Temperature control system of temperature change reliability testing device

A technology of temperature control system and test device, applied in temperature control, control/regulation system, non-electric variable control and other directions, can solve the problems of large temperature influence, poor adjustability, slow response speed, etc., to save space and occupy The effect of space optimization and good temperature control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

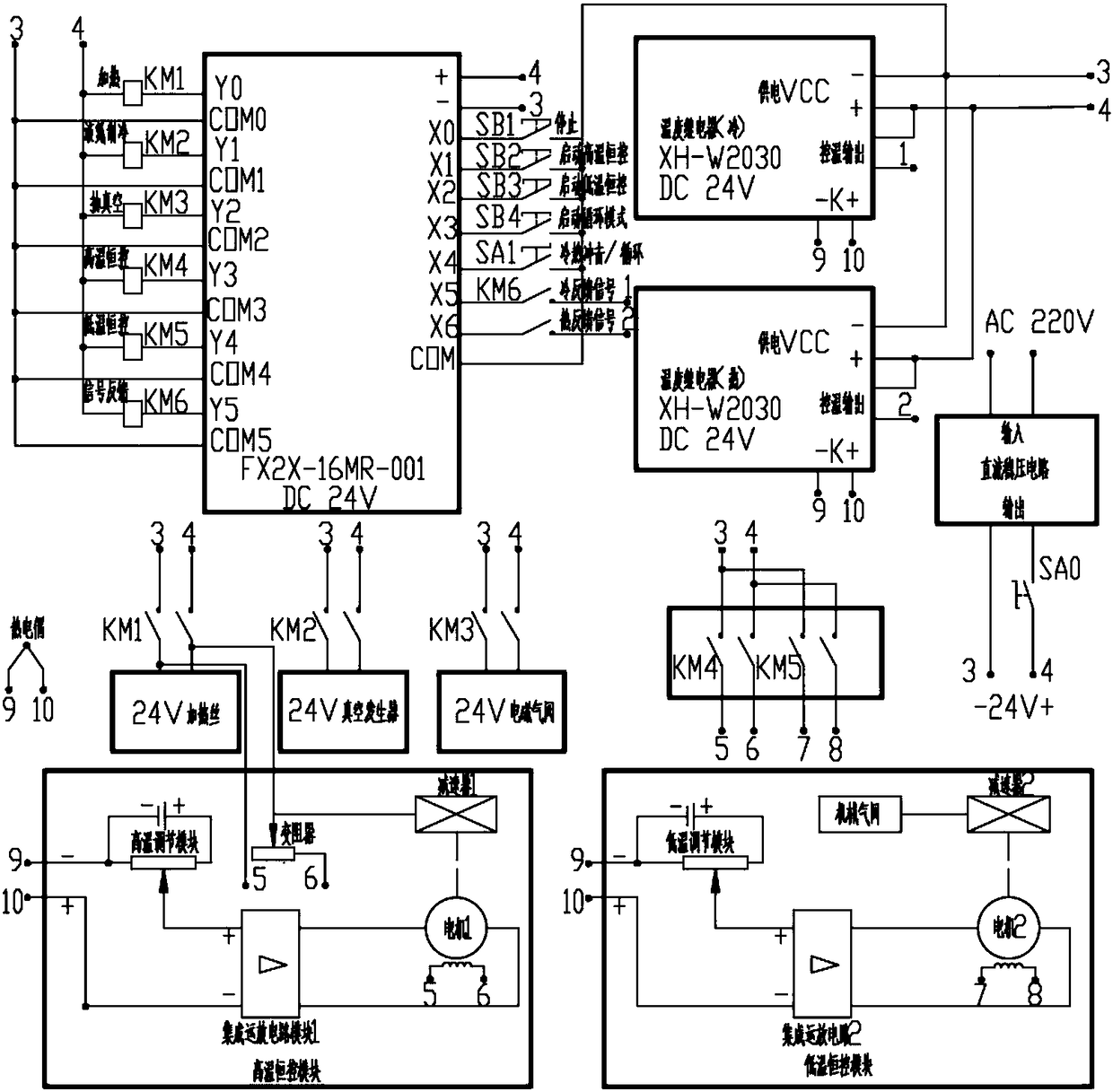

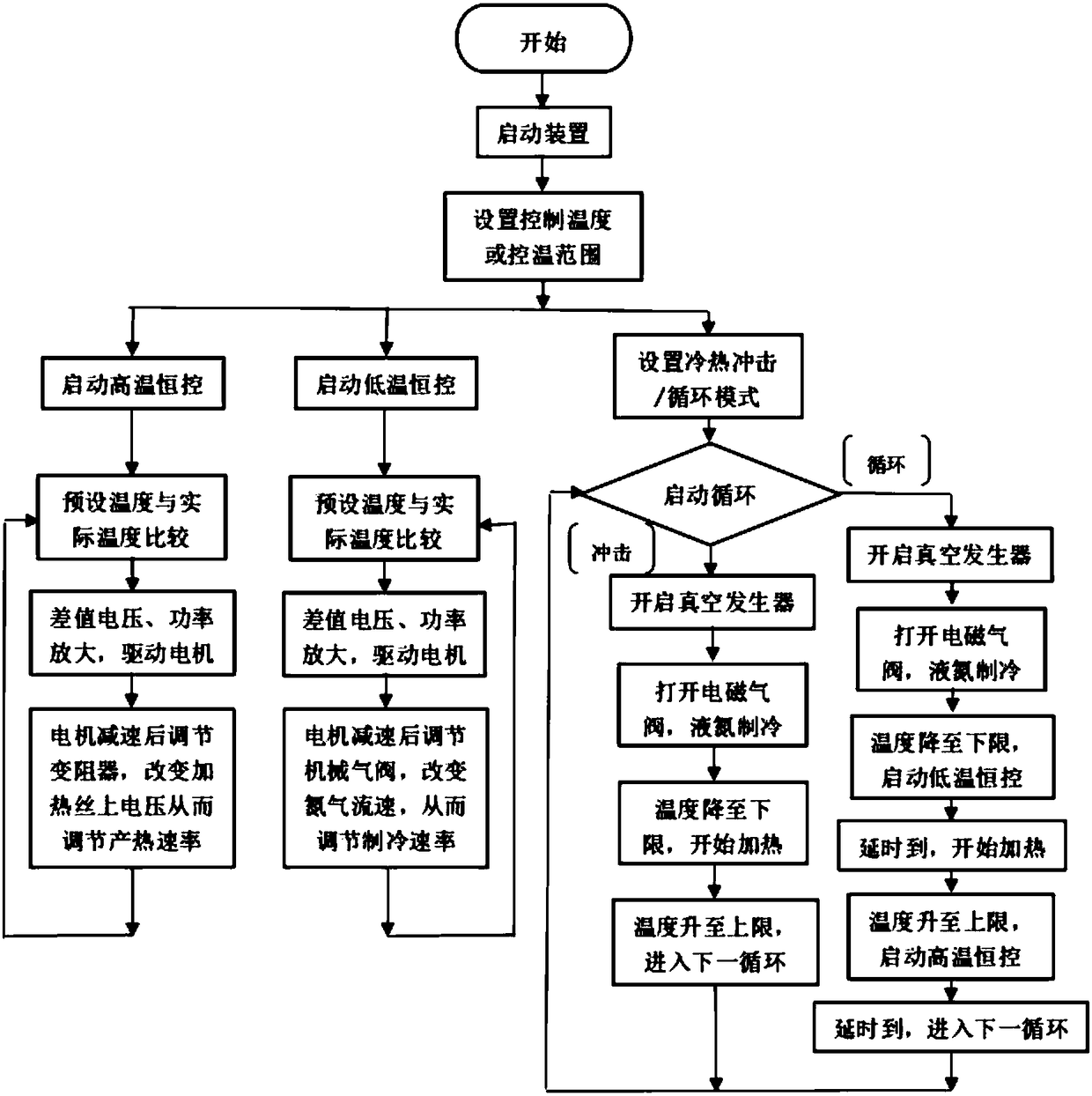

[0026]A temperature control system of a temperature change reliability test device, with a PLC controller as the core component, using a cold temperature relay and a hot temperature relay to set the temperature, after the conversion of the thermocouple, through the rheostat of the high temperature adjustment module and the low temperature adjustment module The regulation of the voltage on the circuit realizes the control of the temperature. After the PLC controller receives the cold and hot feedback signal through the contactor KM6, it can adjust the button SA1 to the cold and hot cycle position. The thermocouple on the cold temperature relay and the hot temperature relay will output the platform temperature felt by the voltage U1 at both ends, the contact point 10 is high level, the contact point 9 is low level, and the temperature signal of the preset temperature is adjusted by the high temperature module And the voltage U2, U3 output on the rheostat of the low temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com