Automatic punching and packaging production line

A packaging production line and automatic punching technology, applied in packaging and other directions, can solve the problems of low production efficiency and high labor costs, and achieve the effect of high work efficiency, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

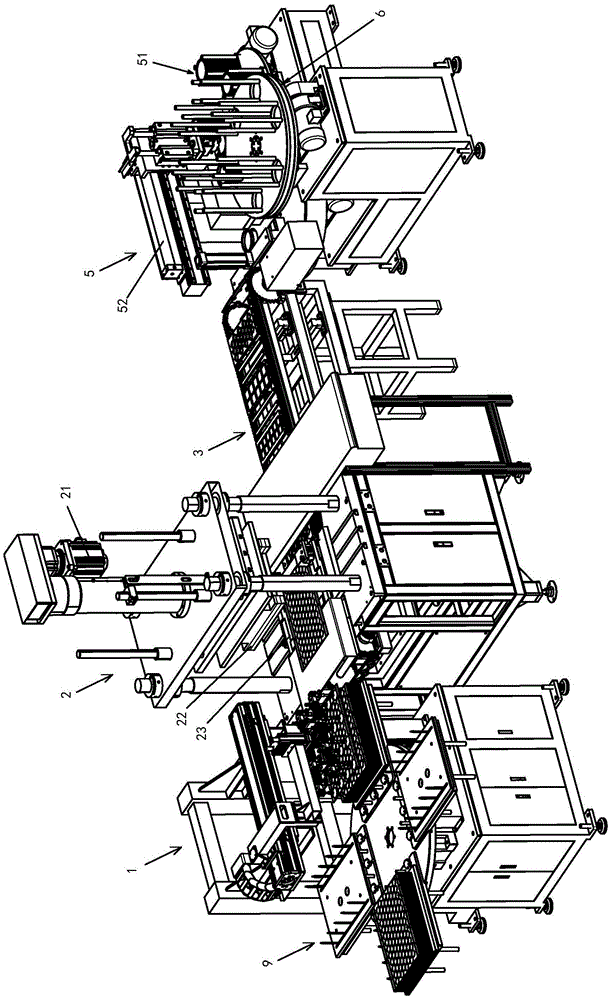

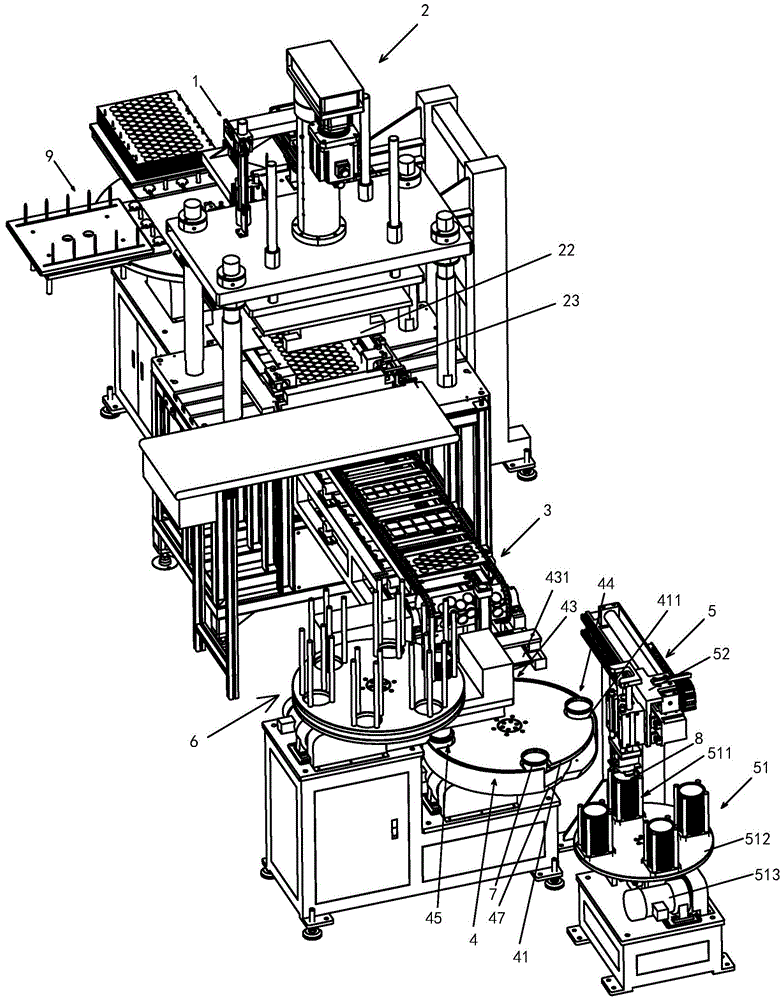

[0025] Example: see Figure 1-7 Shown:

[0026] An automatic punching and packaging production line, including a product feeding mechanism 1, a punching press 2, a product quantitative conveying chain 3, a packaging cylinder turntable mechanism 4, a cylinder capping mechanism 5 and a packaging cylinder feeding mechanism 6 arranged in sequence.

[0027] see figure 1 , figure 2 As shown, the punching press 2 includes a servo pressing mechanism 21, a punching upper die 22 and a punching lower die 23, and the punching lower die 23 is provided with a product blanking through hole.

[0028] see figure 1 , figure 2 As shown, the product feeding mechanism 1 includes a mechanical arm 11 for placing the product to be punched on the punching lower die 23 of the punching press 2 .

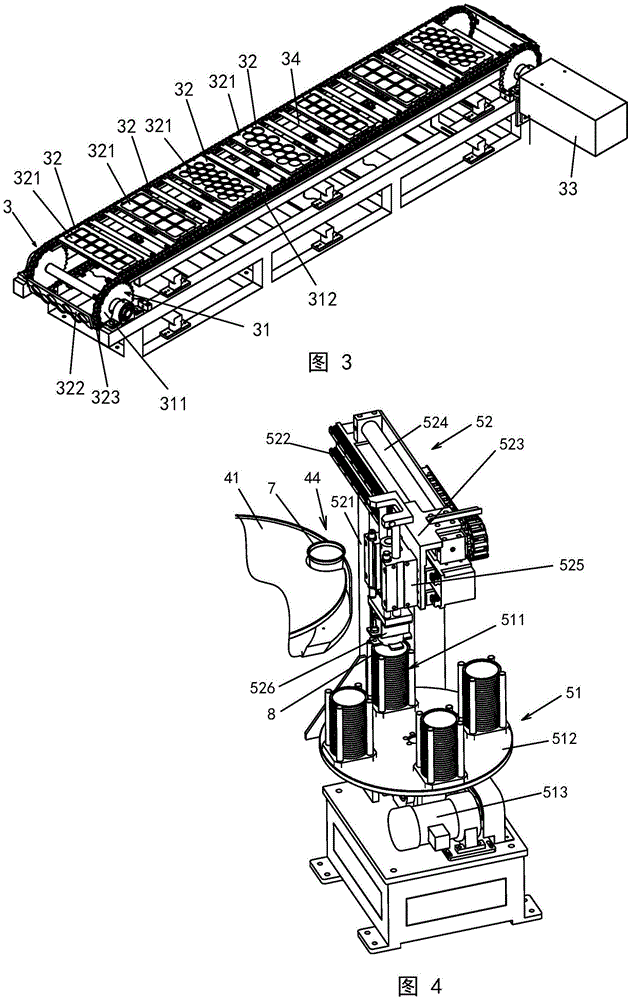

[0029] see figure 1 , figure 2 shown, see image 3 , the head end of the product quantitative conveying chain 3 is set under the punching lower die 23 of the punching press 2, the product quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com