Inkjet printing device for surfaces of vegetable oil packaging barrels

A technology for packaging barrels and vegetable oil, applied in printing, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as inability to dry quickly, inconvenient to use, and affect the quality of coding, to ensure the quality of spraying and improve rapid drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

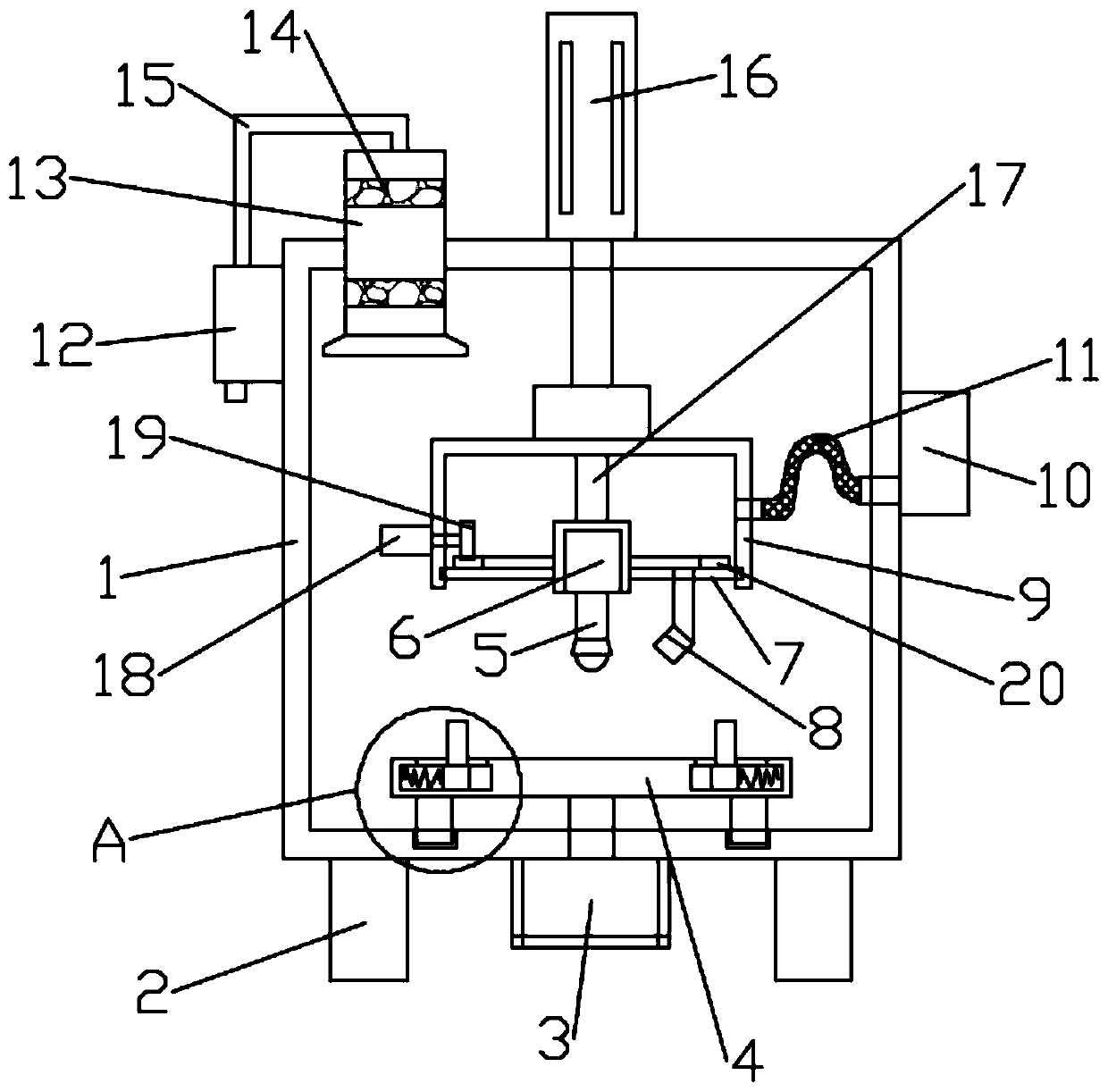

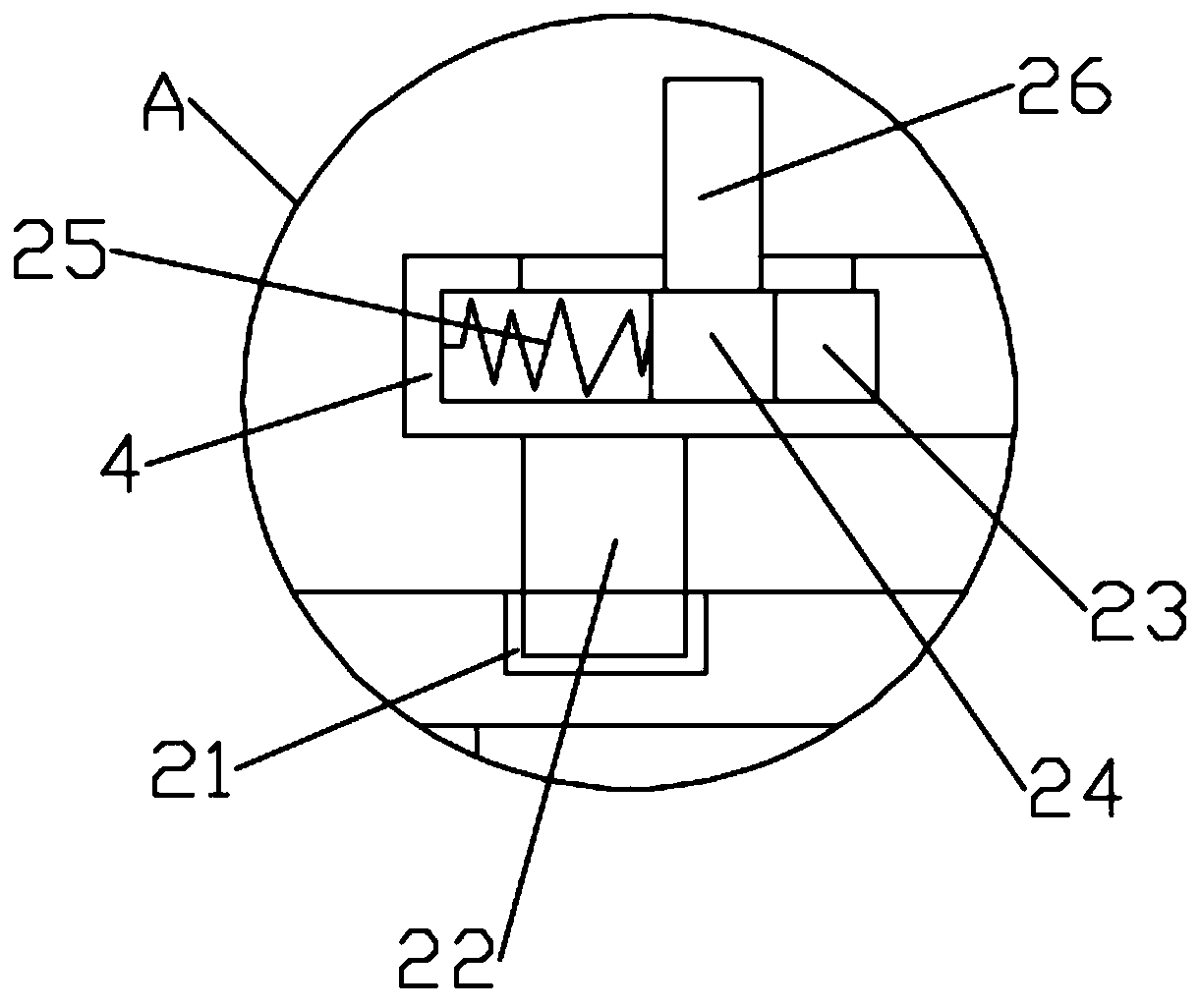

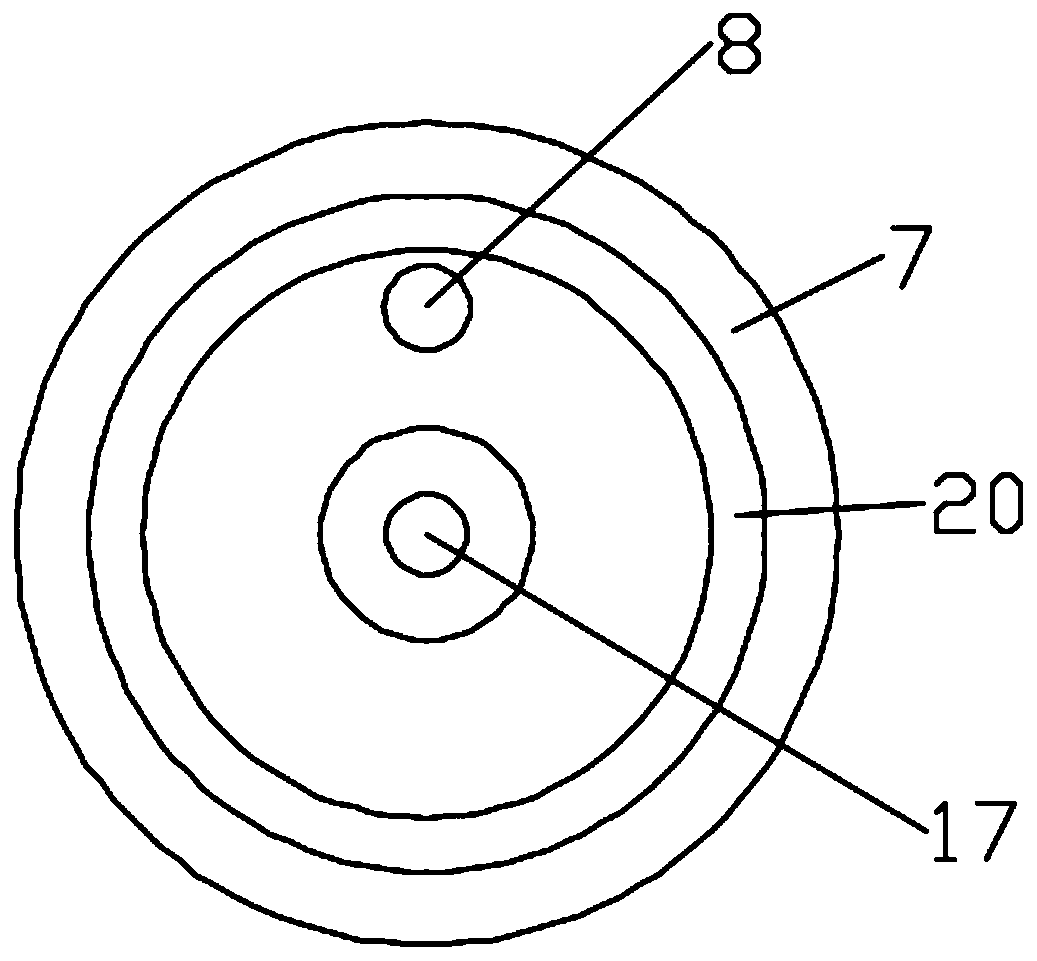

[0023] see figure 1 and image 3 , in the embodiment provided by the present invention, a vegetable oil packaging drum surface inkjet device, including a box 1 with support feet 2 at the four corners of the bottom surface of the bottom plate, a support cover 9 is erected inside the box 1, and the box A telescopic cylinder 16 for adjusting the height of the position of the support cover 9 in the box body 1 is installed on the top plate of the body 1; One side of the support cover 9 is provided with an air blowing port 8 for discharging the air in the support cover 9; the bottom surface of the middle part of the support cover 9 is fixedly installed with a coding gun 6 through a bracket 17, and the coding gun 6 is provided with a jetting terminal 5; the opening of the air blowing port 8 is towards the bottom of the jetting terminal 5;

[0024] Further, in the embodiment provided by the present invention, a servo motor 18 for driving the rotating disk 7 to rotate is installed on...

Embodiment 2

[0029] like figure 1 As shown, different from Embodiment 1, in the embodiment provided by the present invention, an air purification cartridge 13 is fixedly installed on one side of the top plate of the box body 1, and at least two layers of air purification cartridges are arranged in the air purification cartridge 13 Activated carbon filter layer 14, and an exhaust fan 12 is also installed on the box body 1, and the exhaust fan 12 is connected to the air purification cylinder 13 through an exhaust pipe 15. Under the action of the exhaust fan 12, the box body During the process of discharging the gas in the body 1 through the air purification cylinder 13, the activated carbon filter layer 14 is used to purify and filter the air, so as to avoid the odorous gas generated during the coding process from escaping directly into the working environment, ensuring the processing Environmental security.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com