Application of ionic liquid serving as magnetorheological fluid base solution, magnetorheological fluid based on ionic liquid and preparation method thereof

A technology for ionic liquids and magnetorheological fluids, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor stability of water-based magnetorheological fluids, loss of dispersant function, large thermal expansion coefficient, etc., and achieve good design performance, Good thermal stability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

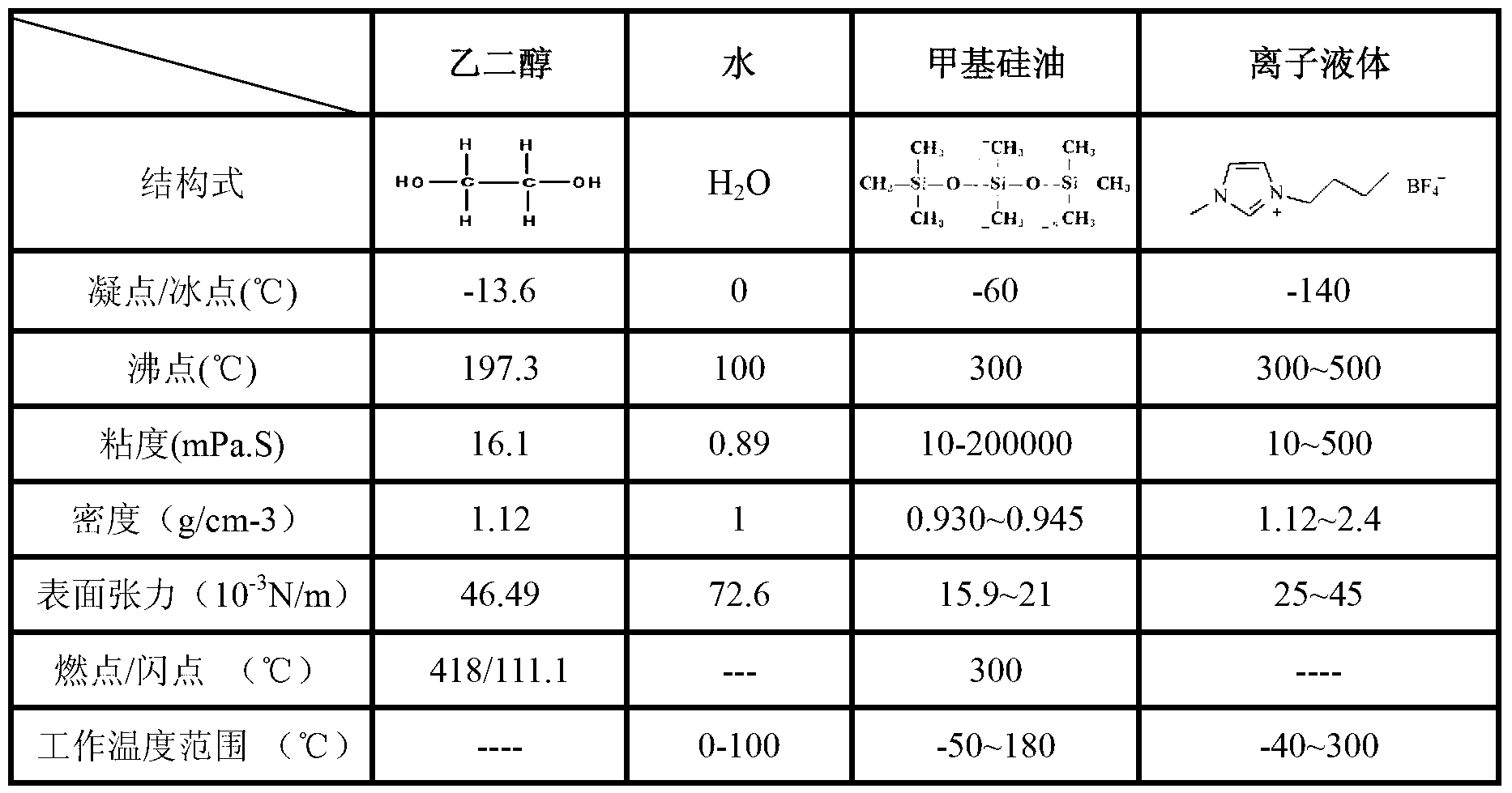

Embodiment 1

[0025] Firstly, the pentacarbonyl iron powder is pyrolyzed and ground to obtain carbonyl iron powder with a particle size of micron or submicron, and the obtained carbonyl iron powder is phosphated to obtain carbonyl iron powder magnetic particles, and then 18 parts by mass of 1- Ethyl-3-methylimidazolium tetrafluoroborate ionic liquid (see Table 1 for its specific parameters), measure the total mass parts as 2 parts of additives, add the additives into the ionic liquid and stir evenly, the thixotropic agent in the additive is selected Organic bentonite, the dispersant is a silane coupling agent, the lubricant is graphite, and the nanoparticles are nano-iron oxides. Finally, 80 parts by mass of phosphated carbonyl iron powder are added to the ionic liquid, and a sand mill is used to disperse the mixer Disperse at a high speed of 3000 rpm for 10 hours, and then prepare the ionic liquid-based magnetorheological fluid.

Embodiment 2

[0027] Firstly prepare iron carbide powder, carry out silicon dioxide coating treatment to the obtained powder mixture to obtain magnetic particles with a particle size of micron or submicron, and then measure 39.5 parts by mass of 1-octyl-3-methylimidazolium tetrafluoro Borate ionic liquid (see Table 1 for its specific parameters), the total mass part is 0.5 part of additive, the additive is added into the ionic liquid and stirred evenly, the thixotropic agent in the additive is organic bentonite, the dispersant is stearate, The lubricant is molybdenum disulfide, and the nanoparticles are nano-silicon oxide. Finally, 60 parts by mass of silicon dioxide-coated iron carbide magnetic particles are taken, and the silicon dioxide-coated iron carbide magnetic particles are added to the ionic liquid. , and disperse at high speed for 5 hours with a sand mill dispersing mixer at a speed of 5000 r / min to prepare an ionic liquid-based magnetorheological fluid.

Embodiment 3

[0029] Preparation of iron oxide powder, polystyrene coating treatment on the obtained powder to obtain magnetic particles with a particle size of micron or submicron, and then measure 25 parts by mass of 1-octyl-3-methylimidazolium chloride ion Liquid (see Table 1 for its specific parameters), the total mass parts are 5 parts of additives, the thixotropic agent in the additives is inorganic bentonite, the dispersant is alkyl sulfate, the lubricant is oleic acid, and the nanoparticles are nano-zinc oxide , and finally take 70 parts by mass of polystyrene-coated iron oxide powder, then add the coated iron oxide magnetic particles into the ionic liquid, and disperse at a high speed of 8000 rpm with a sand mill dispersing mixer Hours, the ionic liquid-based magnetorheological fluid is formulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com