Solid fixation alkaline agent used for reactive dye rolling braizing method dyeing

A technology of reactive dyes and color-fixing alkalis, applied in dyeing, textiles and papermaking, etc., can solve the problems of insoluble soda ash, agglomeration of dyeing machine pipelines, increased waste water treatment load and cost, etc., so as to reduce alkali-containing washing wastewater, The effect of reducing environmental pollution and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

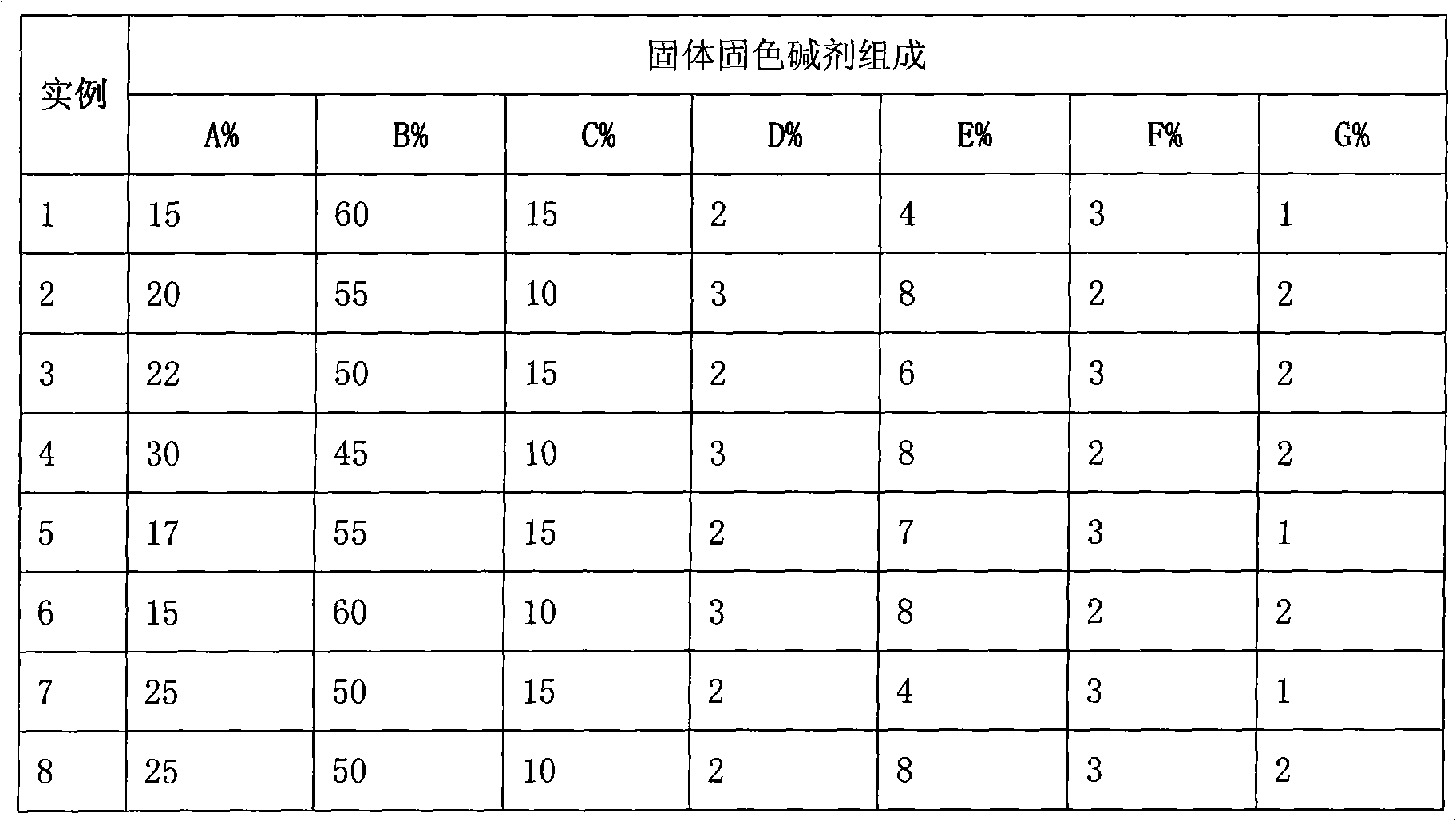

example 1~8

[0069]

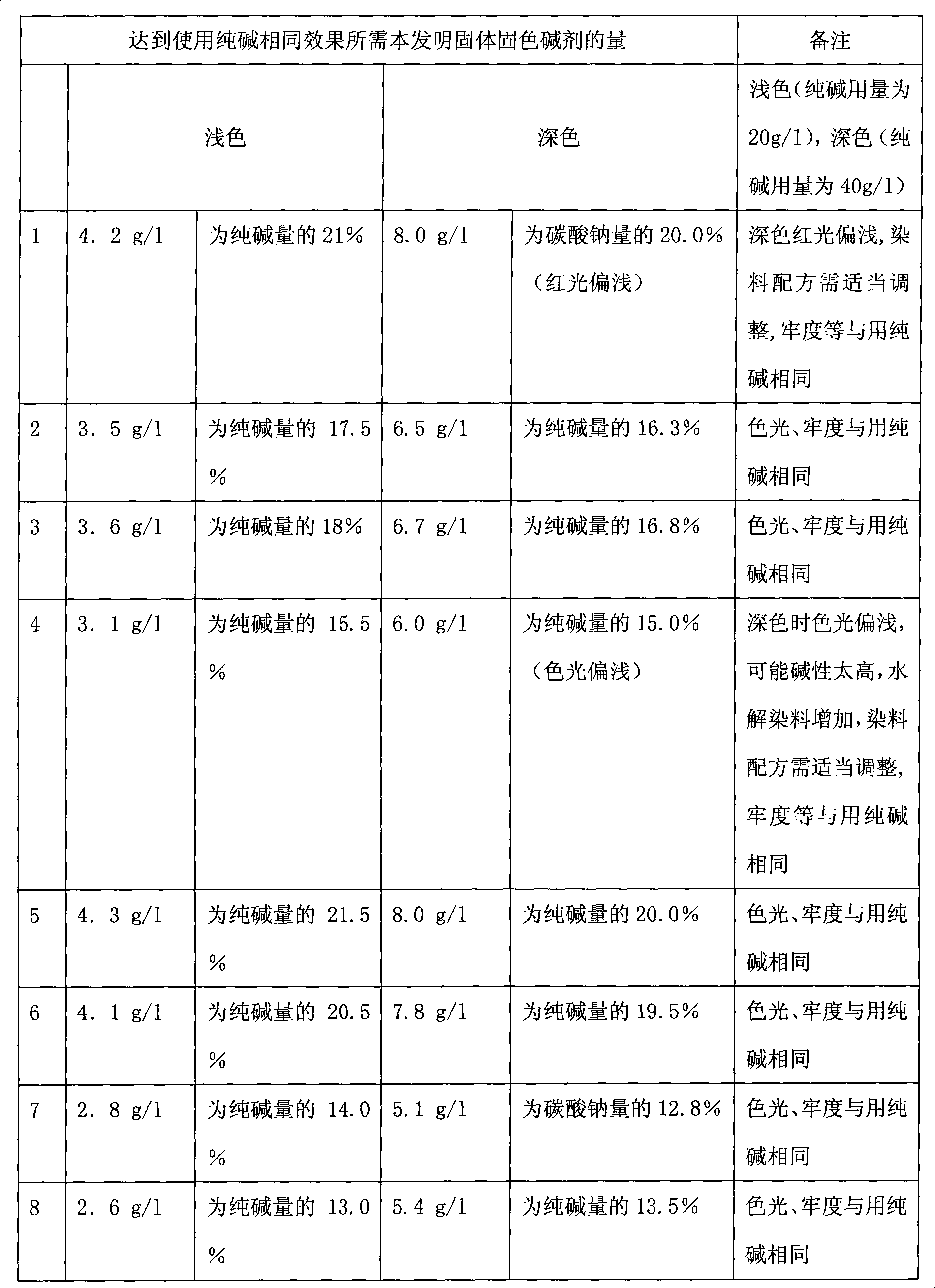

[0070] The contrast of example 1~8 and sodium carbonate consumption in application examples:

[0071] Process flow:

[0072] Padding dye solution (two dipping and two padding, liquid rolling rate 75%)→drying (100℃×2 minutes)→rolling and fixing color solution→steaming (102℃×90 seconds)→water washing (flat washing tank, hot water washing 1 grid, 2 grids of cold water)→neutralization (1 grid, glacial acetic acid 2g / l)→water washing (2 grids of cold water)→soaping (1 grid, soaping agent 2g / l)→water washing (1 grid of hot water, cold water Wash 2 compartments) → dry.

[0073] Dye formula and color fixing solution formula:

[0074] dye solution

Fixing solution

light color

Dye dosage below 10g / L,

NaCl 100g / L, NaCl 2 CO 3 20g / L or use the color-fixing alkali agent of the present invention

dark

Dye dosage below 10g / L,

NaCl 200g / L, NaCl 2 CO 3 40g / L or use color-fixing alkali agent of the present invention

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com