Calcination equipment for producing photocatalyst material

A photocatalyst and calcination technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, lighting and heating equipment, etc. It can solve the problems of failing to keep up with product quality requirements, unstable product quality, and poor continuous production. Achieve the effects of saving energy and manpower, high production continuity, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

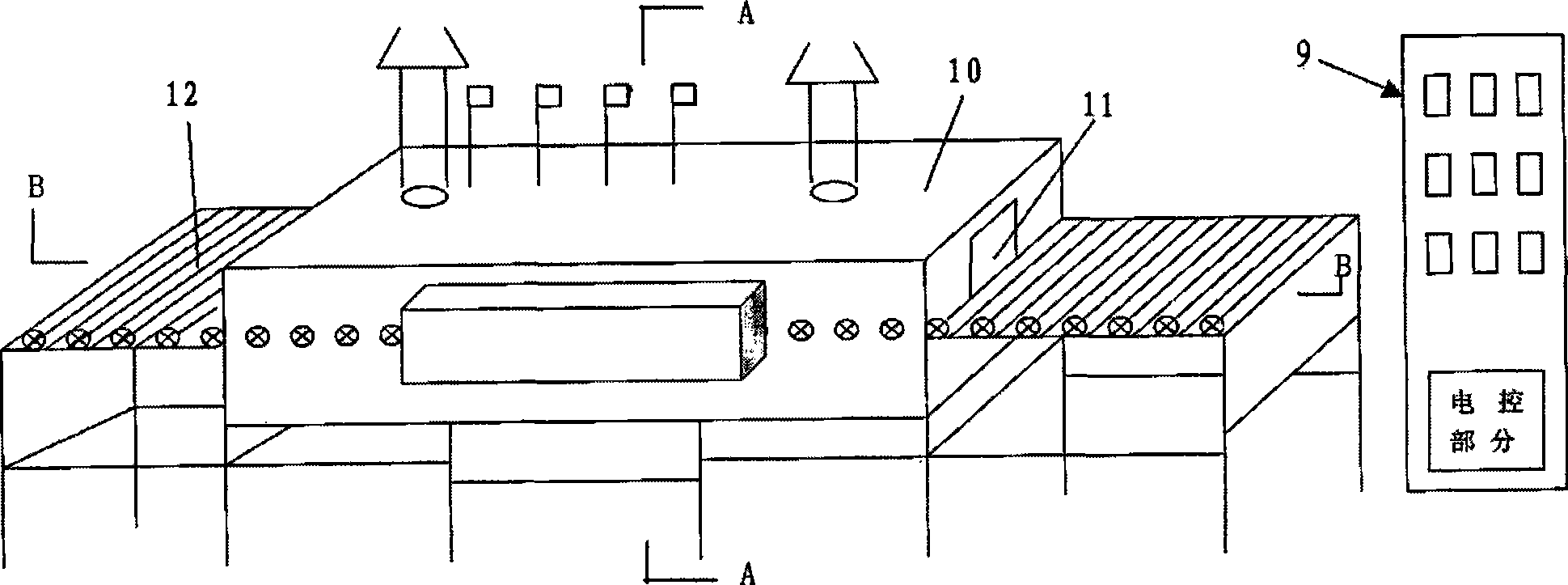

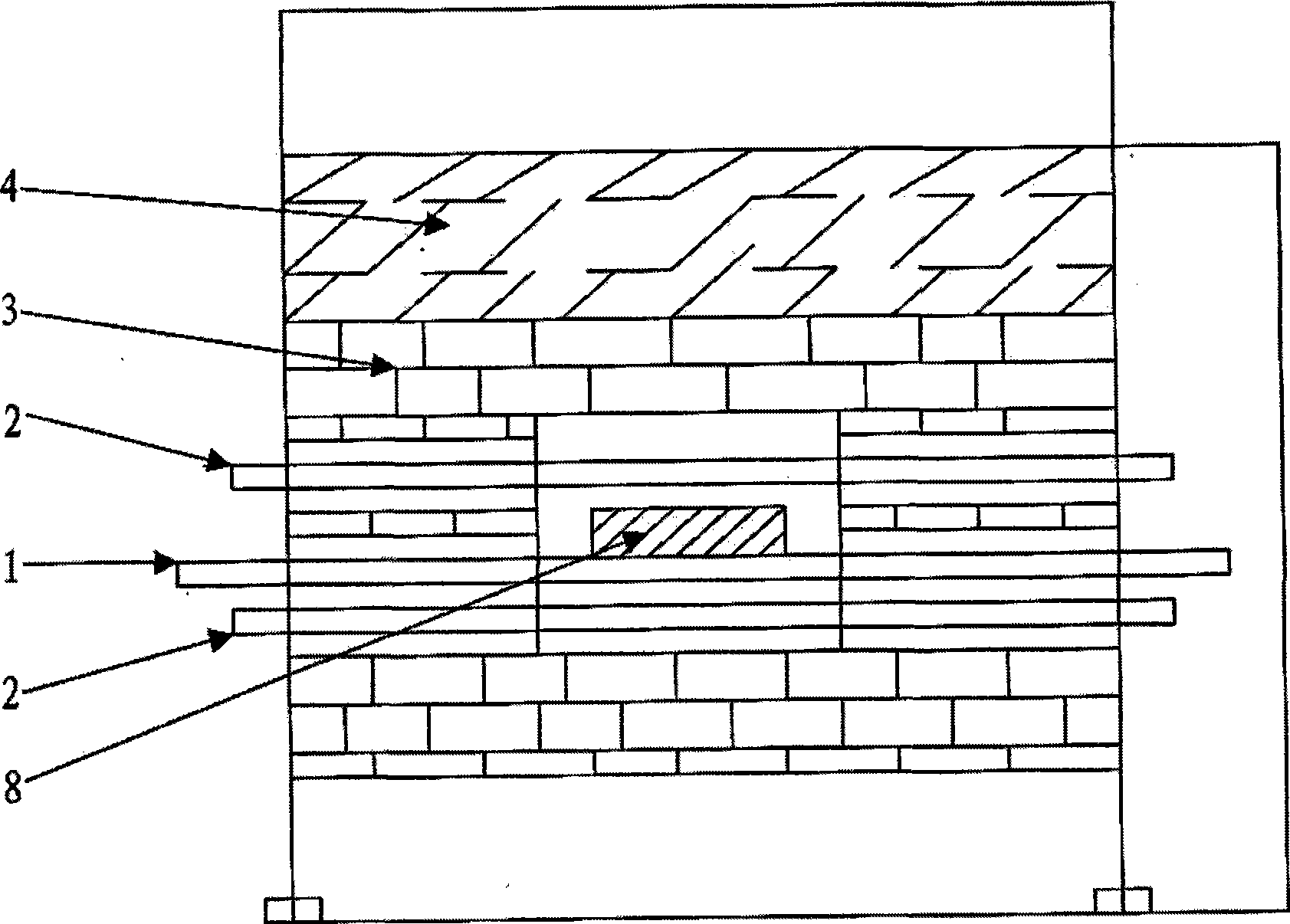

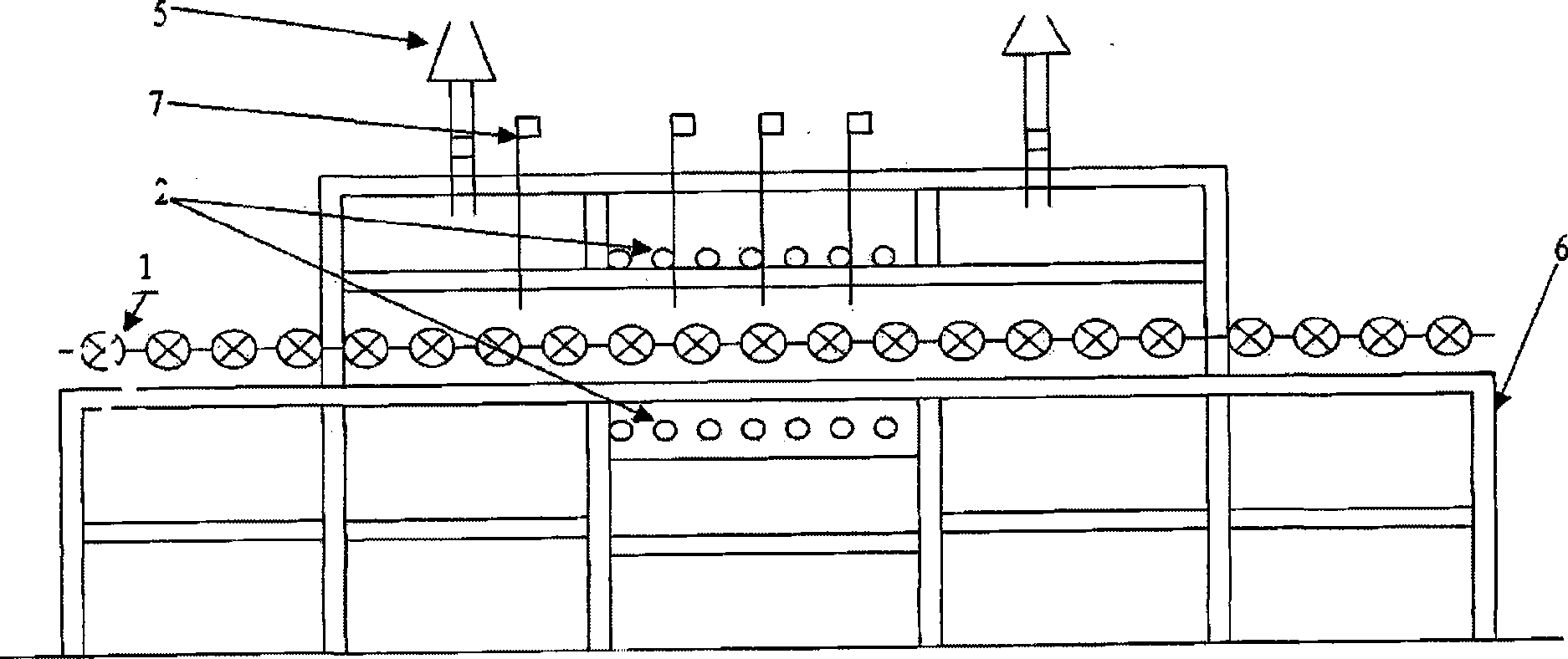

[0017] The calcination equipment reference of the production photocatalyst material of this embodiment Figure 1-4 , including the equipment support 6, on the upper end surface of the equipment support 6 is provided with a transmission roller table 12 laid by evenly distributed transmission sticks 1, on the top of the equipment support 6 is provided with a heating box 10, the transmission stick 1 runs through the heating In the box 10, the heating box 10 is provided with a transmission channel 11 along the direction of the transmission stick 1, and the upper and lower sides of the transmission stick 1 in the heating box 10 are provided with electrically heated silicon carbide rods 2 for heating. The outer layer of 2 is provided with thermal insulation brick 3, and thermal insulation material 4 is arranged on the outermost layer of heating box body 10, is connected with the electric heating silicon carbide rod 2 that is located at the outside electric control part 2 and carries ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com