Drilling solid waste biodegradation device and collected liquid collecting and recycling method thereof

A biodegradation and drilling technology, applied in chemical instruments and methods, biological water/sewage treatment, mining wastewater treatment, etc., can solve the problem of multiple installations of horizontal pipes and horizontal pipes, difficulty in collecting liquid collection, increased workload and investment costs, etc. problems, to achieve the effect of reducing construction raw materials and workload, speeding up liquid flow, and saving construction investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In an exemplary embodiment of the present invention, the drilling solid waste biodegradation device includes a biological treatment mixture layer, a clean soil layer, a vegetation layer, a degradation storage tank, an anti-seepage membrane, a liquid collection pipe and a drainage pipe.

[0022] The degradation stacking pool includes a pool wall and a pool bottom, and the anti-seepage film (for example, the anti-seepage coefficient is less than 1×10 -10 cm / s non-woven geotextiles and / or high-density polyethylene geotextiles) are covered on the bottom of the pool and the pool wall, which can prevent the leachate (hereinafter referred to as the collection) of the biological treatment mixture layer from seeping out of the degradation storage pool.

[0023] The biological treatment mixture layer is arranged in the degradation storage tank (for example, stacked in the degradation storage tank), and is isolated from contact with the tank wall and the tank bottom by the anti-see...

Embodiment 2

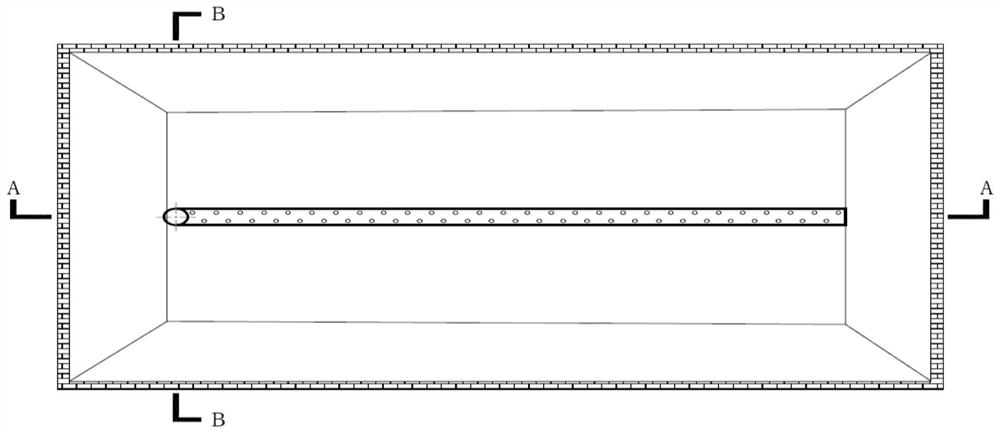

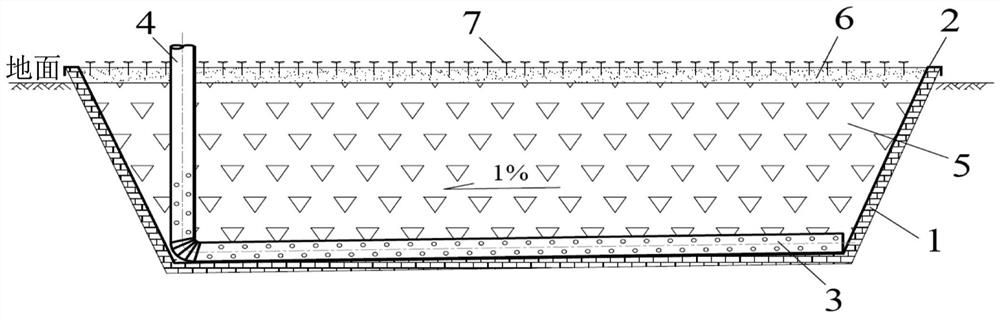

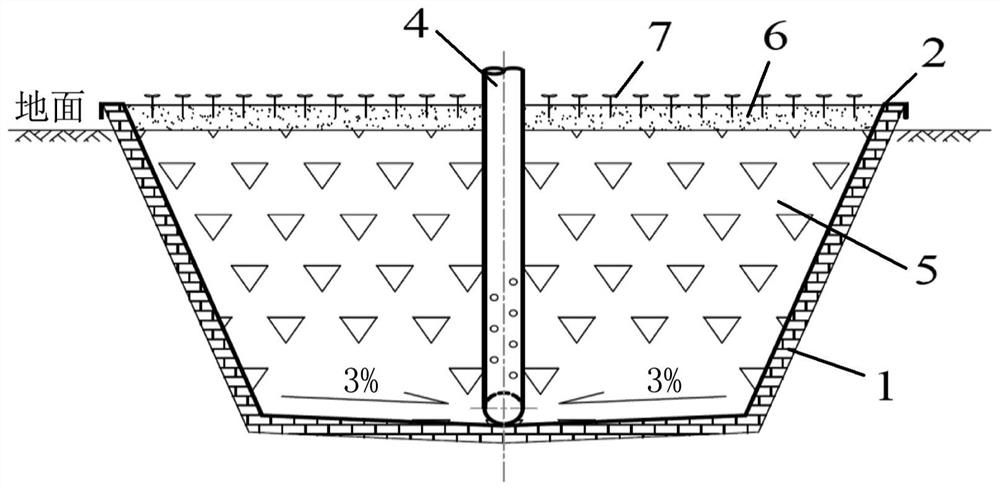

[0041] In an exemplary embodiment of the present invention, as figure 1 , figure 2 and image 3 As shown, the drilling solid waste biodegradation device includes a degradation storage tank 1 , an anti-seepage membrane 2 , a liquid collection pipe 3 , a catheter 4 , a biological treatment mixture layer 5 , a clean soil layer 6 , and a vegetation layer 7 .

[0042] The degradation stacking pool 1 includes a pool wall and a pool bottom. The bottom of the pool includes horizontal (such as figure 1 The left and right directions in the middle) set the groove with an inclination of 1%, the longitudinal direction (such as figure 1 The up and down direction in the groove) is inclined towards the first liquid collecting surface with an inclination of 3%, and the longitudinal direction (such as figure 1 The up and down direction in the groove) is inclined towards the second liquid collecting surface with an inclination of 3%. The pool wall has an inclination of 60%, and the include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com