Sealing material for hatch cover and manufacturing method thereof

A technology of sealing material and manufacturing method, which is applied in the direction of sealing, sealing device, engine sealing, etc., can solve problems such as long time, and achieve the effects of reducing cracks, improving shape recovery rate, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that at this time, the same structural components are shown with the same symbols as far as possible in the drawings. Also, detailed descriptions of well-known functions and structures that would obscure the gist of the present invention will be omitted.

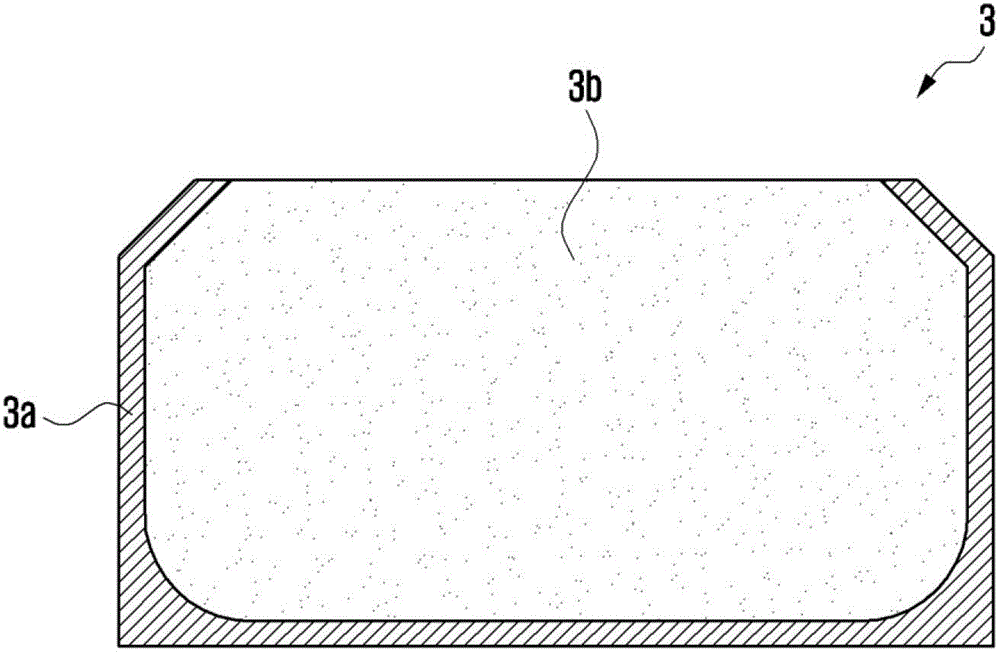

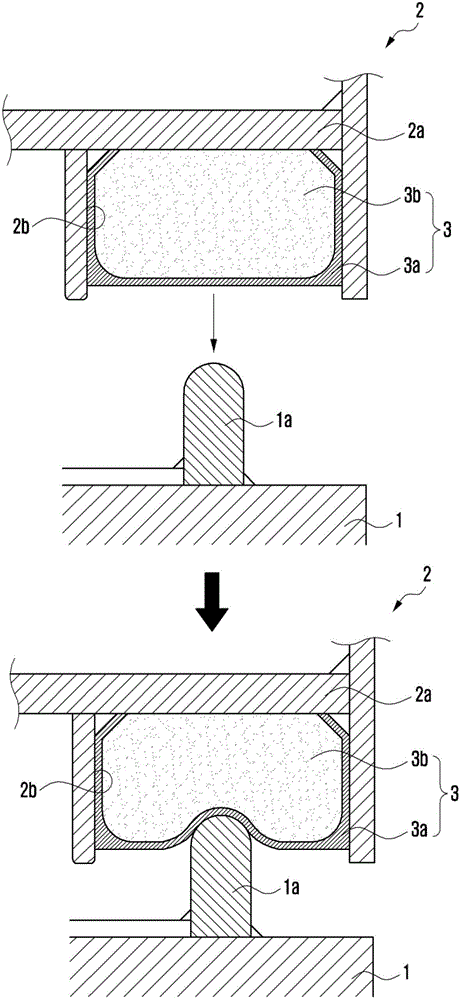

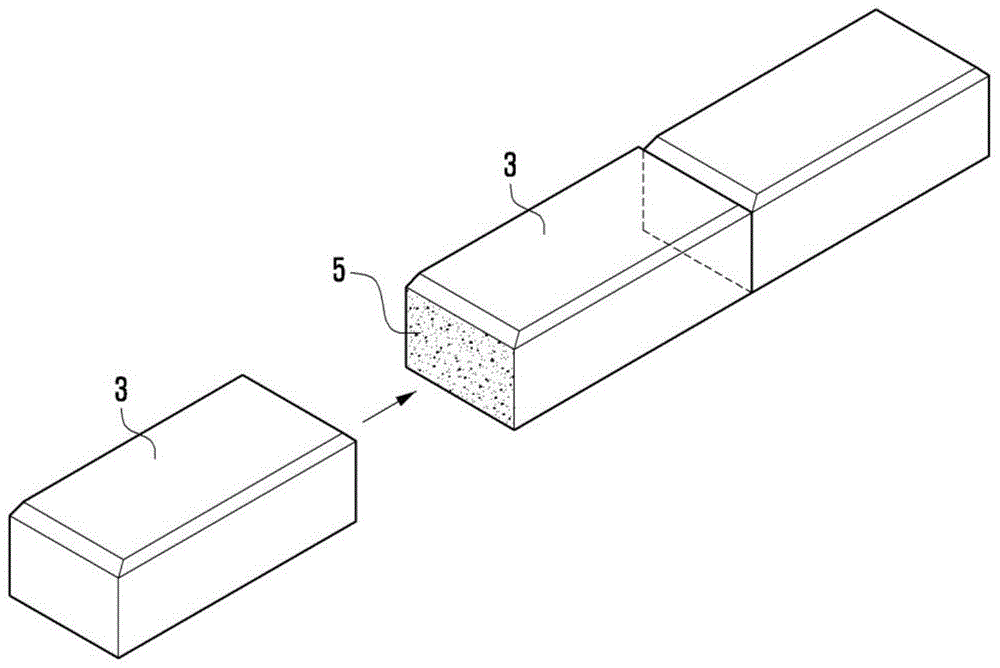

[0035] Figure 4 It is a side cross-sectional view showing a vertical cross-sectional shape of a hatch cover sealing material according to an embodiment of the present invention. Figure 5 It is a side sectional view showing the deformation structure of the sealing material of the embodiment of the present invention during the process of bonding the hatch cover to the hatch. Image 6 It is a perspective view showing the sealing material of the embodiment of the present invention manufactured by extrusion.

[0036] Such as Figure 4 As shown, the hatch cover sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com