Coke oven coal feeding port online uncovering system and method

A technology of coal charging port and coke oven, which is applied in the field of coke oven coal charging port online uncovering system, can solve problems such as difficulty in synchronizing operation and rising pipe cover, human-machine combination safety risks, and restrictions on the realization of intelligent coking, so as to avoid possible The effect of considering pollution and VOCs emissions, improving the coke oven operating environment, and eliminating environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

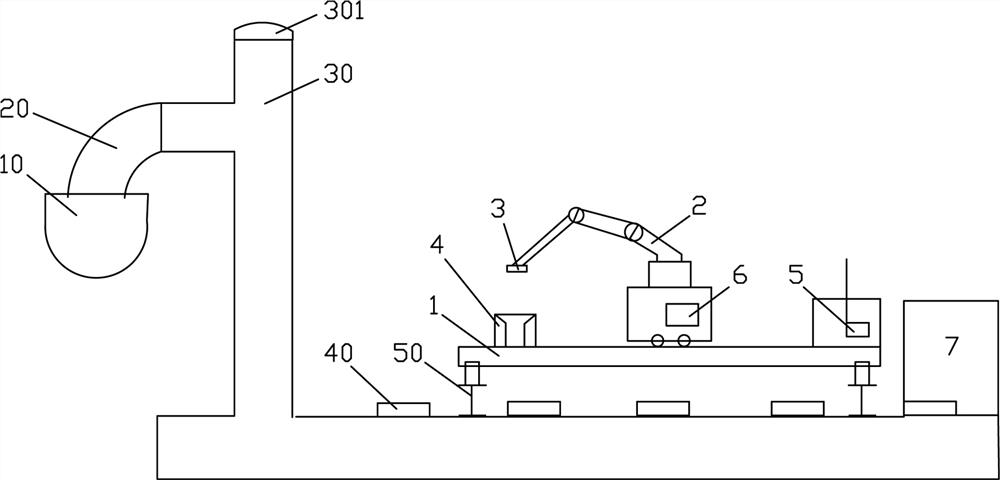

[0054] see figure 1 , an online uncapping system for a coke oven coal filling port according to the present invention, characterized in that,

[0055] The online uncovering trolley 1 runs on the furnace roof rail 50, and it includes a car body and its running wheels and running motor;

[0056] The uncovering device 2 is arranged on the car body of the online uncovering trolley 1, on which an electromagnet 3 capable of extracting the furnace lid is arranged;

[0057] Furnace cover placement frame 4 is arranged on the car body of the online uncovering trolley 1;

[0058] The controller and the vehicle-mounted wireless communication system 5, the traveling motor, the uncovering device, and the electromagnet of the online uncovering trolley are all electrically connected to the controller, and communicate with the coke oven coaling control system through the vehicle-mounted wireless communication system.

[0059] Preferably, the online uncovering trolley 1 has its own battery 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com