A method for controlling the combustion chamber of a turbocharger test bench with a mixing section

A technology of turbocharger and control method, which is applied in control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of improper control method, difficulty in meeting the requirements of high-precision test results, and aggravation of supercharging. It can solve the problems such as the fluctuation of the speed of the device, so as to achieve the effect of stable speed, widening the adjustment range, and improving the temperature and flow adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

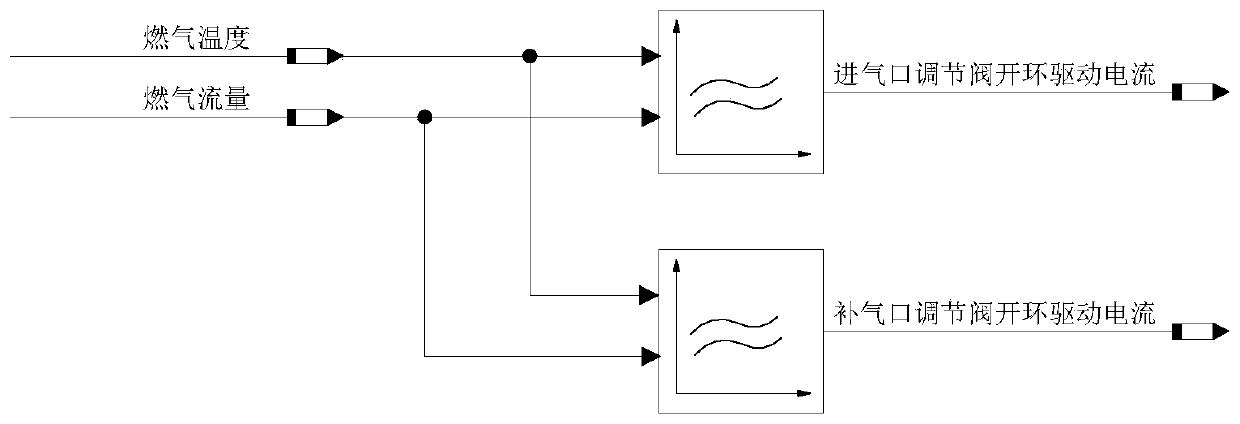

[0023] A method for controlling a combustion chamber of a turbocharger test bench with a mixing section, comprising the steps of:

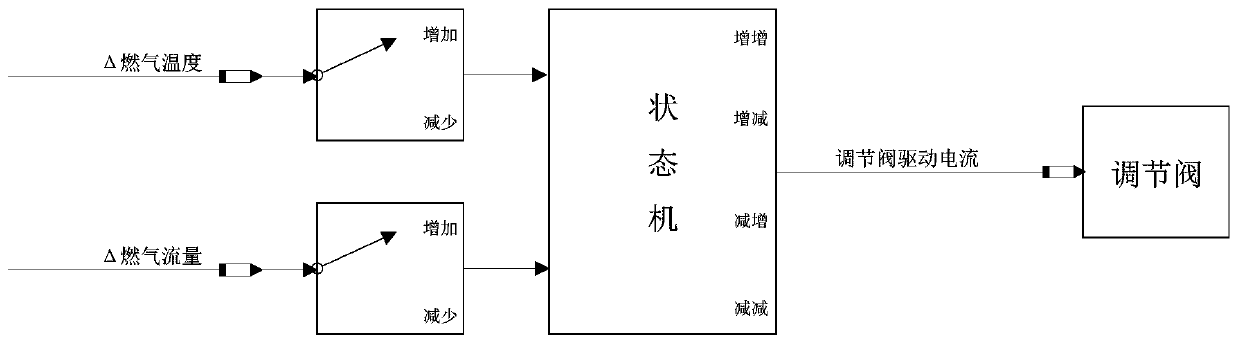

[0024] Collect the real-time gas temperature and real-time gas flow through the outlet flange of the combustion chamber, compare them with the preset target gas temperature and target gas flow, and obtain Δgas temperature deviation and Δgas flow deviation;

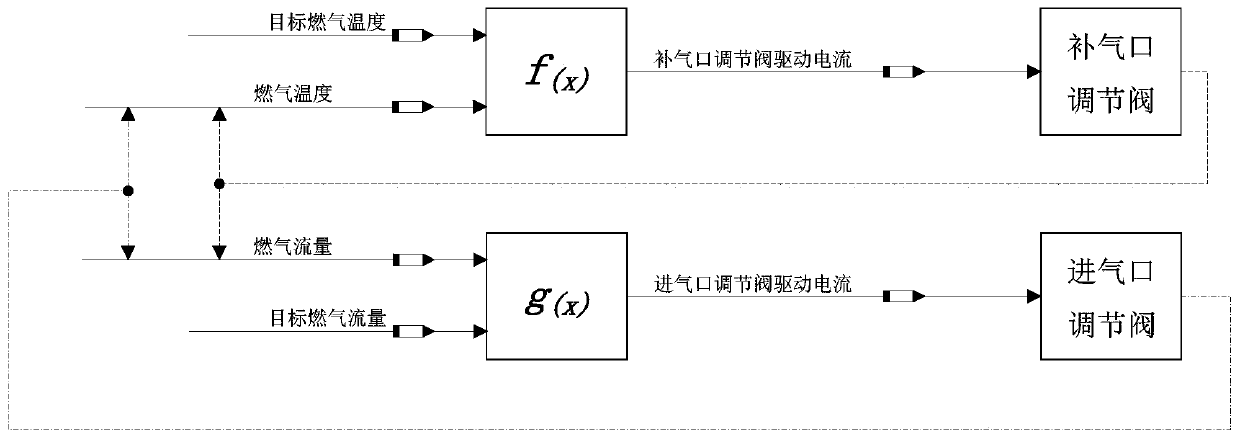

[0025] Closed-loop control: According to the state of Δgas temperature deviation and Δgas flow deviation, abstract such as figure 2 The four states shown, and then according to the state machine, select the corresponding closed-loop control parameters, specifically using the classic PID method, but the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com