500/600KW-5000/6000 KW combined cold and heat supply device

A technology of combined cooling and heating and heat recovery pipes, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as inability to realize combined cooling and heating, small temperature adjustment range, single cooling or heating, etc., to achieve Simple structure, large temperature adjustment range, and the effect of improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

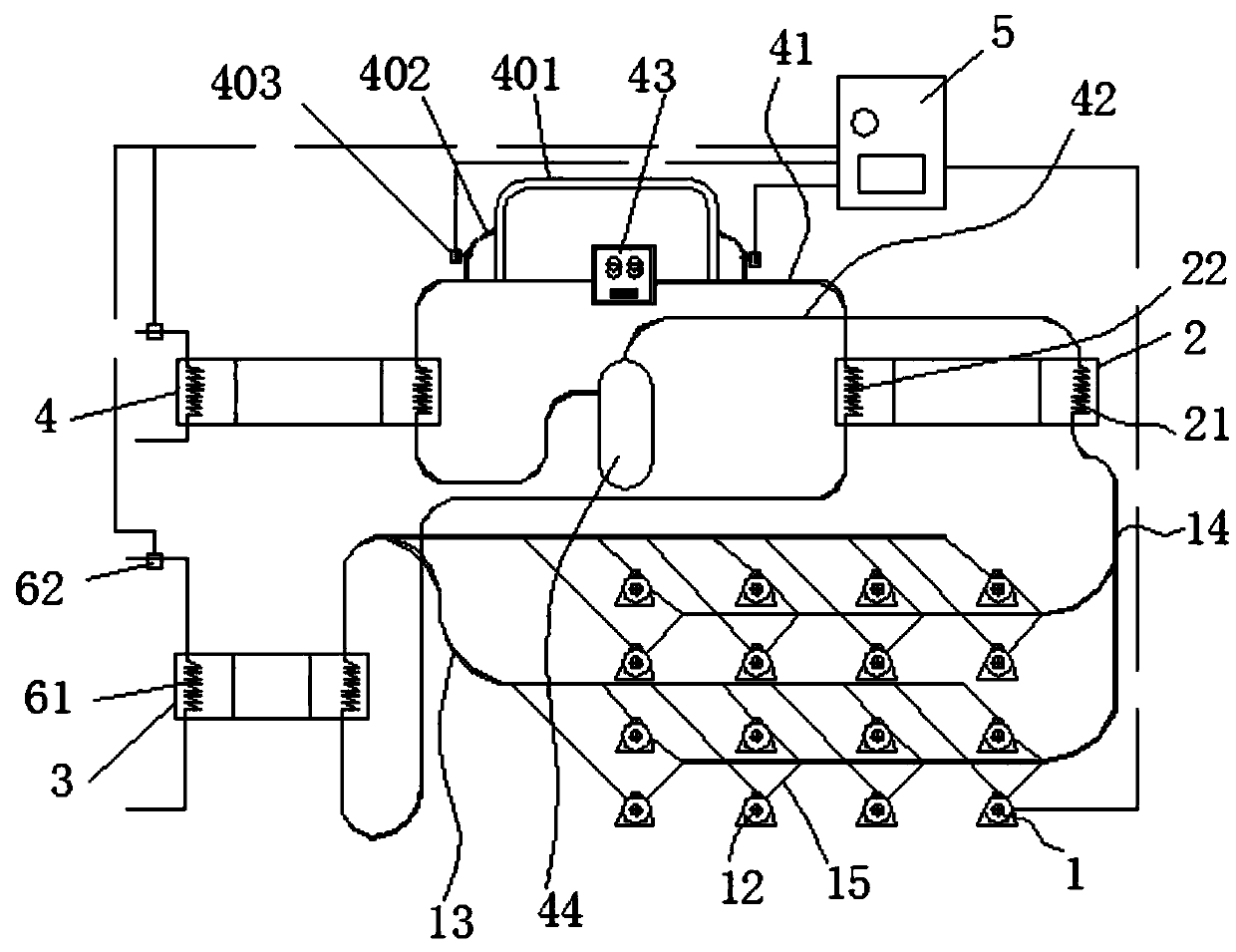

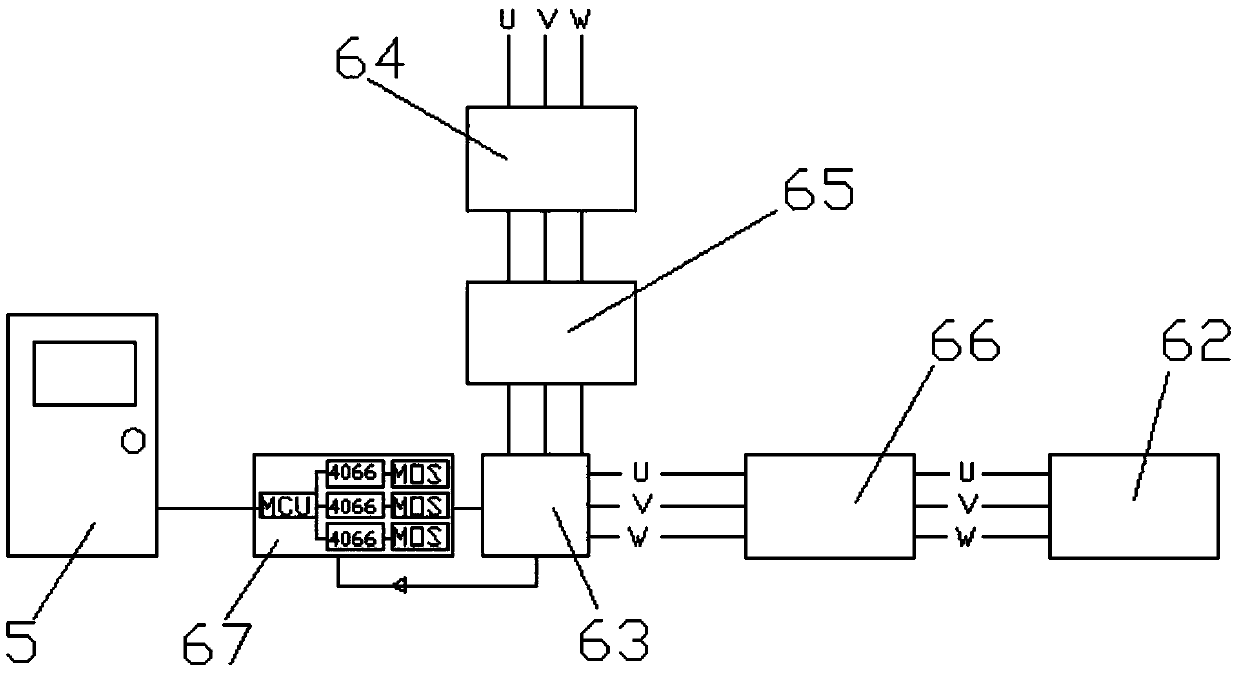

[0025] Such as figure 1 Shown; a 500 / 600KW-5000 / 6000KW combined cooling and heating device, including:

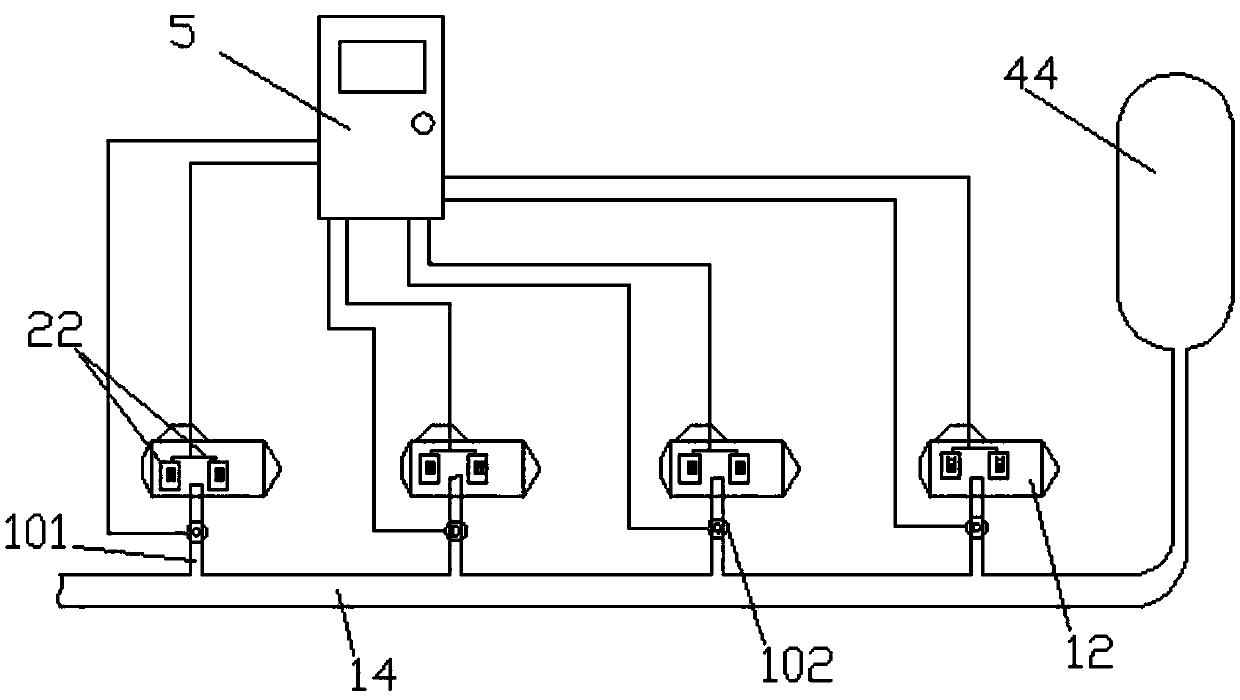

[0026] Compressor unit 1, at least eight groups of CO2 compressors 12 are connected in parallel in the compressor unit 1; a first pressure sensor is installed inside the main output pipeline 13 of the compressor unit 1, and a first pressure sensor is installed inside the main input pipeline 14 of the compressor unit 1 having a second pressure sensor;

[0027] The regenerator 2, the regenerator 2 includes a first heat recovery pipe 21 and a second heat recovery pipe 22, the end of the first heat recovery pipe 21 is connected to the main input pipe 14 of the compressor unit 1,

[0028] An air cooler 3, one end of which is connected to the main output pipeline 13 of the compressor unit 1; the other end of the air cooler 3 is connected to one end of the second heat return pipe 22 of the regenerator 2 through a pipe,

[0029] An evaporator 4, one end of the evaporator 4 is con...

Embodiment 2

[0071] Such as figure 1 Shown; a 500 / 600KW-5000 / 6000KW combined cooling and heating device, including:

[0072] Compressor unit 1, at least eight groups of CO2 compressors 12 are connected in parallel in the compressor unit 1; a first pressure sensor is installed inside the main output pipeline 13 of the compressor unit 1, and a first pressure sensor is installed inside the main input pipeline 14 of the compressor unit 1 having a second pressure sensor;

[0073] The regenerator 2, the regenerator 2 includes a first heat recovery pipe 21 and a second heat recovery pipe 22, the end of the first heat recovery pipe 21 is connected to the main input pipe 14 of the compressor unit 1,

[0074] An air cooler 3, one end of which is connected to the main output pipeline 13 of the compressor unit 1; the other end of the air cooler 3 is connected to one end of the second heat return pipe 22 of the regenerator 2 through a pipe,

[0075] An evaporator 4, one end of the evaporator 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com