Drum-type water bath cleaning machine for scrap iron barrel treatment line

A processing line, roller type technology, applied in the direction of using liquid cleaning methods, dryers, conveyor objects, etc., can solve problems such as damage to workers' health, physical injuries to workers, low degree of automation, etc., to reduce labor Cost, high degree of automation, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

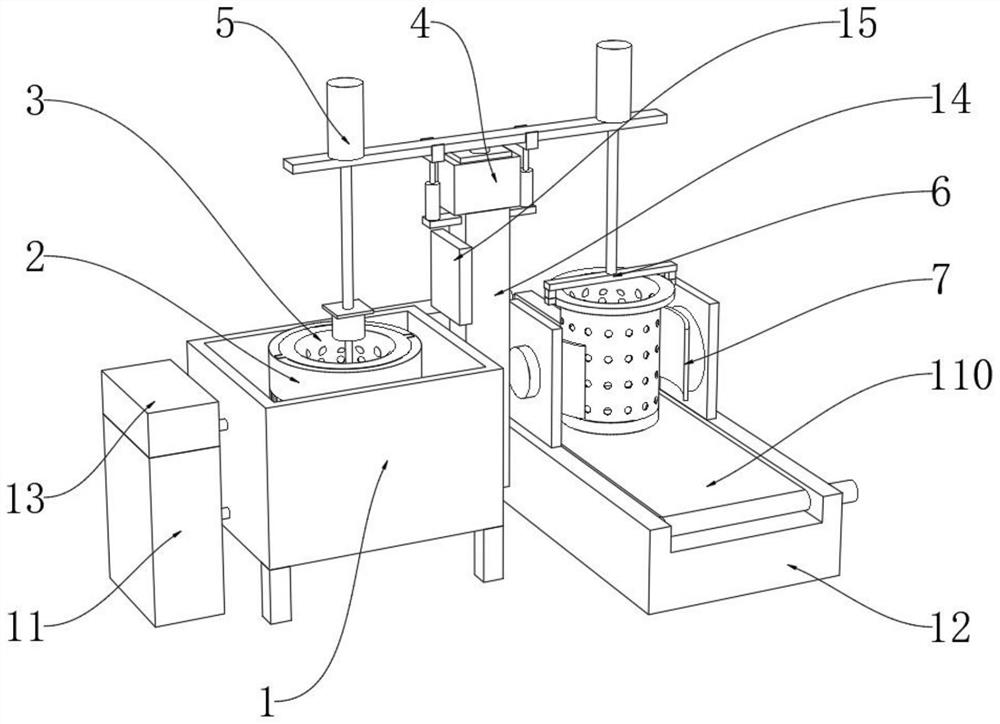

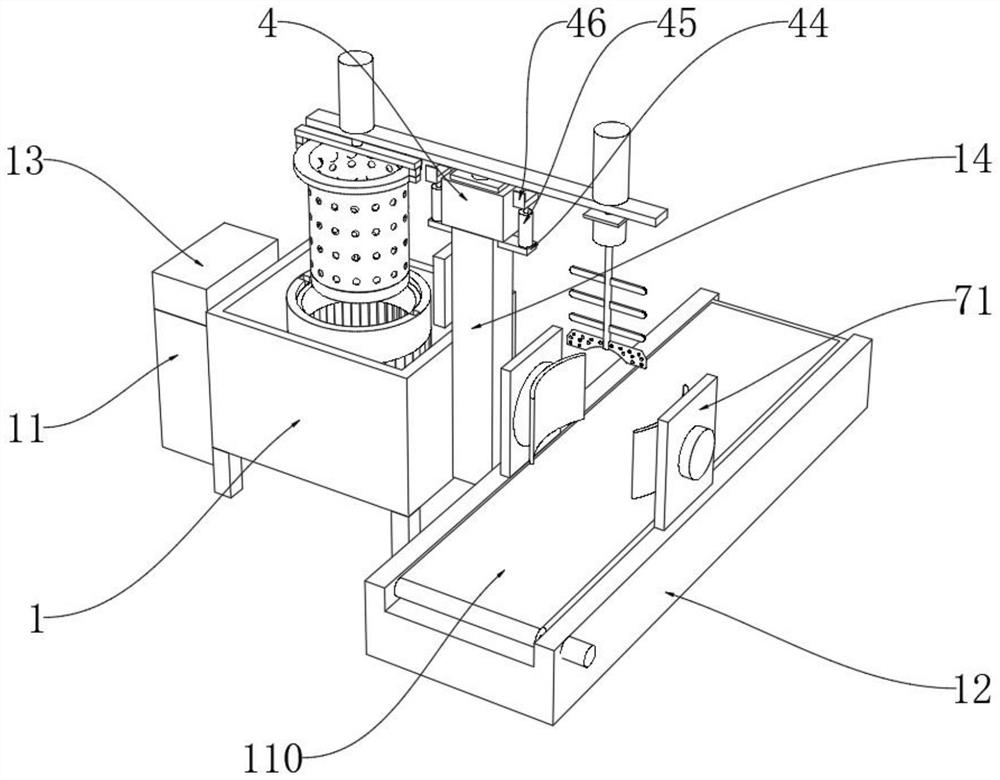

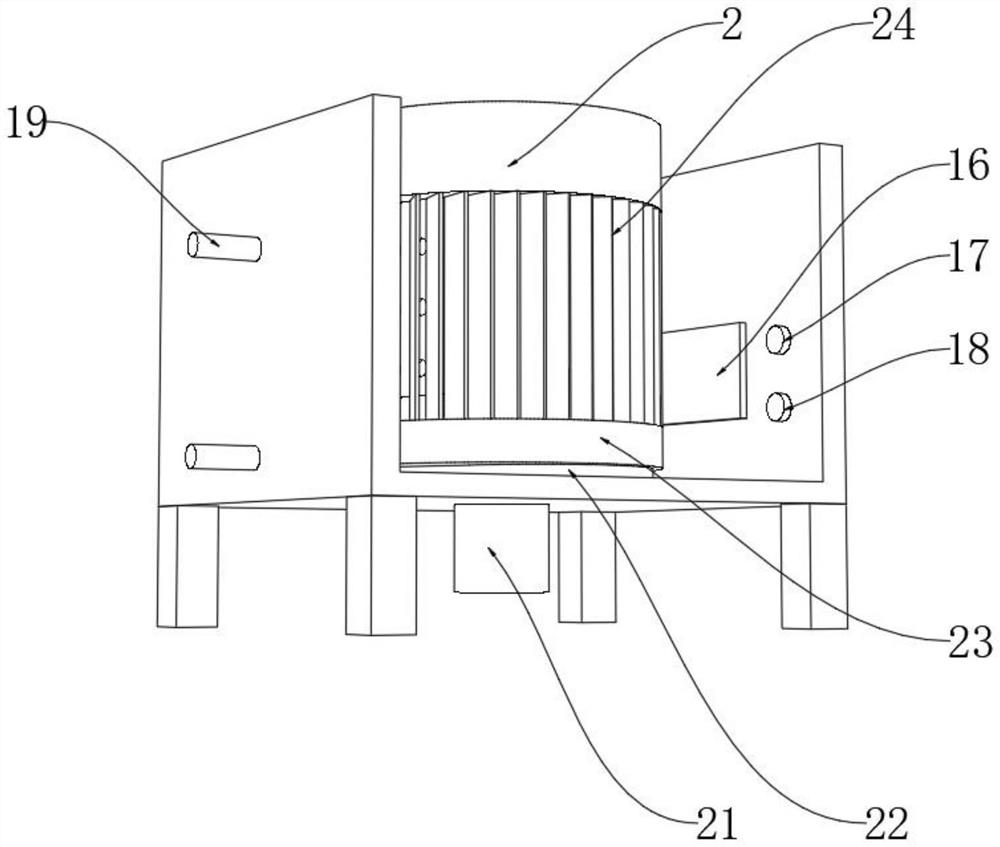

[0042] Such as Figure 1-Figure 8 Shown:

[0043] A drum-type water-bath cleaning machine used in a waste iron drum processing line, comprising a cleaning tank 1, a circulation device 11 and a conveying platform 12, and a control mechanism 2 is arranged inside the cleaning tank 1.

[0044] In this embodiment, the residue on the surface of the waste packaging container is removed by physical methods. First, the high extrusion force and shear force generated inside the shredder are used to shred the waste packaging container into small pieces, and then the shredded waste The bucket pieces are placed inside the cleaning cylinders 33 and transported by the conveyor belt 110 on the conveyor table 12, and then the cleaning cylinders 33 are transported to the inside of the installation cylinder 23 through the adsorption assembly 6 and the rotating mechanism 4, and the inside of the cleaning tank 1 Add alkaline cleaning solution, under the action of alkaline cleaning solution, roll a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com