Microbial treatment process of waste mud from oil and gas drilling operations

A technology for oil and gas and microbial treatment, which is applied in the treatment of waste mud and contaminated soil, and in the field of microbial treatment of waste mud, which can solve the problems of increased risk of treatment time, slow microbial degradation, and high moisture content of the mixture to achieve enhanced degradation Pollution capacity, accelerated evaporation rate, and the effect of reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

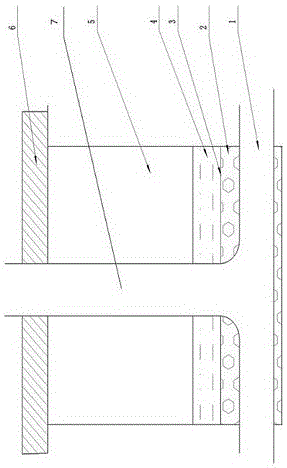

[0030] As a preferred embodiment of the present invention, it utilizes the original mud pool for storing waste water at the well site or builds a new storage pool near the well site. Lay horizontal pipes in parallel on the bottom of the pool, connect the vertical pipes to the horizontal pipes, lay stones on the horizontal pipes, lay non-woven fabrics on the stones, spread coarse sand on the non-woven fabrics, fill the waste mud mixture on the coarse sand, after filling, Laying natural soil, planting plants on the natural soil, the standpipe is higher than the surface of the natural soil.

Embodiment approach

[0032] As the best implementation mode of the present invention, its method is:

[0033] (1) Strain cultivation: The strains can isolate Halomonas and Bacillus strains that grow well in the soil polluted by waste mud, and after cultivation and domestication, they can be used as strains for treating waste mud.

[0034] (2) The soil added to the mud has a moisture content below 35%, and the volume ratio of soil to waste mud is 1.5:1 to 2:1; the volume ratio of bacteria to waste mud is 0.001 to 0.005:1; sawdust and waste mud are added The volume ratio is 0.5-1.5:1.

[0035] (3) Lay PVC or HDPE pipes with diameters of 10-20cm perforated (4×1.25cm aperture, interval 15-20cm) at the bottom of the pool. The horizontal pipes are laid in parallel with a spacing of 8-10m; the vertical pipes are connected to the horizontal pipes without perforation, and the spacing of the vertical pipes is 5-8m. The top of the vertical pipe is 10-20cm higher than the final covering soil.

[0036] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com