High-strength hazardous article packaging plastic barrel and production method

A technology for packaging plastics, dangerous goods, applied in the direction of packaging, transportation and packaging, cans/drums/drums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Further illustrate the present invention below in conjunction with accompanying drawing and example, but the scope of the present invention is not limited to example and accompanying drawing.

[0049] For the convenience of description, it is stipulated that the length dimensions in this example are all in mm, the unit is included in the unit-digit length, and the unit is omitted for the length of more than 10 digits.

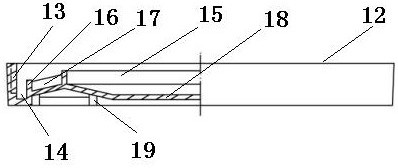

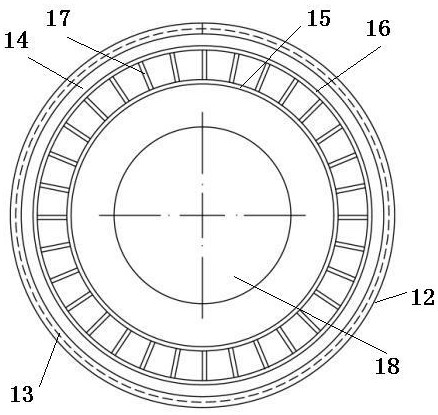

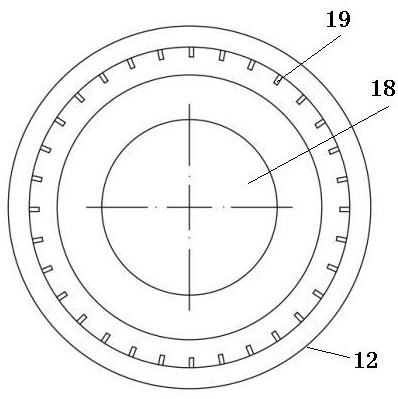

[0050] like Figure 1-7 As shown, the barrel bottom 1 and the barrel wall 4 of the barrel have a thickness of 2mm, a barrel height of 340mm, an upper mouth inner diameter of 255mm, and a barrel bottom inner diameter of 230mm. The bung rim 22 is 7.5mm wide and 3mm thick, and the externally threaded plate 10 below the rim is a discontinuous spiral plate with a helical ring outer diameter of 280mm. The specification is 20L / piece.

[0051] Ring rib I (i.e. the first ring rib) 8 outside diameter 284 under the external thread plate, thickness is also 2mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com