Novel refrigeration system for ice cream machine

An ice cream machine and refrigeration system technology, applied in the field of new refrigeration systems, can solve the problems of reduced system risk stability, increased production costs, complex refrigeration systems, etc., and achieve the effects of improving system stability, reducing production costs, and optimizing refrigeration systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

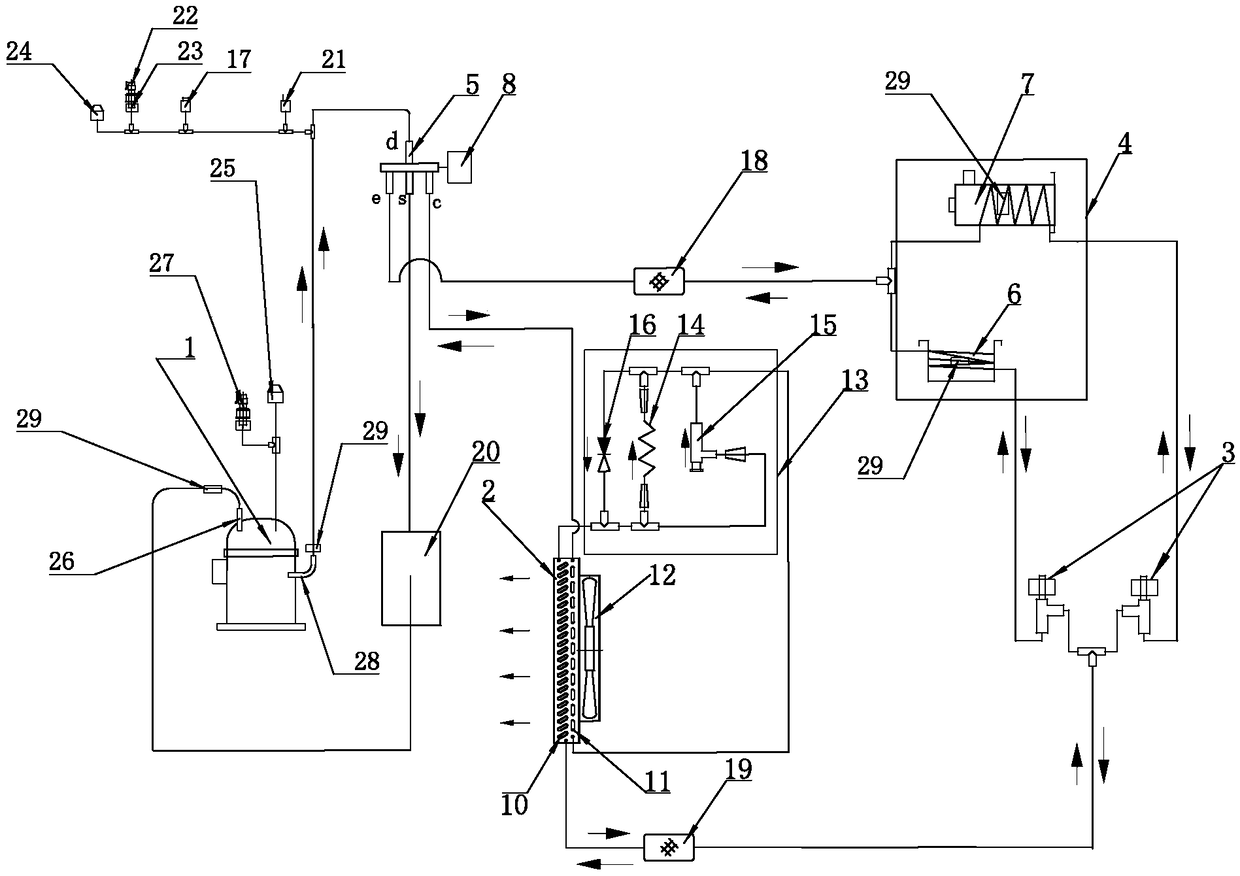

[0016] refer to figure 1 , the present invention is a novel refrigeration system for an ice cream machine, comprising a compressor 1, a condenser 2, an electronic expansion valve 3, a production area 4 and a four-way valve 5, and it is characterized in that: the production area 4 includes stirring Cylinder 7 and accumulator cylinder 6, the four-way valve 5 is controlled by the four-way valve coil 8, the air inlet 26 and the air outlet 28 of the compressor 1 are respectively connected to the d port and the s port of the four-way valve 5 connection, the e port of the four-way valve 5 is connected to the condenser 2, the c port of the four-way valve is connected to the production area 4, and the electronic expansion valve 3 is arranged between the condenser 2 and the production area 4 Between, the four-way valve 5, the condenser 2, the production area 4, and the electronic expansion valve 3 are connected in series in sequence. Refrigeration process: The high-temperature and high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com