Water-cooled rod and crystal growth furnace using the water-cooled rod

A technology of crystal growth furnace and water-cooled rod, which is applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc. It can solve the problems that the sealed crucible cannot be used multiple times, the water-cooled rod cannot effectively adjust the temperature field, and the volatilization of raw materials, etc. Achieve the effect of ensuring balance, wide temperature adjustment range and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

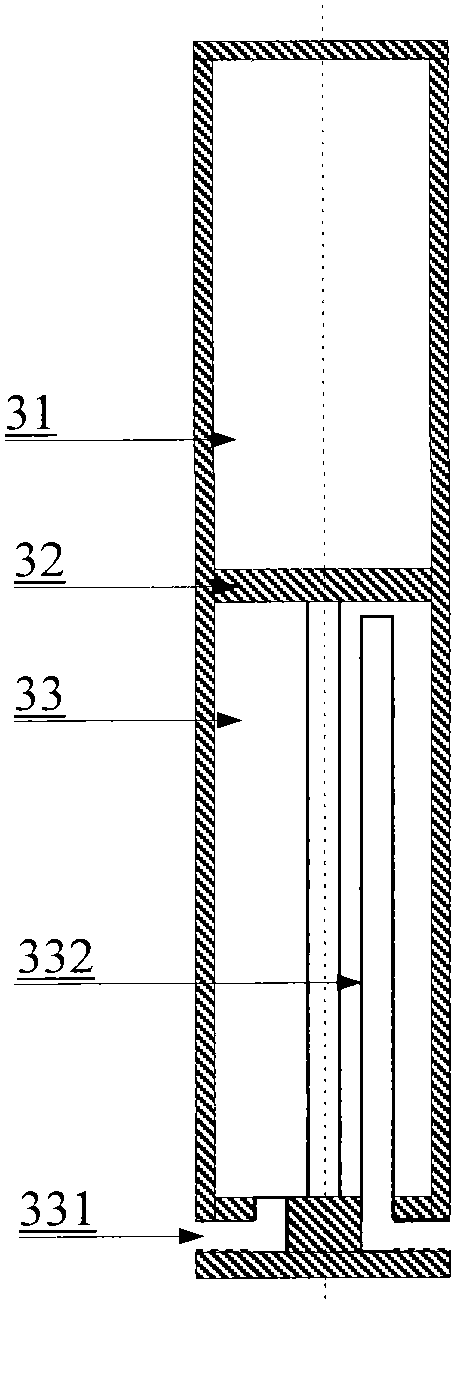

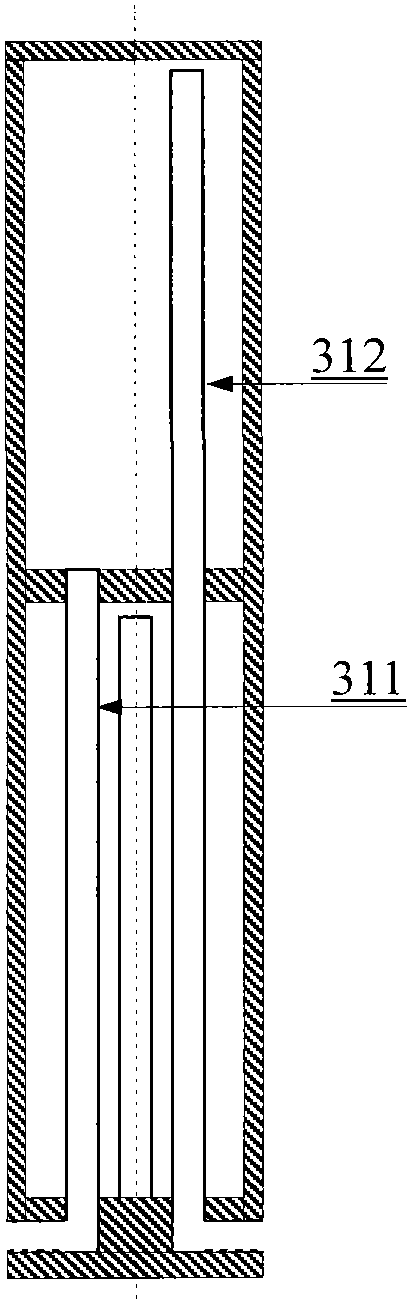

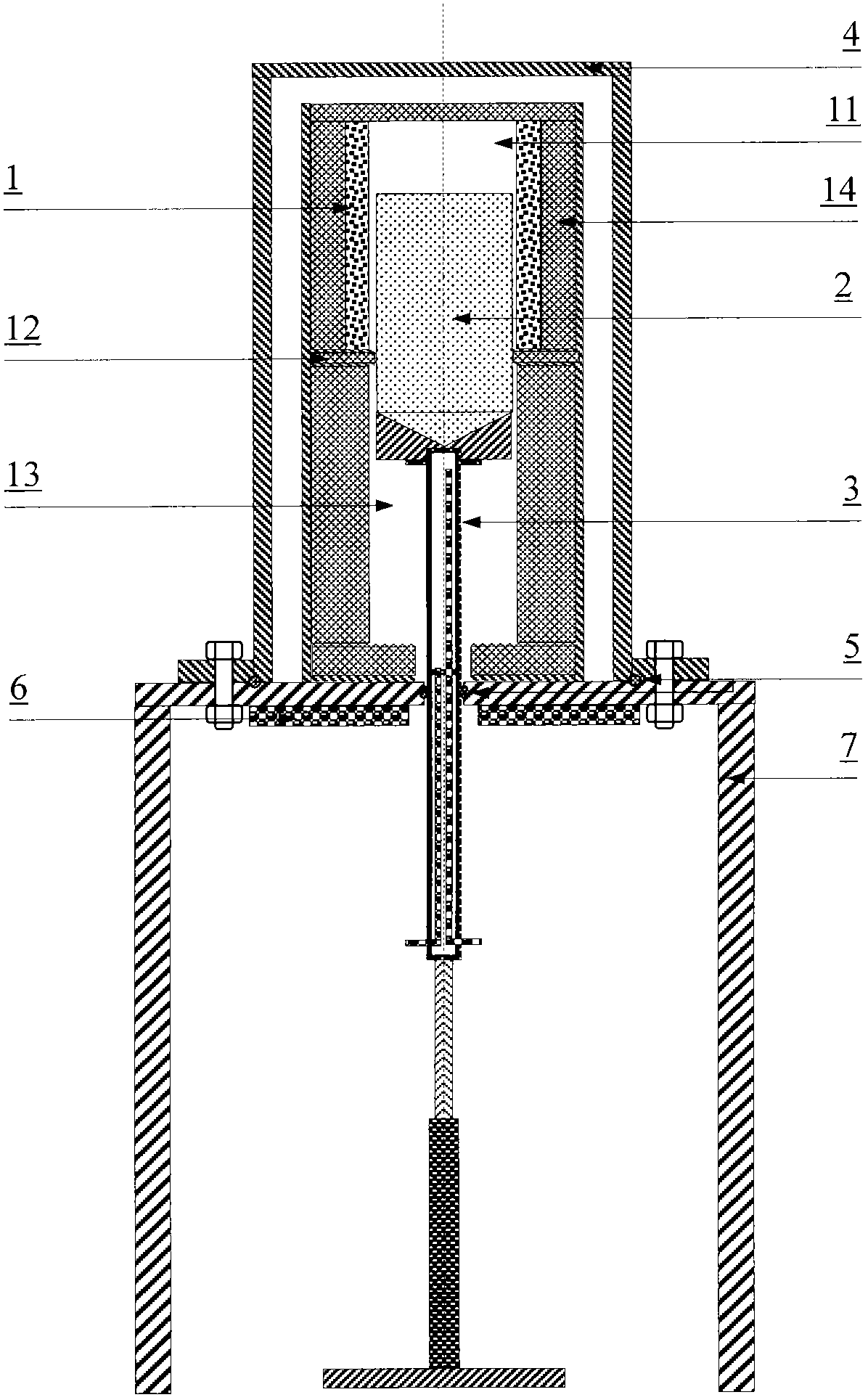

[0029] Combine below figure 1 , figure 2 The water-cooled rod of the present invention will be described in detail.

[0030] The present invention provides a water-cooled rod, which includes an upper water-cooled section 31 and a lower water-cooled section 33 separated by a partition layer 32 , each of which is provided with a water inlet and a water outlet. Compared with conventional water-cooled rods, this sectional water-cooling method enables the upper water-cooling section 31 and the lower water-cooling section 33 to have a better cooling effect on the corresponding positions of each section. In a preferred embodiment, the upper water inlet pipe 311 passes through the water inlet of the lower water cooling section 33 and the water inlet of the upper water cooling section 31, and the upper water outlet pipe 312 passes through the water outlet of the upper water cooling section 31 and the water outlet of the lower water cooling section 33, This way enables the lower wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com