A treatment method and reactor for refractory organic wastewater containing nitrogen and chlorine

A kind of organic wastewater, refractory technology, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamics water/sewage treatment, etc., can solve the problems that cannot be removed at the same time, and achieve the elimination of environmental risks, Easy operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

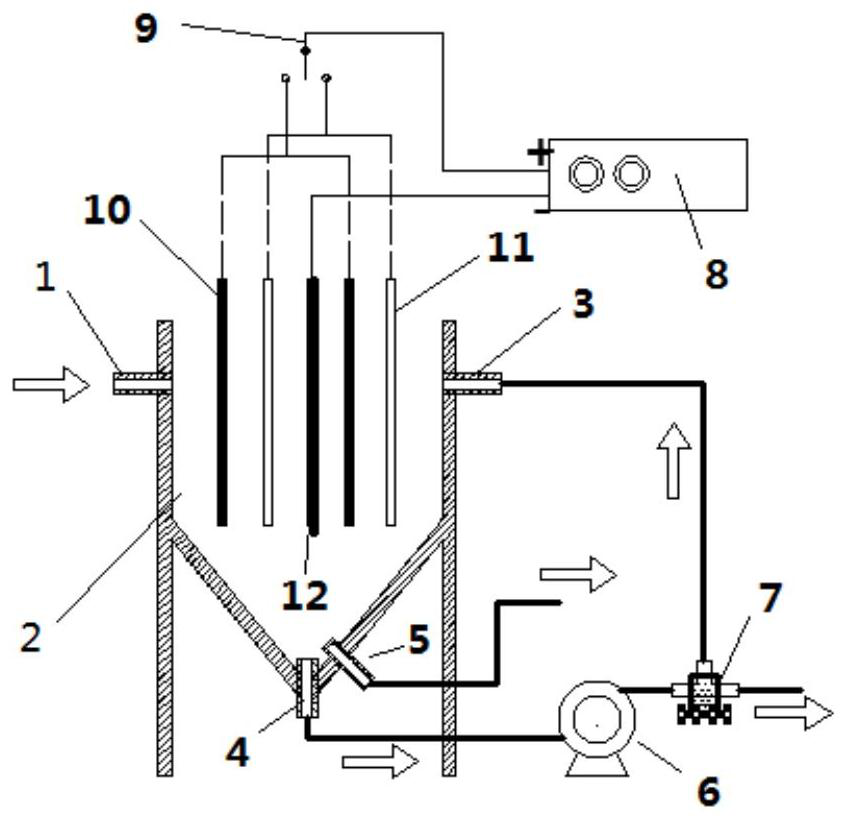

[0052] Such as figure 1 As shown, an electrochemical device for treating refractory organic wastewater containing nitrogen and chlorine, an integrated electrochemical reactor 2; an anode plate and a cathode plate are arranged in sequence in the integrated electrochemical reactor 2, including a cathode plate and 4 anode plates. The order of arrangement is Ti / RuO 2 Anode → iron anode → cathode → Ti / RuO 2 Anode → iron anode. During the operation of the device, a DC power supply 8 is used for power supply. When the reaction starts, the SPDT switch 9 is first connected to the iron anode 11. After 20 minutes of electrolysis, the SPDT switch 9 is connected to the Ti / RuO 2 The anode 10 is similarly replaced sequentially, with 20 minutes as a fixed time interval. Iron anode and Ti / RuO 2 The working order of the anode is: iron anode→Ti / RuO 2 →Iron anode→Ti / RuO 2 →Iron anode→Ti / RuO 2 → Iron anode. During the electrolysis process, the solid-liquid in the reactor is pumped out thr...

Embodiment 2

[0055] The reactor is set up as in Example 1, taking the actual reverse osmosis concentrate as the experimental object (because it has all the characteristics of nitrogen-containing and chlorine-containing refractory organic wastewater), electrolysis reaction 140min, the effluent COD removal rate is 80.1%, and the TN removal rate is 80.1%. 98.6%, the total phosphorus removal rate was 93.9%, and no available chlorine was detected in the effluent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com