Sludge drying treatment system and method

A treatment system and sludge drying technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, special treatment targets, etc., to optimize the overall urban environment, eliminate environmental risks, and achieve a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

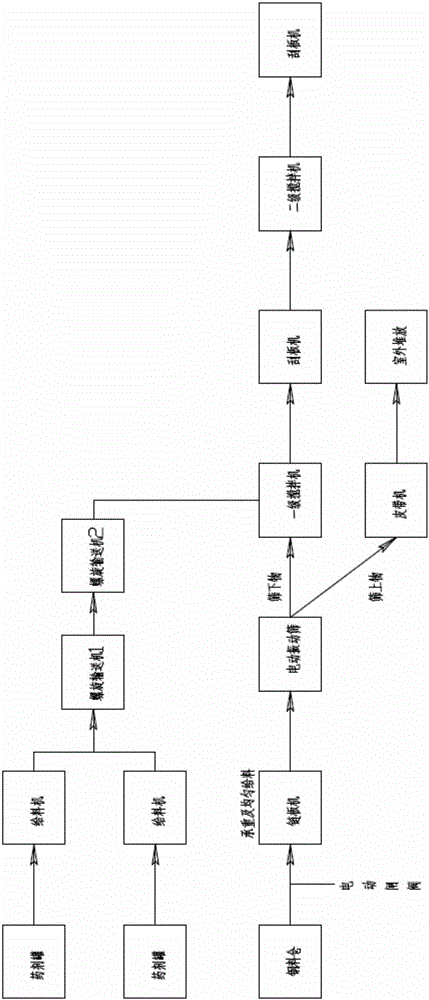

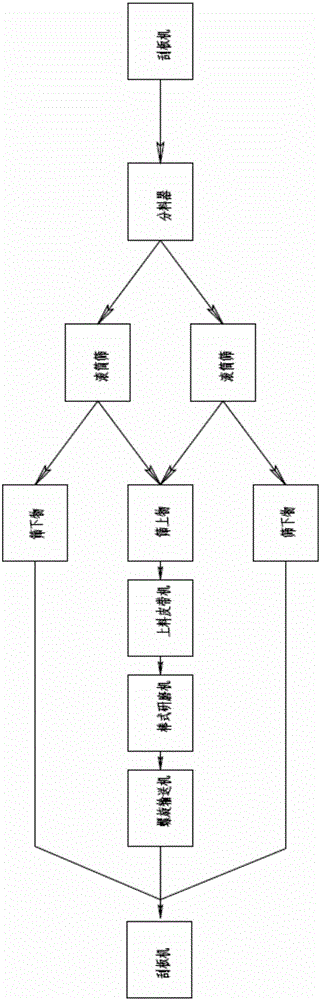

[0038] Embodiment one: if Figure 5 , Figure 6 , Figure 7 As shown, a set of sludge drying treatment system arranged in a closed factory building includes: a stirring device, a chemical feeding device, wherein, the stirring device includes: a primary mixer 6, a scraper machine 12, a secondary Stirrer 11 ; the medicament feeding device includes: at least one medicament tank 13 , a feed valve 14 is provided at the bottom of each medicament tank 13 , and at least one screw conveyor 15 , 17 . In a preferred technical solution, the above-mentioned medicament feeding device is arranged on the platform 16 . By controlling the opening and closing of the feed valve 14 at the bottom of the medicine tank 13, the dry medicine is put into the screw conveyor 15, and the dry medicine is sent to the mixer 6 by the cooperation of the primary screw conveyor 15 and the secondary screw conveyor 17. Two kinds of materials (sludge and dry chemical lime) enter into the mixer 6 for mixing at...

Embodiment 3

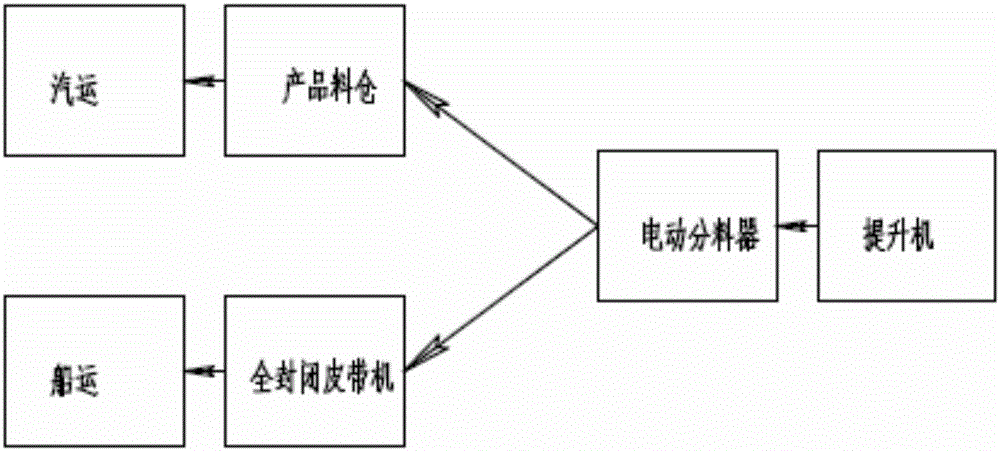

[0051] Embodiment 3, the sludge dehydration and drying treatment system as described in Embodiment 2, compared with Embodiment 2, Embodiment 3 is also equipped with tail gas treatment equipment to ensure that the gas in the plant will not leak out when the sludge is dehydrated and dried. Surroundings. The tail gas treatment equipment includes: gas collection pipes, fans, spray scrubbers, and low-temperature plasma gas purification devices arranged in the top space of the factory building.

[0052] After testing, the waste gas components generated during the sludge dehydration and drying process include: malodorous, ammonia, hydrogen sulfide, non-methane total hydrocarbons, water vapor, etc.

[0053] The gas collection pipes arranged in the top space of the factory building are composed of four main collection pipes. Branch pipes are designed on the main pipes, and suction ports are designed at the end of the branch pipes to achieve uniform collection of exhaust gas in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com