Method for removing contaminated-soil heavy mental with magnetic-modified biochar

A technology of contaminated soil and biochar, which is applied in the field of contaminated soil restoration, can solve the problems of low technical content of foreign soil, poor stability of restoration effect, and long restoration time, so as to reduce direct investment and treatment costs, reduce engineering construction and investment, Eliminate the effects of complex processing workflows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Around 100nm of Fe 3 o 4 Add 50g of granules and 10g of sodium lauryl sulfate into water, keep the solid-liquid mass ratio at 1:3, then add NaOH to adjust the pH to 10, raise the temperature to 95°C, stir for 1 hour, add concentrated nitric acid after the reaction to adjust the pH to 7, rinse with water And isolate the iron ferric oxide particles coated with sodium lauryl sulfate, then add it and sodium dodecylbenzenesulfonate to water with a mass ratio of 4: 1, keep the solid-liquid mass ratio of 1: 3, and heat up Keep at 60°C for 1 hour to prepare a magnetic agent coated with two layers of surfactants; modify and activate biochar and 0.2 mol / L manganese chloride solution at a solid-liquid mass ratio of 1:2 at a pH of 5 for 2 hours , and then wash the pH to 7 with clean water to obtain modified biochar; then add the modified biochar and magnetizer to water at a mass ratio of 1:1, keep the solid-liquid mass ratio at 1:5, heat up to 60°C and stir for 1 hour , and then ...

Embodiment 2

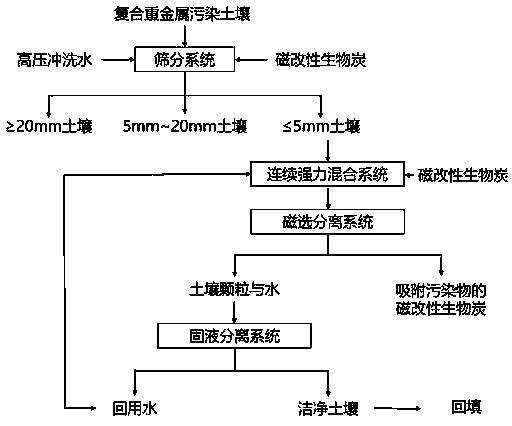

[0030] The polluted soil is located in agricultural land near a watershed. The polluted area is 34 mu. The pH of the soil is between 6.5 and 7.5. The heavy metal pollution is: cadmium 5mg / kg, arsenic 150mg / kg, lead 1000mg / kg. The contaminated soil is transported to the vicinity of the site for purification and disposal. When feeding, the contaminated soil and magnetically modified biochar are mixed with a mass ratio of 500:1 and added to the flushing and screening system. The modified biochar enters the strong stirring mixing system with a mass ratio of 200:1, and the solid-liquid mass ratio is 1:5. The contaminated soil and magnetically modified biochar are stirred and mixed in the mixing system for 1 hour, and then enter the magnetic separation system; Wet permanent magnetic separation is adopted with a magnetic field strength of 300-400mT. After the magnetically modified biochar is separated by magnetic separation, the residue enters the solid-liquid separation system; after...

Embodiment 3

[0032]The polluted soil is located in a site left over from the relocation of an industrial plant. The polluted area is 78 mu. The soil pH is between 6.5 and 7.5. The heavy metal pollution is: cadmium 180mg / kg, lead 3000mg / kg, copper 20000mg / kg, nickel 2800mg / kg. Contaminated soil is transported to the vicinity of the site for purification and disposal. When feeding, polluted soil and magnetically modified biochar are mixed into the flushing and screening system at a mass ratio of 40:1; after screening, soil components with a particle size of less than 5 mm and magnetically modified biochar are mixed at a mass ratio of 20:1 Then enter the strong stirring mixing system, the solid-liquid mass ratio is 1:5, the contaminated soil and magnetically modified biochar are stirred and mixed in the stirring mixing system for 2 hours, and then enter the magnetic separation system, using wet permanent magnet magnetic separation, the magnetic field strength 300-400mT; After magnetic separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com