System and method for treating overhauling slag of aluminum cell by cement kiln bypass incinerating

A technology of aluminum electrolytic cells and cement kilns, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as poor combustion performance, endangering long-term safe operation, and affecting long-term safe operation of cement kilns, achieving environmental friendliness, eliminating secondary Effect of Secondary Pollution Risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0150] The invention will be further described below in conjunction with the embodiments and accompanying drawings, but they are not used to limit the scope of the invention.

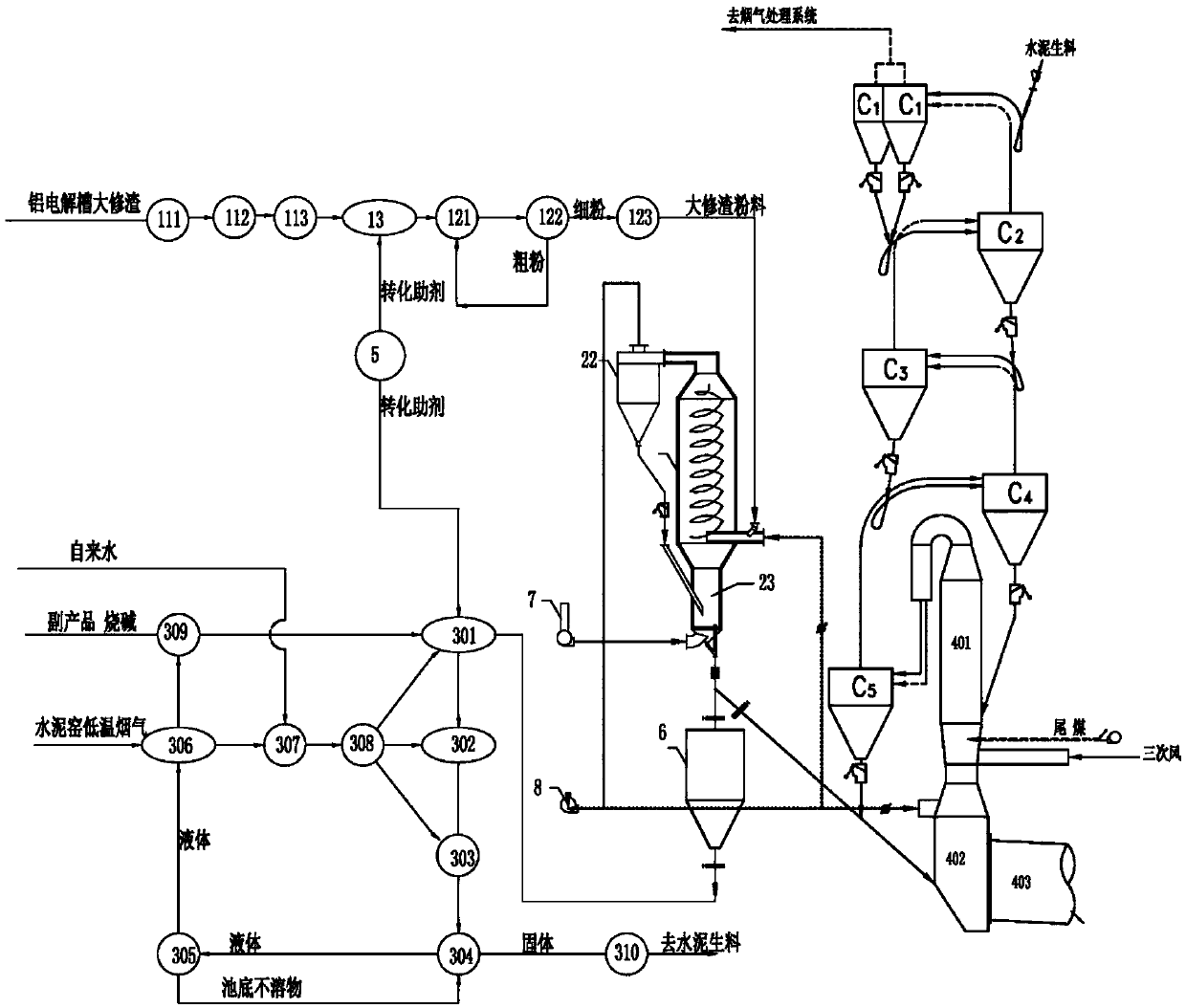

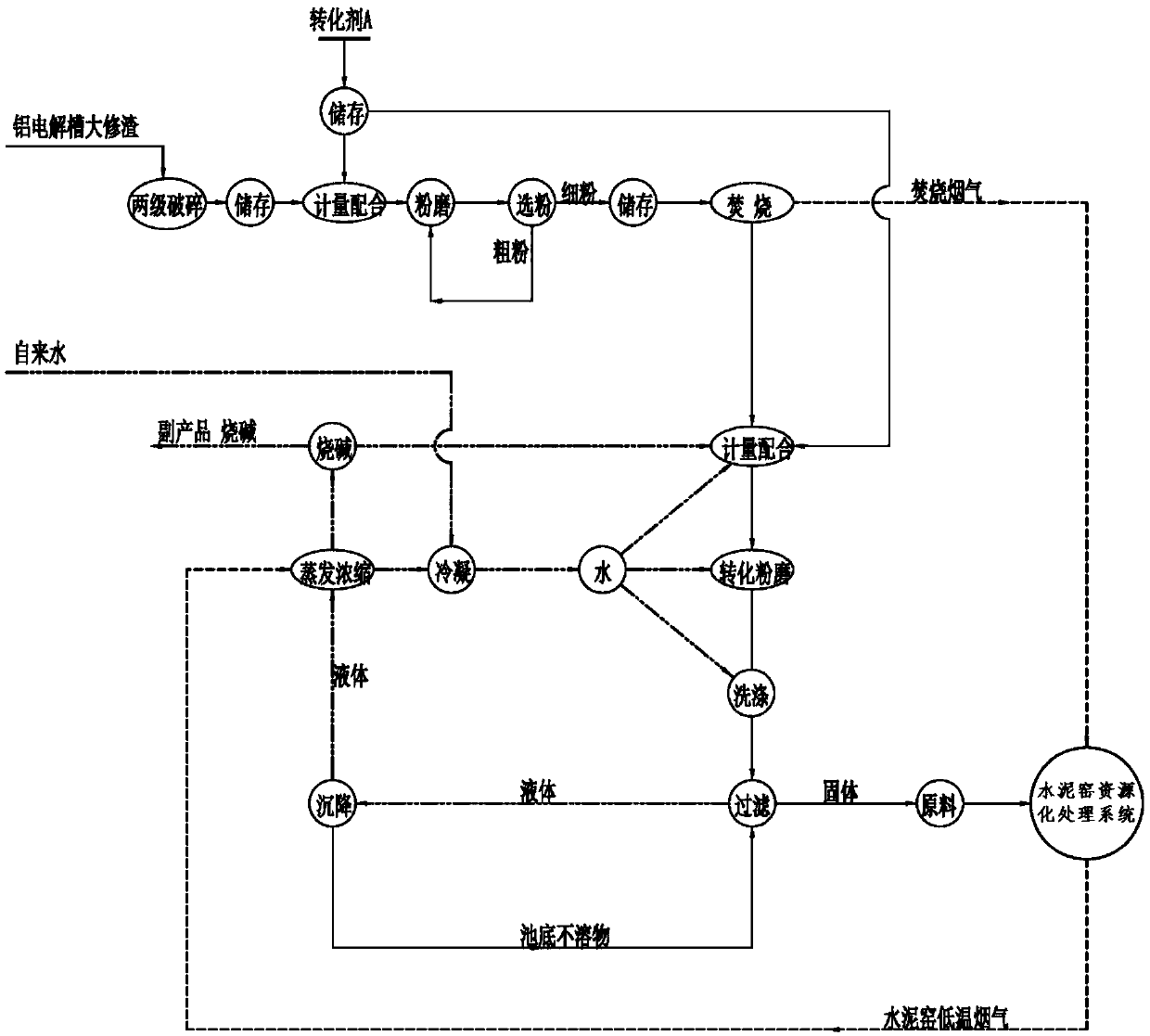

[0151] Such as Figure 1~6 As shown, the present invention provides a system for cement kiln bypass incineration to dispose of overhaul slag of aluminum electrolytic cell, which specifically includes: sequentially connected overhaul slag crushing system, cement kiln bypass incineration system, conversion dealkalization system, and cement kiln resource utilization system ;The devices in the whole system are all sealed devices, and a suction machine is set to form a micro-negative pressure;

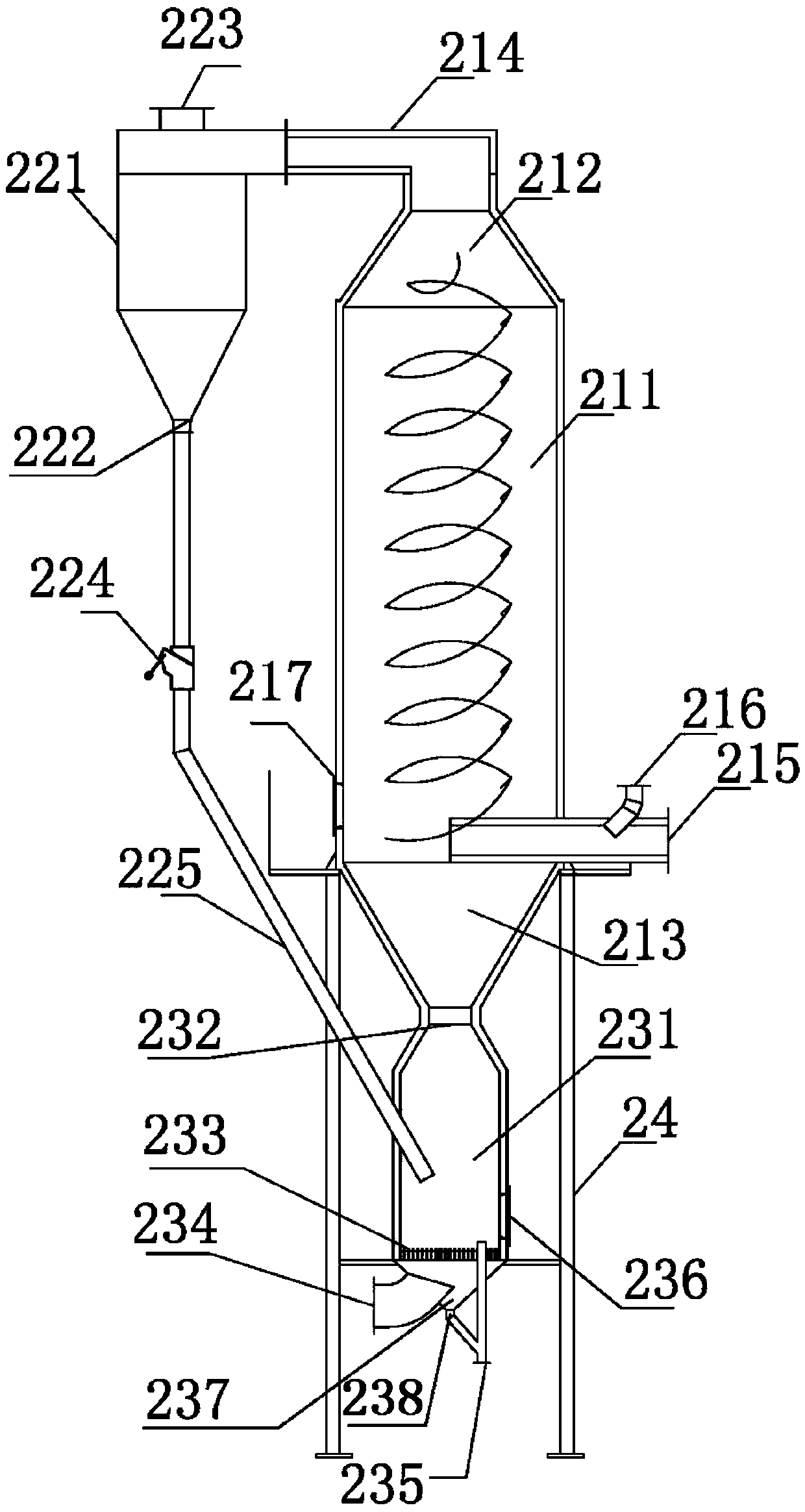

[0152] Such as Figure 4 As shown, the cement kiln bypass incineration system includes a suspension type combined incinerator, and the suspension type combined incinerator is mainly composed of a swirling flow part, a boiling part and a cyclone separator;

[0153] The swirl part 21 includes an upper bell mouth 212,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com