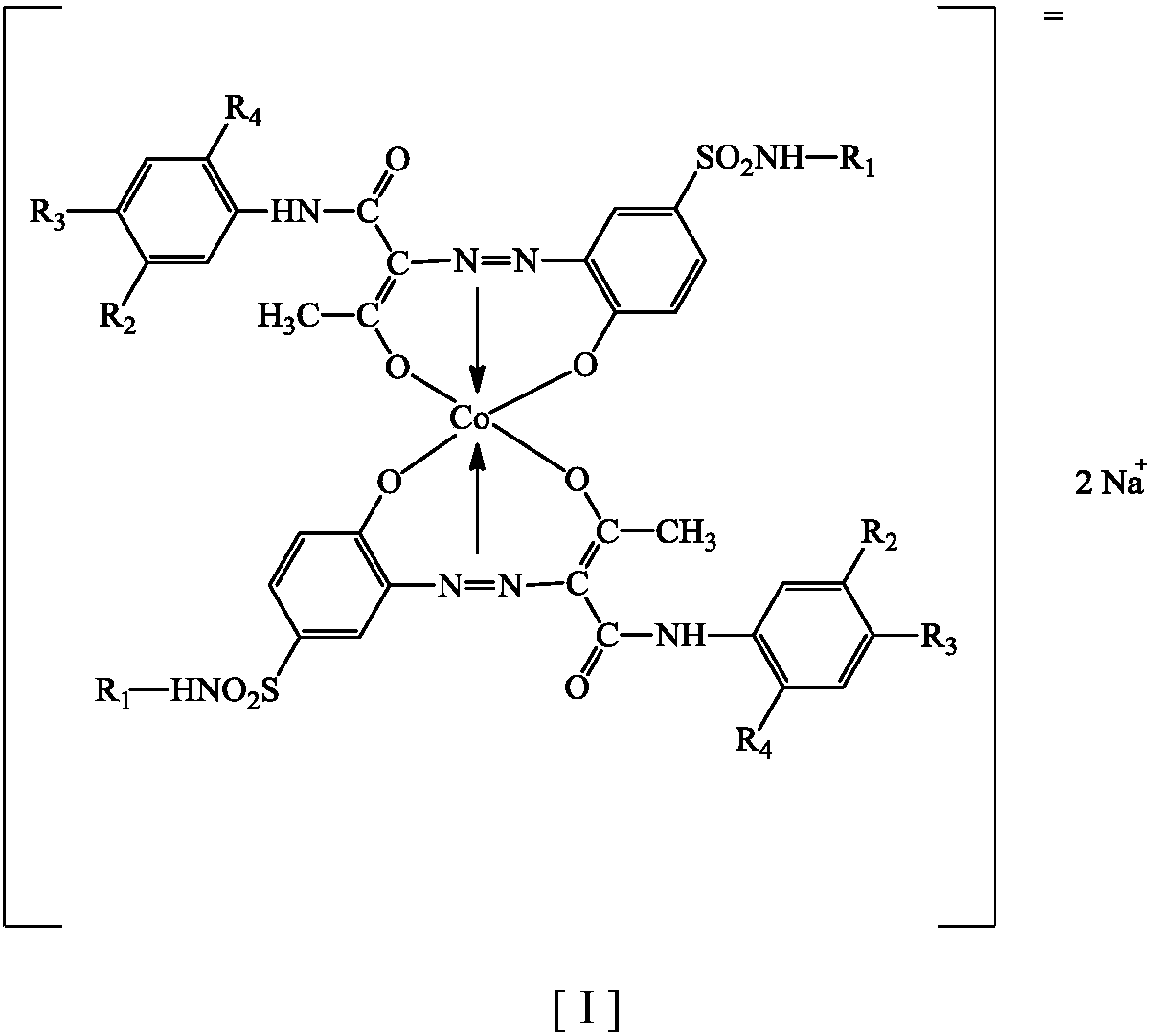

Preparation method of organic cobalt complex

A technology of complexes and organic cobalt, which is applied in the direction of organic dyes, chemical instruments and methods, azo dyes, etc., can solve the problems of high labor intensity, complicated process, dust pollution, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1, a kind of preparation method of organic cobalt complex compound, carry out following steps successively:

[0090] 1), add 3000L water to the reaction kettle, then add 30% (mass%) hydrochloric acid 3.5kmol (about 426kg); slowly add 3.0kmol (564kg) of compound II under stirring, and the feeding time is 1 hour (to ensure that compound II is dissolved) , and then add 30% (mass%) sodium nitrite aqueous solution 715kg (containing sodium nitrite 3.12kmol) within 10 minutes, after adding, stir and react for 1 hour under the condition of 20~30°C, and add an appropriate amount of sulfamic acid , destroy excess sodium nitrite (the addition is based on the iodine-starch test paper no longer showing blue); obtain the acidic solution of compound III;

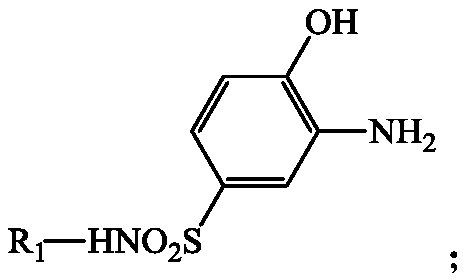

[0091] Compound II is 3-amino-4-hydroxybenzenesulfonamide, and its chemical structural formula is:

[0092]

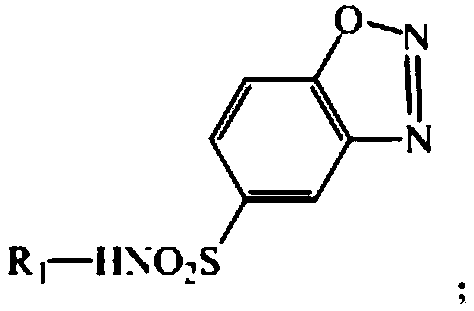

[0093] Compound III is benzoxazole-5-sulfonamide, and its chemical structural formula is:

[0094]

[0...

Embodiment 2

[0107] Embodiment 2, a kind of preparation method of organic cobalt complex, carries out following steps successively:

[0108] 1), add 3000L water in the reactor, then add 401.5kg (3.3kmol) of 30% hydrochloric acid; slowly drop in 925kg (3.0kmol) compound II under stirring, and the feeding time is about 1 hour; then add 30% hydrochloric acid in 10 minutes Sodium nitrate aqueous solution 715kg (containing sodium nitrite 3.12kmol), after adding, stir and react at 20-30°C for 1 hour, add an appropriate amount of sulfamic acid to destroy excess sodium nitrite (the amount added is based on iodine-starch test paper Show blue again); Obtain the acidic solution of compound III;

[0109] Compound II is 2-(3-amino-4-hydroxyphenylsulfonamido)benzoic acid, the chemical structural formula is:

[0110]

[0111] Compound III is 2-(benzoxazole-5-sulfonamido)benzoic acid, the chemical structural formula is:

[0112]

[0113] 2), in the dissolution kettle, add 2000L of water, then add ...

Embodiment 3

[0123] Embodiment 3, a kind of preparation method of organic cobalt complex, carries out following steps successively:

[0124] 1) Add 3000L of water to the reactor, then add 3.53kmol (about 430kg) of 30% hydrochloric acid; slowly add 3.0kmol (606.1kg) of compound II under stirring, and the feeding time is about 1 hour, and then add 30% hydrochloric acid within 10 minutes Sodium nitrite aqueous solution 715kg (containing 3.12kmol sodium nitrite), after adding, stir and react at 20-30°C for 1 hour, then add appropriate amount of sulfamic acid to destroy excess sodium nitrite Show blue prevail); Obtain the acidic solution of compound III;

[0125] Compound II is 3-amino-4-hydroxyl-N-methylbenzenesulfonamide, the chemical structural formula is:

[0126]

[0127] Compound III is N-methylbenzoxazole-5-sulfonamide, and its chemical structural formula is:

[0128]

[0129] 2), in the dissolution kettle, add 2000L of water, then add 400kg of 30% sodium hydroxide aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com