Superconductor cooling structure used for superconductive magnetic suspension micro thrust measurement system

A technology for measuring systems and cooling structures, applied in superconducting magnets/coils, force/torque/work measuring instruments, measuring traction/propulsion power of vehicles, etc., can solve problems such as superconducting stator cooling, and improve temperature uniformity , high cooling efficiency, good uniformity of cooling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

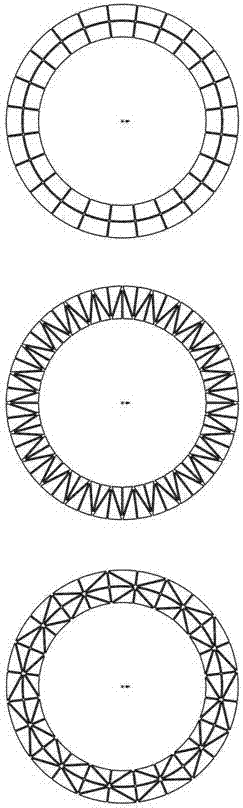

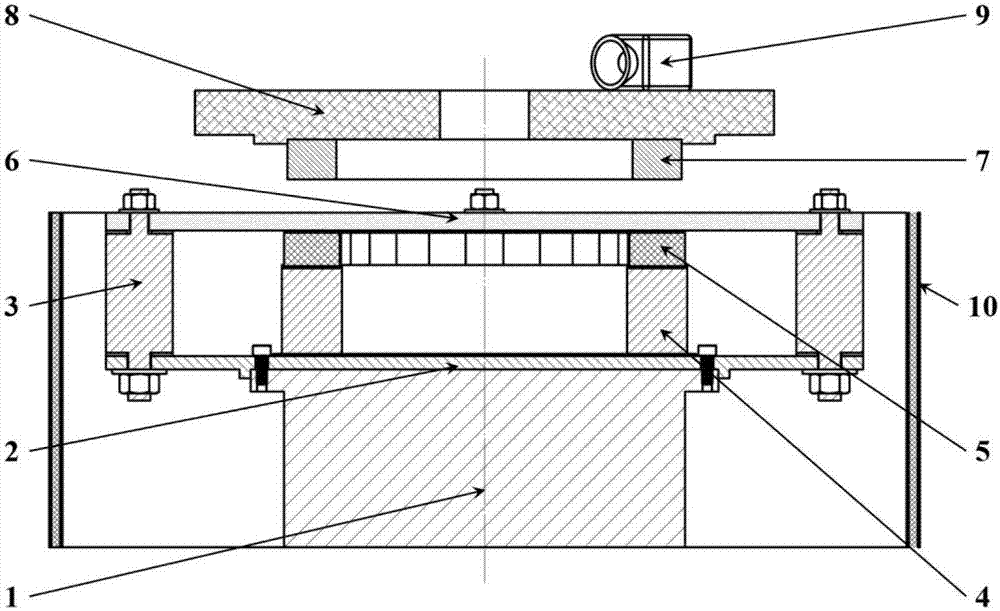

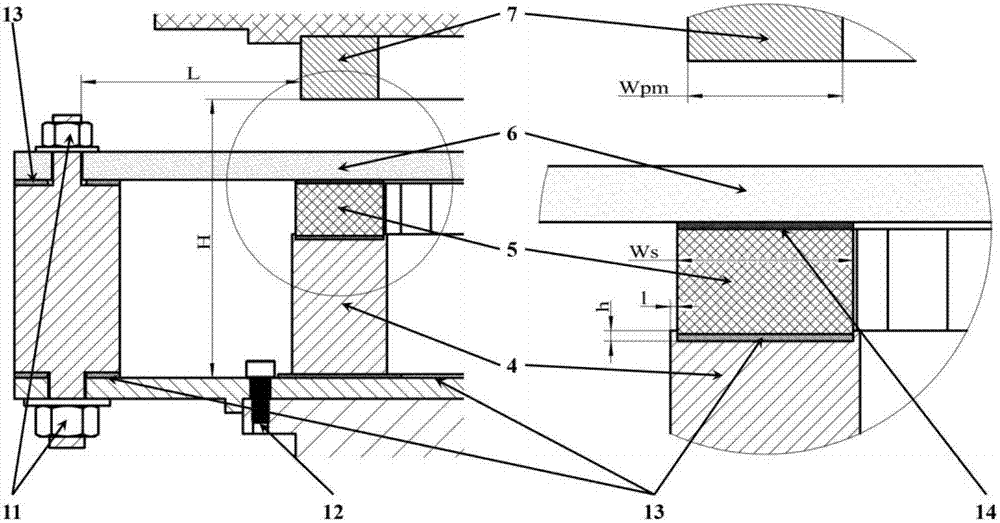

[0023] The core structure of the invention is the conductive cooling structure of the superconducting stator array between the GM refrigerator and the permanent magnetic levitation ring.

[0024] First of all, ensure the correct design and installation of the structure. In order to reduce the eddy current loss of the metal parts, the cooling base 2 and the cooling copper ring 3 are rationally designed so that the minimum distances H and L between the permanent magnetic levitation ring 7 and the two are greater than 60mm during operation. In order to fully utilize the Meissner effect to suppress the eddy current friction loss of the cooling copper ring 3 and the cooling base 2, the width Wpm of the permanent magnetic levitation ring 7 must be smaller than the width Ws of the superconducting stator array, and the depth h of the groove of the cooling copper ring 3 must not exceed 3mm, the edge step width does not exceed 1.5mm. The cooling base 2 and the refrigerator 1 are compre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com