Full-automatic packaging barrel cover-cutting machine

A fully automatic packaging and cap cutting machine technology, applied in metal processing, solid waste removal, etc., can solve the problems of high labor intensity, high operational risk, and poor quality of barrel skins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

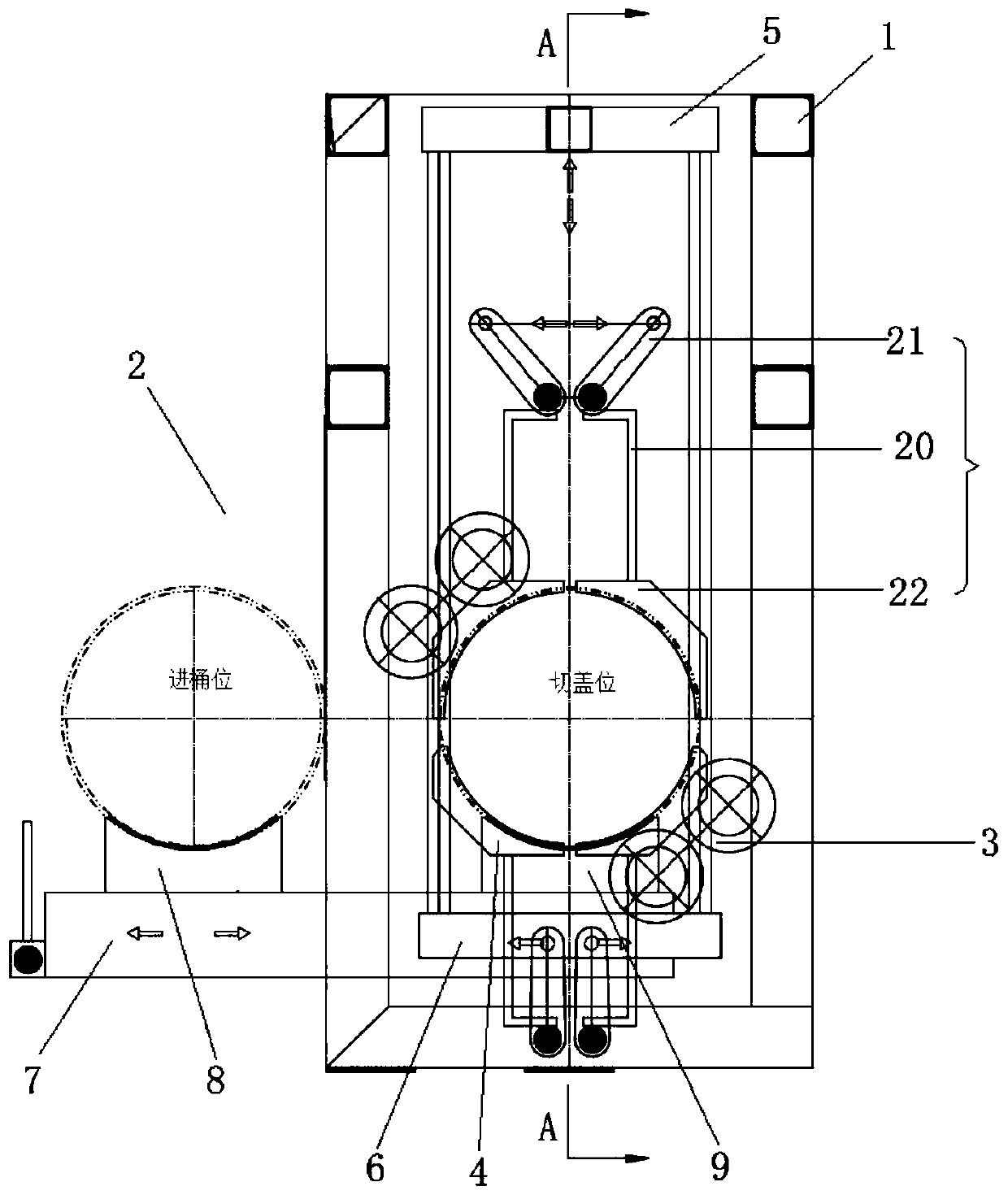

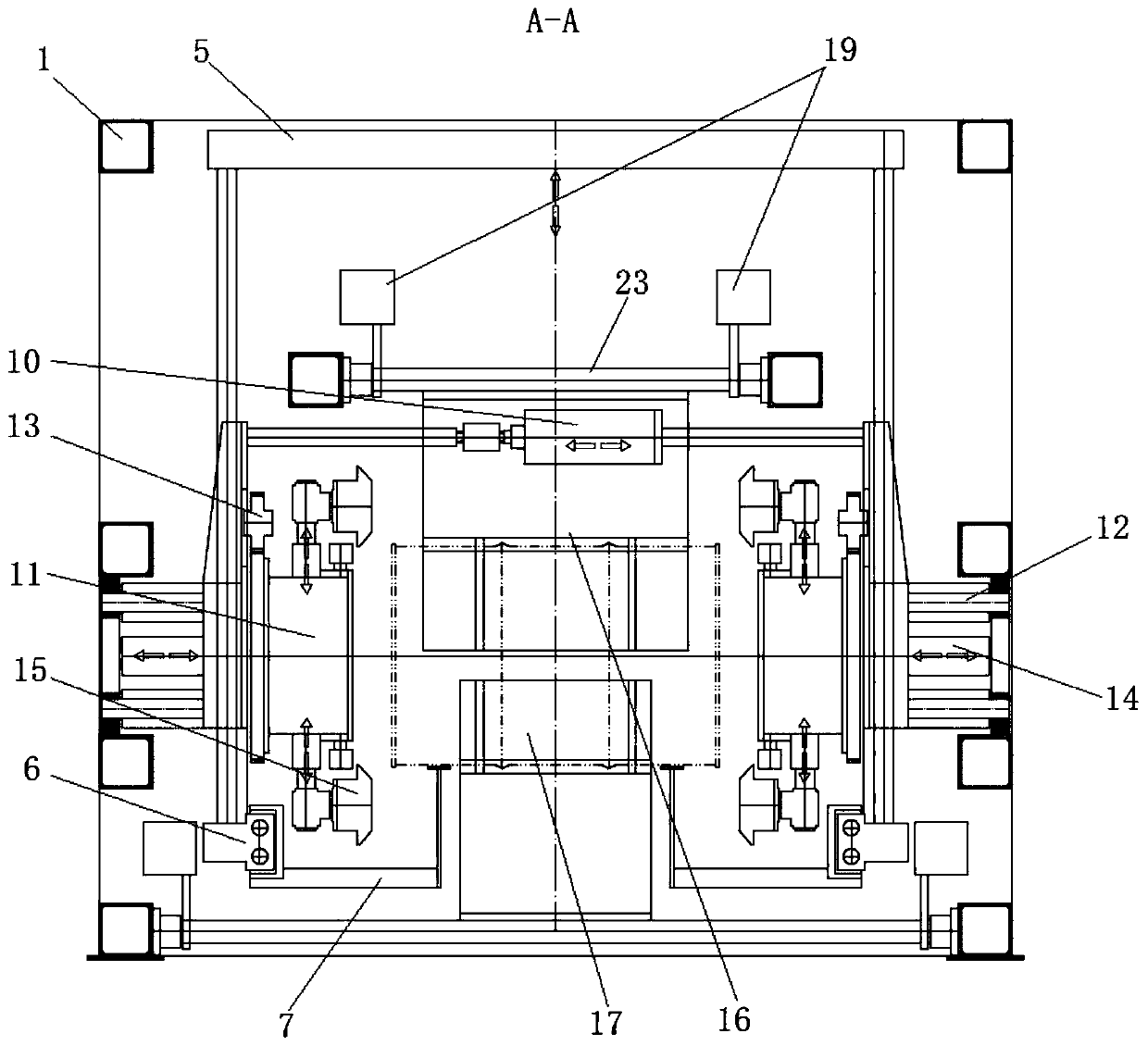

[0023] like Figure 1-2 As shown, this embodiment provides a fully automatic packaging barrel lid cutting machine, including an overall frame 1, a barrel feeding and conveying mechanism 2, a lid cutting assembly 3 and a barrel holding mechanism 4 for fixing the packaging barrel, a barrel feeding and conveying mechanism 2, Both the cap cutting assembly 3 and the barrel holding mechanism 4 are installed on the overall frame 1; the barrel feeding and conveying mechanism 2 is used to transport the packaging barrel to be cut to the cap cutting mechanism.

[0024] In this embodiment, if figure 1 As shown, the barrel feeding and conveying mechanism 2 is arranged at the bottom of one side of the overall frame 1, and two arc-shaped barrel positions are arranged side by side on the station plate 7, that is, the first barrel position 8 and the second barrel position 9, in most cases The lower first barrel position 8 is positioned as the barrel-in position, and the second barrel position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com