Urea-solution-based SCR (selective catalytic reduction) flue gas denitration process and device

A technology of solution and urea, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of unsatisfactory pyrolysis effect, complex structure of pyrolysis chamber, and high operating cost, so as to simplify the approval procedures and eliminate Potential safety hazards and environmental risks, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

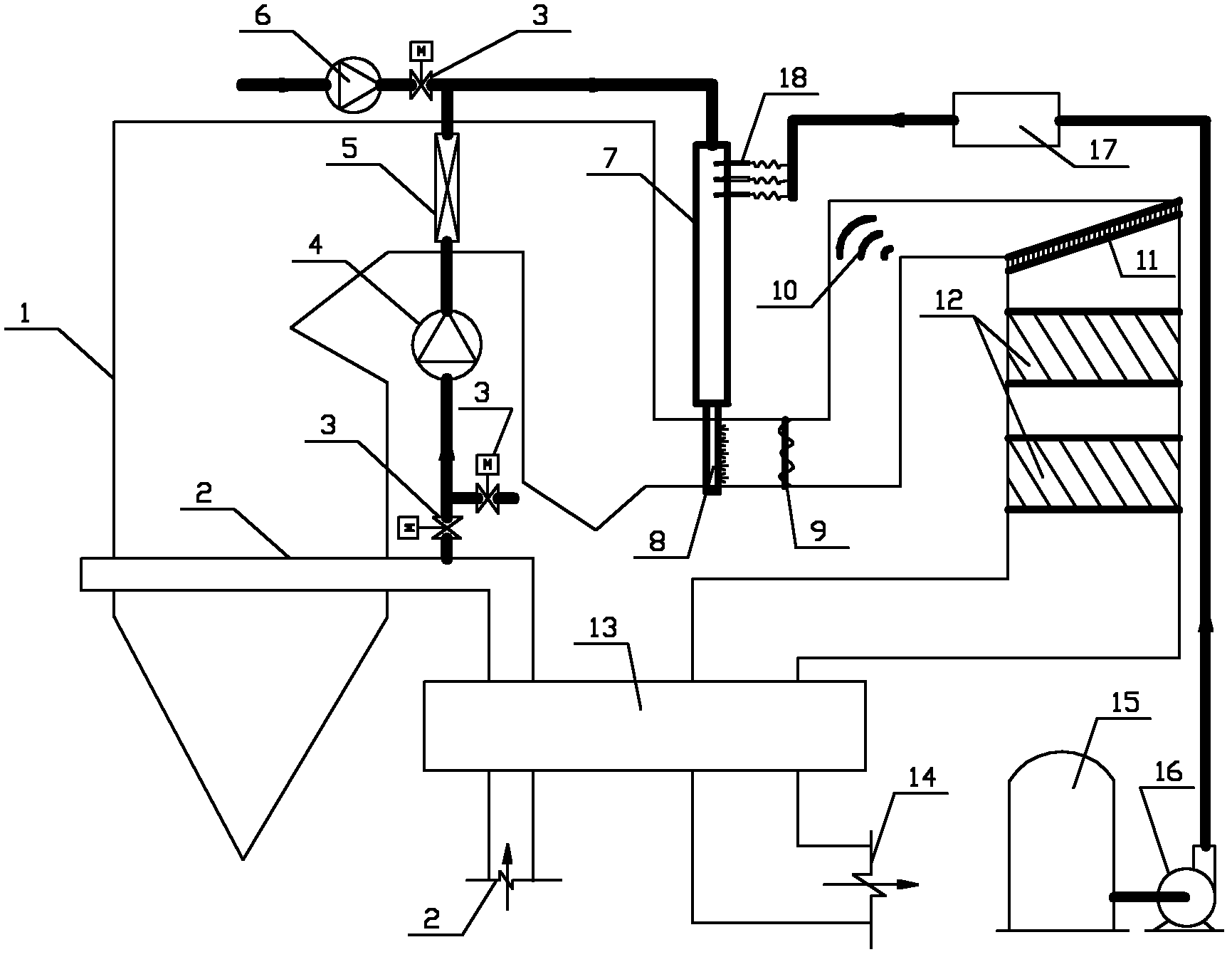

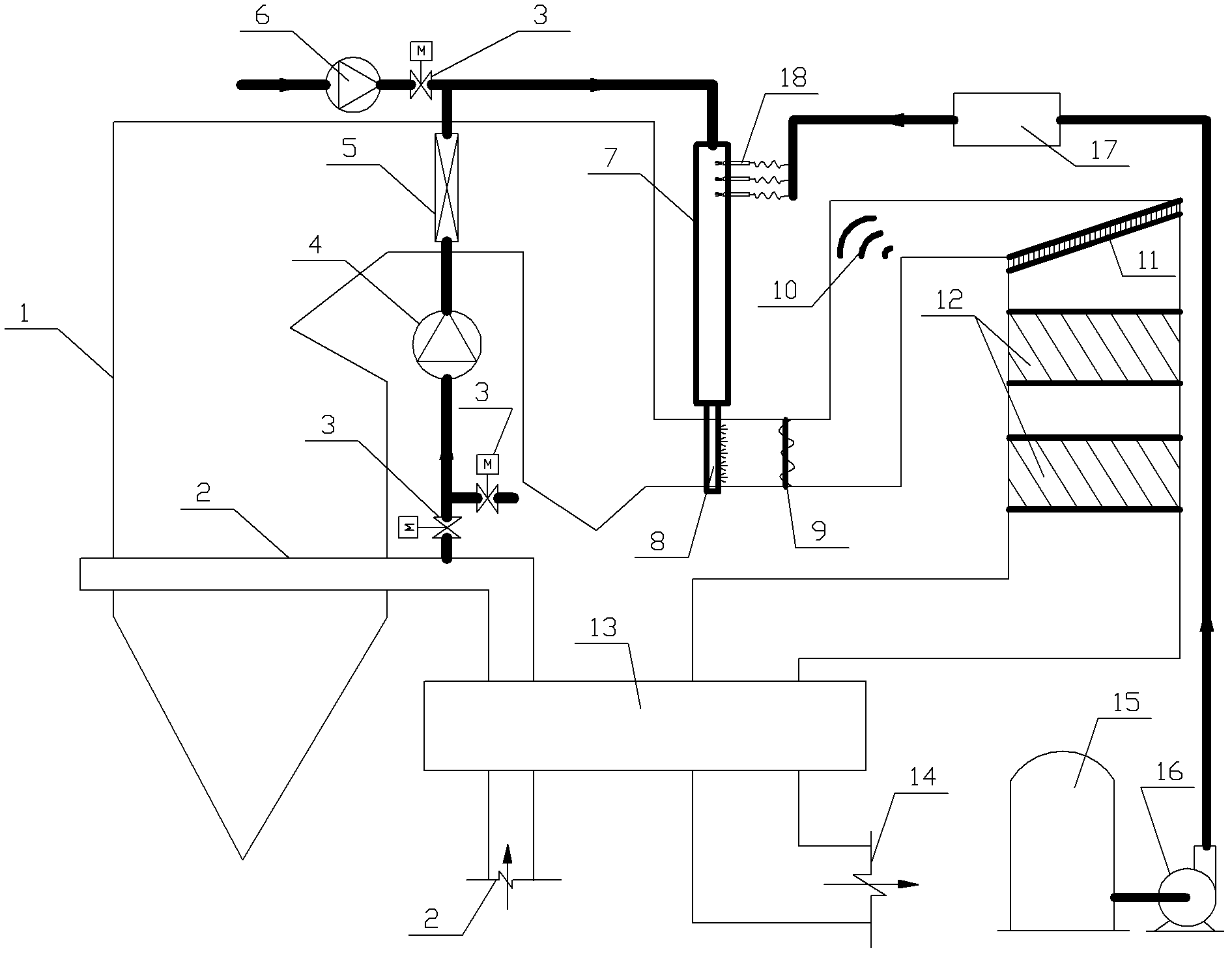

[0044] Example 1: SCR flue gas denitrification process and device based on urea solution:

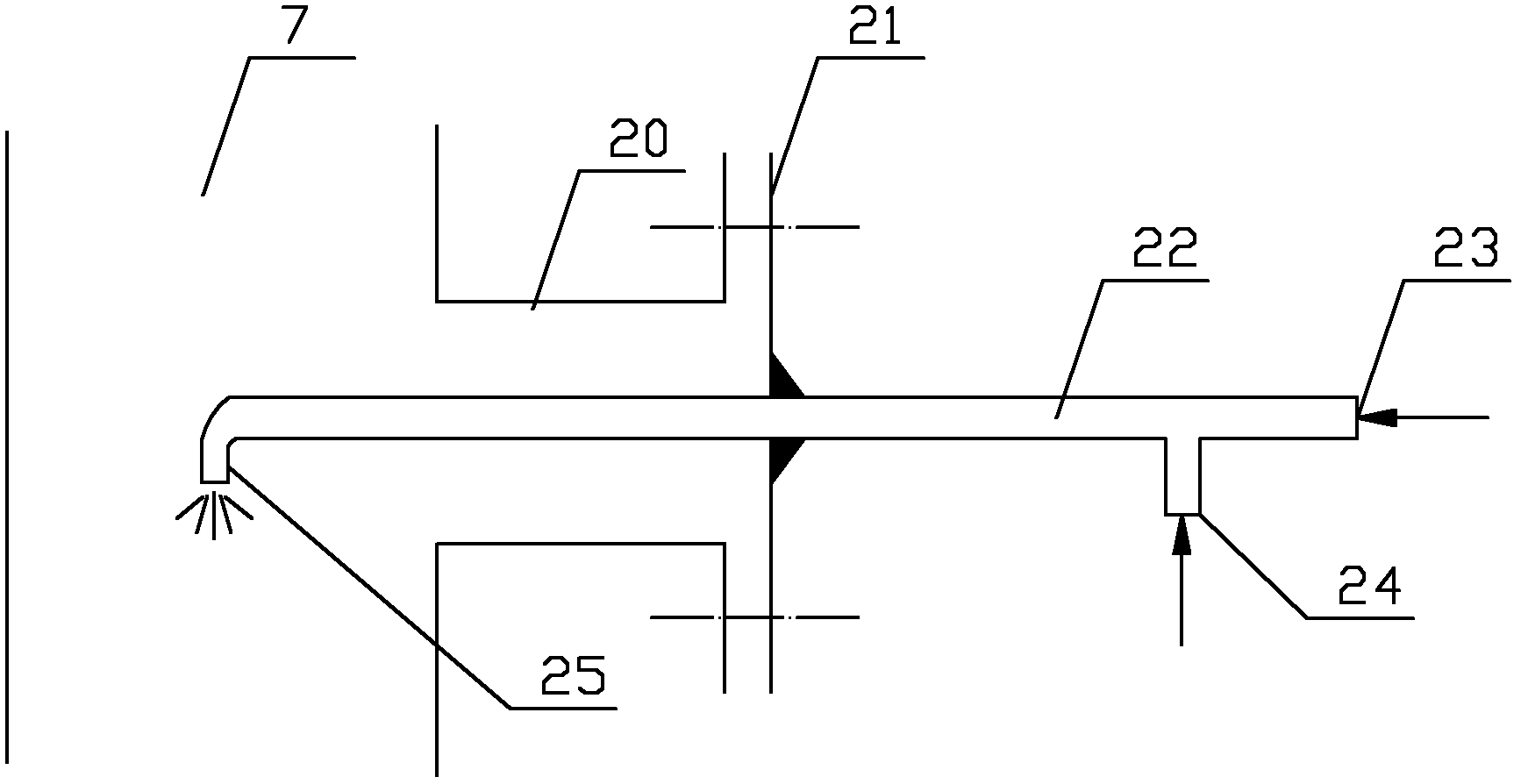

[0045] Such as figure 1 As shown, the pyrolysis air is drawn from the secondary air duct behind the air preheater, and after being pressurized by the first fan (pressurization range 6000-10000Pa, meeting the pressure requirements of the ammonia injection grid), the pyrolysis air heater The interior is heated to 350-700°C by boiler flue gas;

[0046] The prepared 30%-50% urea solution is stored in the storage tank, the flow rate is controlled by the urea solution pump and the metering distribution device, and sprayed into the above-mentioned heated pyrolysis air by the atomizing spray gun;

[0047] The atomized urea is quickly pyrolyzed into gaseous ammonia at high temperature, reaching the safety index of 2 , to complete the denitrification process.

[0048] The first fan adopts a frequency conversion fan, and the pyrolysis air volume is controlled by frequency conversion to match the...

Embodiment 2

[0051] Embodiment 2: SCR flue gas denitrification process and device based on ammonia water:

[0052] Such as figure 1 As shown, the pyrolysis air is extracted from the outside of the furnace, and after being pressurized to 6000-10000Pa by the pyrolysis fan, it is heated to 350-700°C by the boiler flue gas in the pyrolysis air heater.

[0053] The 15%-20% ammonia solution is stored in the storage tank, and the flow is controlled by the ammonia water pump and the metering distribution device, and sprayed into the above-mentioned heated pyrolysis air by the spray gun;

[0054] The atomized ammonia is quickly gasified into gaseous ammonia at high temperature, sprayed evenly into the intake flue of the denitrification reactor through the ammonia injection grid, fully mixed with the flue gas through the mixer, and evenly enters the denitrification reaction after passing through the guide plate and the rectifier device, under the action of a catalyst, NO in the flue gas is reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com