Patents

Literature

50results about How to "Eliminate environmental risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

PendingCN108441642ARealize green and clean cycle productionHigh recovery rateSolid waste disposalAlkali metal sulfite/sulfate purificationWastewaterImpurity

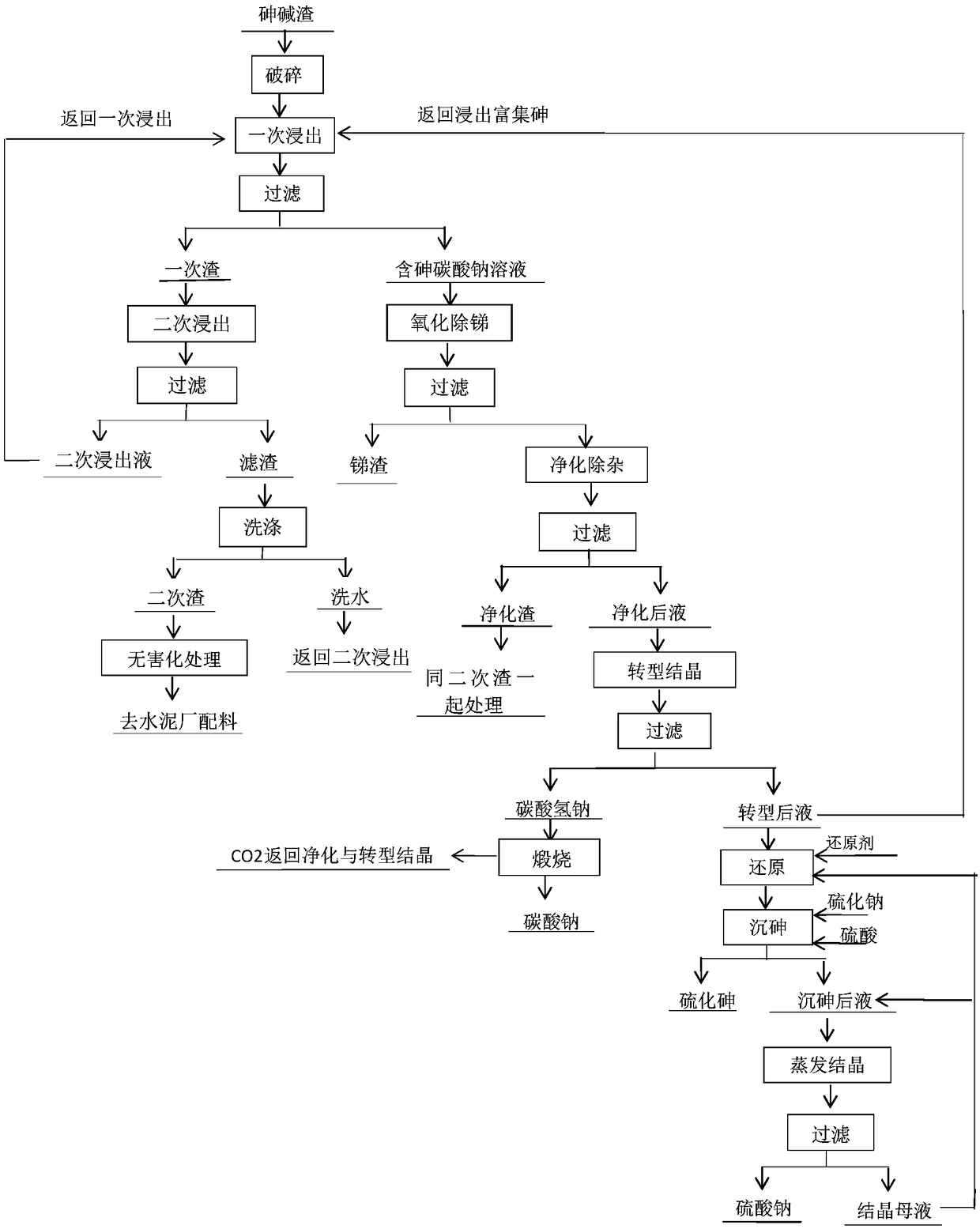

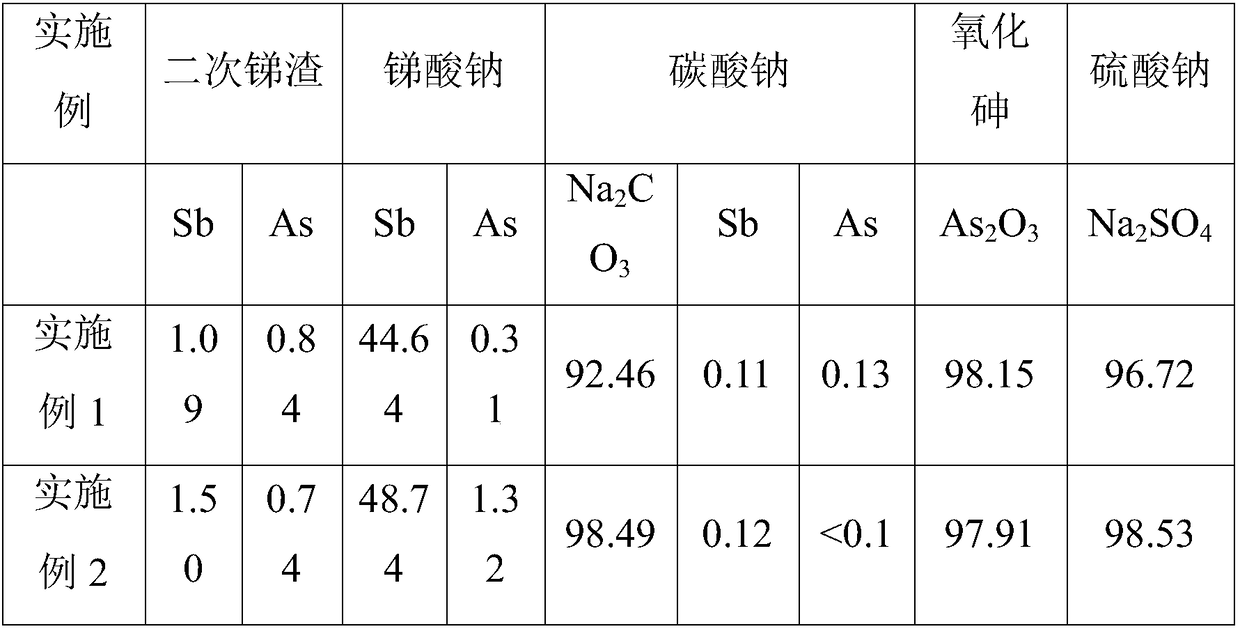

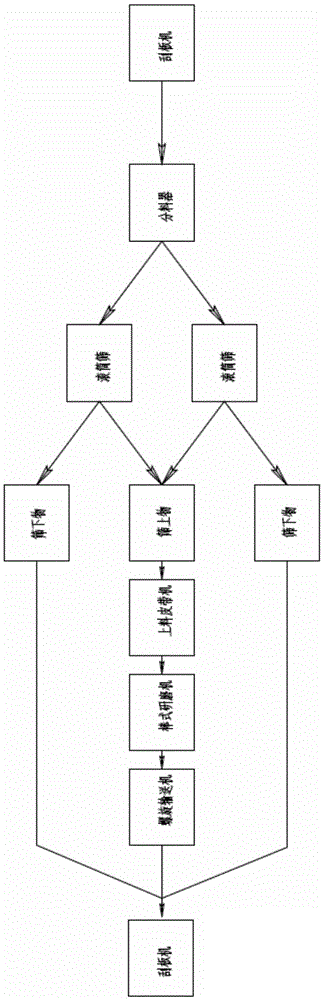

The invention belongs to the field of antimony smelting arsenic alkali residue treatment and particularly discloses a wet-method recycling and harmless treatment process for antimony smelting arsenicalkali residue. The process adopts a whole-wet-method treatment process and mainly comprises the eight working procedures of breaking, dissolving for leaching, oxidation for antimony outlet, purification for impurity removing, transition for crystallizing, reduction for arsenic sinking, evaporative crystallization and secondary residue harmless treatment. Recycling and harmless treatment of the arsenic alkali residue, zero emission of waste residue and waste water and up-to-standard discharge of exhaust gas are thoroughly achieved, the long-term plagued arsenic alkali residue environmental pollution problem in the antimony smelting industry in China is thoroughly solved, and the environmental risk caused by stacking the arsenic alkali residue is eliminated; and meanwhile, separation, enrichment and effective recovering of valuable elements are achieved.

Owner:CHENZHOU YANGTAO CHEM

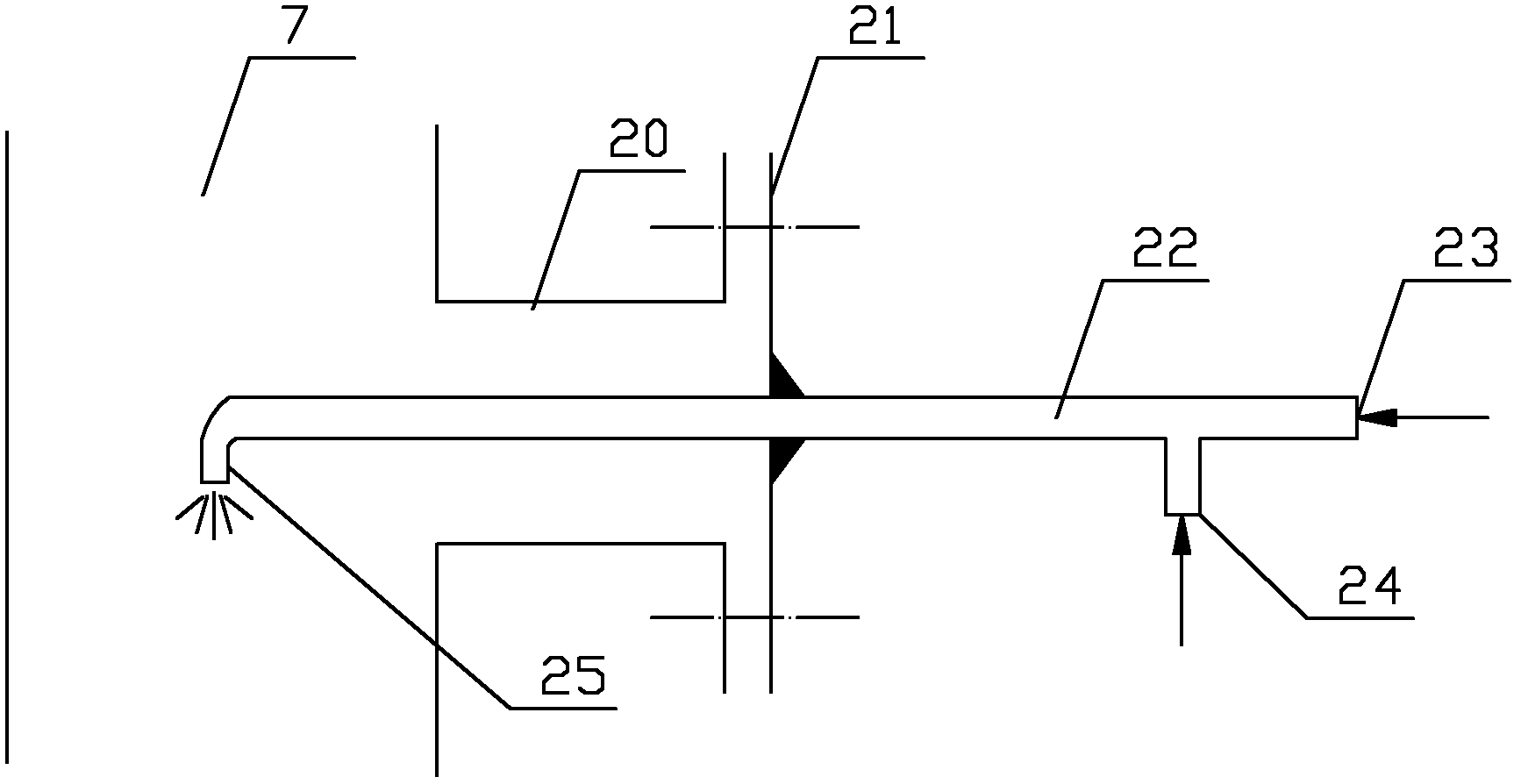

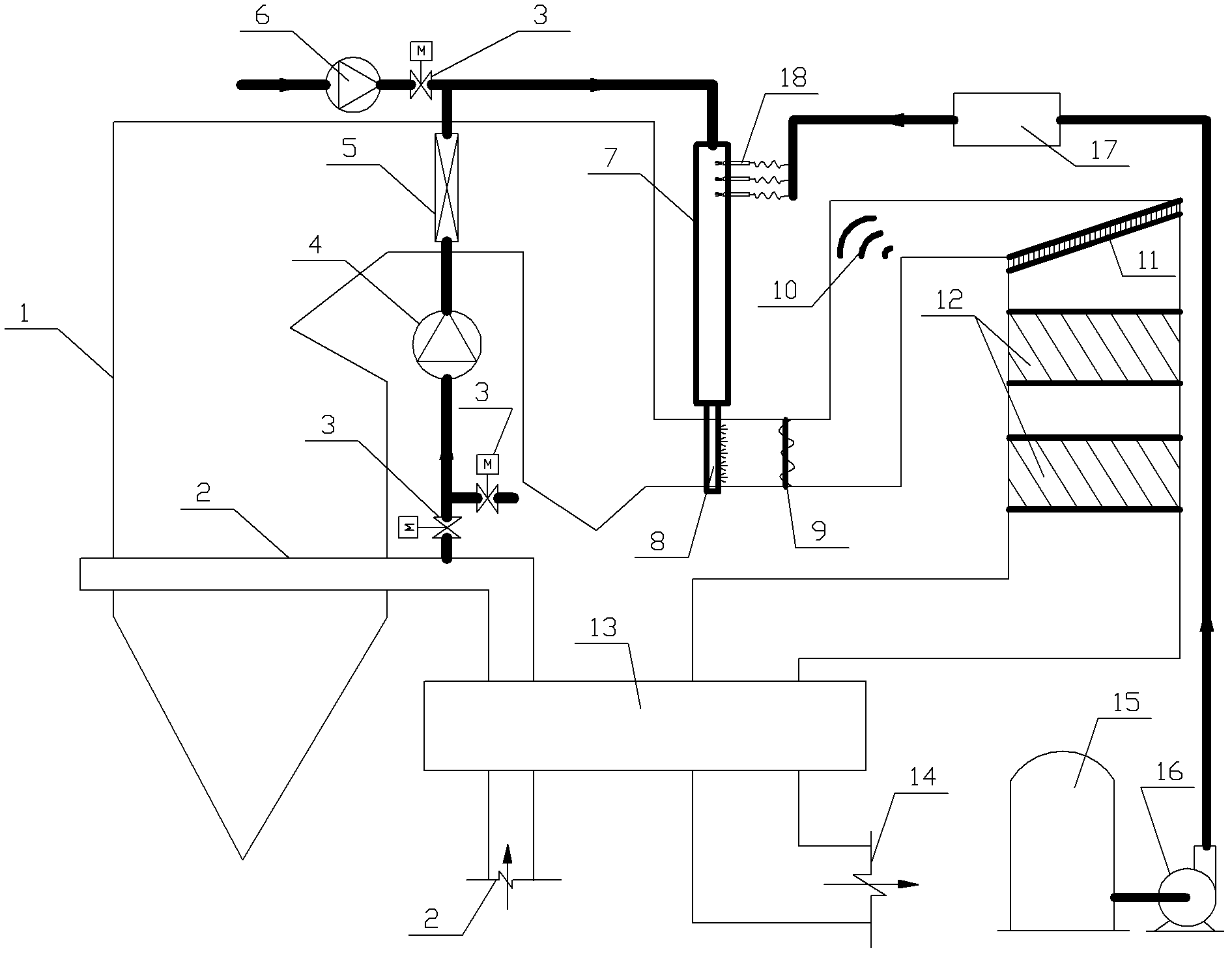

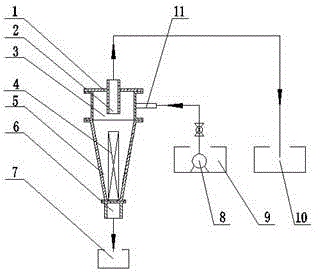

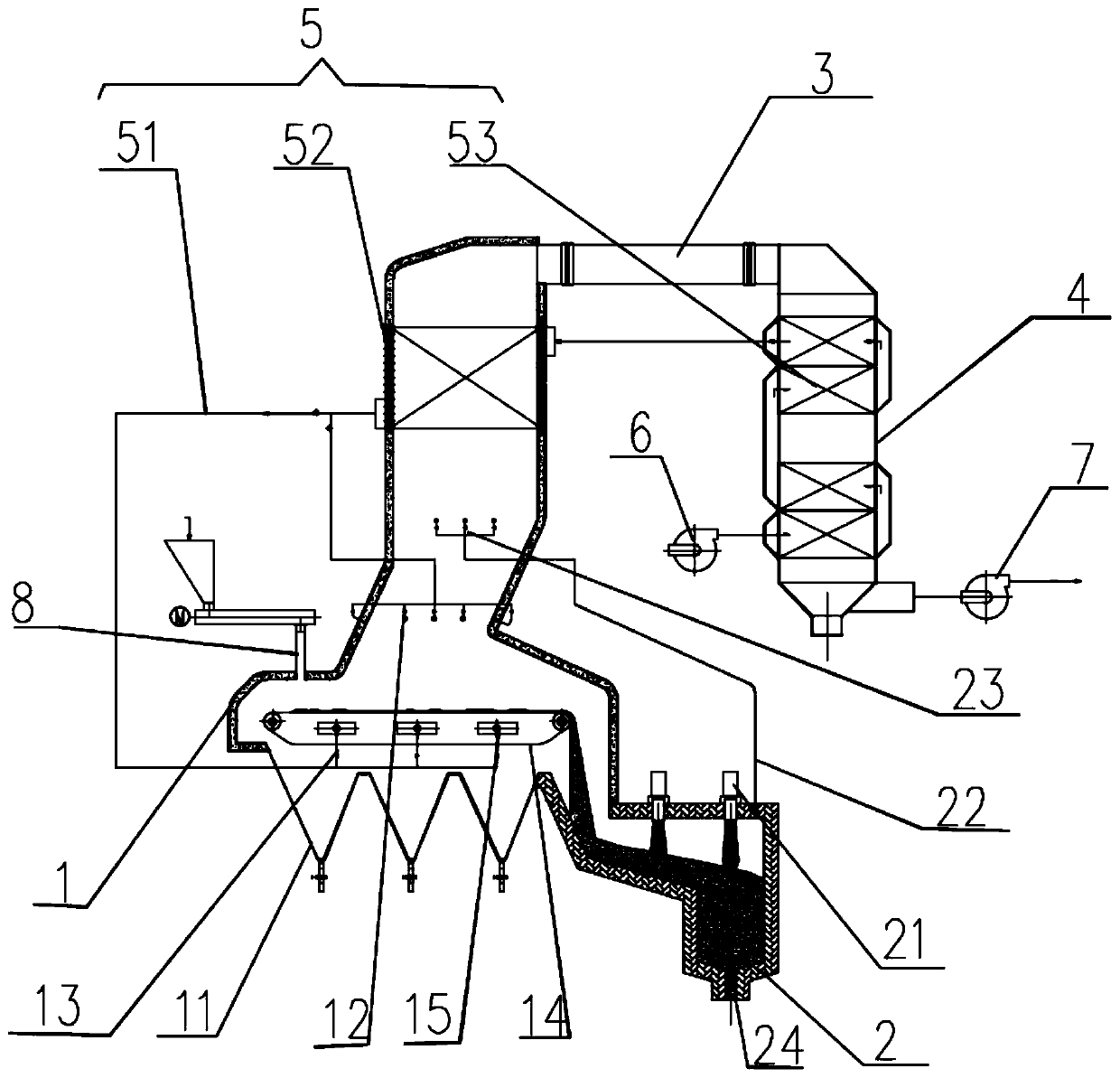

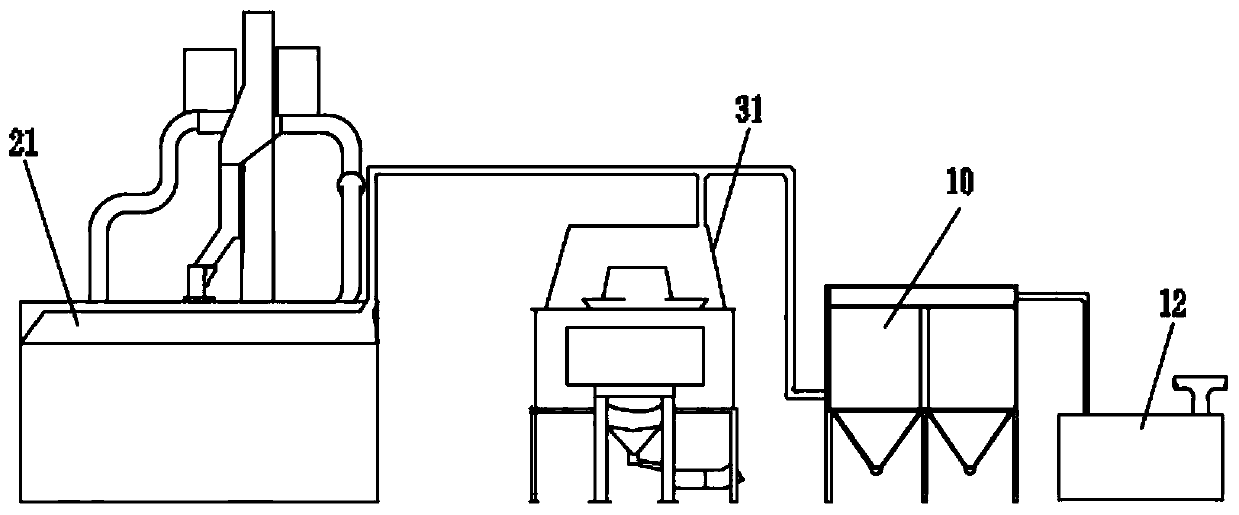

Urea-solution-based SCR (selective catalytic reduction) flue gas denitration process and device

InactiveCN102614758AImprove securityEasy to store and transportDispersed particle separationUreaAir heater

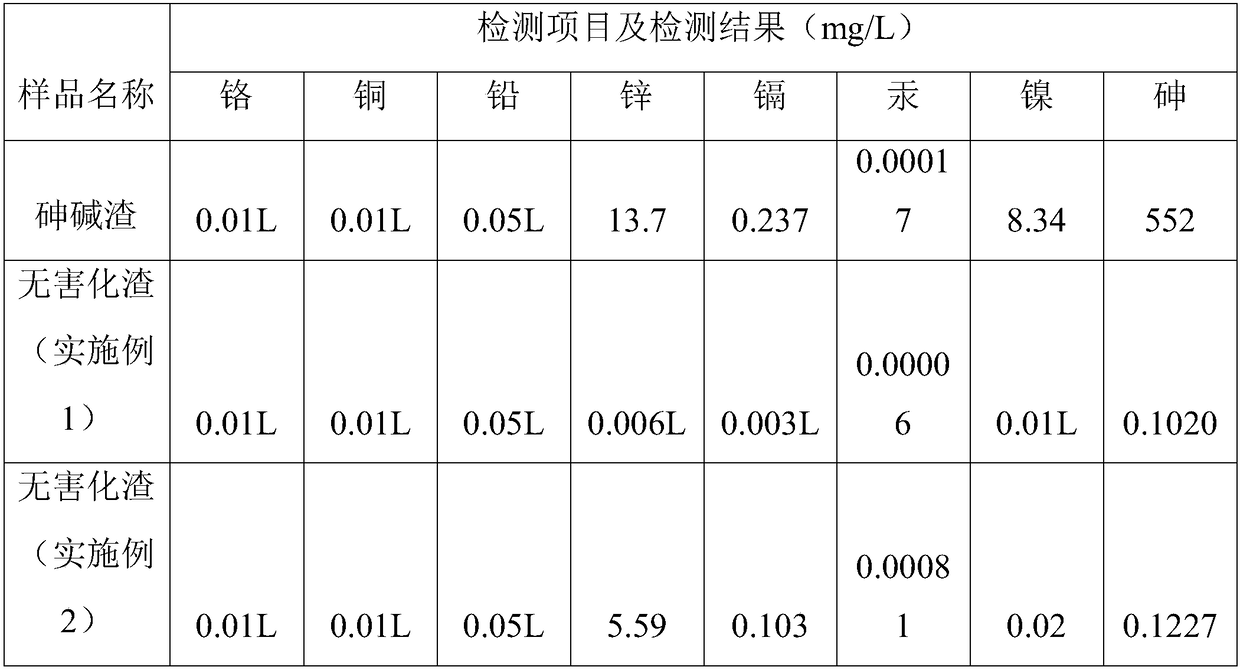

The invention discloses a urea-solution-based SCR (selective catalytic reduction) flue gas denitration process and device. According the process, pyrolysis air is pumped from the outside or a second air channel of a boiler, then is pressurized by a first fan and heated to 350-700 DEG C by a pyrolysis air heater arranged in a boiler hearth or a tail air channel, and the heated pyrolysis air enters a pyrolysis reaction air channel together with fresh air; urea solution is sprayed into the pyrolysis air channel by an atomizing spray gun and the atomized urea solution is pyrolyzed into ammonia gas in the pyrolysis air channel; and after being discharged out of the pyrolysis air channel, the ammonia gas is sprayed into boil flue gas via ammonia spraying grilles to participate in the SCR reaction in an SCR reactor arranged in a tail flue of the boiler. the urea-solution-based SCR flue gas denitration process and device have the advantages of high safety, simple structure and easiness in implementation.

Owner:湖南安普诺环保科技有限公司

Method for removing heavy metals in urban waste incineration flying ash through bioleaching technology

InactiveCN105907981AEfficient extractionGreen ExtractProcess efficiency improvementBrickResource utilization

Flying ash is hazardous waste which is produced during household garbage incineration power generation and contains various toxic metals, the stabilization / solidification landfill cost of the mainstream disposal process of the flying ash is 2000-3000 yuan / ton, and the environmental risk of the toxic metals still exists. Removal of the toxic metals from the flying ash is the premise of low-limit / non-limit resource utilization of the flying ash. Low-price inorganic energy substrates such as sulphur are used as working media, and efficient, environment-friendly and safe extraction of the toxic metals in the flying ash is achieved under the conditions of normal temperature and pressure through the direct / indirect action of autotrophy leaching inocula. Besides, through desalting and dealkalization with water scrubbing, bacterial strain compounding and breeding of high-salt-tolerance bacterial strains, the regeneration performance of leachate organisms is obviously improved, the circulation leaching frequency is greatly increased, and thus the consumption of inorganic salt culture solutions in the leaching process is greatly lowered, and the bioleaching cost is further reduced. The detoxified flying ash is used for resource utilization such as manufacturing of bricks, roadbeds and concrete, the high cost of the traditional landfill process is saved, and the potential environmental risk is eliminated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

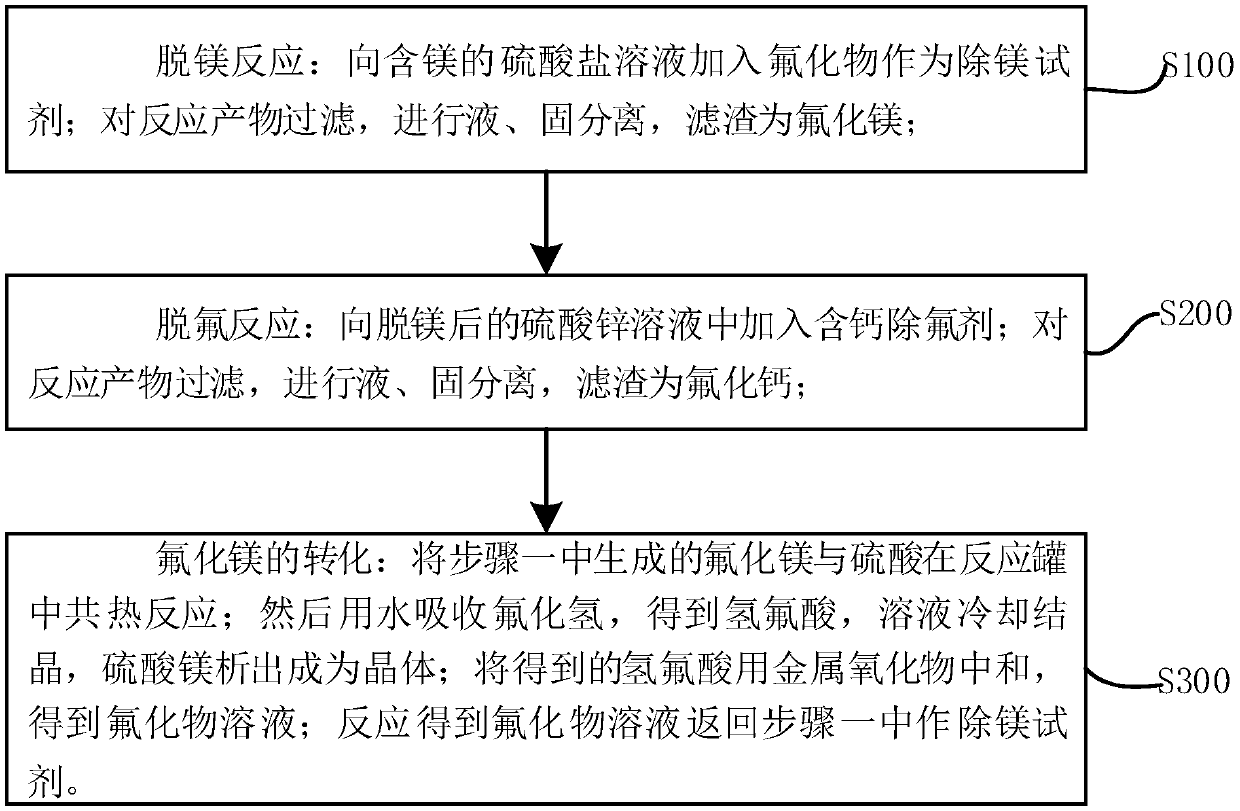

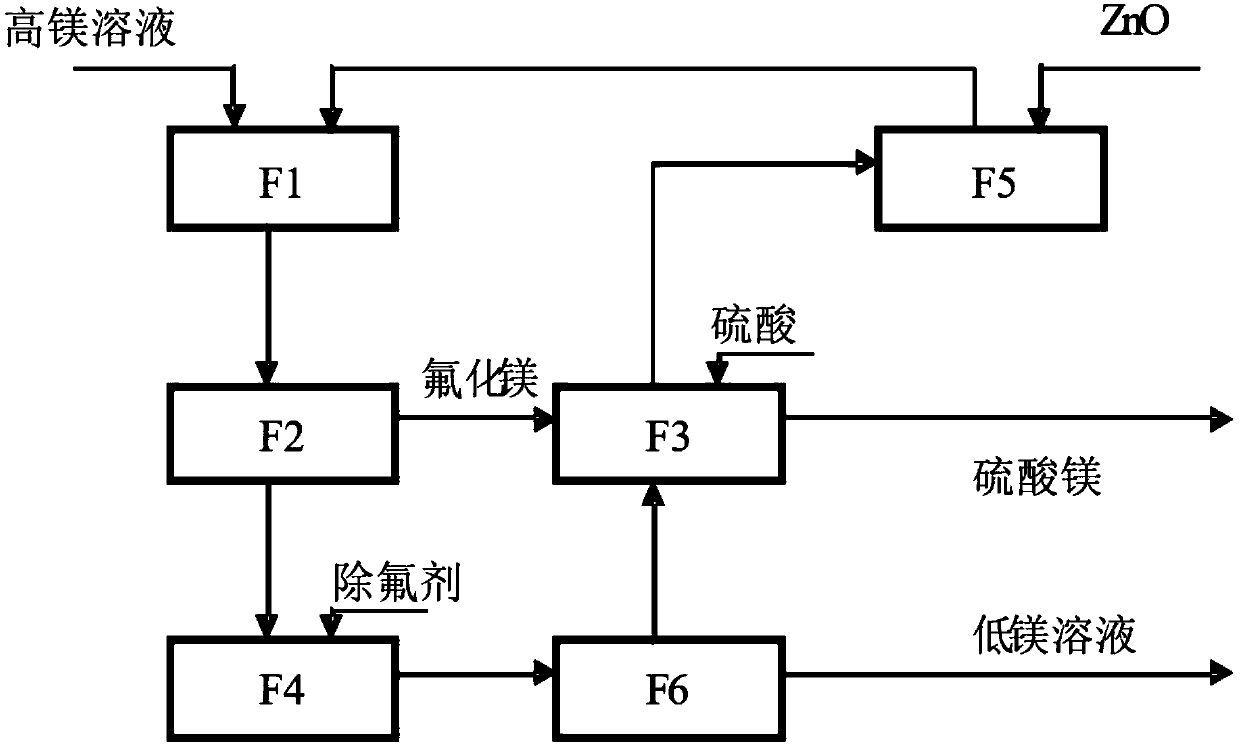

System and process for fluorine-circulation magnesium removal of sulfate solution

PendingCN109665501ARealize recyclingAchieve recyclingZinc sulatesSulfate preparationTreatment costsLiquid solid

The invention discloses a system and process for fluorine-circulation magnesium removal of sulfate solution. The process includes: step one, magnesium removal, to be more specific, adding a fluoride serving as a magnesium removal agent into magnesium-containing sulfate solution, filtering a reaction product, and performing liquid-solid separation, wherein filter residue is magnesium fluoride; steptwo, defluorination, to be more specific, adding a calcium-containing fluorine removal agent into zinc sulfate solution subjected to magnesium removal, filtering a reaction product, and performing liquid-solid separation, wherein filter residue is calcium fluoride; step three, magnesium fluoride conversion, to be more specific, subjecting sulfuric acid and magnesium fluoride generated in the stepone to co-heating reaction in a reaction tank, absorbing hydrogen fluoride by water to obtain hydrofluoric acid, cooling the solution to crystallize, separating out magnesium sulfate crystal, neutralizing obtained hydrofluoric acid by a metal oxide to obtain fluoride solution, and returning the fluoride solution obtained in reaction to the step one to serve as the magnesium removal agent. Therefore, the process realizes fluorine recycling, so that treatment cost is sharply reduced.

Owner:吴红

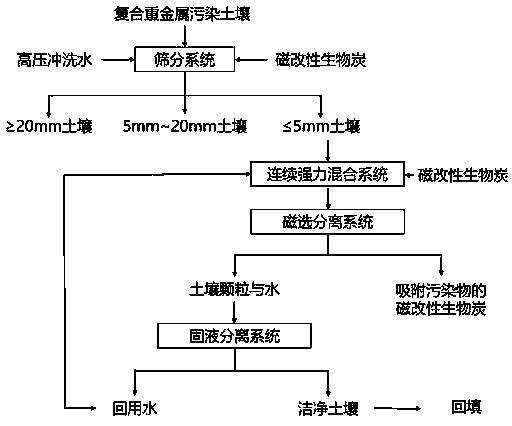

Method for removing contaminated-soil heavy mental with magnetic-modified biochar

InactiveCN109622581AImprove adsorption capacityGood magnetic separation performanceContaminated soil reclamationLiquid wasteSoil remediation

The invention discloses a method for removing contaminated-soil heavy mental with magnetic-modified biochar. The method includes the specific steps that the prepared magnetic-modified biochar serves as a soil remediation agent, water serves as a dispersion medium, heavy metal contaminated soil and the magnetic-modified biochar are mixed and make contact with each other, the steps such as high pressure washing sieving, continuous strong mixing, magnetic separating and solid-liquid separating are carried out, and standard soil for agricultural production and construction is obtained. According to the method, the magnetic-modified biochar is applied to heavy metal contaminated soil remediation, the treatment process of leaching waste liquid is fundamentally eliminated, engineering construction and cost are reduced, heavy metal contaminants in soil are thoroughly removed, and the environmental risk is eliminated. Meanwhile, a large amount agricultural waste can be consumed through resourceutilization of the biochar, and contamination caused by waste incineration and landfill and land occupancy are reduced.

Owner:江西夏氏春秋环境股份有限公司

Microbiological treatment technology for waste mud generated in drilling operation of petroleum and natural gas

ActiveCN104086065AReduce moisture contentReduced anaerobic zoneBiological sludge treatmentThree levelWell drilling

The invention discloses a microbiological treatment technology for waste mud generated in drilling operation of petroleum and natural gas, and relates to the technical field of pollution treatment of exploration drilling for petroleum and natural gas. The technology is executed according to the following steps: a, preparing a pool for performing microbiological treatment on waste mud; b, paving the bottom of the pool with a plurality of transverse pipes, connecting the transverse pipes with vertical pipes, and perforating the transverse pipes; c, paving the bottom of the pool with cobblestones, and controlling the paving thickness of the cobblestones to be larger than the pipe diameter of the transverse pipes; d, paving with a non-woven fabric layer on the cobblestones; e, paving with sand on the non-woven fabric; f, paving with a prepared waste mud mixture on the sand; and g, paving with natural soil on the waste mud mixture, and planting plants. The technology helps to reduce the anaerobic area of a landfill pool, and is capable of finished degradation process in a relatively short time, enabling the mixture to reach national soil three-level standard and eliminating environment risk.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

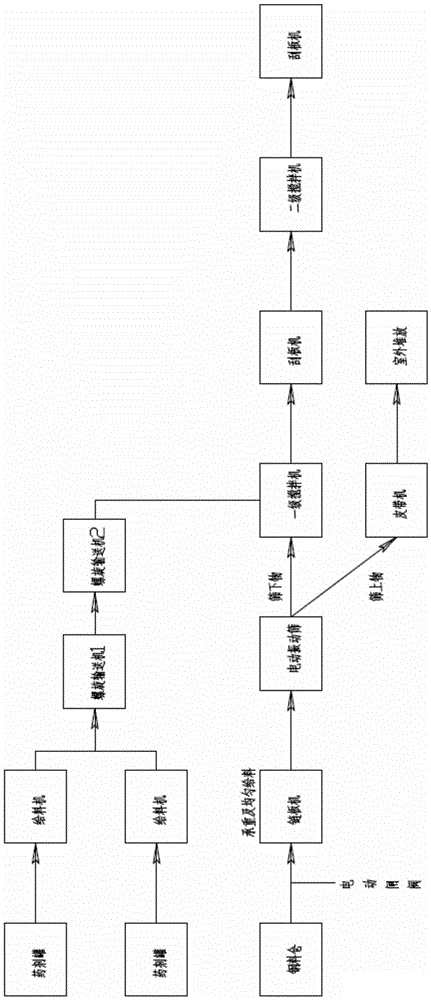

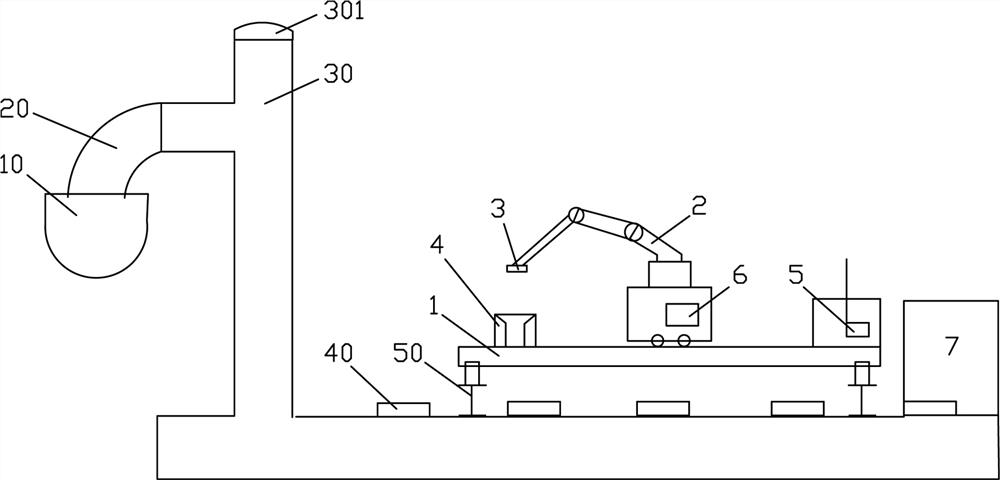

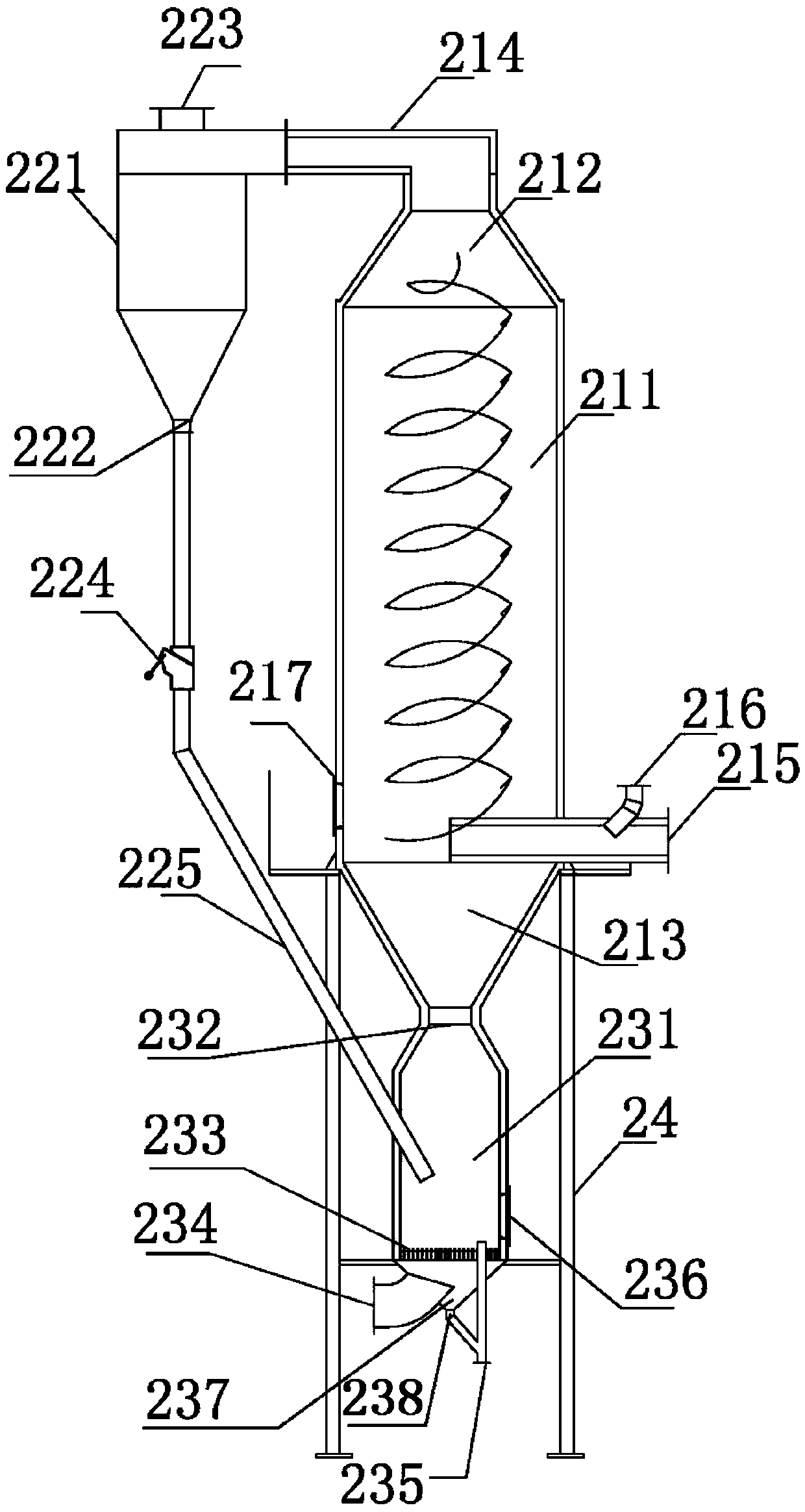

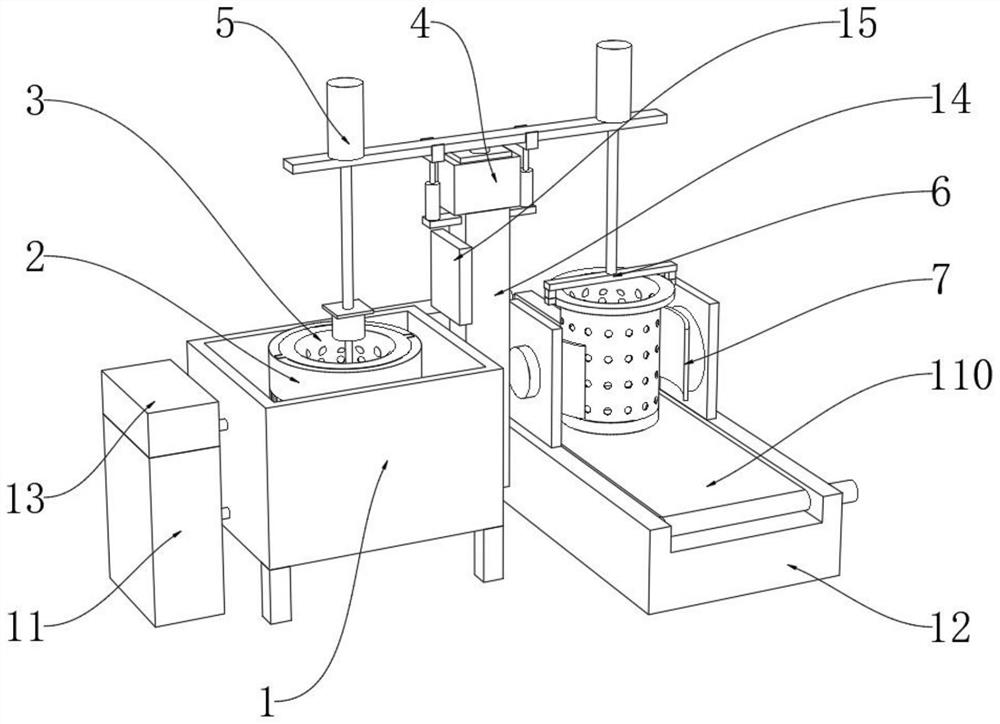

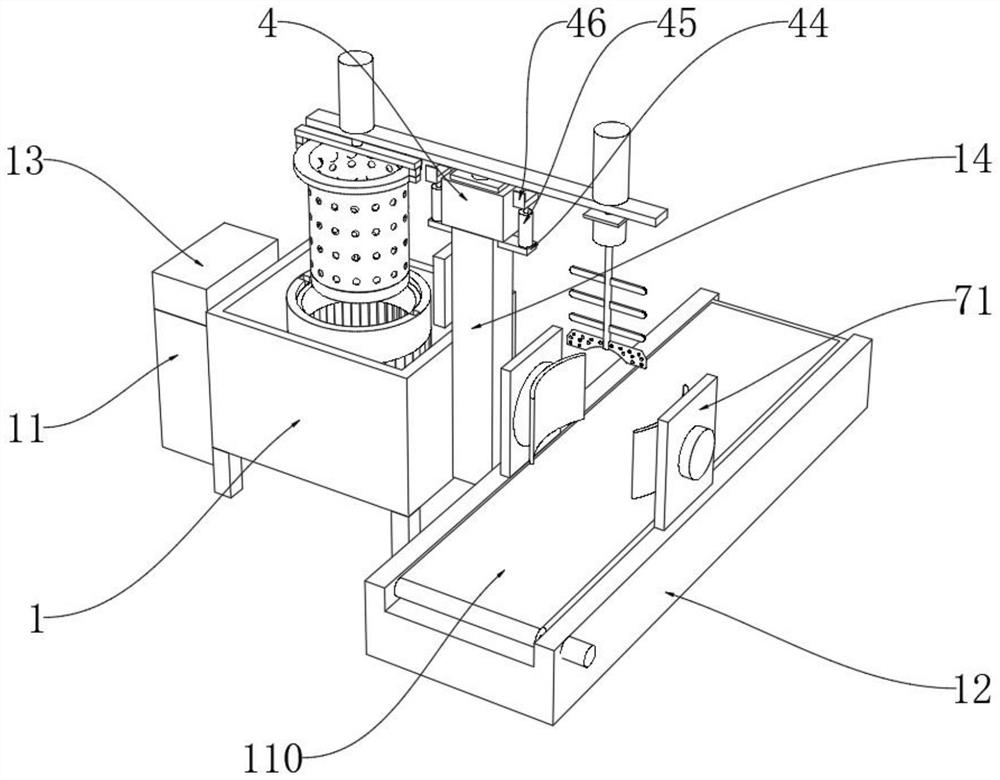

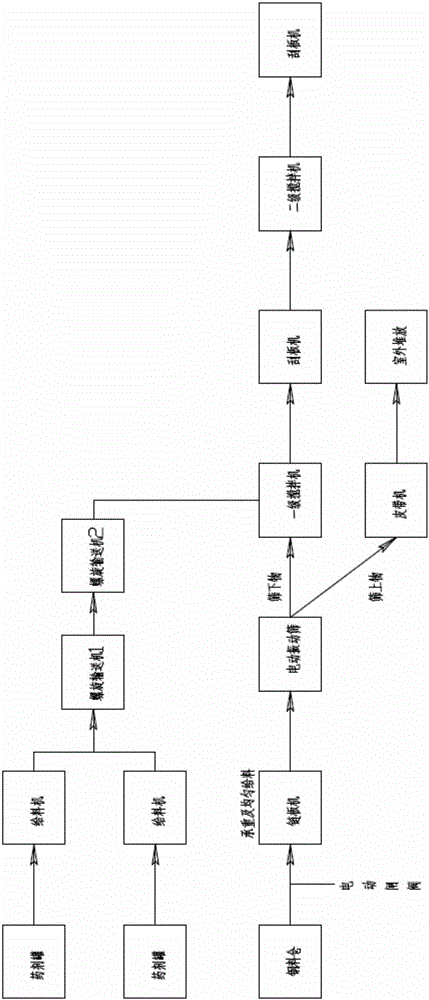

Sludge dewatering and drying treatment system and method

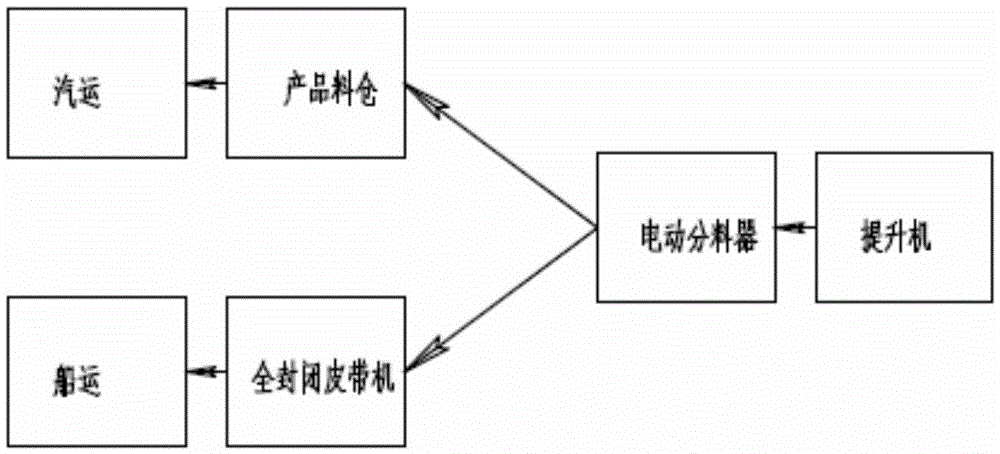

ActiveCN105668986AHigh degree of automationPrecise regulationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWater treatment systemProcess engineering

The invention belongs to the field of sludge treatment and particularly relates to a system and method for treating the sludge from a domestic sewage plant. The sludge dewatering and drying treatment system comprises a sludge feed screening system, a sludge dosing drying system, a dry sludge screening and grinding system and a dry sludge transport system. According to the sludge dewatering and drying treatment system provided by the invention, the automation degree is high, the links such as dosing, stirring and conveying are integrally finished, and the production conditions of each link can be accurately controlled, thereby being safe and reliable; and moreover, main technological links are implemented in a closed plant, supporting tail gas treatment equipment is provided, and thus the system is friendly to the surrounding environment.

Owner:SUZHOU NIBAO ENVIRONMENT TECH

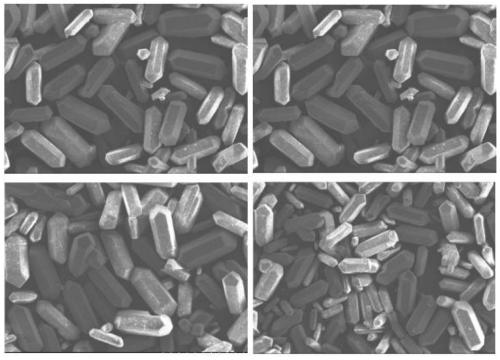

Concrete lightweight aggregate and preparation method thereof

The invention discloses concrete lightweight aggregate and a preparation method thereof. The concrete lightweight aggregate is prepared from the following raw materials by mass percent: 60-80% of oil-base drilling cuttings, 10-30% of civil sludge, 0.8-7% of a pore-forming agent and 9-9.3% of water. The preparation method comprises the following steps: (1) evenly mixing the dry oil-base drilling cuttings with the civil sludge and the pore-forming agent, and then carrying out ball-milling on the obtained mixture to obtain a raw material; (2) putting the prepared raw material into an automatic ball forming mill for balling, evenly sprinkling water in a balling process, aging the prepared green body after balling is finished, and then drying; (3) calcining the dried green body, and then cooling the product along with a furnace so as to obtain the concrete lightweight aggregate. The main raw materials of the concrete ceramsite lightweight aggregate prepared by the method are solid wastes, and all technical indexes of the concrete ceramsite lightweight aggregate meet the related requirements of standard in China; furthermore, the concrete lightweight aggregate is good in leaching resistance, does not cause secondary pollution and low in cost, thus having better industrial application prospect.

Owner:YANGTZE NORMAL UNIVERSITY

Process system and method for cooperatively disposing arsenic alkali residues in recycling manner by cement kiln

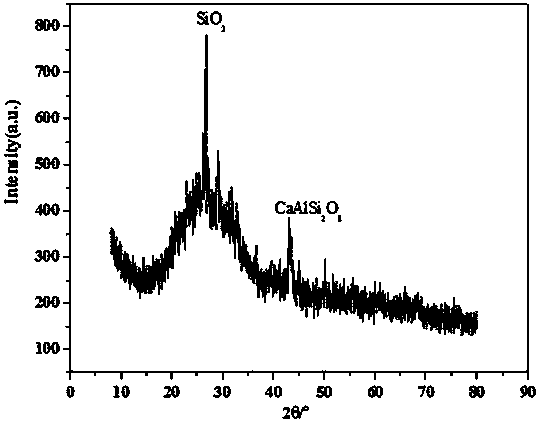

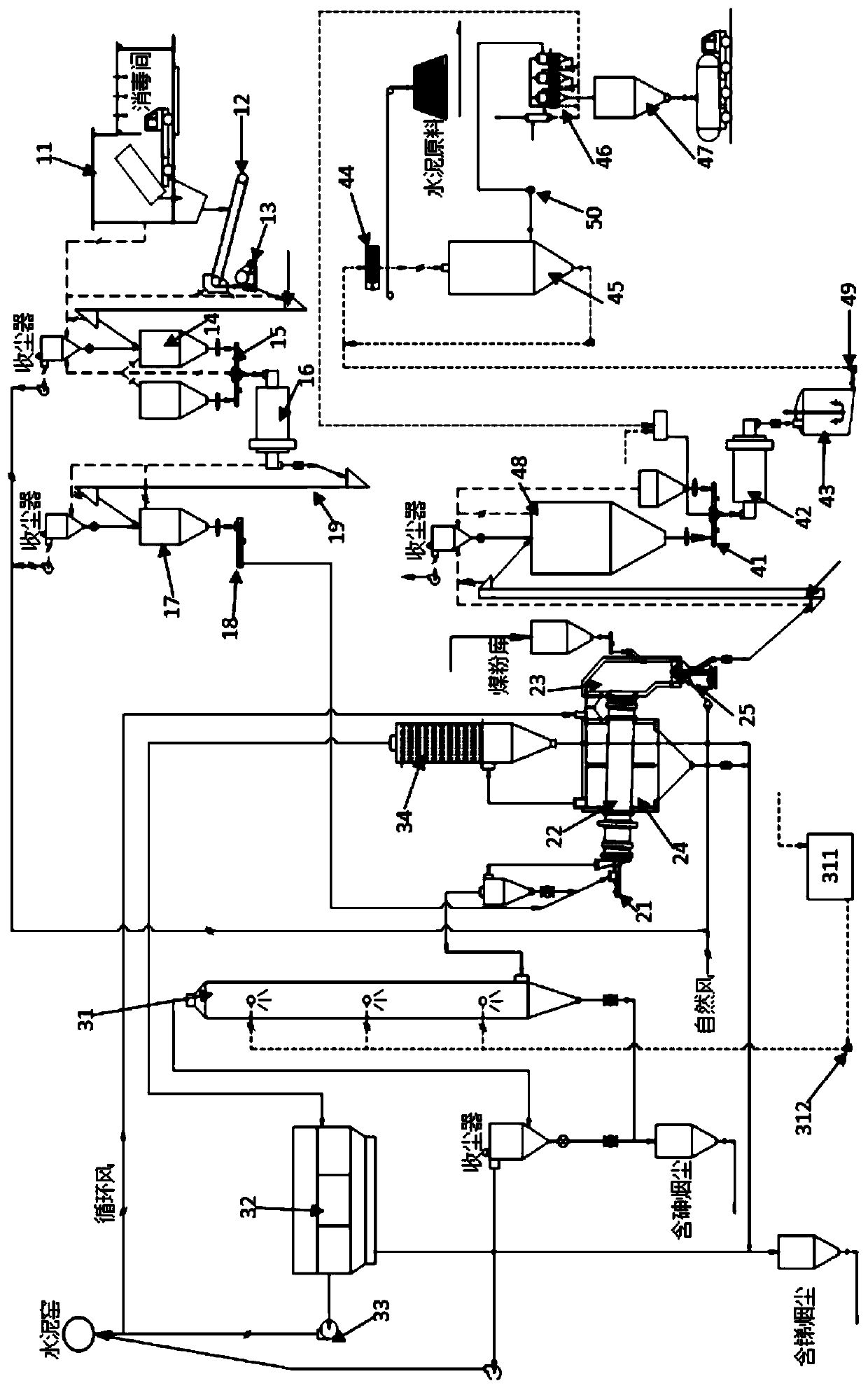

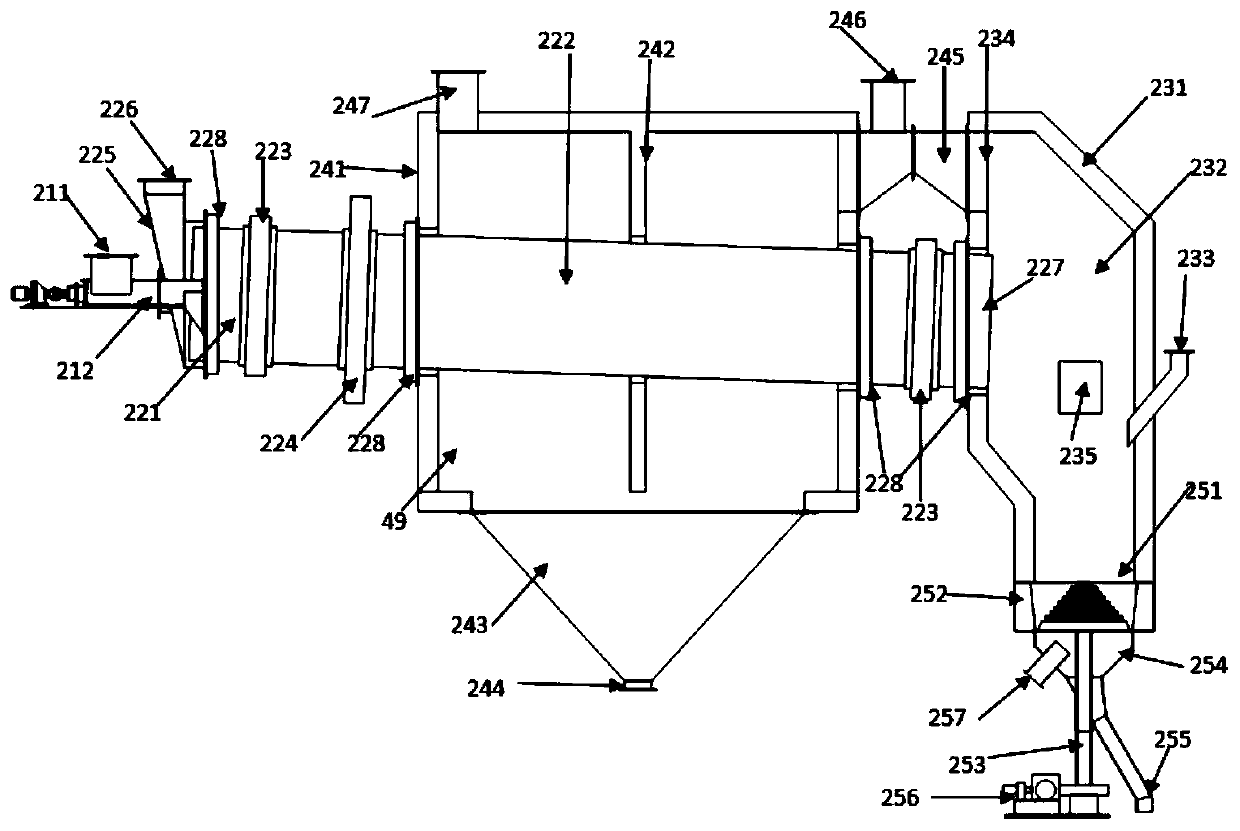

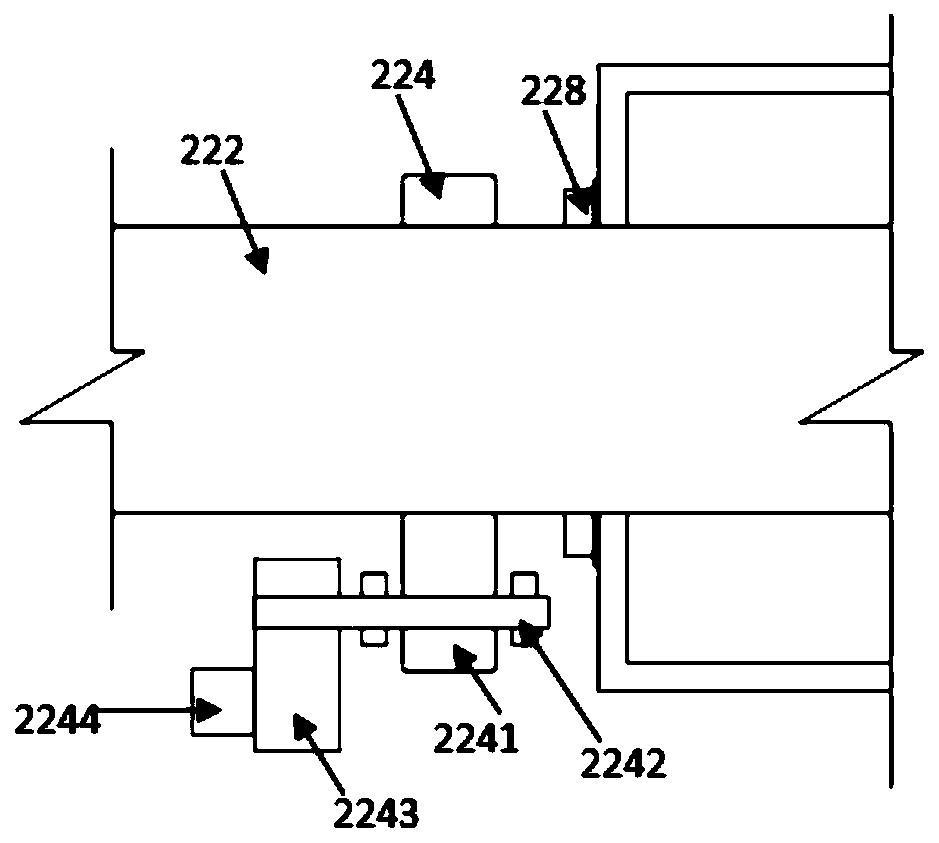

ActiveCN109748526AReduce power consumptionReduce disposal costsRotary drum furnacesCement productionProcess systemsHigh concentration

The invention discloses a process system and method for cooperatively disposing arsenic alkali residues in a recycling manner by a cement kiln. The system comprises an arsenic alkali residue crushingsystem, a low-melting-point heavy metal waste residue combined smelting furnace incineration system, a cement kiln cooperative enhanced flue gas arsenic and antimony removal system, a cement early strength agent preparation system and an alkali removal system. The method comprises the following steps: after crushing the arsenic alkali residues, adding a silica raw material and coal in the arsenicalkali residues, and carrying out high-temperature calcination; sublimating arsenic and antimony in the arsenic alkali residues at different high temperatures and separating the arsenic and the antimony from entering flue gas by the low-melting-point heavy metal waste residue combined smelting furnace incineration system; after treating generated high-temperature flue gas, delivering the high-temperature flue gas into a cement kiln system to be incinerated and solidified again; separately taking collected arsenic-containing dust and antimony-containing dust as raw materials for smelting the arsenic and the antimony; and preparing a cement early strength agent or a high-concentration soda ash solution by using a remaining lumpy material. According to the invention, the arsenic alkali residues are incinerated at a high temperature, so that the toxic hazard of the arsenic alkali residues is eliminated, and the requirements of developing circular economy and sustainable development are met.

Owner:长沙中硅环保科技有限公司

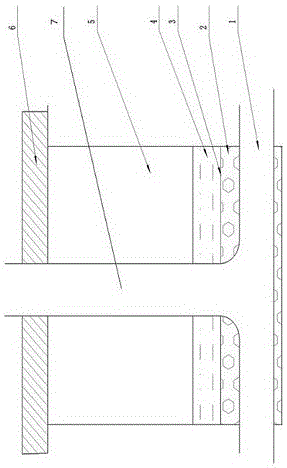

Non-asbestos high-density temperature and wear resisting heat insulation plate and processing technology thereof

ActiveCN105084812AEliminate environmental risksHigh temperature resistantSolid waste managementFiberGlass fiber

The invention discloses a non-asbestos high-density temperature and wear resisting heat insulation plate. The heat insulation plate is characterized by comprising, by weight, 200-260 parts of kaolin, 15-40 parts of alumina powder, 200-260 parts of aluminum silicate refractory fiber, 10-20 parts of dry paper pulp, 5-15 parts of glass fiber, 10-20 parts of cationic starch, 1-1.5 parts of polyvinyl alcohol and 1-1.5 parts of high-elastic emulsion. The non-asbestos high-density temperature and wear resisting heat insulation plate completely has no asbestos, eliminates environment risks brought by asbestos fiber in the production, maintenance and cleaning processes, is environmentally friendly and has the advantages of resisting high temperature, high pressure, bending and wear, being high in density and good in tenacity and the like. The high temperature lower than or equal to 1200 DEG C can be resisted, and the density reaches up to 900-1100 kg / m<3>. The tenacity is good, and the compression ratio can reach 1:1.4. The shot content in the non-asbestos high-density temperature and wear resisting heat insulation plate is low, and it is ensured that products making contact with the heat insulation plate are not damaged in the using process.

Owner:JINGMEN KAIDI IND TECH CO LTD

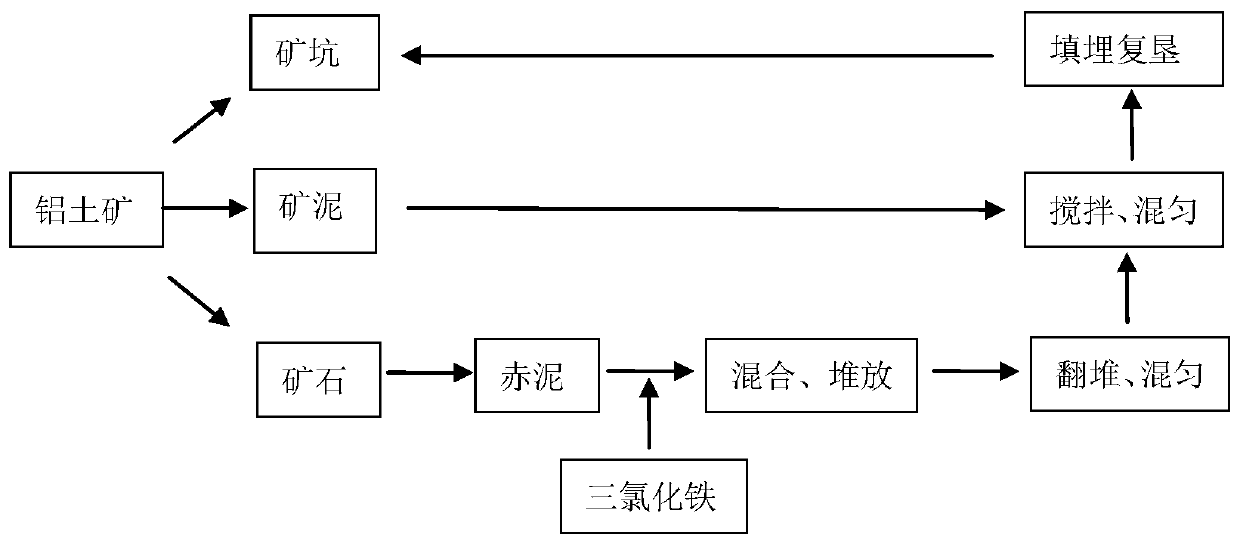

Method for backfilling reclamation mining pits by weathering type bauxite beneficiation and slurry and red mud generated by smelting

ActiveCN111485940APromote sustainable developmentEliminate environmental risksMaterial fill-upOrganic fertilisersRed mudMining engineering

The invention discloses a method for backfilling mining pits and mine land reclamation by weathering type bauxite beneficiation and slurry and red mud generated by smelting. Materials are matched according to the following weight percentage (by dry weight): 60%-95% of a slurry, 5%-40% of red mud and a plurality of ferric trichloride (anhydrous); and after the red mud is subjected to mixed stacking, turning and blending and ageing and alkali reduction with ferric trichloride powder, and then the red mud is mixed and blended with the slurry and to be fed to the mining pits for landfilling reclamation. According to the method for backfilling the mining pits and mine land reclamation by the weathering type bauxite beneficiation and slurry and red mud generated by smelting, a natural law of ''where come from and where go back'' is followed, the weathering type bauxite ore washing slurry and the smelting red mud are backfilled into the original mining pits after alkali reduction and blending, old red mud with huge stockpile is digested, a slurry library with large-scale storage is emptied, the hanging environment risk is excluded, the ecological environment is protected, land resources are regenerated, and the sustainable development of a bauxite industry is further facilitated, so that the bauxite industry has good ecological benefits, environment benefits and sustainable economicalbenefits.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

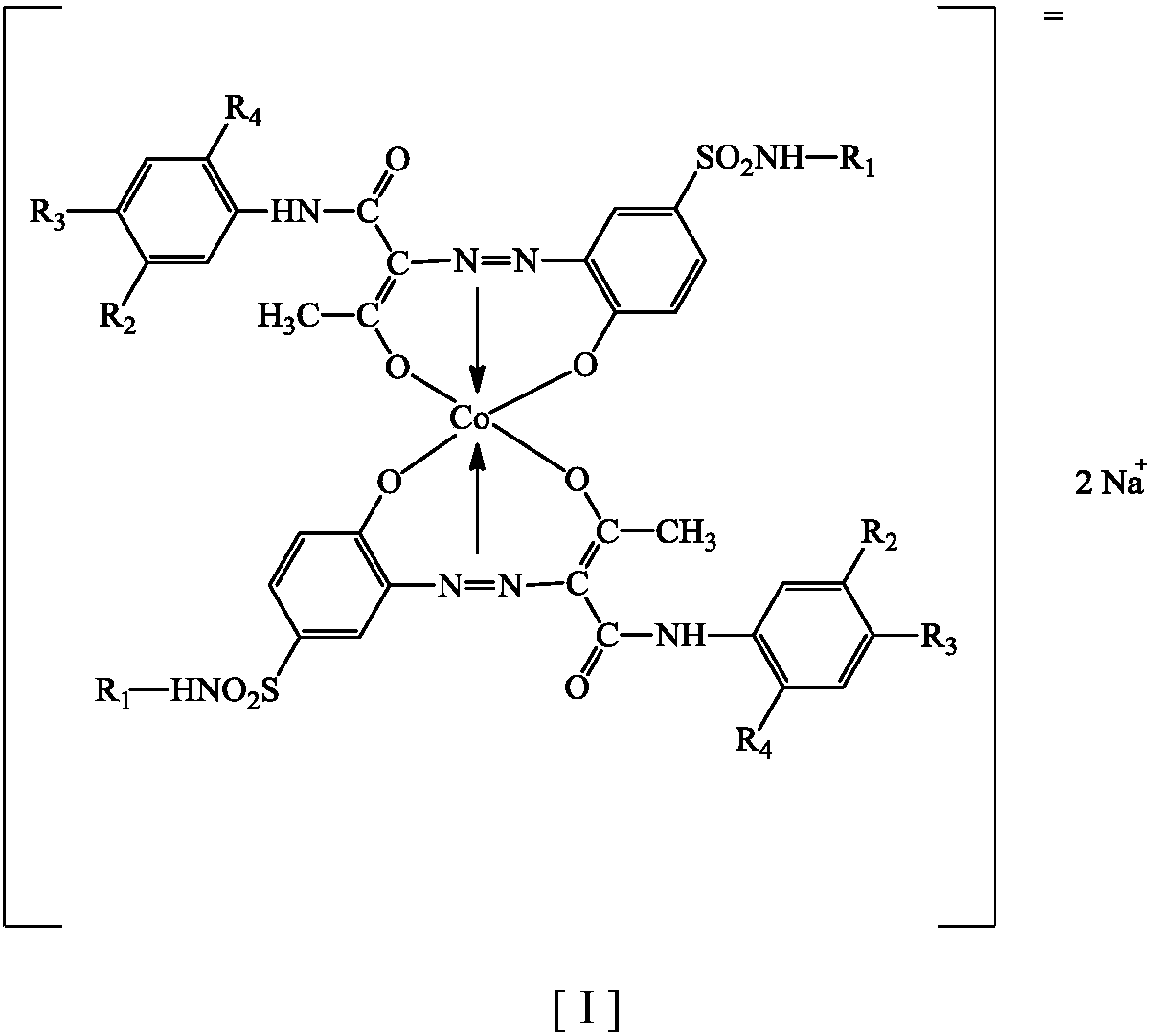

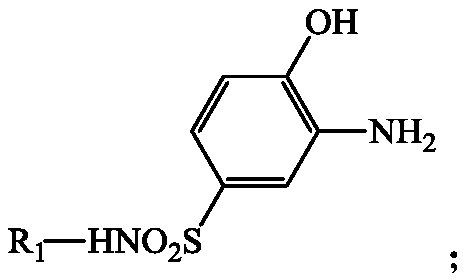

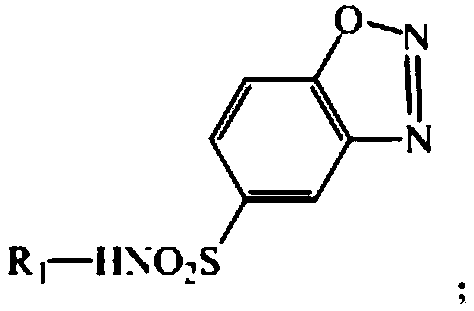

Preparation method of organic cobalt complex

The invention discloses a preparation method of an organic cobalt complex. The preparation method comprises the following steps: 1) in an acidic aqueous solution, mixing and then reacting a compound II and sodium nitrite, and adding sulfamic acid until the rest sodium nitrite is reacted completely; 2) adding a compound IV into an alkaline aqueous solution to prepare a compound IV aqueous solution,slowly adding the compound IV aqueous solution into the product obtained in step 1), and performing coupling reaction at 10-40 DEG C for 2-3 hours; and 3) heating the obtained product, adding a cobalt salt, and performing complexation reaction at 50-95 DEG C for 2.5-4 hours, wherein the obtained reaction solution contains an organic cobalt complex. The organic cobalt complex prepared by the method provided by the invention has the technical advantages of reducing material consumption, shortening process flow and having a remarkable environmental protection effect.

Owner:JINHUA SHUANGHONG CHEM CO LTD

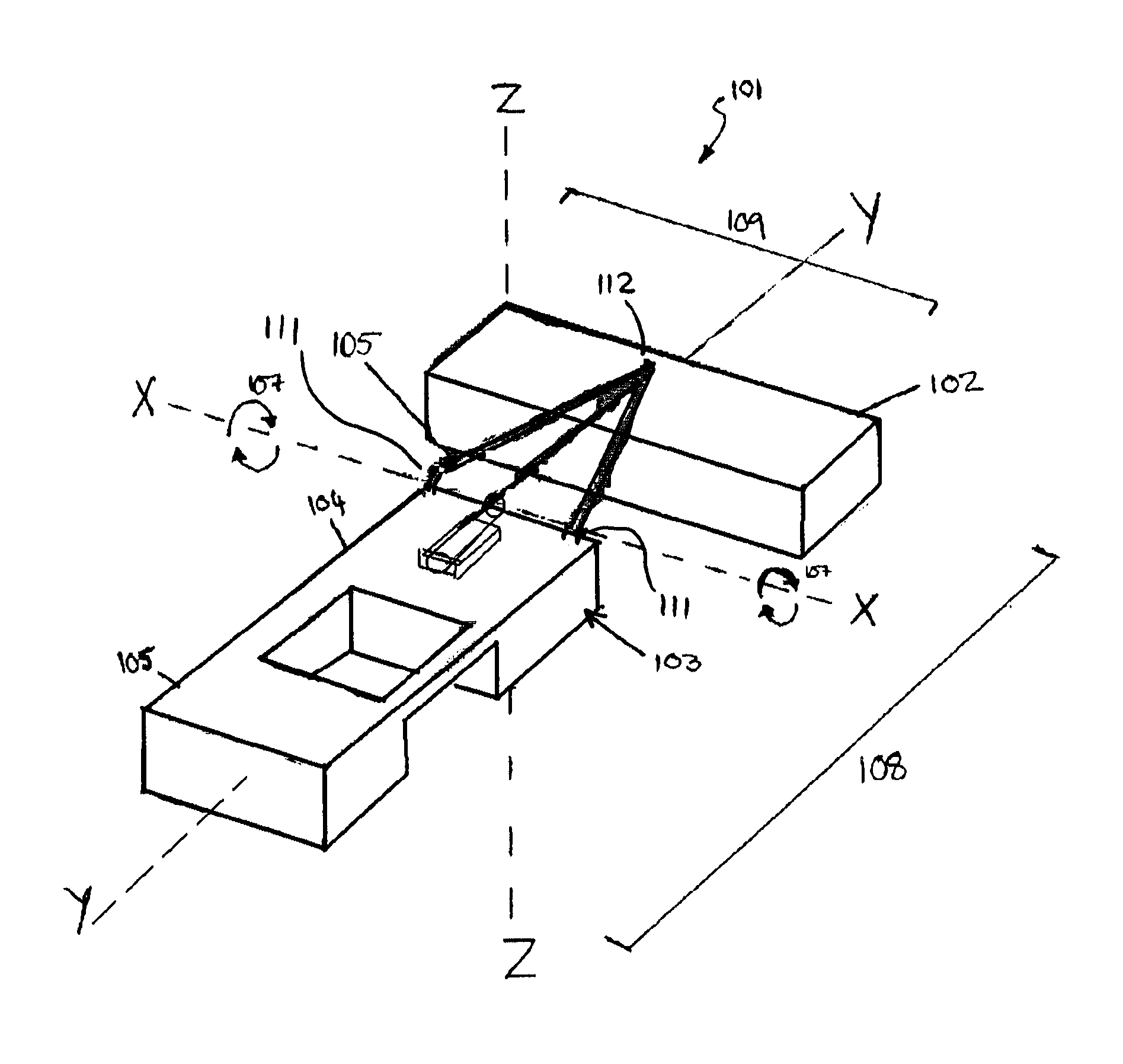

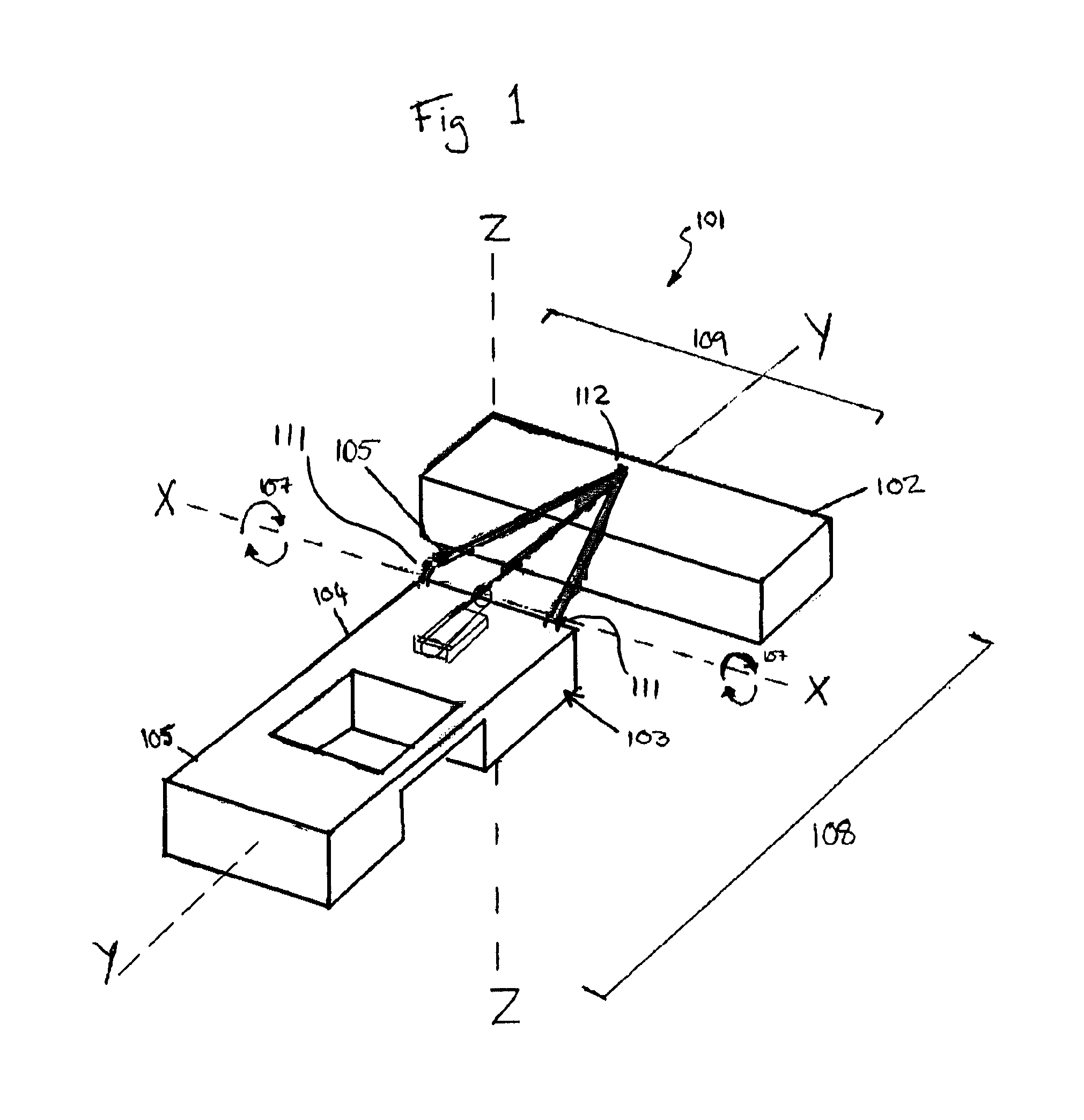

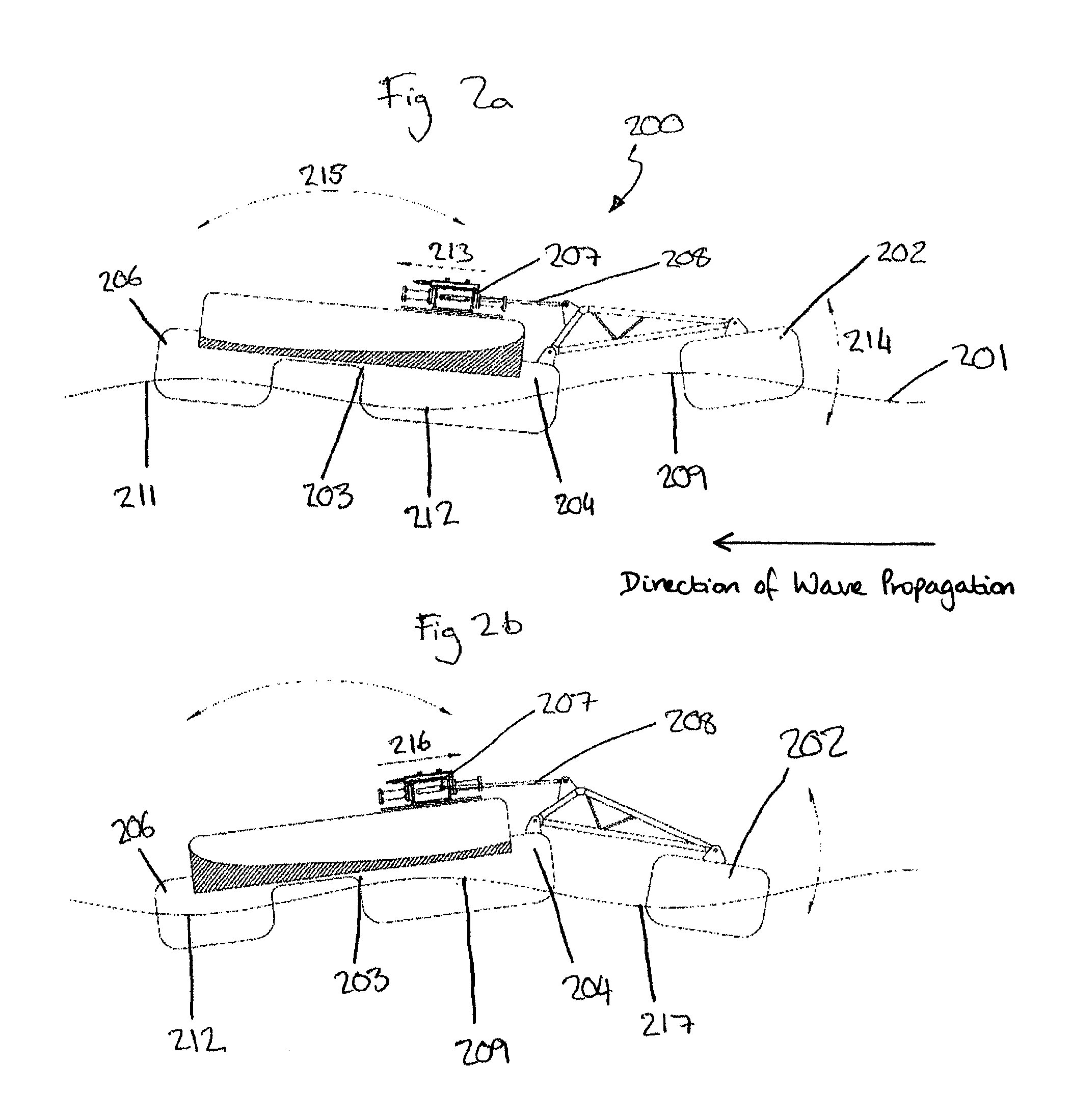

Wave energy conversion device

ActiveUS9429135B2Improve energy conversion efficiencyDesigned for marine environmentMachines/enginesEngine controlForms of energyClassical mechanics

A wave energy conversion device including a first pontoon configured to respond to an incident wave by operating in at least a first mode of motion and a second pontoon movably attached to the first pontoon by attachment means and configured to respond to an incident wave by operating in at least one mode of motion different from the first mode of motion. The relative motion of the first pontoon to the second pontoon in response to an incident wave is converted into a desired form of energy.

Owner:SEAPOWER

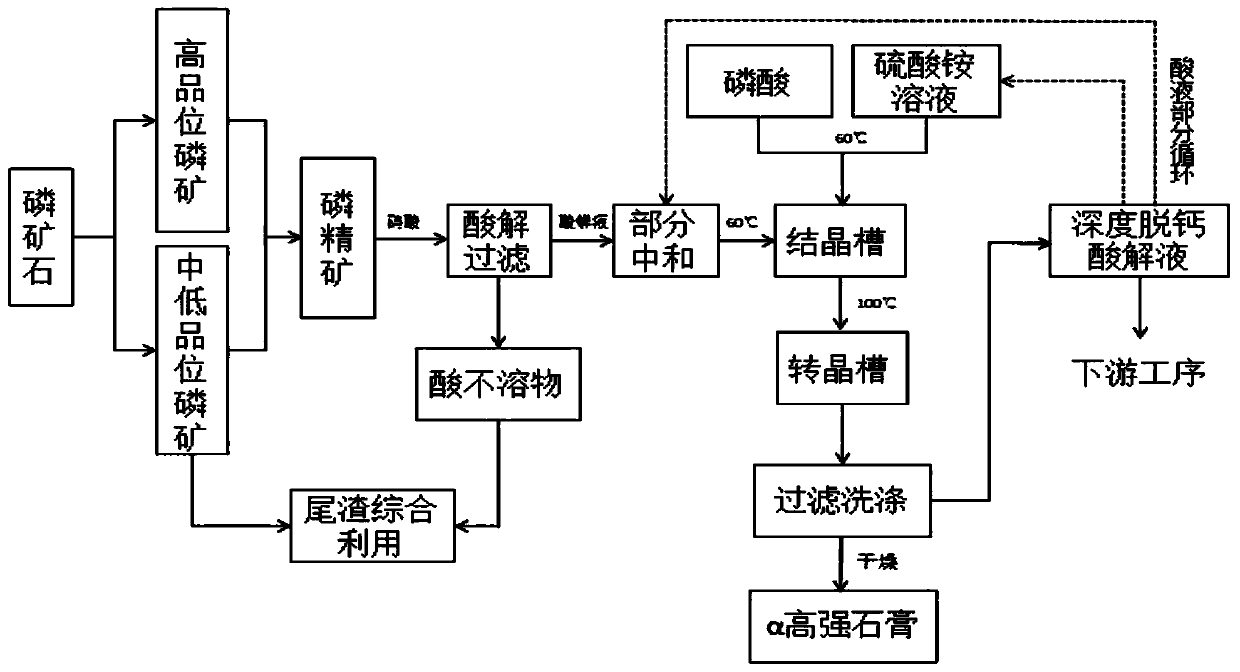

Method for decomposing phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum

ActiveCN111533154AReduce manufacturing costTake advantage ofCalcium/strontium/barium sulfatesPhosphoric acidChemical industryO-Phosphoric Acid

The invention discloses a method for decomposing a phosphate rock acidolysis liquid by nitric acid to remove calcium byproduct alpha high-strength gypsum. The method comprises: decomposing phosphoriteby nitric acid, filtering out acid insoluble substances, partially neutralizing the acidolysis liquid, regulating and controlling the concentration of calcium ions in the acidolysis liquid, adding the acidolysis liquid into a crystallization tank containing a mixed solution of additional phosphoric acid and ammonium sulfate, controlling the reaction temperature to be 50-70 DEG C and the reactiontime to be 0.5-2 hours to firstly generate dihydrate gypsum, then, making the reaction slurry flow into a crystal transformation tank, and raising the temperature to 95 to 110 DEG C for reacting for aperiod of time so that an alpha-type high-strength gypsum product can be produced as a byproduct. According to the invention, the acidolysis liquid can be used for producing products such as fine phosphate, high-water-solubility phosphate fertilizer and the like, meanwhile, calcium resources in the acidolysis liquid are converted into an alpha high-strength gypsum product, solid waste phosphogypsum is changed into product phosphogypsum, environmental risks caused by the fact that a large amount of solid waste phosphogypsum is produced as a byproduct in the ammonium phosphate industry are eliminated, the phosphorus compound fertilizer industry is promoted to adjust the product structure, solid waste emission is reduced, and sustainable development of the phosphorus chemical industry is promoted.

Owner:GUIZHOU UNIV

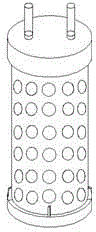

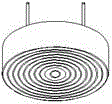

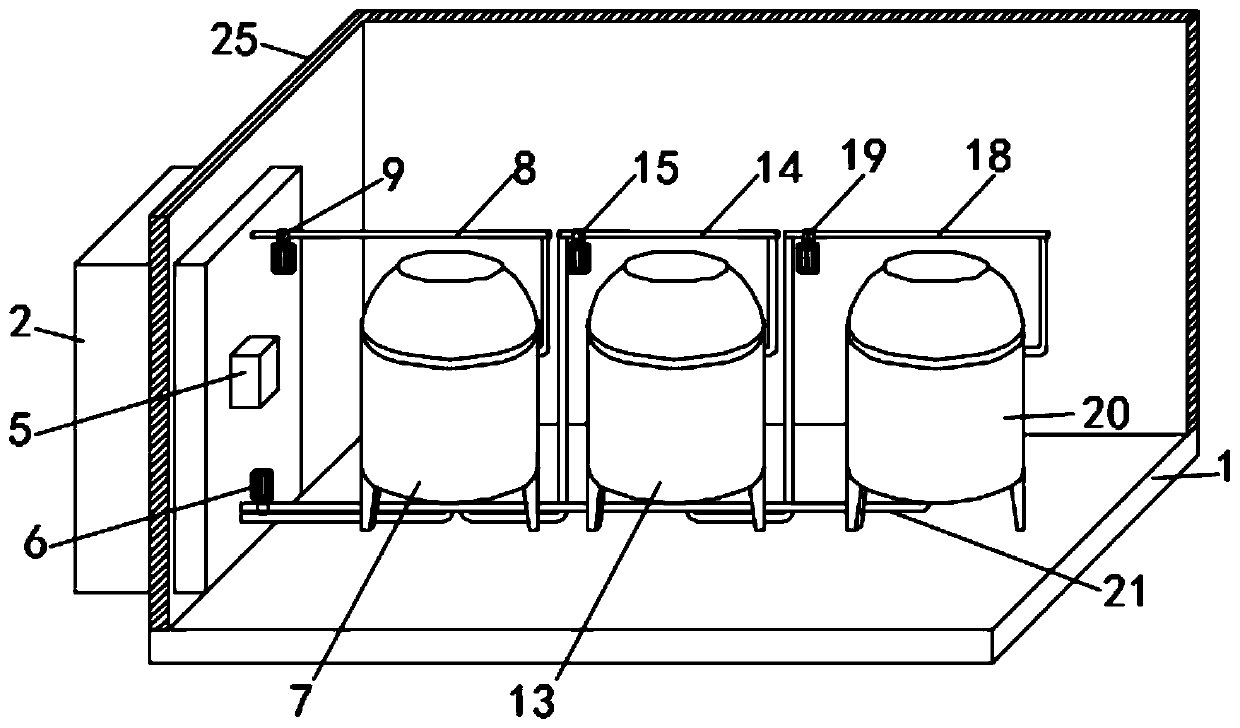

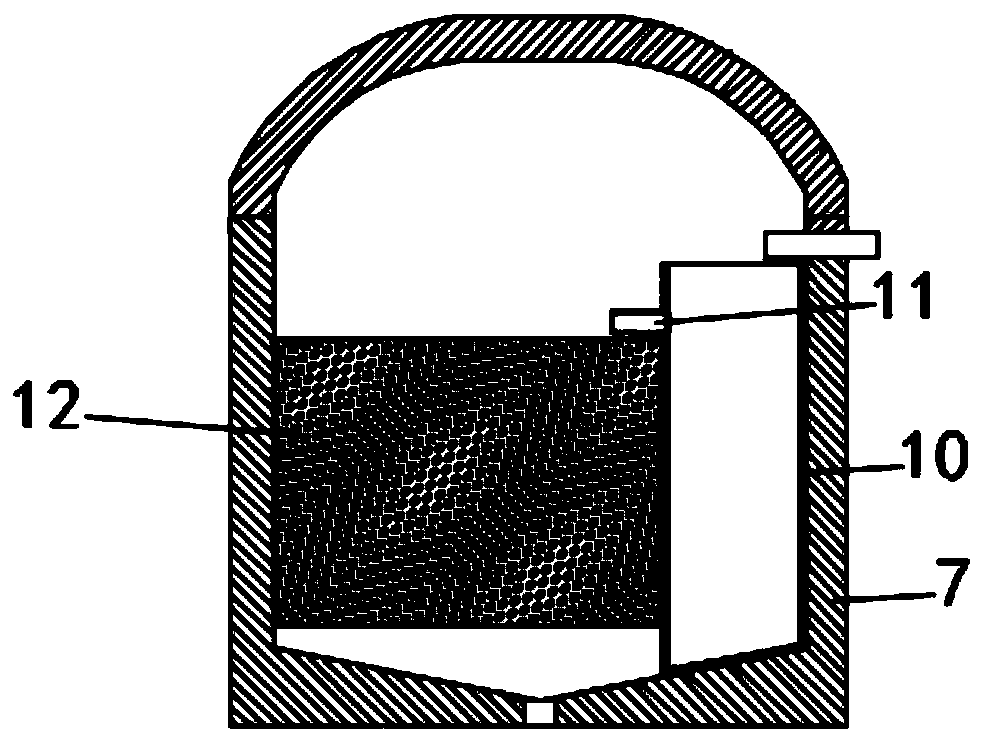

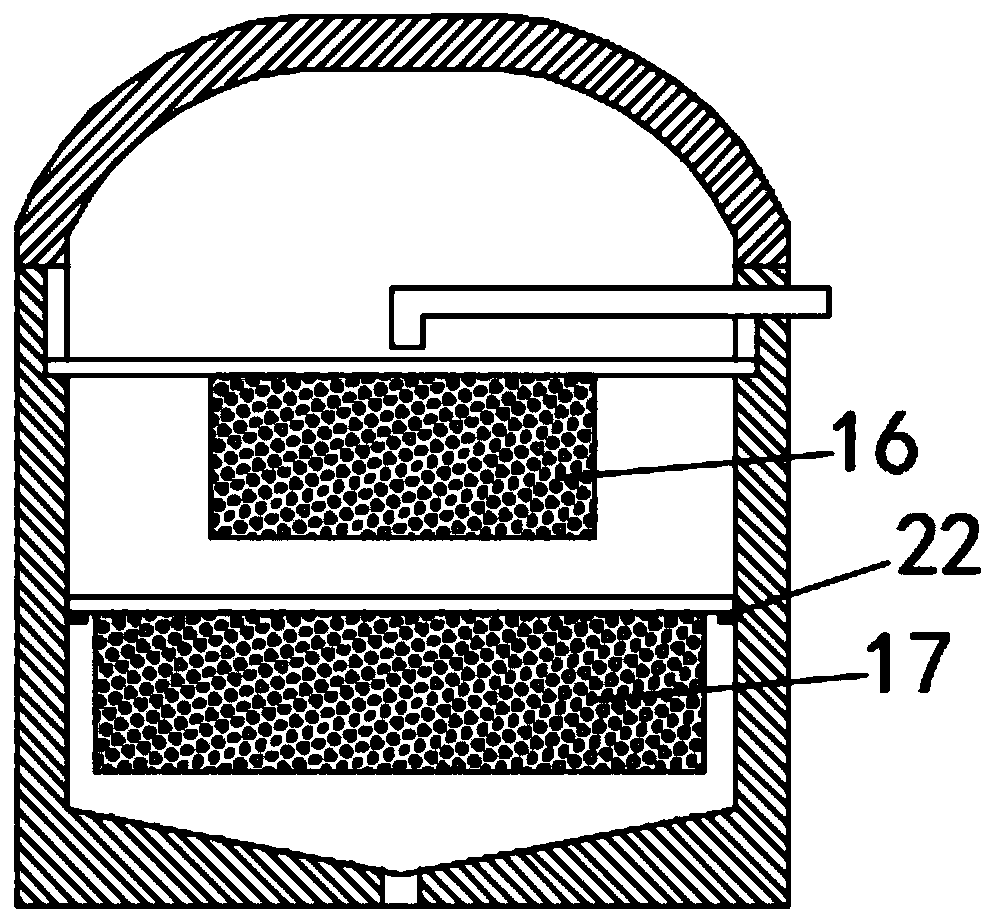

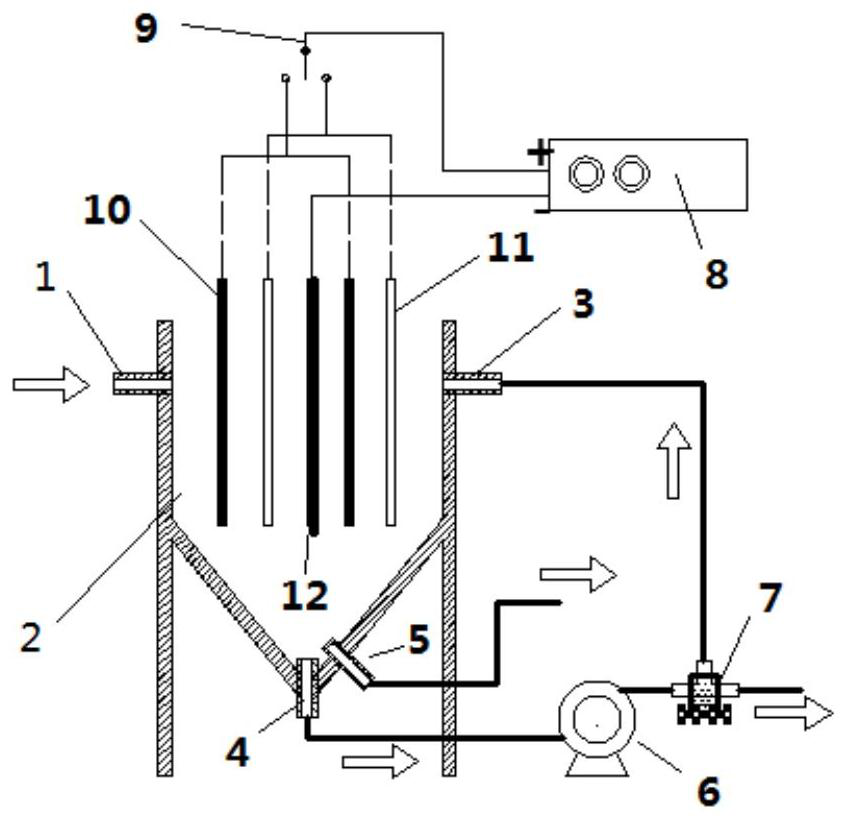

Electrochemical recycling method and electrochemical recycling device for claus tower tail gas by cooperating with absorption liquid

InactiveCN103537176BReduce electricity consumptionLow running costDispersed particle separationSulfur preparation/purificationElectrochemical responseLiquid storage tank

The invention relates to an electrochemical recycling method and an electrochemical recycling device for claus tower tail gas by cooperating with absorption liquid. According to the technical solution, the cooperated absorption liquid inside a liquid storage tank (9) subjected to absorption reaction of claus tail gas enters an inner rotational flow type electrochemical reactor from a liquid inlet (11) through an infusion pump (8), and a reaction product, namely elemental sulfur, is discharged to a sulfur collecting tank (7) after being collected by a sulfur separator (6) at the bottom of the inner rotational flow type electrochemical reactor and discharged to a buffer tank (10) from an overflow pipe (2) at the top of the inner rotational flow type electrochemical reactor after being oxidized by a barrel type electrode (4). Then, the cooperated absorption liquid subjected to electrode oxidation discharged into the buffer tank (10) is regulated at 20-90 DEG C, the chemical components of the cooperated absorption liquid subjected to regulation are the same as those of the cooperated absorption liquid before the absorption reaction of claus tail gas so as to be recycled for the absorption reaction of claus tail gas. The electrochemical recycling method and the electrochemical recycling device have the advantages of low operating cost, convenience in operation, high sulfur recovery rate, few byproducts, long service life of device and suitability for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +2

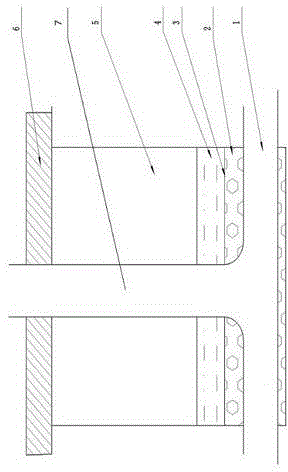

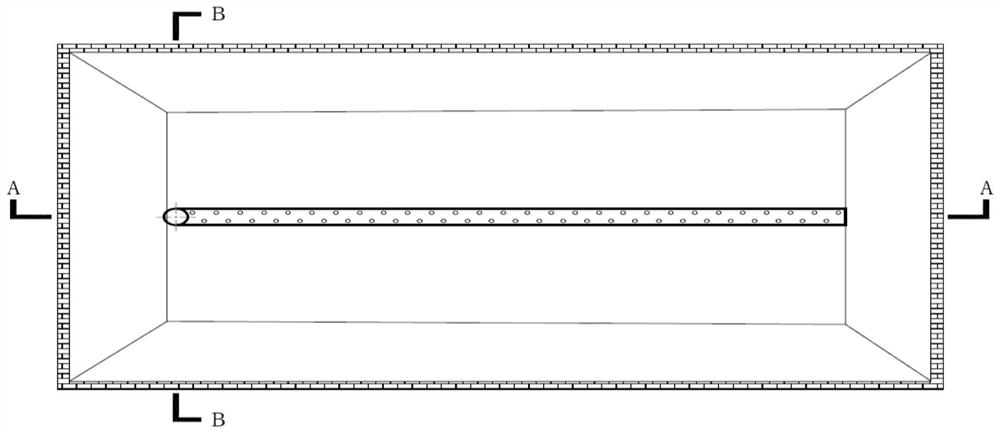

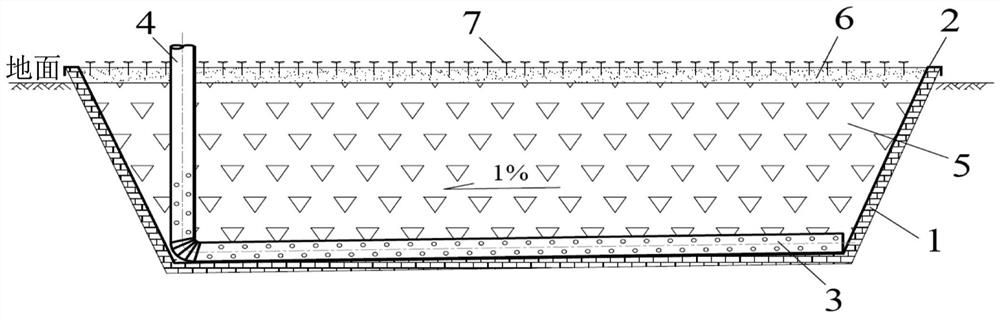

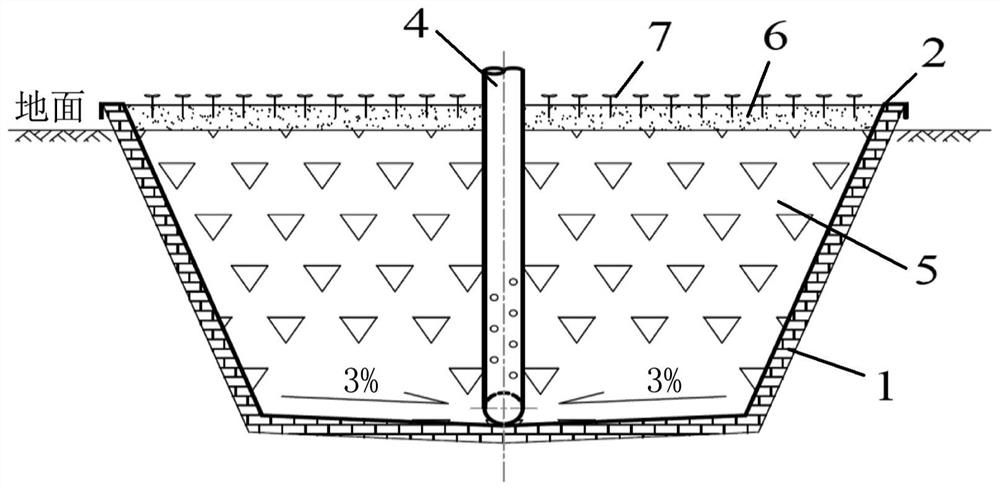

Drilling solid waste biodegradation device and collected liquid collecting and recycling method thereof

PendingCN112093908AReduced anaerobic zoneIncrease the processing volumeWaste water treatment from quariesBiological water/sewage treatmentWell drillingEnvironmental engineering

The invention provides a drilling solid waste biodegradation device and a collected liquid collecting and recycling method thereof, and relates to the field of oil and gas exploration drilling solid waste biodegradation treatment. The device comprises a biological treatment mixture layer, a clean soil layer, a vegetation layer, a degradation stacking pool, an impermeable film, a liquid collectioncollecting pipe and a liquid guide pipe. The bottom of the degradation stacking pool comprises a groove with the inclination degree of 1%, a first liquid collecting face with the inclination degree of2-3% towards the groove and a second liquid collecting face with the inclination degree of 2-3% towards the groove. And the impermeable film completely covers the degradation stacking pool. The liquid collection collecting pipe with a first through hole in the pipe wall is mounted in the groove, one end of the liquid guide pipe is connected with the liquid collection collecting pipe, and the other end is higher than the surface of the degradation stacking pool. According to the method, the device is used, and the collected liquid in the liquid guide pipe is sucked and sprayed to the surface of the degradation stacking pool to be collected and recycled. The device has the beneficial effects that the collected liquid can be collected and reused, and degradation of drilling solid waste is accelerated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

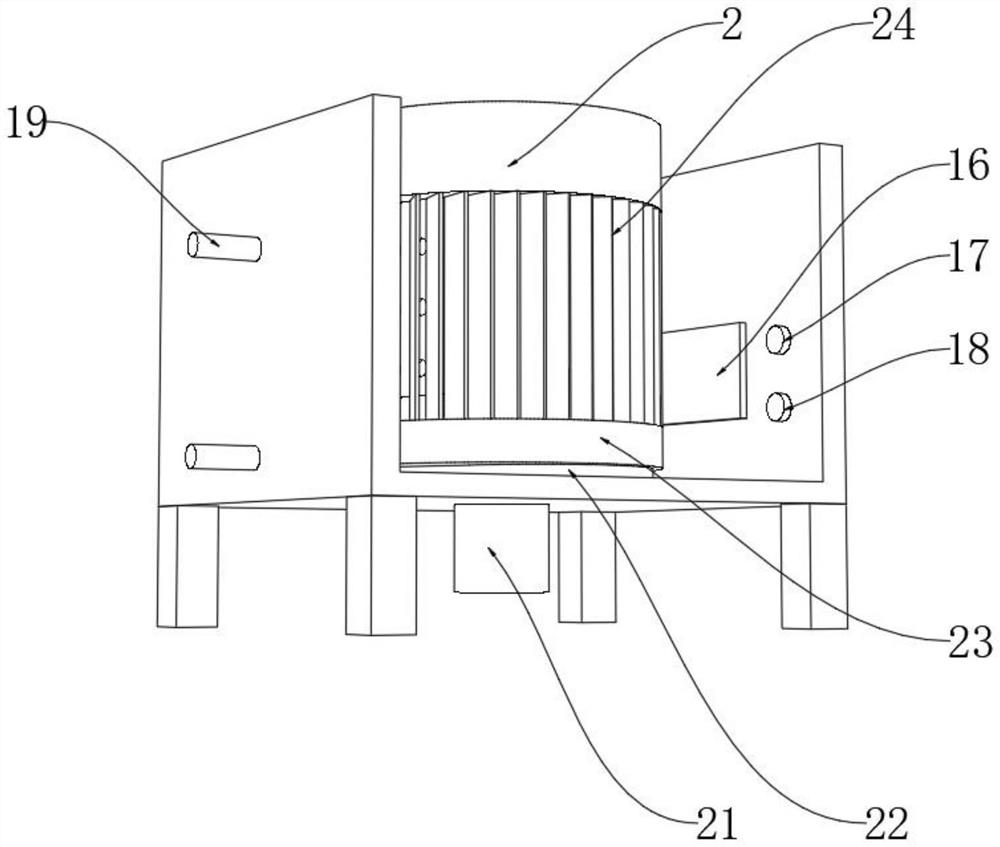

Chain grate furnace type fly ash pre-combustion melting device

The invention provides a chain grate furnace type fly ash pre-combustion melting device which includes a pre-combustion furnace and a melting furnace which are arranged left and right and are in communication with each other. The pre-combustion furnace is internally provided with a chain grate, a feeding port is arranged at the position, above the chain grate, of the pre-combustion furnace, the bottom of the pre-combustion furnace is provided with an ash discharge bucket, and the tail end of the chain grate is located at the communicating part of the pre-combustion furnace and the melting furnace; the melting furnace is internally provided with at least one combustion nozzle, a smoke exhaust pipe is arranged, and a slag discharge port is arranged at the bottom of the melting furnace. By means of the chain grate furnace type fly ash pre-combustion melting device, granular materials made by mixing fly ash and pre-combustion agents are subjected to pre-combustion and melting to form glassy residues with stable physical properties, the problem of difficult handling of the fly ash is solved, meanwhile, exhaust gas and flue gas waste heat of all links are rationally utilized, and the purposes of energy saving and emission reduction are achieved.

Owner:武汉致衡环境安全工程技术有限公司

Coke oven coal feeding port online uncovering system and method

ActiveCN113122287AEliminates unburned fugitive problemsAvoid emissionsCoke oven safety devicesCharging devicesRemote controlControl cell

The invention relates to a coke oven coal feeding port online uncovering system and method. The online uncovering system is an independent control unit and is linked with an existing riser system and a coal charging car, an uncovering device travels along a fixed rail and automatically travels to a certain oven number according to a remote instruction, and an oven cover is opened and flatly placed by utilizing an electromagnet principle; and the oven cover can run to other areas for operation and residence or continue to be opened, and can also return to a certain furnace number according to a remote instruction, and the furnace cover is put into a corresponding coal feeding opening again. According to the invention, remote control and unmanned operation can be realized, and manual furnace cover opening and closing operation at the top of the existing coke oven can be completely replaced; and ordered empty burning of coaling residual graphite and secondary coke can be realized, coke oven refractory masonry damage caused by excessive empty burning of a local carbonization chamber can be avoided, the problem that raw coke oven gas is not burnt and escapes in the process of opening an ascending pipe cover can also be eliminated, unorganized emission of VOCs in the coking production process is reduced, environmental pollution is reduced, and the coke oven operation environment is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

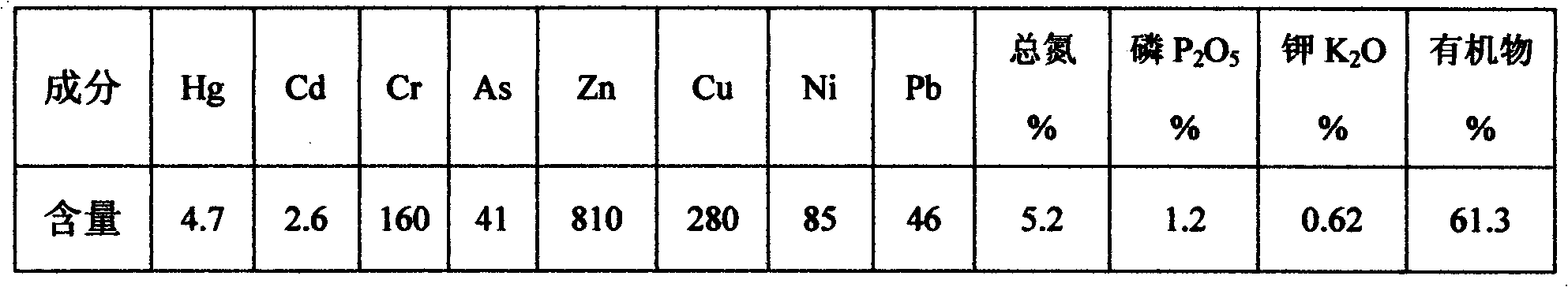

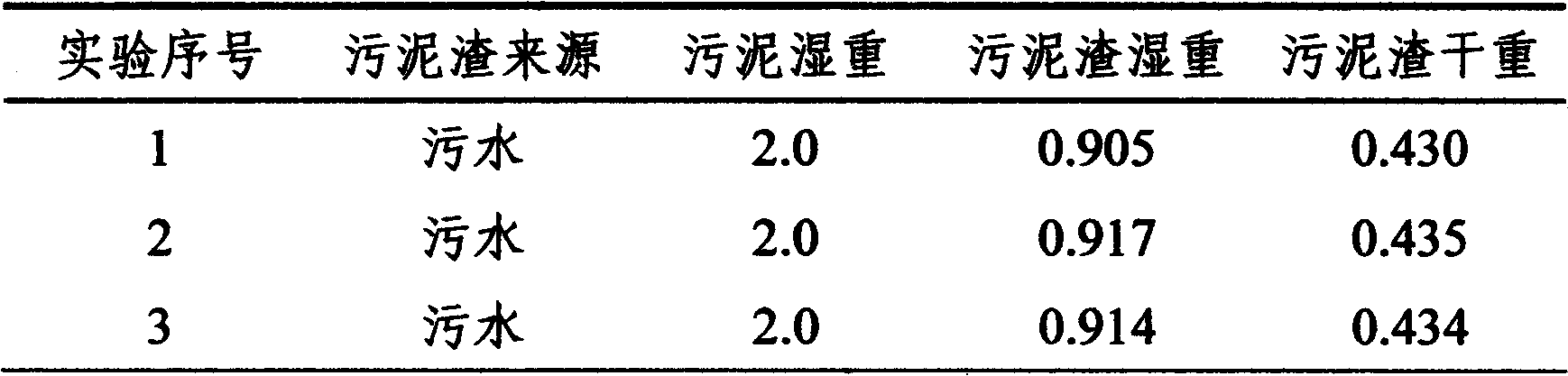

Method for preparing compound fertilizer from sludge produced by treatment of town sewage

InactiveCN101913921AEnsure safetyEliminate environmental risksClimate change adaptationSewage/sludge fertilisersSludgeResource utilization

The invention relates to a method for preparing a compound fertilizer from sludge produced by treatment of town sewage. The method comprises the following steps of: (1) pretreating the sludge by acidifying; (2) heating and reacting the acidified sludge; (3) separating solid from liquid and washing; (4) neutralizing sludge silt; and (5) preparing the compound fertilizer from the sludge silt. In the compound fertilizer prepared by the method, heavy metals are removed from the sludge so that the use safety of the compound fertilizer prepared from the sludge in agricultural production can be ensured, the environmental risk of the resource utilization of the sludge is eliminated and a precondition is created for large-scale agricultural use of the sludge.

Owner:CHANGSHA JIEXIANG ENVIRONMENTAL ENG

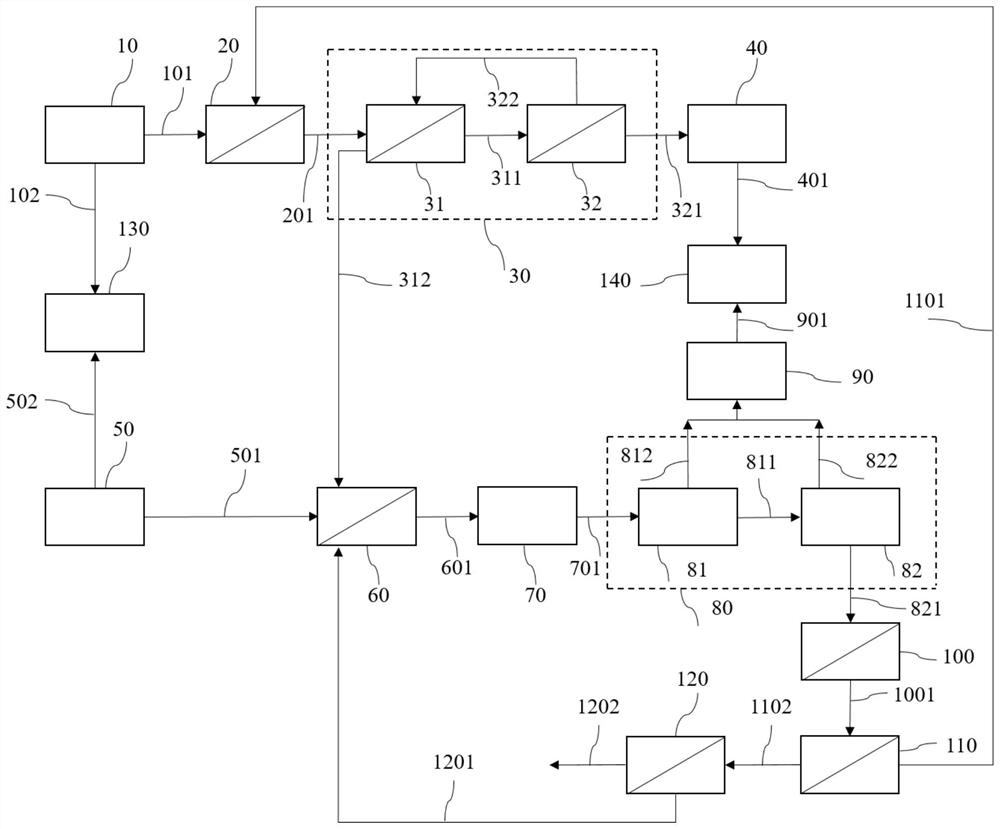

Chemical waste salt separation and recovery system and method

PendingCN114804156AImprove qualityEliminate environmental risksSolid waste disposalTransportation and packagingIon exchangeIon-exchange resin

The invention discloses a chemical waste salt separation and recovery system, and belongs to the field of industrial waste salt separation and recovery. The process comprises a sodium chloride waste salt calcining system, a sodium chloride tubular membrane system, a sodium chloride nanofiltration system, a sodium chloride evaporation system, a sodium sulfate waste salt calcining system, a sodium sulfate tubular membrane system, an ion exchange resin system, a sodium sulfate primary crystallization system and a sodium sulfate secondary crystallization system. The system comprises a sodium sulfate mother liquor tubular membrane system, a sodium sulfate nanofiltration system, a sodium sulfate ultrafiltration system, a waste gas treatment system and a carnallite drying system. Different types of industrial waste salt can be separated and recycled, resource utilization of the waste salt mainly containing sodium chloride and the waste salt mainly containing sodium sulfate is achieved, the cost of the hazardous waste treatment industry is reduced, the environmental protection problem is solved, and meanwhile certain economic value is created.

Owner:安徽普朗膜技术有限公司

Low-cost emulsion purification and regeneration system

InactiveCN111320296AKill completelyFast sterilizationSpecific water treatment objectivesTreatment involving filtrationBiotechnologyBacterial virus

The invention discloses a low-cost emulsion purification and regeneration system. The system comprises a mounting bottom plate and a storage box, a protective cover is fixedly mounted at the top of the mounting bottom plate; a storage box is fixedly mounted at one end of the protective cover; a control panel is fixedly mounted on one side of the storage box; a primary filter box is fixedly mountedat one end, close to the storage box, of the top of the mounting bottom plate; and the storage box is connected with the primary filter box through a first conveying pipe. The system has the advantages that when germs in water contact with small balls, instant killing without blind spots can be realized; no harmful substance is released into water, the sterilization speed is high, bacteria are killed when the system contacts with bacteria and viruses, the bacteria are directly and radically killed; while ozone and ultraviolet rays can only inhibit the increasing of bacteria under many situations and cannot completely kill bacteria; meanwhile, the system ahs a wide bactericidal spectrum, and the efficiency is high and can be maintained stably.

Owner:SHENZHEN BUSTIN TECH

Microbial treatment process of waste mud from oil and gas drilling operations

ActiveCN104086065BReduce moisture contentReduced anaerobic zoneBiological sludge treatmentThree levelWell drilling

The invention discloses a microbiological treatment technology for waste mud generated in drilling operation of petroleum and natural gas, and relates to the technical field of pollution treatment of exploration drilling for petroleum and natural gas. The technology is executed according to the following steps: a, preparing a pool for performing microbiological treatment on waste mud; b, paving the bottom of the pool with a plurality of transverse pipes, connecting the transverse pipes with vertical pipes, and perforating the transverse pipes; c, paving the bottom of the pool with cobblestones, and controlling the paving thickness of the cobblestones to be larger than the pipe diameter of the transverse pipes; d, paving with a non-woven fabric layer on the cobblestones; e, paving with sand on the non-woven fabric; f, paving with a prepared waste mud mixture on the sand; and g, paving with natural soil on the waste mud mixture, and planting plants. The technology helps to reduce the anaerobic area of a landfill pool, and is capable of finished degradation process in a relatively short time, enabling the mixture to reach national soil three-level standard and eliminating environment risk.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A treatment method and reactor for refractory organic wastewater containing nitrogen and chlorine

ActiveCN109264834BEnsure complete removalEasy to operateWater contaminantsWater/sewage treatment using germicide/oligodynamic-processElectrochemical responseIndustrial waste water

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

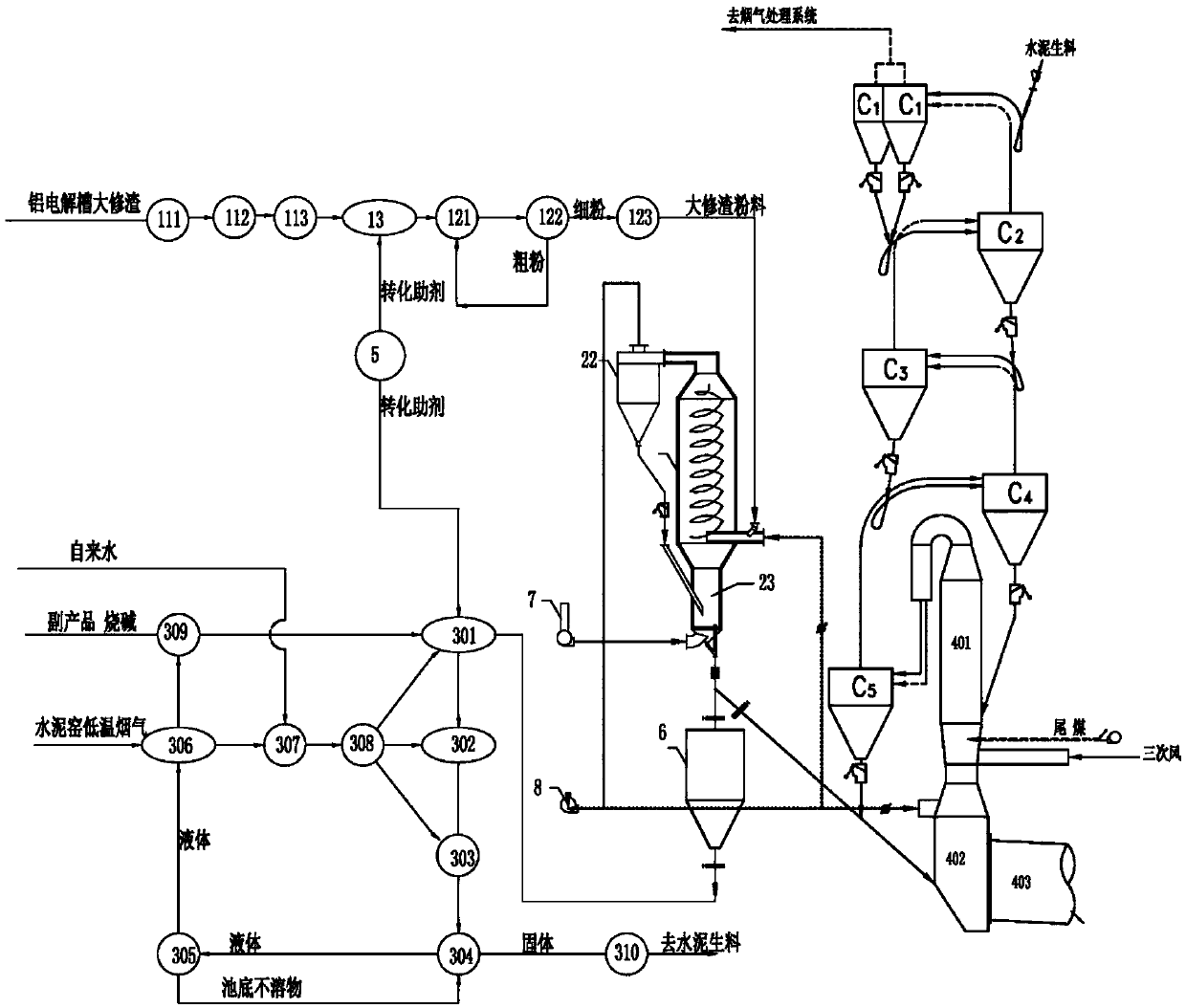

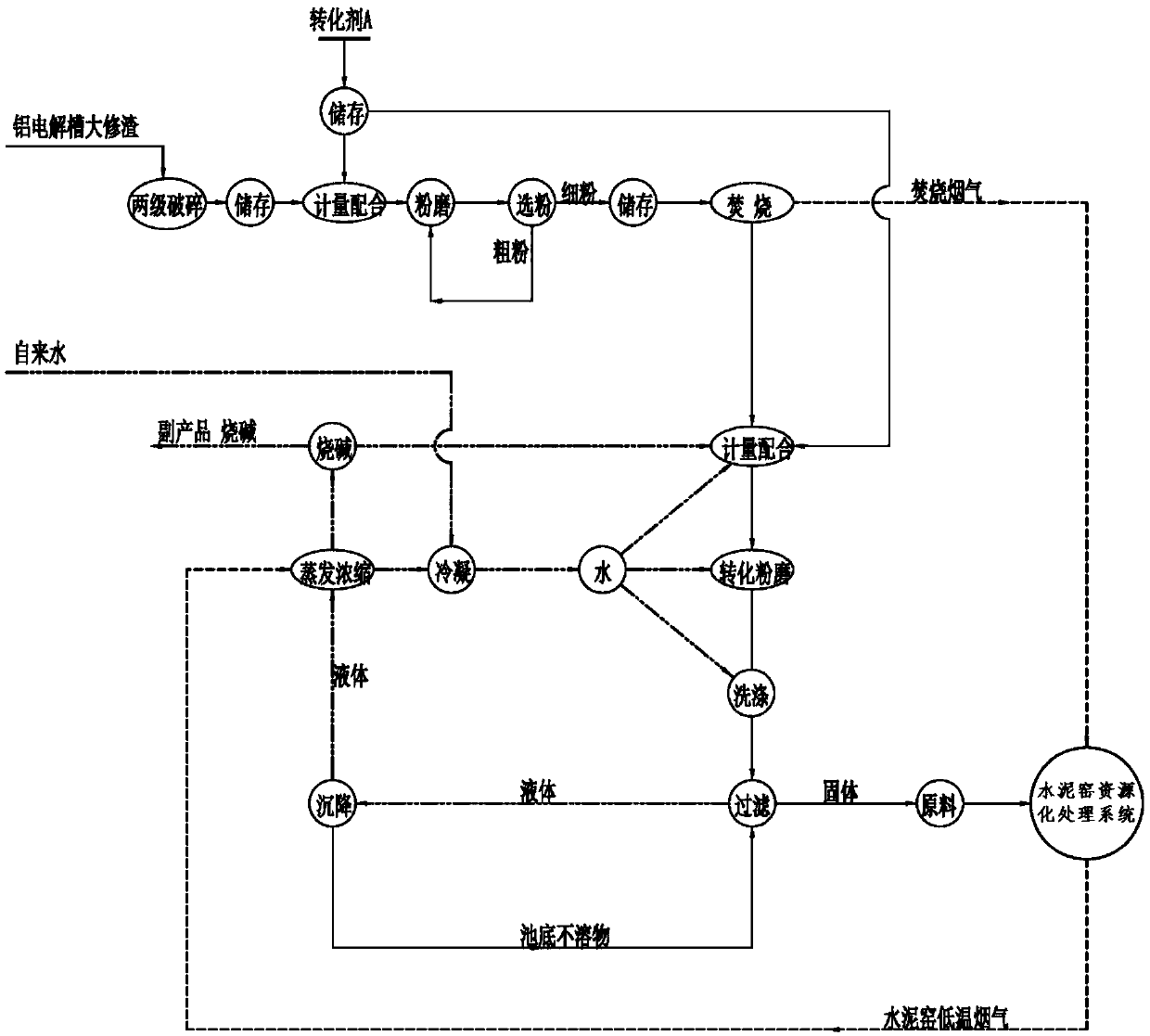

System and method for treating overhauling slag of aluminum cell by cement kiln bypass incinerating

ActiveCN108679628AEliminate the risk of secondary pollutionPromote safe productionIndirect carbon-dioxide mitigationIncinerator apparatusCyanideSlag

The invention provides a system and method for treating overhauling slag of an aluminum cell by cement kiln bypass incinerating. The system comprises an overhauling slag crushing system, a cement kilnbypass incinerating system, a conversion and dealkalizing system and a cement kiln resourceful treatment system which are sequentially connected. The method comprises the steps of S1, crushing and powdering the overhauling slag; S2, performing cement kiln bypass incinerating and disinfecting; S3, performing conversion and dealkalizing; and S4, performing resourceful treatment on a cement kiln. According to the system and the method, a suspension combined incinerating furnace is arranged at a cement kiln bypass; the crushed overhauling slag is incinerated under the conditions of high temperature, rich oxygen and long staying time, so that carbon materials in the overhauling slag can fully burn, and moreover, cyanide in the overhauling slag can be oxidized to remove the toxicity under high-temperature aerobic and alkaline conditions; the cinder obtained after incinerating of the overhauling slag is washed through alkaline liquid in order to be converted into a mineralizer containing fluorite for the cement kiln, and a caustic soda byproduct can be obtained, and as a result, the harmless, resourceful, ultimate and massive treatment of the overhauling slag of the aluminum cell can beachieved.

Owner:长沙中硅环保科技有限公司

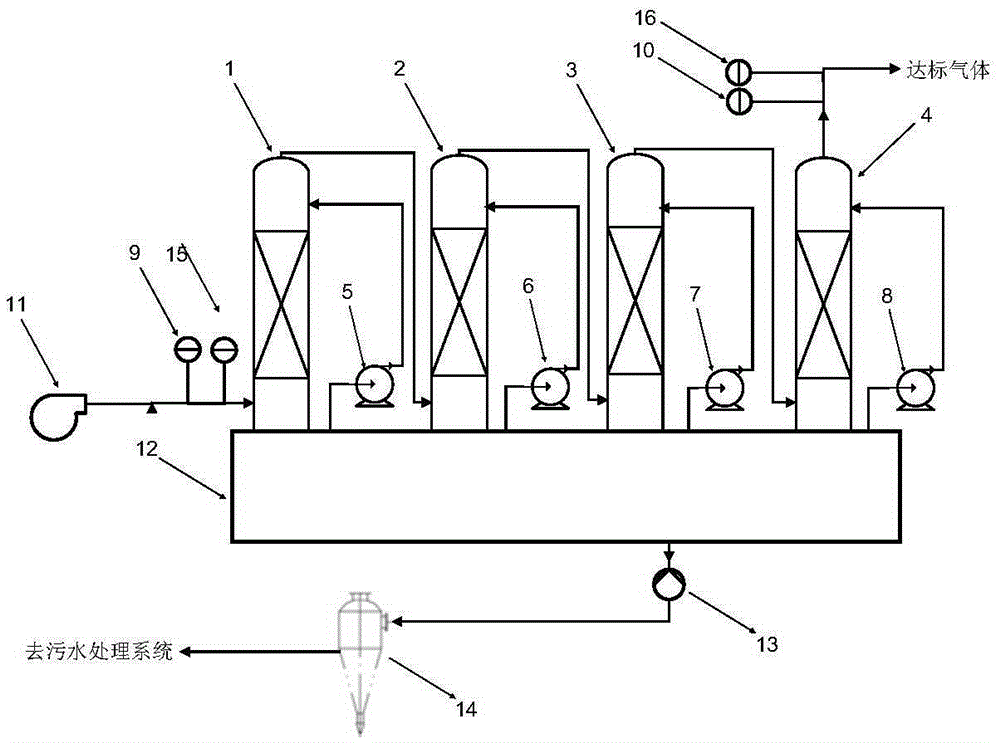

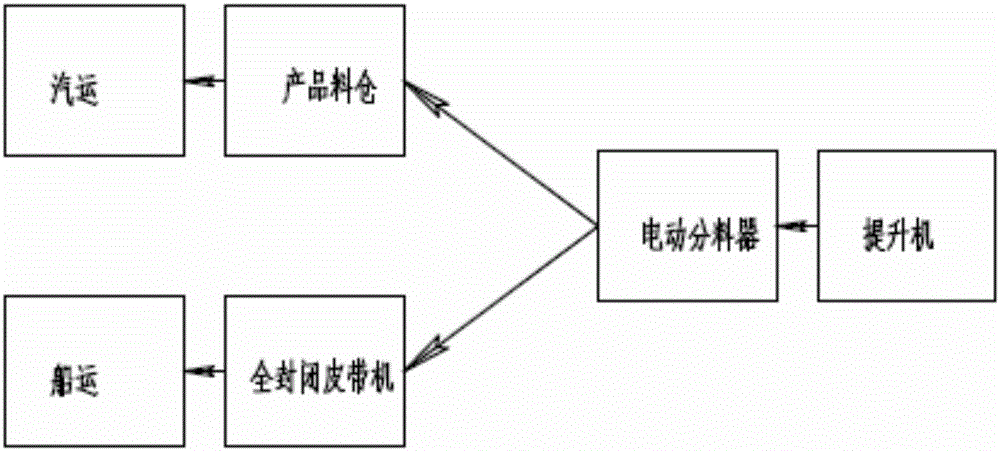

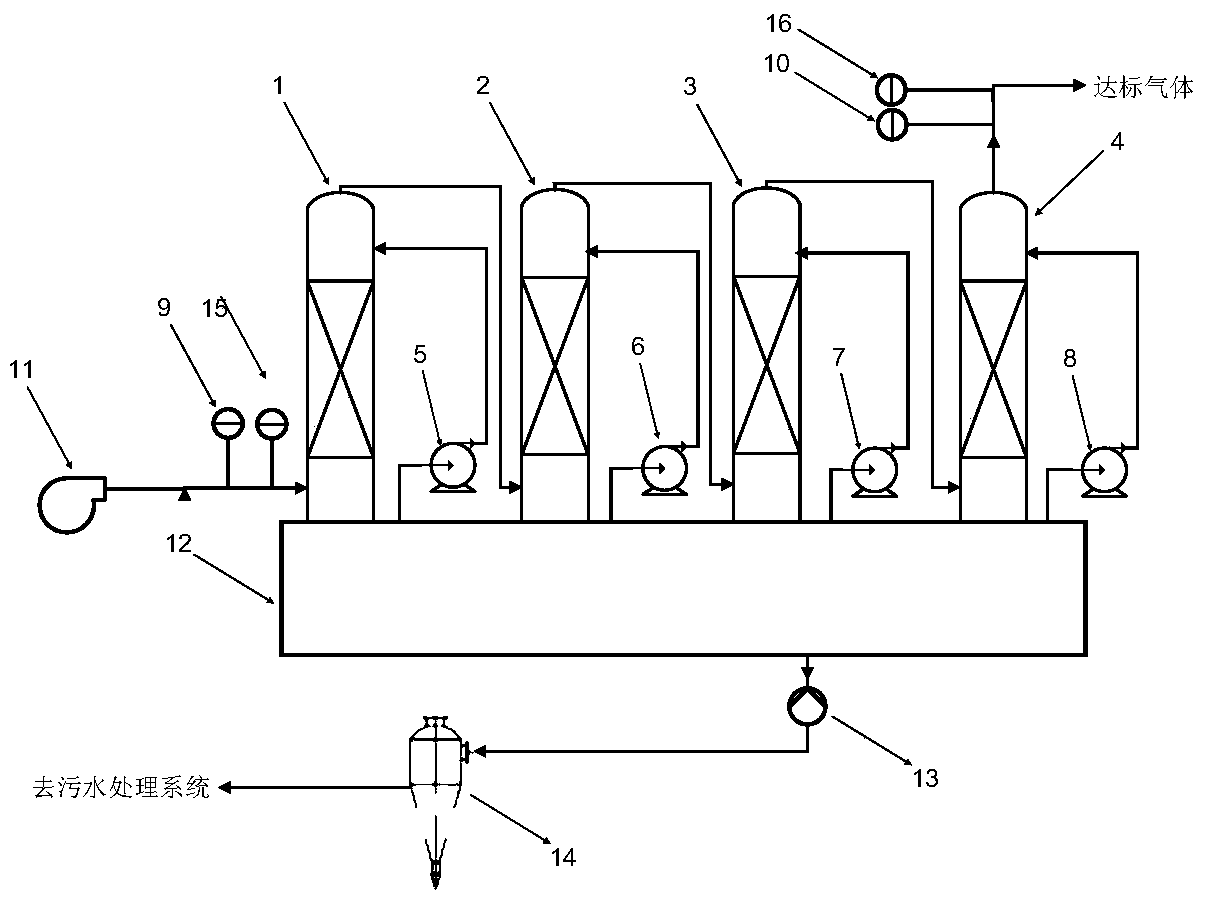

Styrene waste gas treatment device

ActiveCN105327594AEmission reductionEliminate environmental risksDispersed particle separationExhaust gas emissionsLiquid storage tank

The invention discloses a styrene waste gas treatment device. The styrene waste gas treatment device comprises an absorption tower. A packing layer is arranged in the absorption tower, a styrene waste gas input pipeline is connected to the bottom of the absorption tower, a high-pressure draught fan is arranged on the styrene waste gas input pipeline, an exhaust gas emission pipeline is connected to the top of the absorption tower, an absorption liquid storage tank is arranged below the abortion tower, the bottom of the absorption tower is communicated with the absorption liquid storage tank, the absorption liquid storage tank is connected with the top of the absorption tower through an absorption liquid circulation pipe, and a circulation pump is arranged on the absorption liquid circulation pipe. By adopting the mode that a potassium permanganate solution is sprayed for absorbing styrene, styrene-containing waste gas generated by styrene materials in refinery enterprises on various occasions such as highway loading, wharf shipping and storage tank breathing can be simultaneously treated, and high treatment efficiency can be achieved; meanwhile, the process is simple, the occupied area is small, energy consumption is low, and the requirement of the newest national environmental protection standard for the styrene emission limit can be met.

Owner:CHINA PETROLEUM & CHEM CORP +2

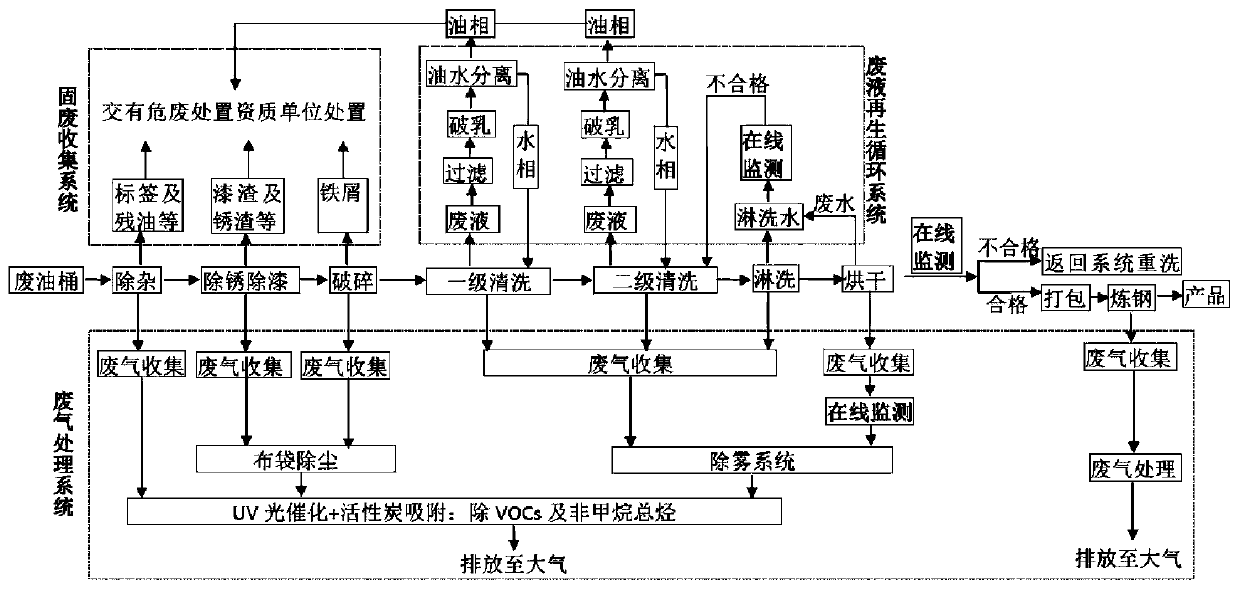

A process and system for environmental protection and resource utilization of hazardous waste waste oil drums

ActiveCN110721978BIncrease productionEliminate hazardous propertiesSolid waste disposalTransportation and packagingSteelmakingProcess engineering

Owner:山西丽浦创新科技有限公司

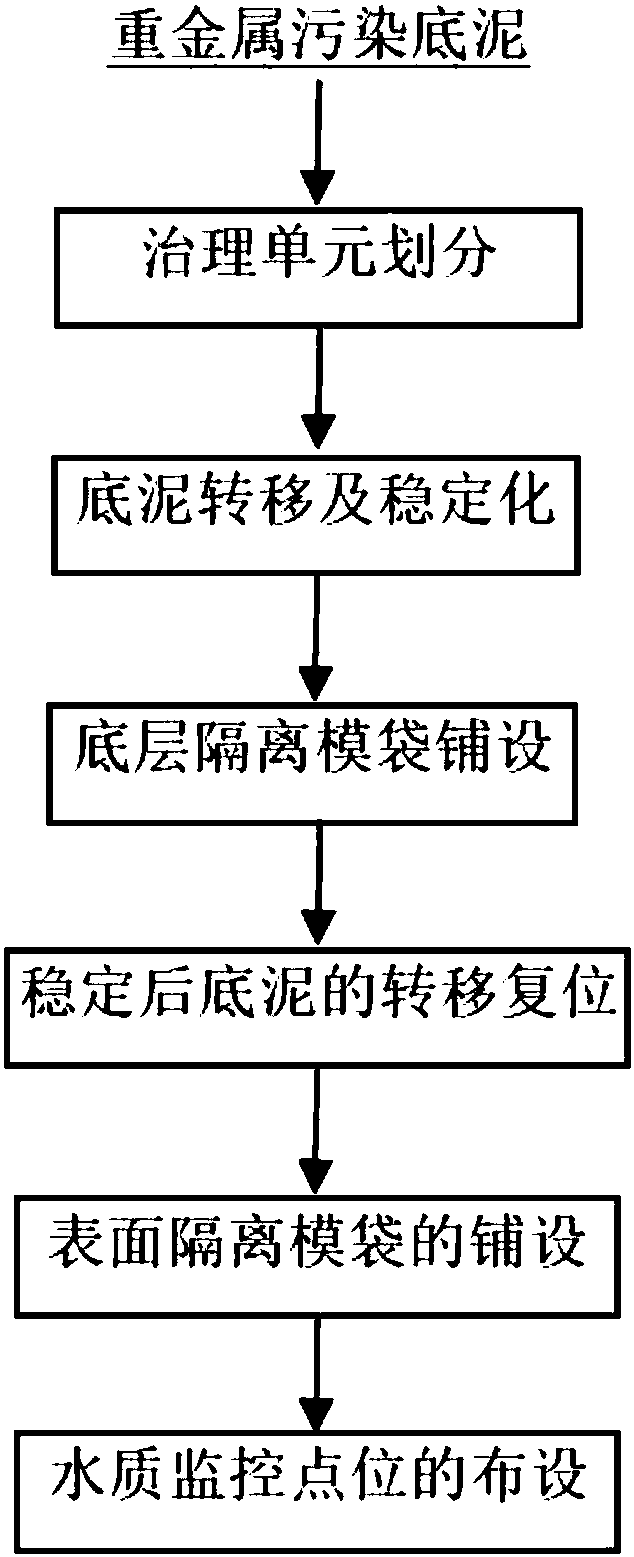

Method for in-situ blocking and remediating heavy metal contaminated bottom mud

InactiveCN108298783AEliminate environmental risksPrevent proliferationWater contaminantsSludge detoxificationSludgeUnderwater

The invention discloses a method for in-situ blocking and remediating heavy metal contaminated bottom mud. The method comprises the steps of dividing an area to be remediated into mesh units, arranging a sludge temporary storage tank, transferring the contaminated bottom mud in the mesh unit area into the temporary storage tank, fully mixing the contaminated bottom mud and a heavy metal stabilizing reagent in the temporary storage tank for reacting, and then returning to the original mesh unit area. Heavy metal diffusion blocking layers are arranged on the bottom part and the upper part of theoriginal mesh unit area, so that trace heavy metals released from the bottom mud are prevented from diffusing and migrating into underwater and surface water. Compared with traditional treatment technologies such as using the bottom mud for manufacturing building materials, and landfilling with the bottom mud, the method is beneficial to the effective inhibition of the dissolving and the releasing of the heavy metals in the bottom mud and the prevention of secondary pollution of the bottom mud, avoids the problem that the sludge is finally difficult to treat, has the characteristics of high treatment efficiency, investment and operation cost reduction, and the like, is suitable for remediating the heavy metal contaminated bottom mud of rivers, lakes and the like, and has higher popularization and application value.

Owner:中化工程集团环保有限公司

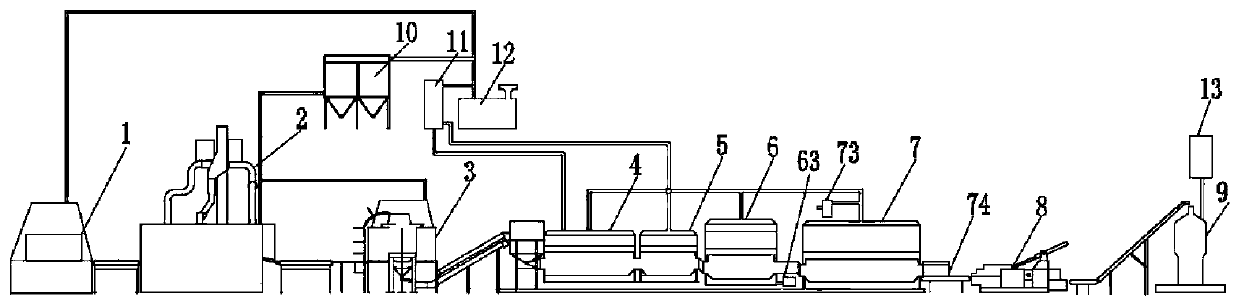

Drum-type water bath cleaning machine for scrap iron barrel treatment line

ActiveCN114178243AEfficient removalAchieve recyclingDrying gas arrangementsCleaning using liquidsWater bathsProcess engineering

The invention belongs to the technical field of hazardous waste treatment, and particularly relates to a drum-type water bath cleaning machine for a scrap iron drum treatment line, the drum-type water bath cleaning machine comprises a cleaning pool, a circulating device and a conveying table, and a control mechanism is arranged in the cleaning pool; according to the device, alkaline cleaning liquid is added into the cleaning pool, then through cooperation of the control mechanism and the cleaning mechanism, under the action of the alkaline cleaning liquid and the stirring assembly, iron bucket fragments in the cleaning bucket can be powerfully cleaned, and residual substances on the iron bucket fragments can be effectively removed; hazardous waste iron drum fragments are recycled, the harmless target of hazardous waste is ensured, the environmental risk in the recycling process is eliminated, through cooperation of the rotating mechanism, the stirring assembly and the adsorption assembly, the cleaning drum can be automatically replaced and conveyed, the automation degree is high, and the recycling efficiency is high. And the working efficiency is effectively improved, the labor cost is reduced, and accidents in the production process are reduced.

Owner:恩彻尔天津环保科技有限公司

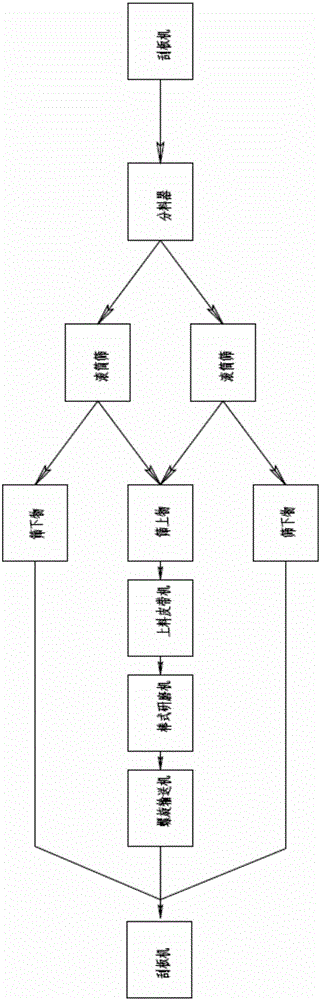

Sludge drying treatment system and method

InactiveCN105668985AHigh degree of automationPrecise regulationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeProcess engineering

The invention belongs to the field of sludge treatment and particularly relates to a drying treatment system for treating the sludge from a domestic sewage plant. The sludge drying treatment system comprises a chemical dosing device and a stirring device, wherein the chemical dosing device comprises at least one chemical tank and at least one spiral conveyor; and the stirring device comprises a first-level stirrer, a scrapper and a second-level stirrer. According to the sludge drying treatment system provided by the invention, the automation degree is high, the links of dosing and stirring are integrally finished, and the production conditions of each link can be accurately controlled, thereby being safe and reliable; and moreover, main technological links are implemented in a closed plant, supporting tail gas treatment equipment is provided, and thus the system is friendly to the surrounding environment.

Owner:SUZHOU LVDI SOIL REMEDIATION TECH CO LTD

A kind of styrene waste gas treatment method

ActiveCN105344224BEmission reductionEliminate environmental risksGas treatmentDispersed particle separationSmall footprintPotassium permanganate

The invention discloses a styrene exhaust gas treatment method including the following steps: carrying out countercurrent contact of styrene exhaust gas with an alkaline solution of potassium permanganate, carrying out an oxidation reaction of styrene with the alkaline solution of potassium permanganate in the contact process, and after completion of the reaction, discharging the exhaust gas having styrene consumed into the atmosphere. With adopting of the technological process of spraying the potassium permanganate solution to absorb styrene, styrene-containing exhaust gas generated by refinery enterprise styrene materials and generated in highway car loading, wharf shipment, storage tank breathing and other various places can be treated at the same time, and the method has higher treatment efficiency, besides, is simple in flow, small in occupied land area and low in energy consumption, can meet the national latest environmental protection standard requirements for styrene emission limit values, effectively reduces the styrene emission and eliminates environmental risks and security risks at refinery enterprise styrene workplaces.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com