Method for preparing compound fertilizer from sludge produced by treatment of town sewage

A technology for urban sewage and compound fertilizer, applied in sewage/sludge fertilizer, application, organic fertilizer, etc., can solve problems such as odor generation and slow process, and achieve the effect of ensuring safety and eliminating environmental risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

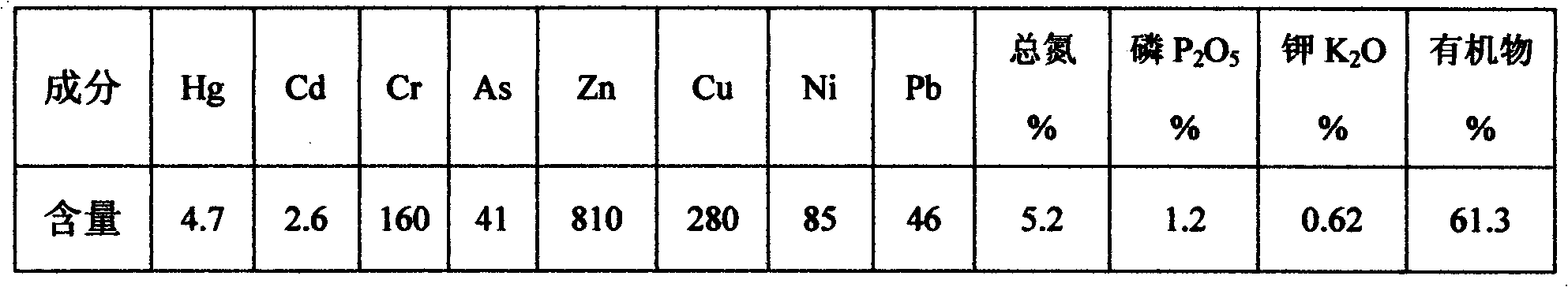

[0017] Example 1 The sludge sample was taken from a sewage treatment plant in Hunan, with a water content of 82.3% and a solid content of 17.7%. The composition analysis of the sample for analysis after drying to constant weight at 103-110°C is shown in Table 1:

[0018] The component analysis (mg / Kg) of table 1 sludge sample (dry basis)

[0019]

[0020] Take 2.0Kg of sludge and put it in a beaker, add 1.0L of water, add 0.04L of industrial grade acetic acid with a mass concentration of 93%, heat and stir in a water bath, make the temperature of the slurry reach 60°C and maintain it for 40min, and then solidify the slurry Separate the liquid from the sludge and wash it with 2L of water to obtain sludge and slurry. Add an appropriate amount of lime powder to the sludge and stir evenly to adjust the pH value of the sludge to 6.0. Prepare the sludge with a diameter of 4.5 mm of granule, dried to obtain granule compound fertilizer, the moisture content in the dry granule comp...

Embodiment 2

[0028] Example 2 The sludge sample was taken from the sewage treatment plant in Yuelu District, Hunan Province, with a water content of 80.4% and a solid content of 19.6%. Table 5 shows the component analysis of the sample for analysis after drying to constant weight at 103-110°C.

[0029] The component analysis (mg / Kg) of table 5 sludge sample (dry basis)

[0030]

[0031]

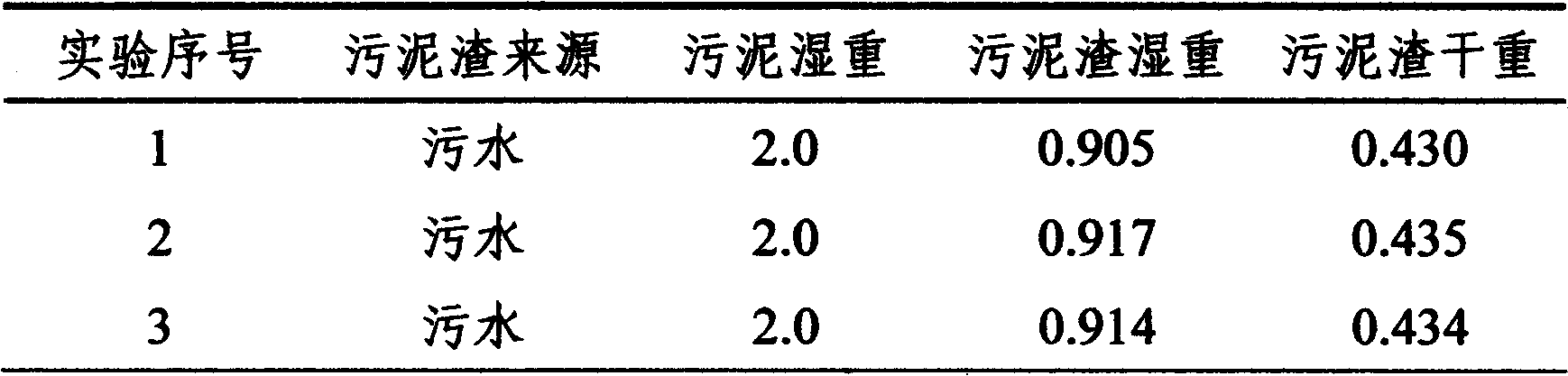

[0032] The treatment method is the same as in Example 1, and 2.0 Kg of sludge is also taken for experimentation. The wet weight and dry weight of the sludge slag obtained in three consecutive experiments are shown in Table 6, the average content of heavy metals in the granular compound fertilizer obtained in the three experiments is shown in Table 7, and the average nutrients in the granular compound fertilizer obtained in the three experiments are shown in Table 6. 8.

[0033] The wet weight and dry weight (Kg) of the sludge residue that table 6 successive experiments obtain for 3 times

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com