Air mixing and distributing device with temperature adjustment function

A technology for temperature adjustment and distribution devices, which is applied in the direction of valve operation/release devices, valve devices, air handling equipment, etc., and can solve problems such as poor temperature adjustment effect and weak ventilation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

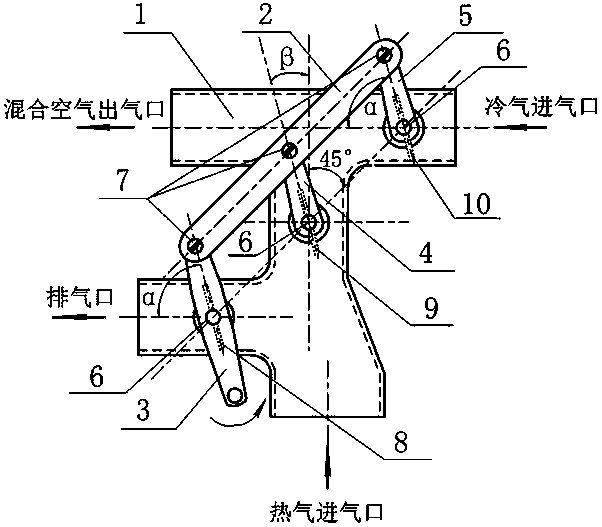

[0008] as attached figure 1 As shown, the air distribution device of the present invention includes a housing [1], a connecting rod [2], a large rocker arm [3], a small rocker arm I [4], a small rocker arm II [5], a rotating shaft [6], Bolt [7], valve piece I[8], valve piece II[9] and valve piece III[10], when the air distribution device is specifically manufactured and installed, all required components are designed and prepared according to technical and process requirements. Manufacture and installation must follow the following process and installation requirements: When the shell [1] is cast, the direction of the exhaust pipe of the shell [1] and the hot air pipe are 90°±30', and the direction of the cold air pipe and the hot air pipe is 90°±30'. 90°±30', shell [1] casting draft angle 1°~1.5°, the shell should be airtight test, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com