Side offset paper and preparation method thereof

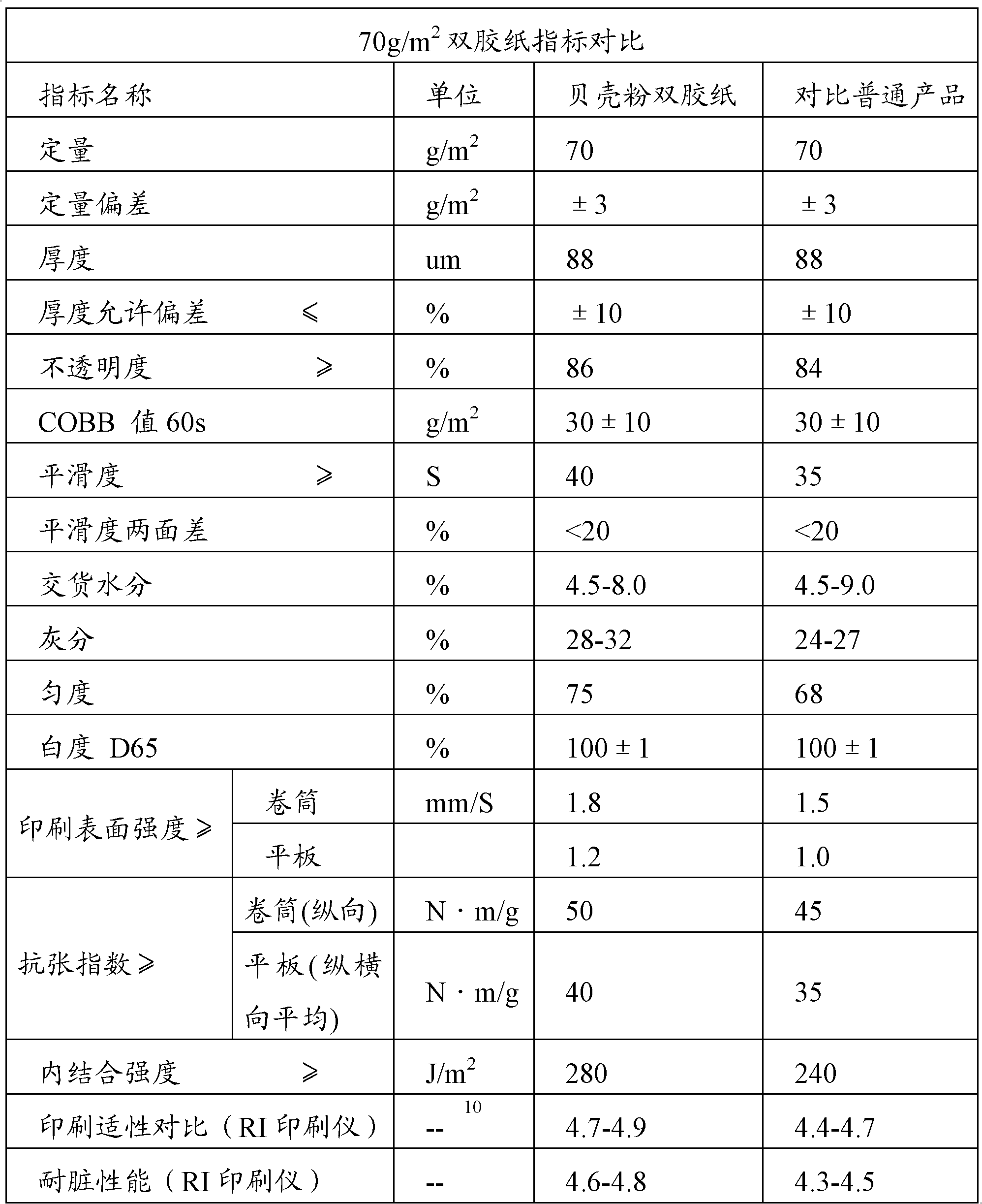

A technology of double-adhesive paper and guar gum, applied in the field of papermaking, can solve the problems of easy occurrence of hair loss, powder loss, unnatural color tone of finished paper, high calcium carbonate consumption, and achieve product quality, pure color and less dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of offset paper; calculated according to the content per ton of paper, the ratio of the raw materials used is:

[0046] (1), fiber slurry 1 680kg,

[0047] Including: 10% bleached chemical softwood pulp, 80% high white chemical hardwood pulp and 10% high white chemical pulp;

[0048] (2), wet end chemicals,

[0049] Including: shell powder 350kg, cationic starch 9kg, whitening agent (stilbene triazine derivative with 4 sulfonic acid groups) 10kg, AnKD 0.8kg, retention aid PAM 0.2kg, defoamer (ether defoamer ) 0.5kg, fungicide (trichloroisocyanuric acid) 0.5kg, pigment 0.05kg;

[0050] The shell powder has a whiteness of 90-92%, a particle size of ≤2 μm and a content of 40%, 325-mesh sieve residue: ≤0.5%, pH value: 6-8, and dark foreign matter ≤20 pieces / 100g;

[0051] (3), adhesive,

[0052] Including: 45kg of raw starch, 0.02kg of amylase, and 4kg of guar gum.

[0053] The method for preparing the double-adhesive paper; including fiber slurry treatment proc...

Embodiment 2

[0066] A kind of offset paper; calculated according to the content per ton of paper, the ratio of the raw materials used is:

[0067] (1), fiber slurry 1 750kg,

[0068] Including: 15% bleached chemical softwood pulp, 70% high white chemical hardwood pulp and 15% high white chemical pulp;

[0069] (2), wet end chemicals,

[0070] Including: shell powder 300kg, cationic starch 10kg, whitening agent (stilbene triazine derivative with 2 sulfonic acid groups) 6.7kg, AnKD 1.1kg, retention aid PAM0.2kg, defoamer (ether defoamer agent) 0.9kg, fungicide (dichloroisocyanuric acid) 1.0kg, pigment 0.15kg;

[0071] The shell powder has a whiteness of 90-92%, a particle size of ≤2 μm and a content of 40%, 325-mesh sieve residue: ≤0.5%, pH value: 6-8, and dark foreign matter ≤20 pieces / 100g;

[0072] (3), adhesive,

[0073] Including: 40kg of raw starch, 0.03kg of amylase, and 5kg of guar gum.

[0074] The preparation method is the same as in Example 1.

Embodiment 3

[0076] A kind of offset paper; calculated according to the content per ton of paper, the ratio of the raw materials used is:

[0077] (1), fiber slurry 1 700kg,

[0078] Including: 12% bleached chemical softwood pulp, 75% high white chemical hardwood pulp and 13% high white mechanical pulp;

[0079] (2), wet end chemicals,

[0080] Including: shell powder 340kg, cationic starch 9kg, whitening agent (stilbene triazine derivative with 6 sulfonic acid groups) 7kg, AnKD 0.8kg, retention aid PAM0.3kg, defoamer (ether defoamer ) 1.0kg, fungicide (sodium hypochlorite) 1.2kg, pigment 0.1kg;

[0081] The shell powder has a whiteness of 90-92%, a particle size of ≤2 μm and a content of 40%, 325-mesh sieve residue: ≤0.5%, pH value: 6-8, and dark foreign matter ≤20 pieces / 100g;

[0082] (3), adhesive,

[0083] Including: 42.6kg of raw starch, 0.04kg of amylase, and 4kg of guar gum.

[0084] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com