Three-counterfeit-proof plastic barrel

A technology for packaging barrels and plastics, applied in the directions of packaging, transportation and packaging, clamping devices, etc., can solve the problems of easy release of the barrel cover, less obvious effect, single anti-counterfeiting structure, etc., and achieve good anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

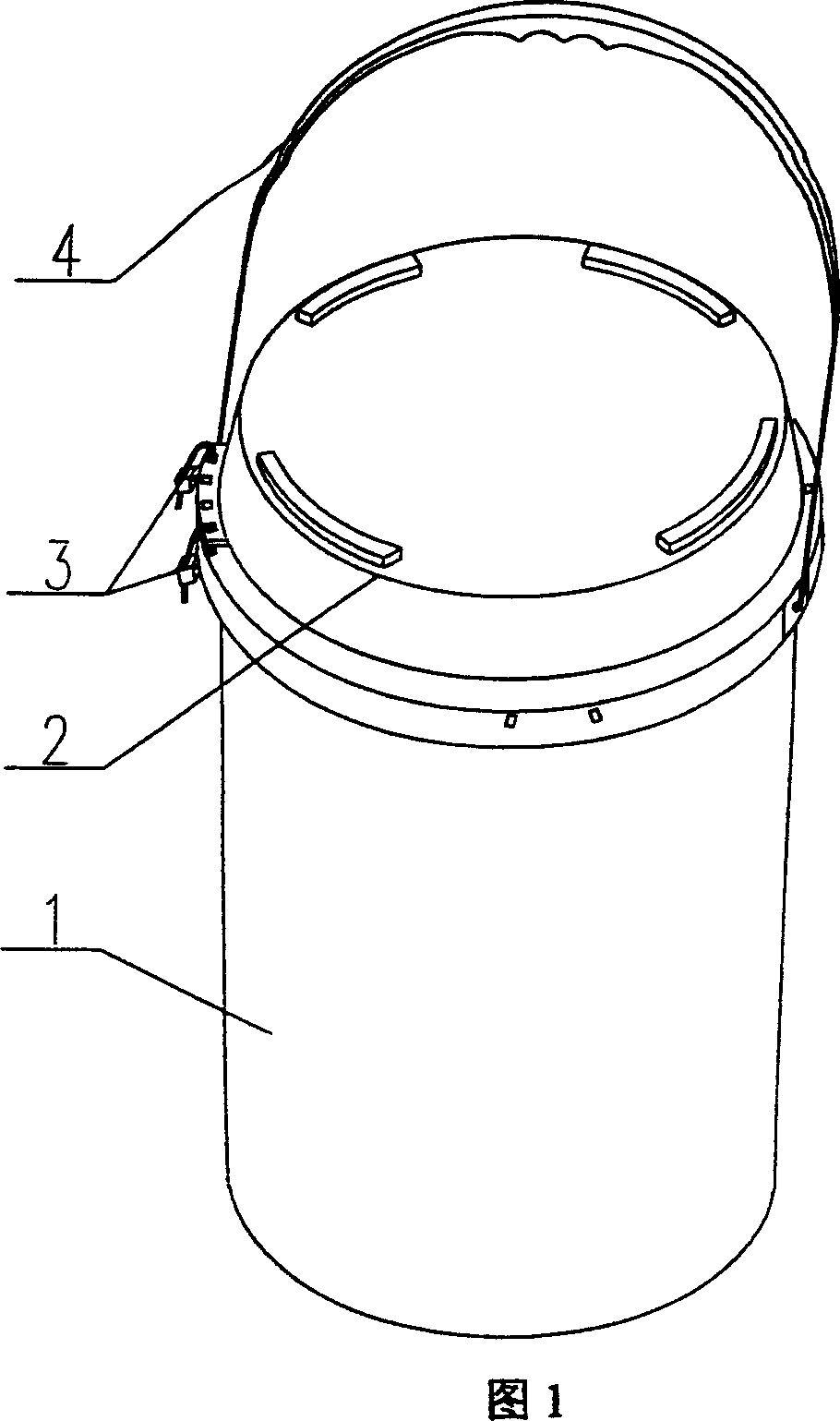

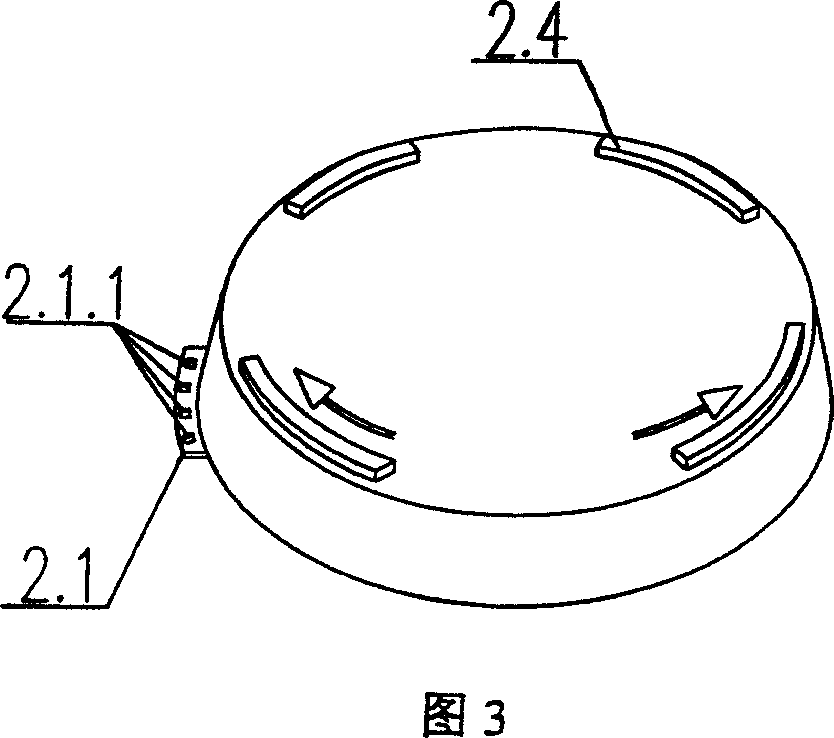

[0020] Referring to Figure 1, the three anti-counterfeiting plastic packaging barrels of the present invention are mainly composed of a barrel body 1, a barrel lid 2, and a handle 4. The lid 2 is placed on the barrel 1, and the handle 4 is installed on both sides of the barrel 1.

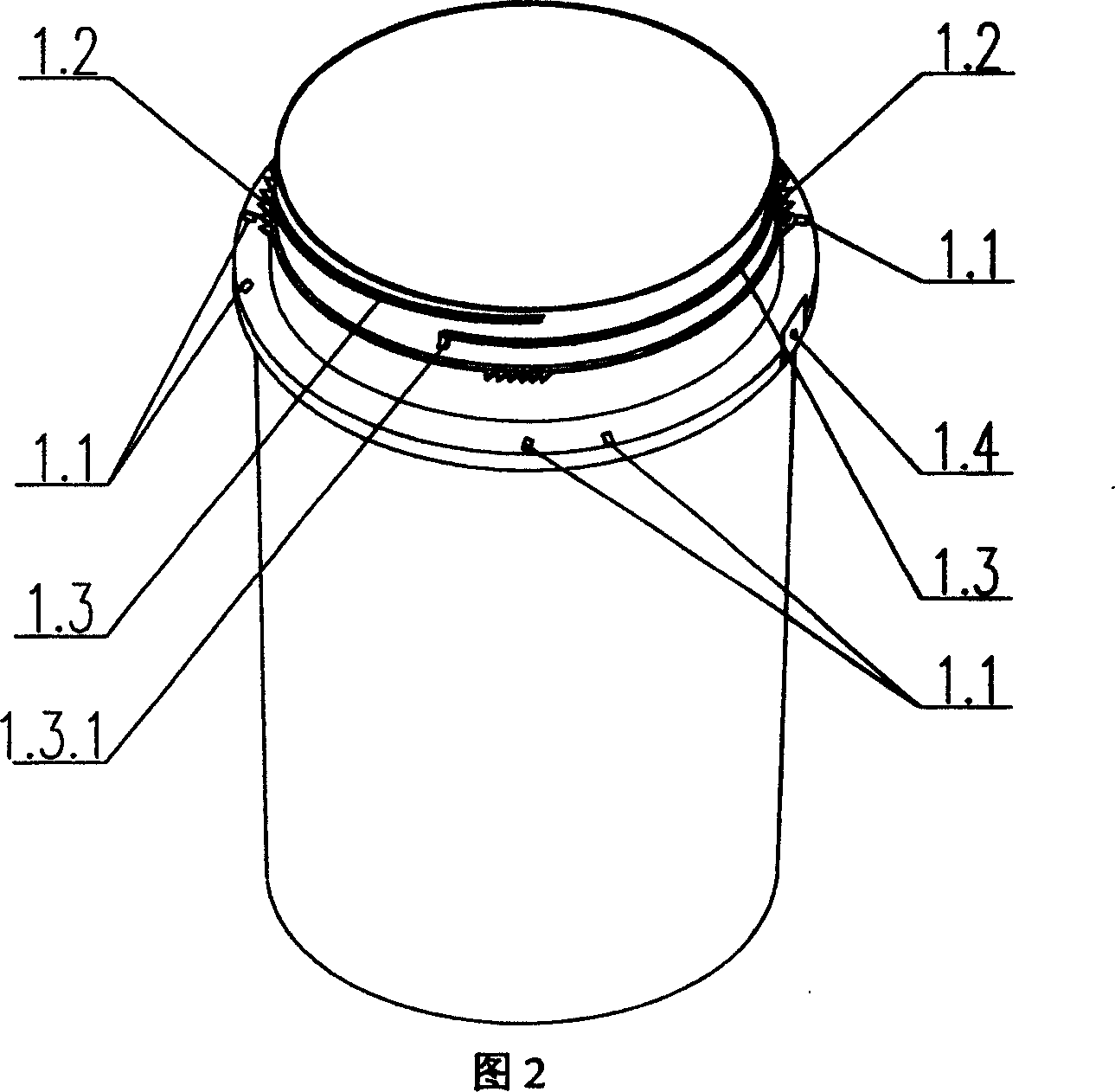

[0021] Referring to Figure 2, the barrel body 1 has four spiral locking threads 1.3 evenly distributed on the outer edge of the barrel mouth, and a stop block 1.3.1 is provided at each end of the four spiral locking threads 1.3; on the spiral locking threads Four sets of serrations 1.2 are evenly distributed on the outer wall of the barrel 1 slightly below; a reinforcing rib is ringed on the outer wall of the barrel 1 slightly below the four sets of serrations 1.2, and four strap holes 1.1 are evenly distributed on the reinforcing ribs. , There are two tie holes in each place, as shown in Figure 1 and Figure 2. In addition, mounting holes 1.4 for the handle 4 are also provided on both sides of the barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com