High-temperature smoke cooling, metering and packaging integrated device and process method thereof

A fume and packaging technology, which is applied in the field of metering and packaging integrated devices and high temperature fume cooling, can solve the problems of increasing the damage progress of the kneader, the high cost of using the kneader, and increasing the maintenance workload, so as to eliminate environmental risks, The effect of eliminating the problem of smoke and dust and reducing the risk factor of the post

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

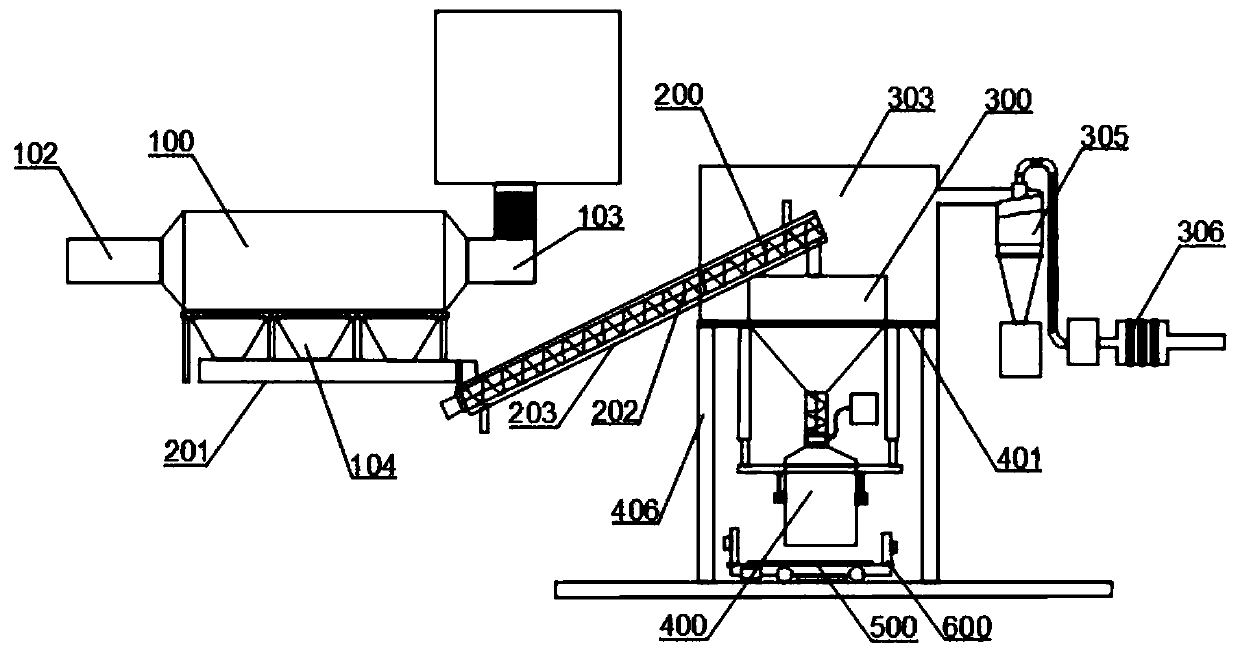

[0052] An integrated device for cooling, measuring and packaging high-temperature smoke and dust, including a smoke and dust collection device 100, a smoke and dust cooling and conveying system 200, a packaging device 400, a single bag weighing device 500, and a soot conveying device 600;

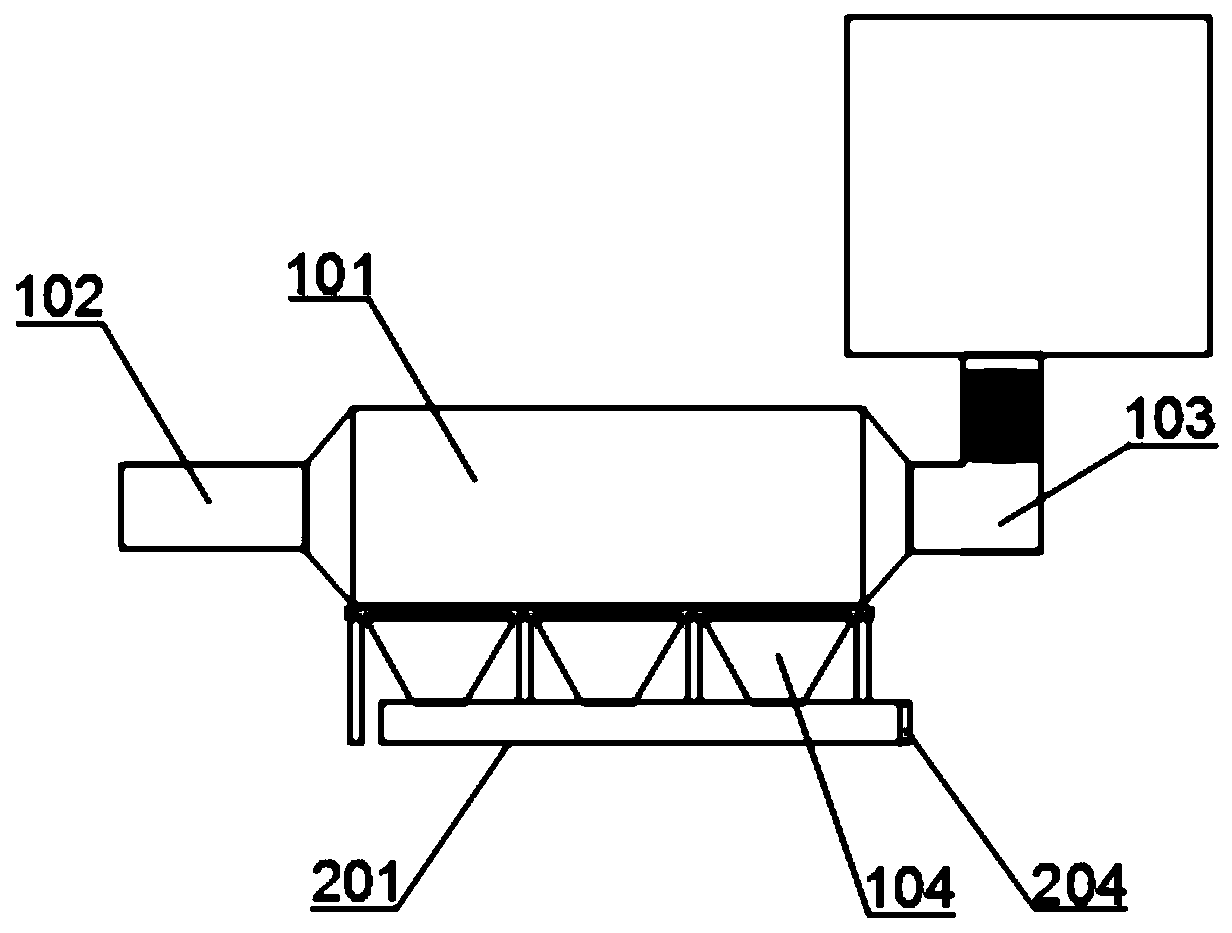

[0053] The dust collecting device 100 includes an electric dust collector 101; the two ends of the electric dust collector 101 are respectively provided with an air inlet 102 and an air outlet 103; the bottom of the electric dust collector 101 is provided with an ash hopper 104;

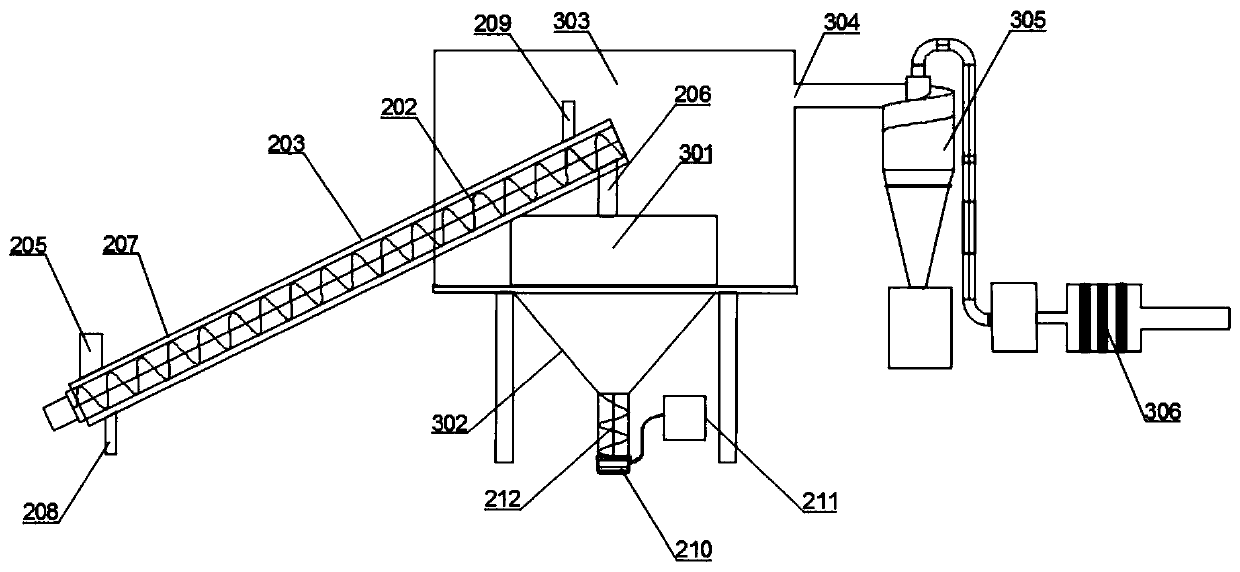

[0054] The soot cooling and conveying system 200 includes a buried scraper conveyor 201, a screw conveyor 202 and a water cooling jacket 203; a buried scraper conveyor 201 is arranged at the bottom of the ash discharge bucket 104; a buried scraper is arranged at the end of the buried scraper conveyor 201 Conveyor discharge port 204; the bottom of the screw conveyor 202 is provided with a screw conveyor feed port 205;...

Embodiment 2

[0059] On the basis of Embodiment 1, an intermediate storage bin 300 is arranged on the discharge port 206 of the screw conveyor; the intermediate storage bin 300 is fixedly arranged on the support frame 401; the upper part of the intermediate storage bin 300 is provided with a square storage bin 301 , the bottom is provided with a funnel-shaped lower silo 302.

Embodiment 3

[0061] On the basis of Embodiment 1-2, the lifting hook 409 is provided with a weighing device 410 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com