Electrochemical recycling method and electrochemical recycling device for claus tower tail gas by cooperating with absorption liquid

A Claus tail gas, cyclic regeneration technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of limited oxygen solubility, affecting desulfurization efficiency, and cumbersome process, so as to avoid environmental risks and reduce Three waste pollution, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

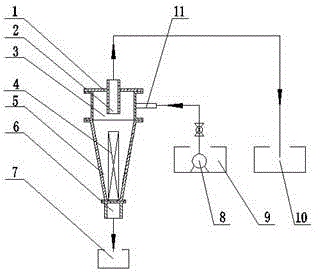

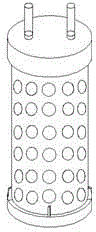

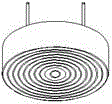

[0039] A method and device for electrochemical cycle regeneration of Clausta tail gas combined with absorption liquid. Such as figure 1As shown, the combined absorption liquid after the Claus tail gas absorption reaction in the liquid storage tank 9 is passed through the infusion pump 8 from the liquid inlet 11 into the internal swirl flow electrochemical reactor, and the reaction product elemental sulfur is passed through the internal swirl flow electrochemical reactor. The sulfur separator 6 at the bottom of the chemical reactor collects and discharges it to the sulfur collecting tank 7, and discharges it to the buffer tank 10 from the overflow pipe 2 at the top of the internal swirling electrochemical reactor after being oxidized by the cylindrical electrode 4. Then adjust the combined absorption solution after electrode oxidation discharged into the buffer tank 10 at 20-70°C, the chemical composition of the adjusted combination absorption solution is the same as the chemic...

Embodiment 2

[0056] A method and device for electrochemical cycle regeneration of Clausta tail gas combined with absorption liquid. Such as figure 1 As shown, the combined absorption liquid after the Claus tail gas absorption reaction in the liquid storage tank 9 is passed through the infusion pump 8 from the liquid inlet 11 into the internal swirl flow electrochemical reactor, and the reaction product elemental sulfur is passed through the internal swirl flow electrochemical reactor. The sulfur separator 6 at the bottom of the chemical reactor collects and discharges it to the sulfur collecting tank 7, and discharges it to the buffer tank 10 from the overflow pipe 2 at the top of the internal swirling electrochemical reactor after being oxidized by the cylindrical electrode 4. Then the electrode oxidized combined absorption solution discharged into the buffer tank 10 is adjusted under the condition of 50-90°C. The content of the components is the same, and it is used for the recycling of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com