Styrene waste gas treatment device

A waste gas treatment device, styrene technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of easy polymerization, large polymerization heat effect and adsorption heat effect, inability to regenerate, difficult to maintain, etc., to eliminate environmental problems. Risks and safety hazards, reduction of styrene emissions, effect of high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

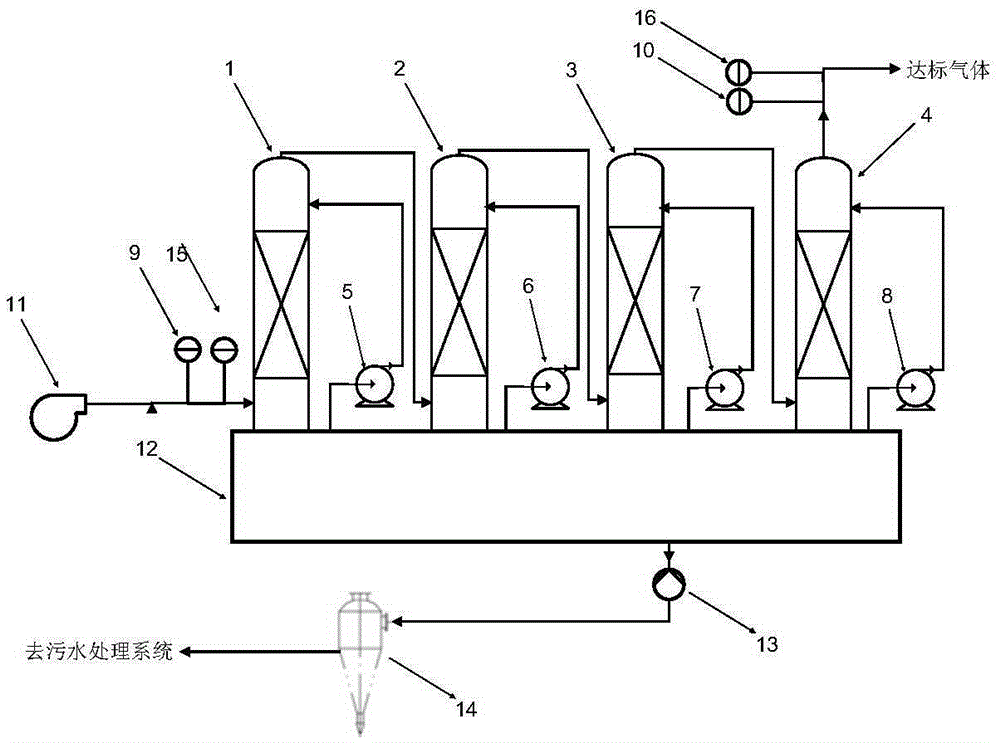

[0017] With reference to the accompanying drawings, a styrene waste gas treatment device includes a primary absorption tower 1 , a secondary absorption tower 2 , a tertiary absorption tower 3 and a fourth absorption tower 4 . The bottom of the primary absorption tower 1 is connected to a styrene waste gas input pipeline, and a high-pressure induced draft fan 11 , an inlet styrene concentration analyzer 9 and an inlet flowmeter 15 are installed on the styrene waste gas input pipeline. The top of the first-level absorption tower 1 is connected to the bottom of the second-level absorption tower 2 through the first waste gas delivery pipeline, and the top of the second-level absorption tower 2 is connected to the bottom of the third-level absorption tower 3 through the second waste gas delivery pipeline. The top is connected to the bottom of the fourth-stage absorption tower 4 through the third waste gas conveying pipeline, and the top of the fourth-stage absorption tower 4 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com