Corrosive solution filling system

A filling system and corrosive technology, which is applied in the field of corrosive solution filling system, can solve the problems of material contamination and limited corrosion resistance of high-quality stainless steel, and achieve the effects of low cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

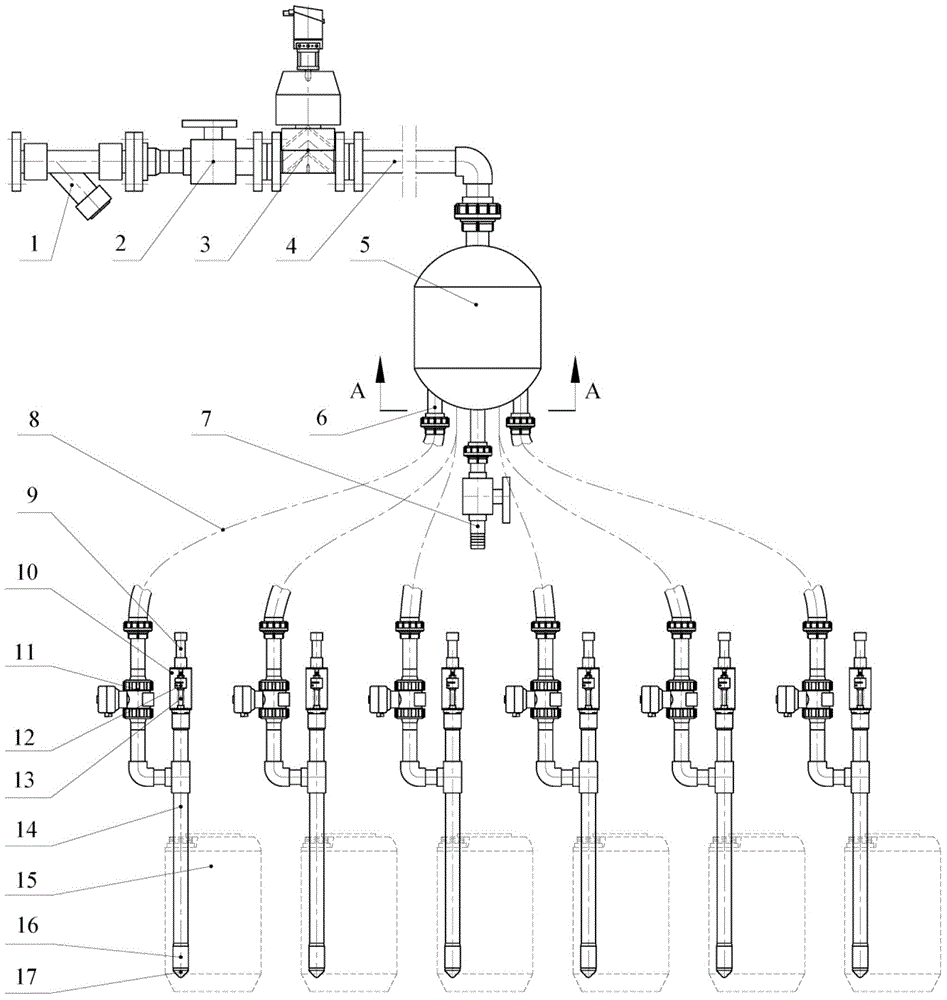

[0020] The corrosive solution filling system of this embodiment is a six-station corrosive solution filling system, including: a liquid inlet pipeline 4, a liquid separation tank 5, a liquid separation pipeline 6 and a filling valve;

[0021] The liquid inlet pipeline 4 is sequentially provided with a filter 1, a hand valve 2 and a diaphragm valve 3 from the liquid inlet; the end communicates with the upper end of the liquid separator tank 5;

[0022] Set the filter 1 to filter impurities, set the hand valve 2 to facilitate cleaning the filter, and set the electric diaphragm valve 3 to control the pipeline pressure;

[0023] The tank top and tank bottom of the liquid separation tank 5 are hemispherical; specifically, the liquid separation tank 5 is formed by two identical pipe caps by hot-melt welding;

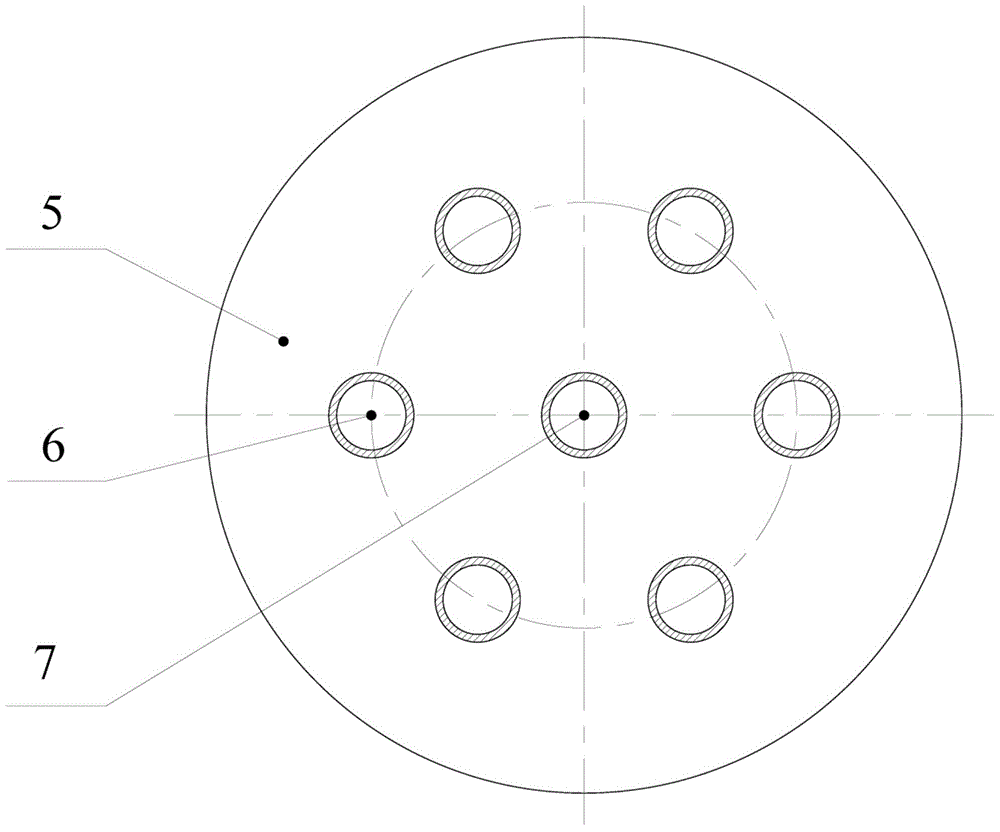

[0024] Such as figure 2 As shown, the liquid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com