN109099608ALarge temperature adjustment rangeRealize digital controlMechanical apparatusFrozen sweetsFour-way valveSystem requirements

The invention discloses a novel refrigeration system for an ice cream machine, comprising a compressor, a condenser, an electronic expansion valve, a production area and a four-way valve, wherein theproduction area comprises a stirring tank and a storage tank, and the electronic expansion valve is used in a refrigeration system. During refrigeration, a high-temperature high-pressure superheated steam working medium flows out of the compressor, enters the condenser to release heat and cool down, then enters the electronic expansion valve for throttling, and then becomes a low-temperature low-pressure liquid working medium, and the low-temperature low-pressure liquid working medium cools the stirring tank and the storage tank and finally flows back to the compressor for a next cycle. Duringheating, the coil of the four-way valve is adjusted, and a superheated steam flows out from an e-port of the four-way valve, and heats up the stirring tank and the storage tank separately. The advantages of the novel refrigeration system comprise that the stirring tank and the storage tank can fully absorb heat or release heat, and the electronic expansion valve can adjust the temperature of theproduction area according to system requirements, realizes digital control and remote control, improves product quality and ensures production efficiency, thereby achieving the purpose of efficientlyproducing different products.

Owner:江门市新会区康美制品有限公司

Calcination equipment for producing photocatalyst material

InactiveCN101497050BLarge temperature adjustment rangeReasonable structural designCatalyst activation/preparationFurnace typesBrickBiochemical engineering

The invention relates to calcining equipment for producing a photocatalyst material, which belongs to the technical field of calcinating equipment structures. The calcining equipment for producing the photocatalyst material comprises an equipment support 6, and is characterized in that the upper end surface of the equipment support 6 is provided with a live-roll table 12 spread by evenly distributed live rolls 1; a heater box body 10 is arranged above the equipment support 6; the live-rolls 1 pass through the inside of the heater box body 10; the heater box body 10 is provided with a transmission channel 11 along the direction of the live-rolls 1; the upper side and the lower side of each live-roll 1 inside the heater box body 10 are provided with an electric heating silicon carbide rod 2used for heating respectively; an insulating brick 3 is arranged on the outer layer of the electric heating silicon carbide rod 2; and an insulating material 4 is arranged on the outmost layer of theheater box body 10. The equipment with arbitrarily adjusted temperature between 100 and 2,000 DEG C is applicable to calcination oxidation for different materials at different temperatures, and has the advantages of reasonable structure design, adjustable operating speed of between 0.01 and 1m / min in continuous running without outage, energy and manpower conservation, high stability and production continuity, product quality and yield improvement and energy consumption reduction.

Owner:莱阳子西莱环保科技有限公司

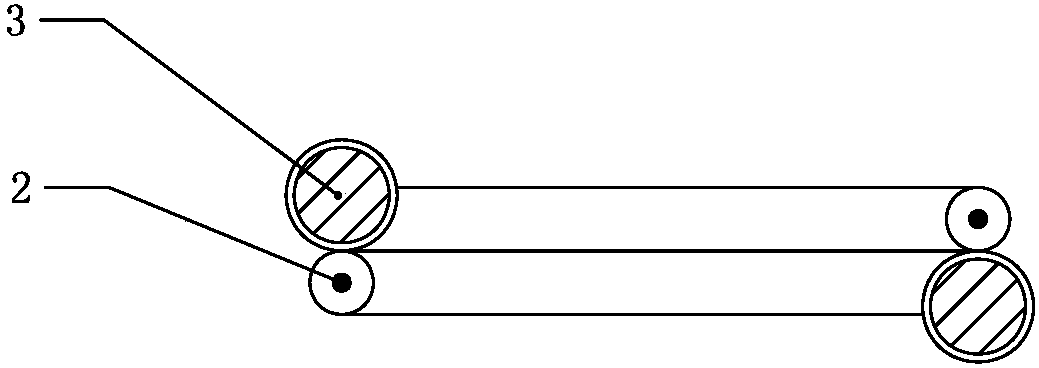

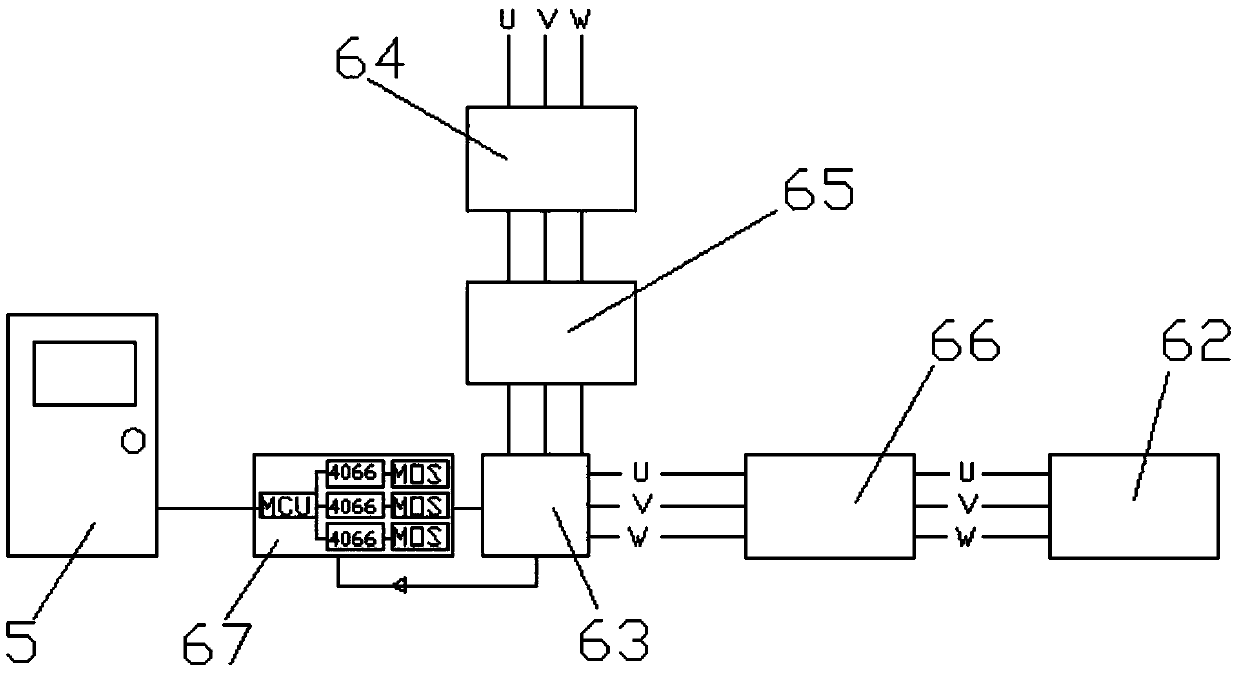

Secondary optical fiber plastic sleeving water temperature control device

ActiveCN103692639AThe water temperature control process is simple and safeHigh control precisionFibre mechanical structuresEngineeringControl switch

The invention discloses a secondary optical fiber plastic sleeving water temperature control device, and relates to auxiliary equipment in optical fiber production. The device comprises a water pump outlet, a water pump inlet, a water pump, a water temperature controller, a control cabinet, a water tank, heat exchangers and a compressor, wherein the water pump outlet is connected with the water pump; the water pump is connected with one end of the water pump inlet; the other end of the water pump inlet is connected with the water tank; the heat exchangers are distributed inside the water tank and are connected with the compressor; a pump control switch is arranged inside the control cabinet; the water temperature controller is arranged inside the control cabinet. The device is high in control precision and simple in control process, and energy consumption is reduced.

Owner:浙江东通光网物联科技有限公司

System suitable for simulating dielectric discharge in complex environment and use method

PendingCN111665423ASimple structureImprove reliabilityTesting dielectric strengthCompression machinesDielectricThermodynamics

The invention discloses a system suitable for simulating dielectric discharge in a complex environment and a use method. The system comprises a tested sample, a controller, an ultrahigh vacuum deviceand a high-low temperature dielectric discharge test device. The tested sample is arranged in the high-low temperature dielectric discharge test device; and the ultrahigh vacuum device and the high-low temperature dielectric discharge test device are electrically connected with the controller. The ultrahigh vacuum device mainly comprises a vacuum chamber, a mechanical vacuum pump, a compound molecular pump and a pipeline, wherein the mechanical vacuum pump, the compound molecular pump and the vacuum chamber are sequentially connected through the pipeline; and the high-low temperature dielectric discharge test device comprises a high-voltage insulating sleeve, a test workbench and refrigeration equipment, wherein the test workbench is arranged at the bottom of the vacuum chamber, the testedsample is placed on the test workbench, and the high-voltage insulating sleeve applies voltage to the tested sample. The system has a high-low temperature conversion function, is high in reliability,strong in operability and long in service life, and can reduce the dispersity of a surface flashover discharge test and improve the discharge stability and uniformity.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

500/600KW-5000/6000 KW combined cold and heat supply device

ActiveCN109631379AReduce wasteSimple structureCompression machinesRefrigeration safety arrangementEngineeringPressure sensor

The invention discloses a 500 / 600KW-5000 / 6000 KW combined cold and heat supply device. The 500 / 600KW-5000 / 6000 KW combined cold and heat supply device comprises a compressor unit, a regenerator, an air cooler, an evaporator and a DCS control cabinet, wherein at least eight groups of CO2 compressors are connected in parallel in the compressor unit; the regenerator comprises a first backheating pipeand a second backheating pipe, and the end socket of the first backheating pipe is connected to an input pipeline of the compressor unit; one end of the air cooler is connected to an output pipelineof the compressor unit, and the other end of the air cool is connected with one end of the second backheating pipe of the regenerator through a pipeline; one end of the evaporator is connected with the other end of the second backheating pipe of the regenerator through a backflow pipeline, and the other end of the evaporator is connected with the other end of the first backheating pipe of the regenerator through a connecting pipe; and the input end of the DCS control cabinet is separately and electrically connected with a first pressure sensor, a second sensor and the groups of compressors inthe compressor unit, and the control output end of the DCS control cabinet is separately connected with the groups of CO2 compressors in the compressor unit.

Owner:安徽正刚新能源科技有限公司

Multi-start spiral flow channel liquid cooler for heat dissipation of electronic component

InactiveCN109285821ACompact structureGuaranteed to workSemiconductor/solid-state device detailsSolid-state devicesCooling effectEngineering

Owner:刘梅

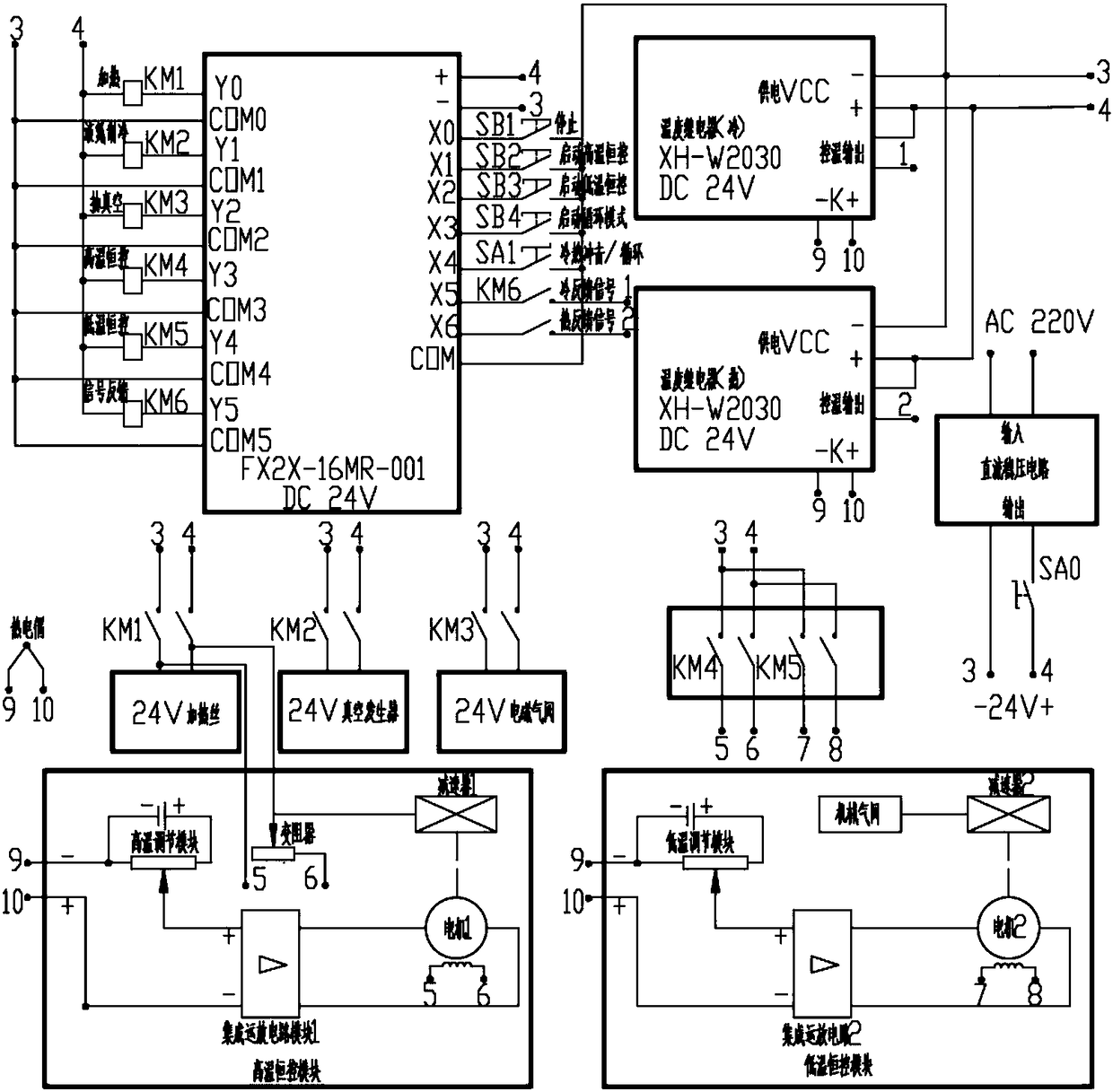

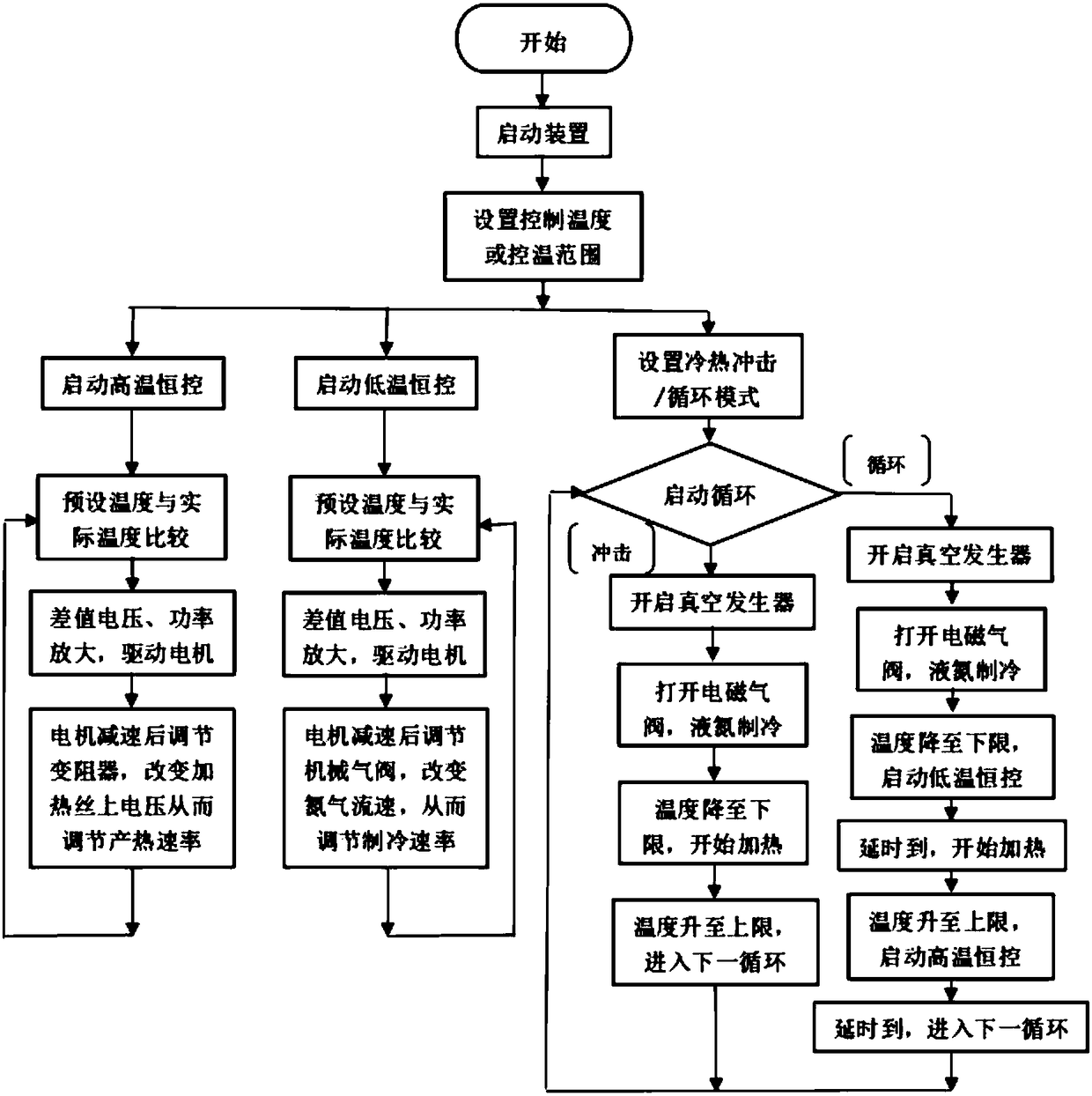

Temperature control system of temperature change reliability testing device

ActiveCN108445932ASave the waste of transferring back and forthReduce wasteTemperatue controlTemperature controlControl system

The invention discloses a temperature control system of a temperature change reliability testing device. The system comprises a PLC, a high temperature constant control module, a low temperature constant control module, a cold temperature relay, a hot temperature relay, a DC voltage stabilizing circuit, a thermocouple, heating wires, a power supply, a vacuum generator, an electromagnetic air valve, a plurality of contactors and a plurality of buttons. The temperature control system of a temperature change reliability testing device can realize constant temperature steady state control and coldand hot shock of a cold and hot cycle testing device, the anti-interference ability and sensitivity of the system are improved, and the system is optimized to a certain extent in space occupation.

Owner:HOHAI UNIV CHANGZHOU

An air mixing and distributing device with temperature regulating function

ActiveCN104019252BImprove comfortImprove ventilationOperating means/releasing devices for valvesAir-treatment apparatus arrangementsCold airEngineering

An air mixing and distributing device with a temperature adjustment function comprises a shell, a connection rod, a large rocker arm, a small rocker arm I, a small rocker arm II, rotary shafts, a bolt, a valve piece I, a valve piece II and a valve piece III, wherein the connection rod, the large rocker arm, the small rocker arm I, the small rocker arm II and the rotary shafts on the shell form a parallel rocking shaft connection rod mechanism. When the large rocker arm is shaken, the valve pieces can be controlled to rotate around the rotary shafts in respective pipelines in a linkage mode through the parallel rocking shaft connection rod mechanism. When the included angle alpha of the valve piece I of an air exhaust path and the axis of the pipeline of the air exhaust path and the included angle alpha of the valve piece III of a cold air path and the axis of the pipeline of the cold air path are larger than 10 degrees and smaller than 80 degrees, at the time, the included angle beta of the valve piece II of a hot air path and the axis of the pipeline of the hot air path is equal to 90 degrees minus alpha, cold air and hot air are in a mixed state, and the mixing ratio of the cold air and the hot air can be controlled by controlling the included angle alpha. According to the device, the ventilation capacity of a ventilation system of a plane is improved, the temperature adjustment range is widened, circulation of fresh air in a cabin is improved and environment comfort of the cabin is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

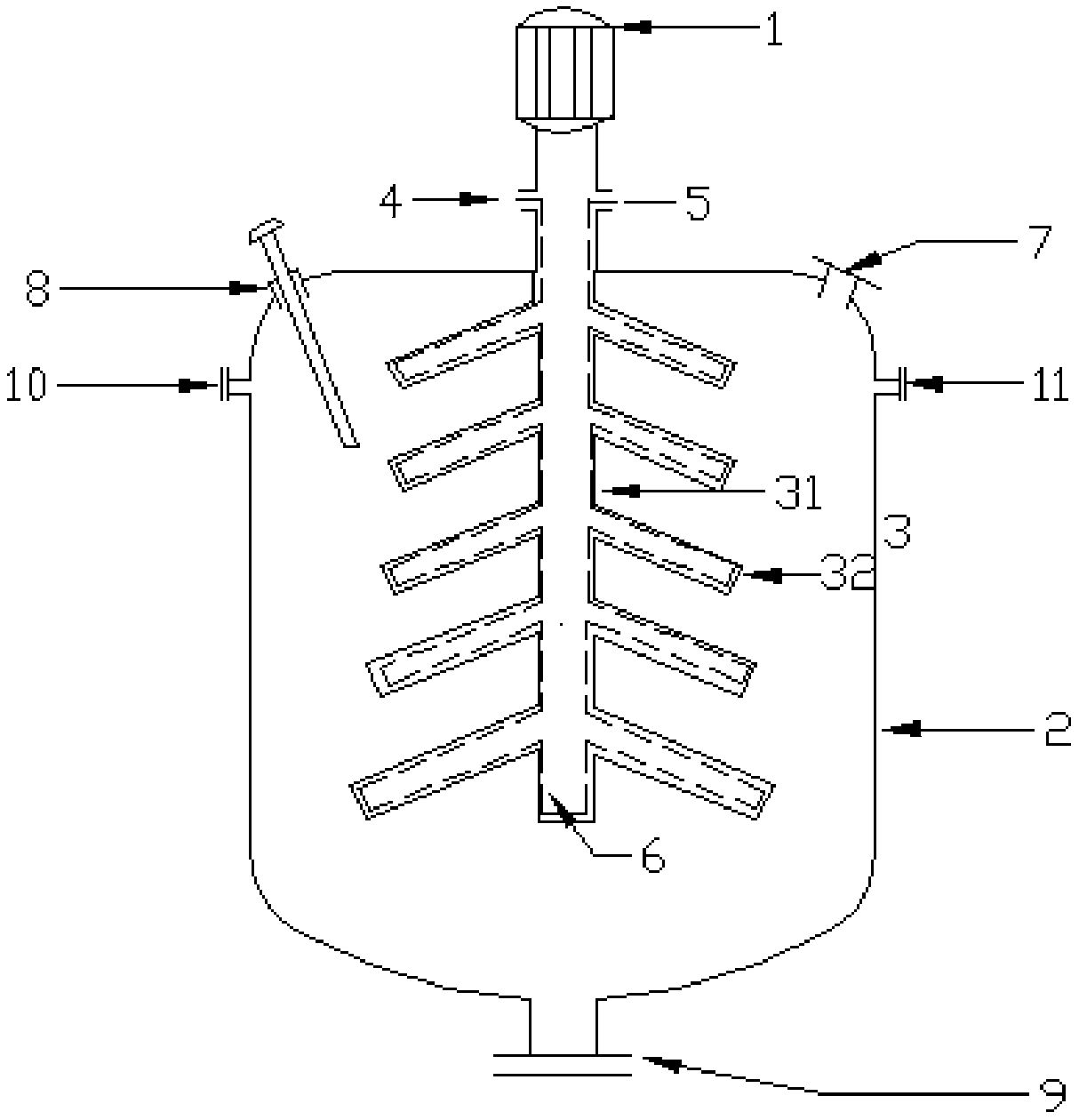

Biological fermentation apparatus

PendingCN108070522ALarge temperature adjustment rangeGood effectBioreactor/fermenter combinationsBiological substance pretreatmentsWater deliveryEngineering

The invention provides a biological fermentation apparatus. A stirring rod and stirring blades are driven by the rotation of a motor to rotate so as to stir a fermentation sample, and when a fermentation temperature in a tank body is changed, a temperature sensor transmits information to a controller, the fermentation temperature is adjusted by adjusting the temperature of water in a water delivery pipeline located in the stirring rod and the stirring blades. Along with the rotation of the stirring rod and the stirring blades, the water delivery pipeline rotates, so that the heating range is greater, and the heating effect is better. According to the biological fermentation apparatus provided by the invention, the water delivery pipeline is arranged in the stirring rod and the stirring blades, so that the temperature adjusting range is greater, the temperature adjusting effect is better, and the space is also saved; by arranging the temperature sensor, the temperature of a fermentationtank is adjusted in real time; and the biological fermentation apparatus is reasonable in design, simple and convenient in operation, capable of integrating the stirring and temperature control, andmore precise and effective in temperature control.

Owner:天津奥华通航科技有限公司

Refrigerator with unfreezing and heat insulation functions

InactiveCN107328157ALarge adjustment rangeIncrease humidityLighting and heating apparatusDomestic refrigeratorsFreezing chamberEngineering

The invention discloses a refrigerator with heat insulation and unfreezing functions. The refrigerator comprises a freezing chamber, a refrigerating chamber, an unfreezing and heat insulation chamber, a condenser and a control device, wherein the condenser comprises a lower coiled pipe, a first metal hose, an upper coiled pipe, a second metal hose and a condensing pipe; the upper coiled pipe can be horizontally placed or vertically placed through manual operation; the unfreezing and heat insulation chamber comprises a water groove provided with a water pump, a water sprinkler, a support, a vertical fixing mechanism and a second fan; the vertical fixing mechanism is installed at a rear side of an inner cavity of the unfreezing and heat insulation chamber, and used for fixing a position of the upper coiled pipe while being vertically placed; and the control device comprises a setting module, a control module and a third temperature sensor. The refrigerator disclosed by the invention is simple in structure and convenient to install; and the refrigerator carries out food unfreezing through adopting different unfreezing modes, so that heat dissipation of the condenser of the refrigerator can be effectively reduced, and no spoilage of foods due to a too high temperature or long-time placement because of forgetting can be effectively guaranteed.

Owner:台山市爱生电器有限公司

A refrigerator with functions of thawing and keeping warm

InactiveCN107328157BReduce the temperatureLarge temperature adjustment rangeLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention discloses a refrigerator with heat insulation and unfreezing functions. The refrigerator comprises a freezing chamber, a refrigerating chamber, an unfreezing and heat insulation chamber, a condenser and a control device, wherein the condenser comprises a lower coiled pipe, a first metal hose, an upper coiled pipe, a second metal hose and a condensing pipe; the upper coiled pipe can be horizontally placed or vertically placed through manual operation; the unfreezing and heat insulation chamber comprises a water groove provided with a water pump, a water sprinkler, a support, a vertical fixing mechanism and a second fan; the vertical fixing mechanism is installed at a rear side of an inner cavity of the unfreezing and heat insulation chamber, and used for fixing a position of the upper coiled pipe while being vertically placed; and the control device comprises a setting module, a control module and a third temperature sensor. The refrigerator disclosed by the invention is simple in structure and convenient to install; and the refrigerator carries out food unfreezing through adopting different unfreezing modes, so that heat dissipation of the condenser of the refrigerator can be effectively reduced, and no spoilage of foods due to a too high temperature or long-time placement because of forgetting can be effectively guaranteed.

Owner:台山市爱生电器有限公司

Treating system and method for governing waste gas of volatile organic compounds (VOCs) through plasma, and application of treating system

PendingCN110548373AImprove processing efficiencyReduce environmental pollutionGas treatmentDispersed particle separationCombustion chamberAtmosphere

The invention relates to a treating system for governing waste gas of volatile organic compounds (VOCs) through plasma. The treating system comprises a heat exchanger, a combustion chamber, an induceddraft fan, a plasma spray gun, a waste gas connecting pipeline and a valve; a waste gas source is connected with the combustion chamber through the heat exchanger and is a place or equipment capableof generating the waste gas of the VOCs, and the heat exchanger can initially heat the waste gas of the VOCs; and the combustion chamber is connected with the induced draft fan through the heat exchanger, the heat exchanger can conduct heat exchanging on gas and water generated in the combustion chamber, and the induced draft fan can discharge the gas treated through the heat exchanger into atmosphere. The treating system can be used in the aspect of governing the waste gas, generated by various industries and equipment, of the VOCs, the treated waste gas can meet the requirements of the emission standard of emitted gas in China, through the treating system, the treating efficiency of the waste gas of the VOCs is significantly improved, the waste gas is discharged to reach the standard, environment pollution is reduced, and the application prospects are quite wide.

Owner:AEROSPACE ENVIRONMENTAL ENG

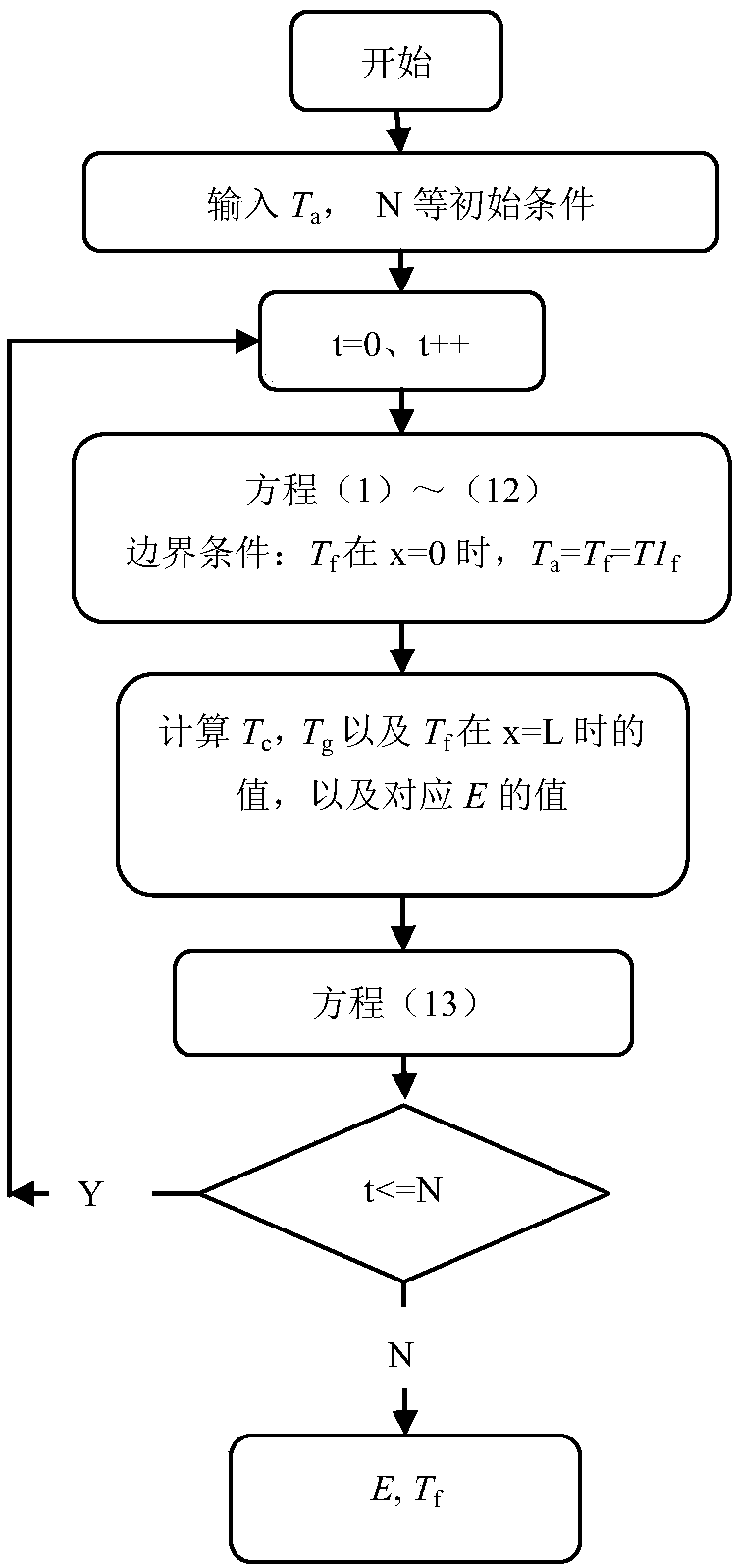

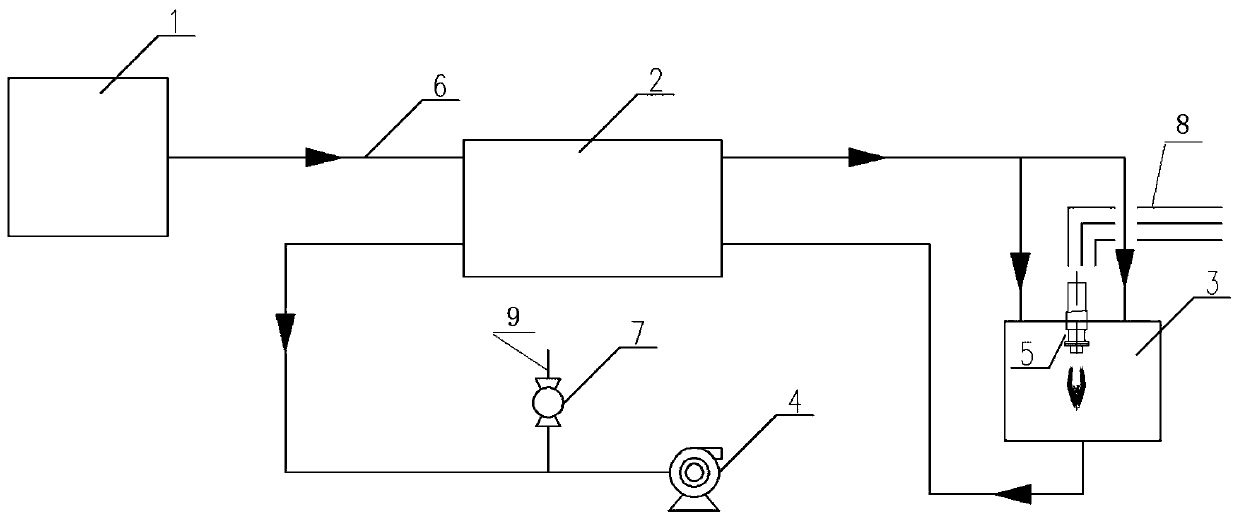

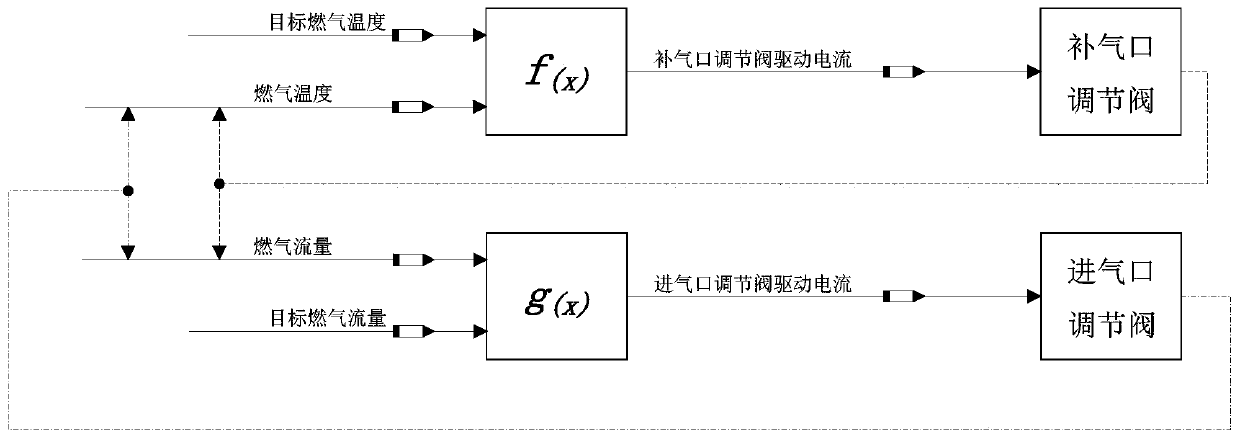

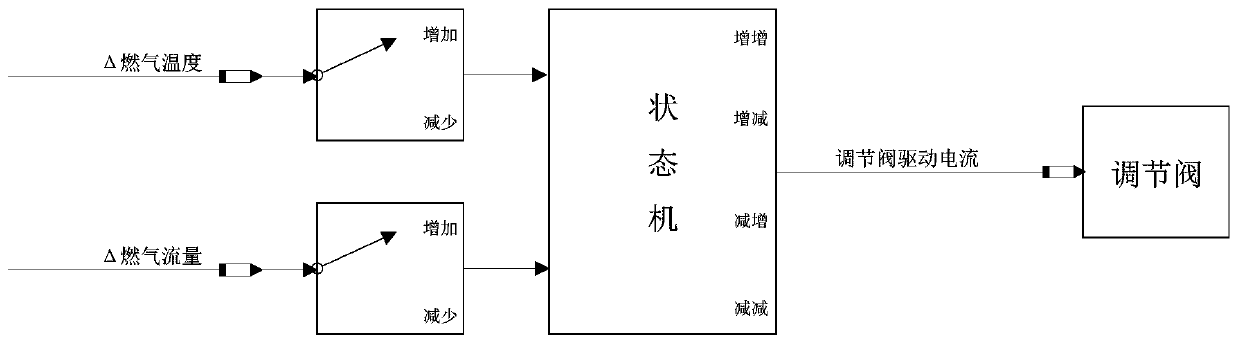

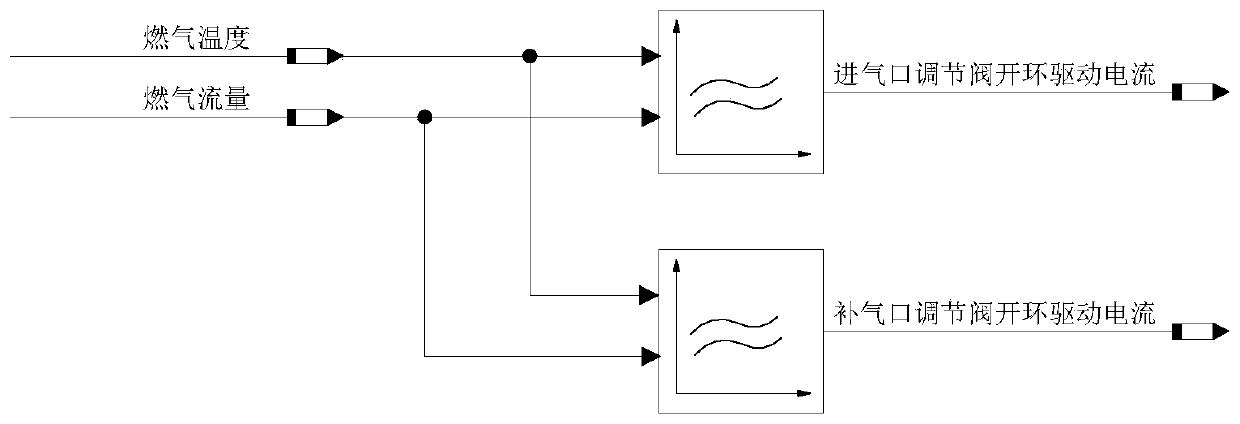

A method for controlling the combustion chamber of a turbocharger test bench with a mixing section

ActiveCN108181955BLarge temperature adjustment rangeIncrease temperatureSimultaneous control of multiple variablesThermodynamicsCombustion chamber

The invention provides a control method of a turbocharger testing stand combustion chamber with a mixing section. The control method includes following content: acquiring a real-time combustion gas temperature and a real-time combustion gas flow passing a flange of an outlet of the combustion chamber, comparing the real-time combustion gas temperature and the real-time combustion gas flow with a preset target combustion gas temperature and a preset target combustion gas flow, and obtaining a delta combustion gas temperature deviation and a delta combustion gas flow deviation; closed-loop control: abstracting four states according to the states of the delta combustion gas temperature deviation and the delta combustion gas flow deviation, then selecting a corresponding closed-loop control method according to a state machine, and calculating control currents of an air-inlet regulating valve and an air supply port regulating valve; and introducing a feedforward control link to shorten theregulation period. The control method is advantageous in that through the combustion gas temperature and the combustion gas flow of the rear flange, the opening degree of valves of an air inlet and anair supply port can be rapidly adjusted, the air flow and the combustion temperature of the outlet of the combustion chamber are changed, and stable rotating speed of a turbocharger in a test processis guaranteed.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com