Sludge dewatering and drying treatment system and method

A drying treatment and sludge dewatering technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, special treatment targets, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

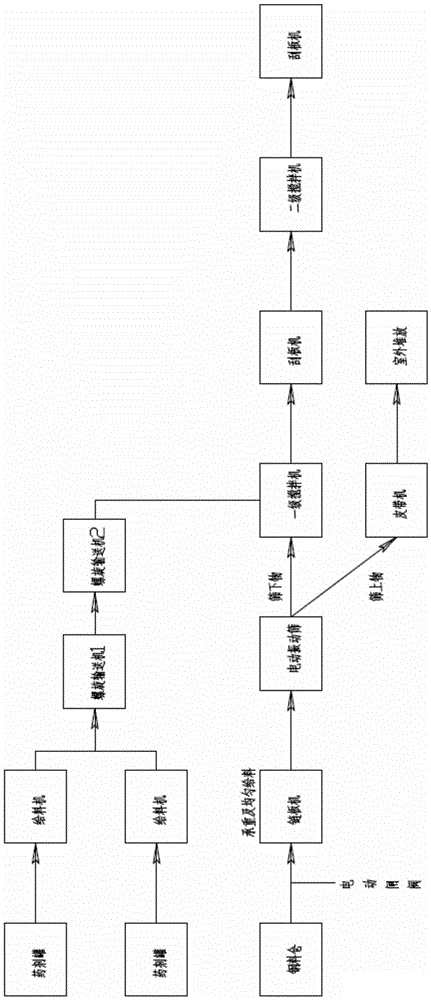

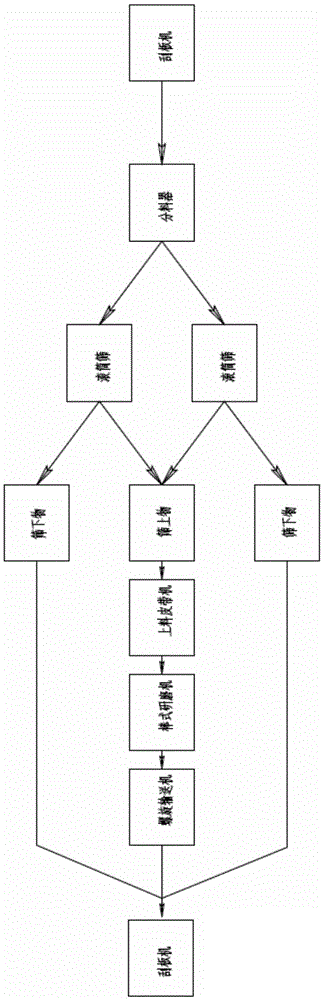

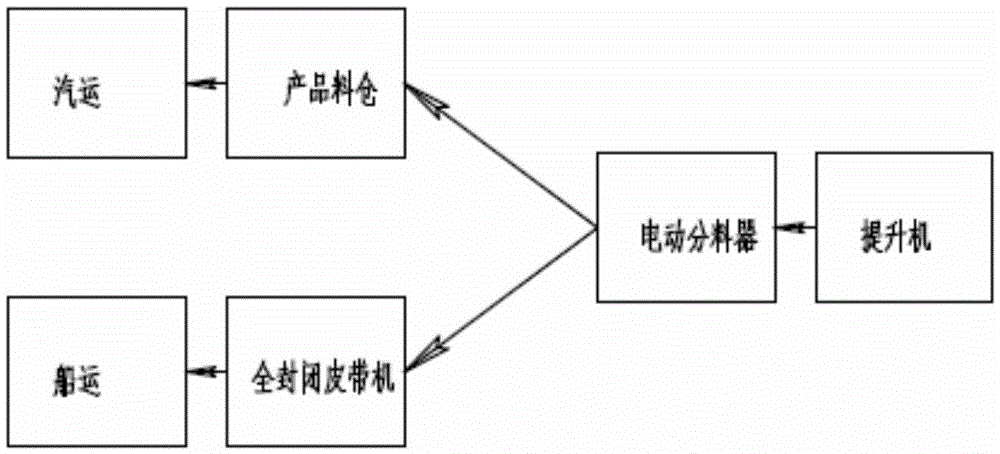

[0037] Such as Figure 4 As shown, a set of sludge feeding and screening system is set up in a closed factory building. The roof of the closed factory building is a transparent lighting board. The vehicle unloading area adopts a double-layer door design. The factory building is designed with a slight negative pressure and is equipped with exhaust gas treatment equipment. Ensure that the gas in the plant will not leak out and affect the surrounding environment when the sludge is dehydrated and dried. The sludge feeding system includes: a sludge feeding hopper 1, a flapper valve 2, a chain conveyor 3, a vibrating screen 4, and a scraper conveyor 8; the sludge feeding hopper is a The steel silo is used to receive the sludge dumped by the transport vehicle; the gate valve is an electric gate valve. The sludge feeding system also includes: a sieve feeding belt conveyor 7 and a hopper 9; the belt conveyor 7 and hopper 9 cooperate with the electric vibrating screen 4, and the slud...

Embodiment 2

[0049] Embodiment 2, the sludge dehydration and drying treatment system as described in Embodiment 1, compared with Embodiment 1, Embodiment 2 is also equipped with tail gas treatment equipment to ensure that the gas in the plant will not leak out when the sludge is dehydrated and dried. Surroundings. The exhaust gas treatment equipment includes: gas collection pipes, fans, spray scrubbers, and low-temperature plasma gas purification devices arranged in the top space of the plant.

[0050] After testing, the waste gas components generated during the sludge dehydration and drying process include: malodorous, ammonia, hydrogen sulfide, non-methane total hydrocarbons, water vapor, etc.

[0051] The gas collection pipes arranged in the top space of the factory building are composed of four main collection pipes. Branch pipes are designed on the main pipes, and suction ports are designed at the end of the branch pipes to achieve uniform collection of exhaust gas in the factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com