Preparation method of shape memory high polymer material based on thermoplastic vulcanizate

A technology of thermoplastic vulcanizate and polymer materials, applied in the field of rubber-plastic ratio of permanent vulcanizate, can solve the problems of control, product flexibility, complex preparation process, etc., and achieve the effect of simple preparation process, easy molding, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

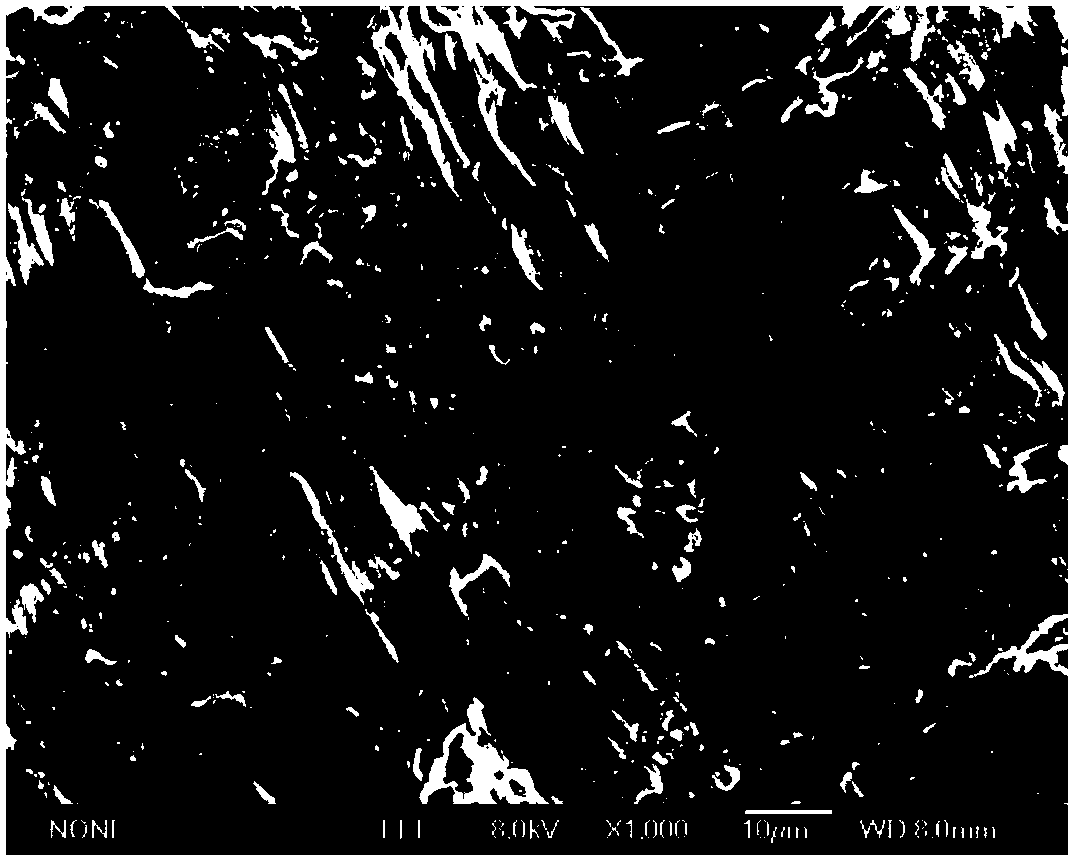

Image

Examples

Embodiment 1

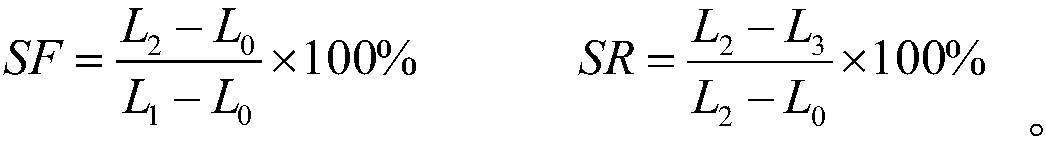

[0027] (1) Draw two parallel scale lines in the middle of the dumbbell-shaped tensile spline of ethylene-vinyl acetate copolymer / nitrile rubber thermoplastic vulcanizate, and the distance between the scale lines is L 0 =20.00mm, fix it on a simple tensile fixture, and preheat it at 75°C for 10 minutes; wherein, the mass ratio of ethylene-vinyl acetate copolymer to nitrile rubber in the thermoplastic vulcanizate is 8:2;

[0028] (2) Put the preheated thermoplastic vulcanizate under the condition of 75°C, and apply an external force on the stretching fixture to deform the spline. After reaching 100% deformation, stretch it while maintaining the external force The jig and the spline are quickly immersed in the ice-water mixture to cool down and set the temperature. At this time, the distance between the scale lines is L 1 =40.00mm;

[0029] (3) Remove the sample strip of thermoplastic vulcanizate from the simple tensile fixture, place it naturally at room temperature for 24 hour...

Embodiment 2

[0034] (1) Draw two parallel scale lines in the middle of the dumbbell-shaped tensile spline of ethylene-vinyl acetate copolymer / nitrile rubber thermoplastic vulcanizate, and the distance between the scale lines is L 0 =20.00mm, fix it on a simple tensile fixture, and preheat it at 80°C for 10 minutes; wherein, the mass ratio of ethylene-vinyl acetate copolymer to nitrile rubber in the thermoplastic vulcanizate is 7:3;

[0035] (2) Put the preheated thermoplastic vulcanizate under the condition of 80 ℃, apply an external force on the stretching fixture to deform the spline, and after reaching 100% deformation, stretch it under the condition of maintaining the external force The jig and the spline are quickly immersed in the ice-water mixture to cool down and set the temperature. At this time, the distance between the scale lines is L 1 =40.00mm;

[0036](3) Remove the sample strip of thermoplastic vulcanizate from the simple tensile fixture, place it naturally at room tempera...

Embodiment 3

[0040] (1) Draw two parallel scale lines in the middle of the dumbbell-shaped tensile spline of ethylene-vinyl acetate copolymer / nitrile rubber thermoplastic vulcanizate, and the distance between the scale lines is L 0 =20.00mm, fix it on a simple tensile fixture, and preheat it at 75°C for 10 minutes; wherein, the mass ratio of ethylene-vinyl acetate copolymer to nitrile rubber in the thermoplastic vulcanizate is 9:1;

[0041] (2) Put the preheated thermoplastic vulcanizate under the condition of 75°C, and apply an external force on the stretching fixture to deform the spline. After reaching 100% deformation, stretch it while maintaining the external force The jig and the spline are quickly immersed in the ice-water mixture to cool down and set the temperature. At this time, the distance between the scale lines is L 1 =40.00mm;

[0042] (3) Remove the sample strip of thermoplastic vulcanizate from the simple tensile fixture, place it naturally at room temperature for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com