Multi-start spiral flow channel liquid cooler for heat dissipation of electronic component

A technology of electronic components and spiral flow channels, applied in the field of micro-channel liquid coolers, can solve problems such as asymmetry rise, radiator rise, chip deformation, etc., to reduce adverse effects, prolong service life, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

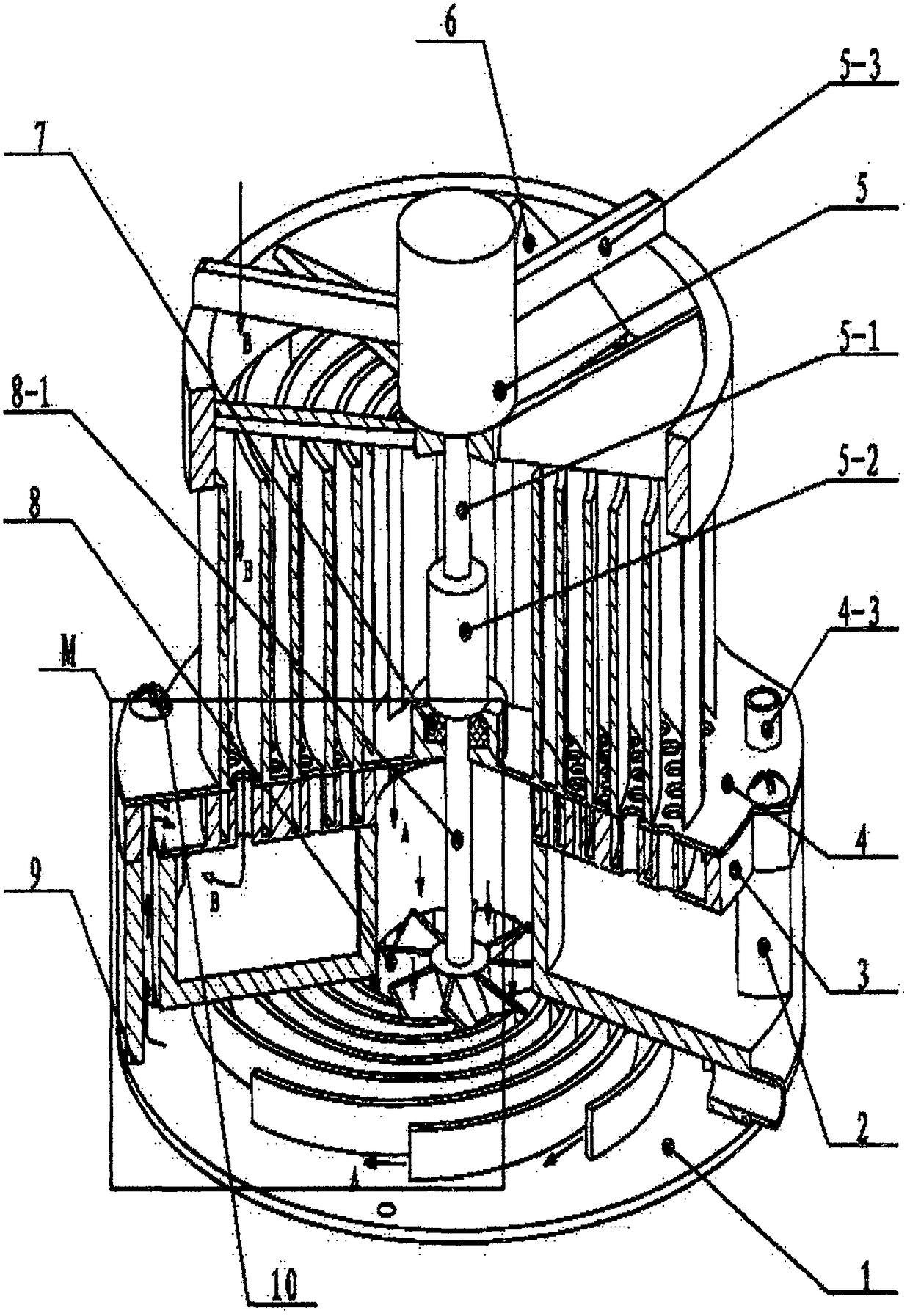

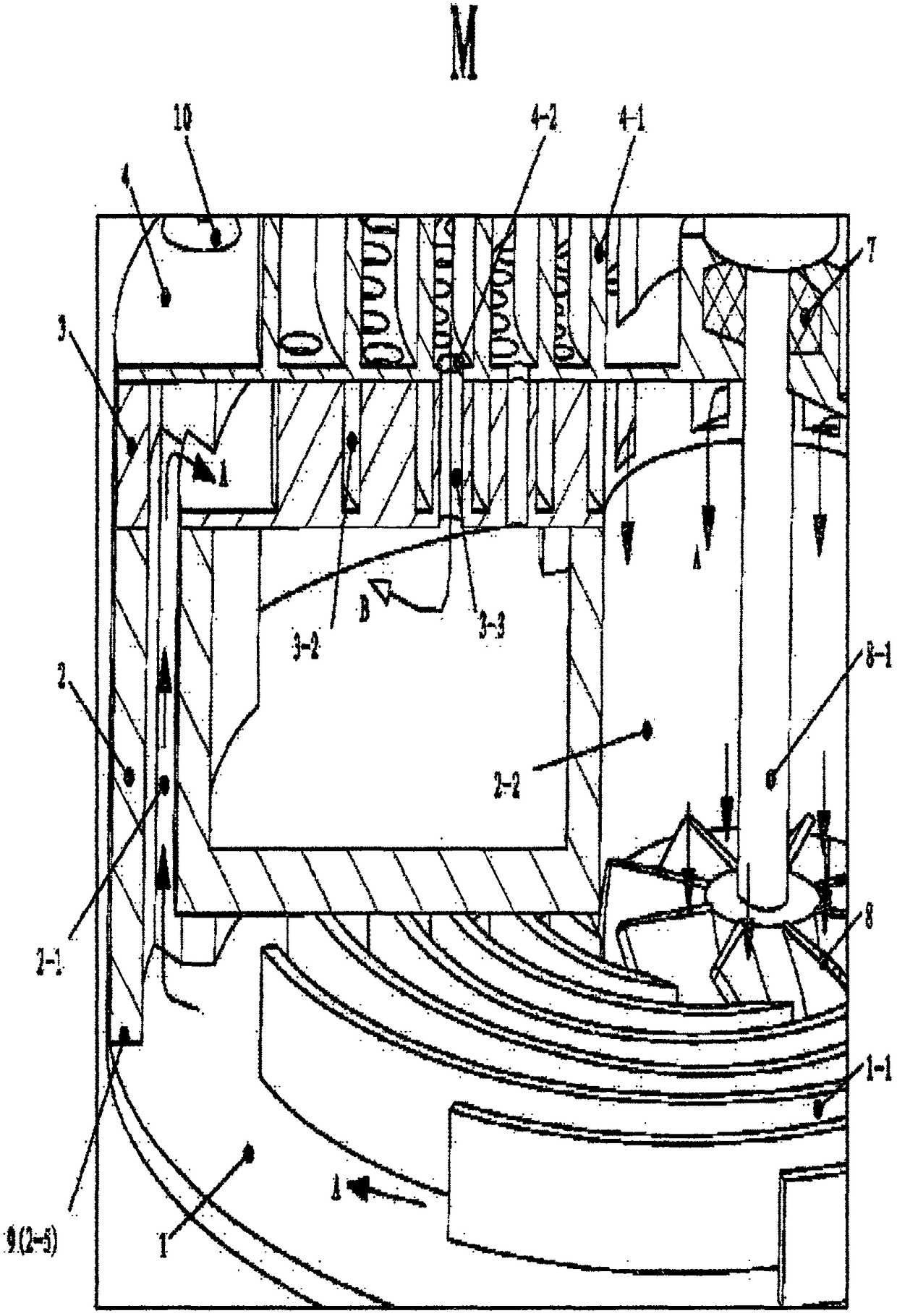

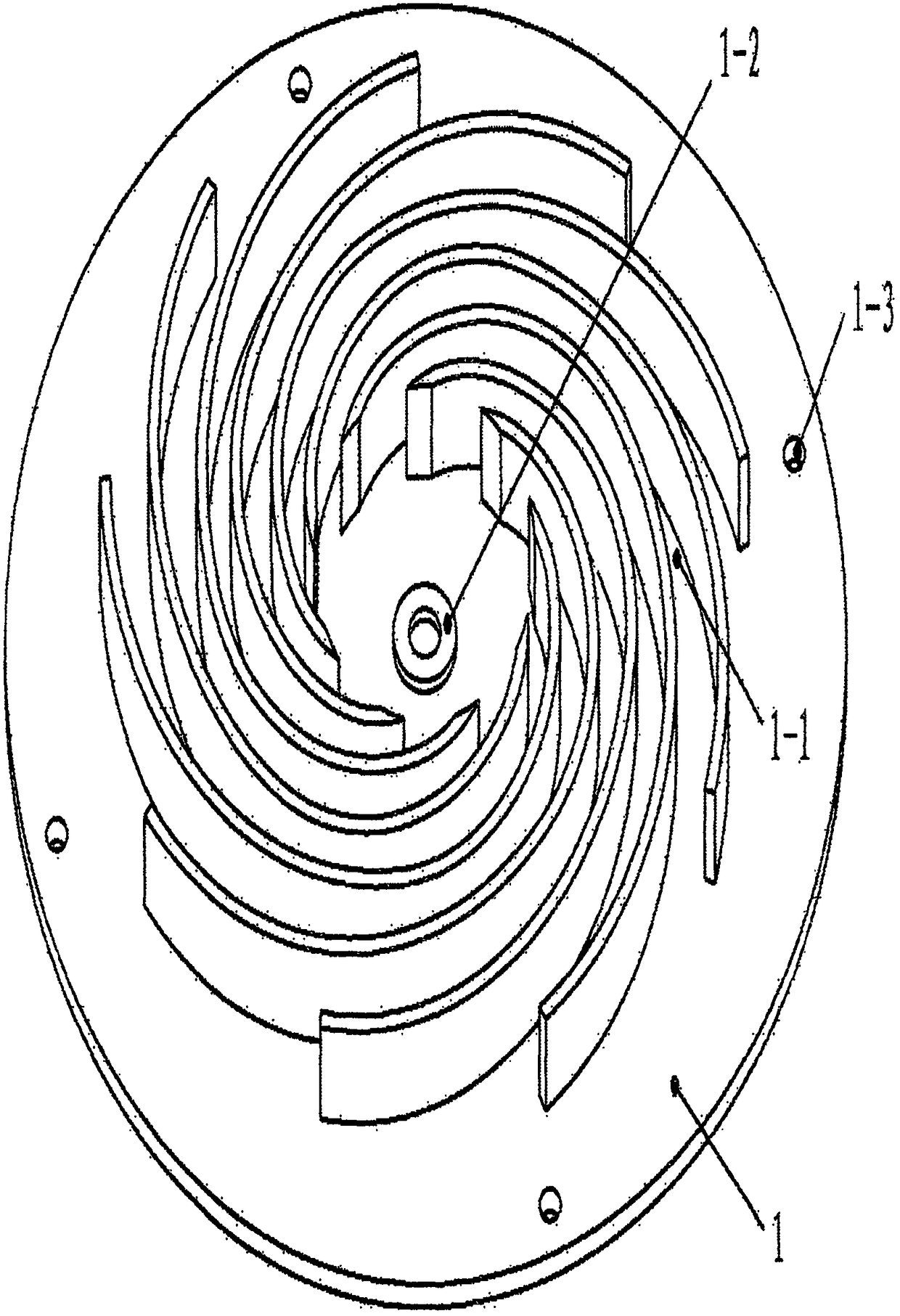

[0015] In this embodiment, the CPU heat dissipation cooler with the maximum power of 100W for PC is taken as an example, wherein: (spiral flow channel) cooling plate 1 has a diameter of Φ65mm, and 9 spiral flow channels are opened on it, and its spiral flow channel 1-1 is a pair of Several spiral flow channels, each flow channel is 58mm long, 3mm deep, 1mm wide at the inlet, and 3mm wide at the outlet; the airflow cooling chamber 2 has a diameter of Φ65mm and a height of 12mm, and there are four symmetrical cooling fluid diversion grooves 2-1 on it. and the arc-shaped platform with fixed connection holes 2-3, the arc-shaped platform is 14mm long and 8mm high, and the coolant guide groove 2-1 axially runs through the entire arc-shaped platform and the bottom plate of the cavity, and is respectively connected with the (lower) spiral The cooling liquid inlet 3-1 of the runner cooling plate 1 and the (upper) spiral groove cooling liquid cooling plate 3 is connected, and the diversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com