Preparation method of epispastic material employing electron beam radiation crosslinking and compositions thereof

A technology of electron beam radiation and manufacturing method, which is applied in the field of foaming material manufacturing method and its composition, can solve problems such as pollution sources, achieve the effects of increasing crosslinking density, uniform foaming, and reducing crosslinking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable the examiner to have a further understanding and understanding of the structural features and achieved effects of the present invention, the preferred embodiments and detailed descriptions are as follows:

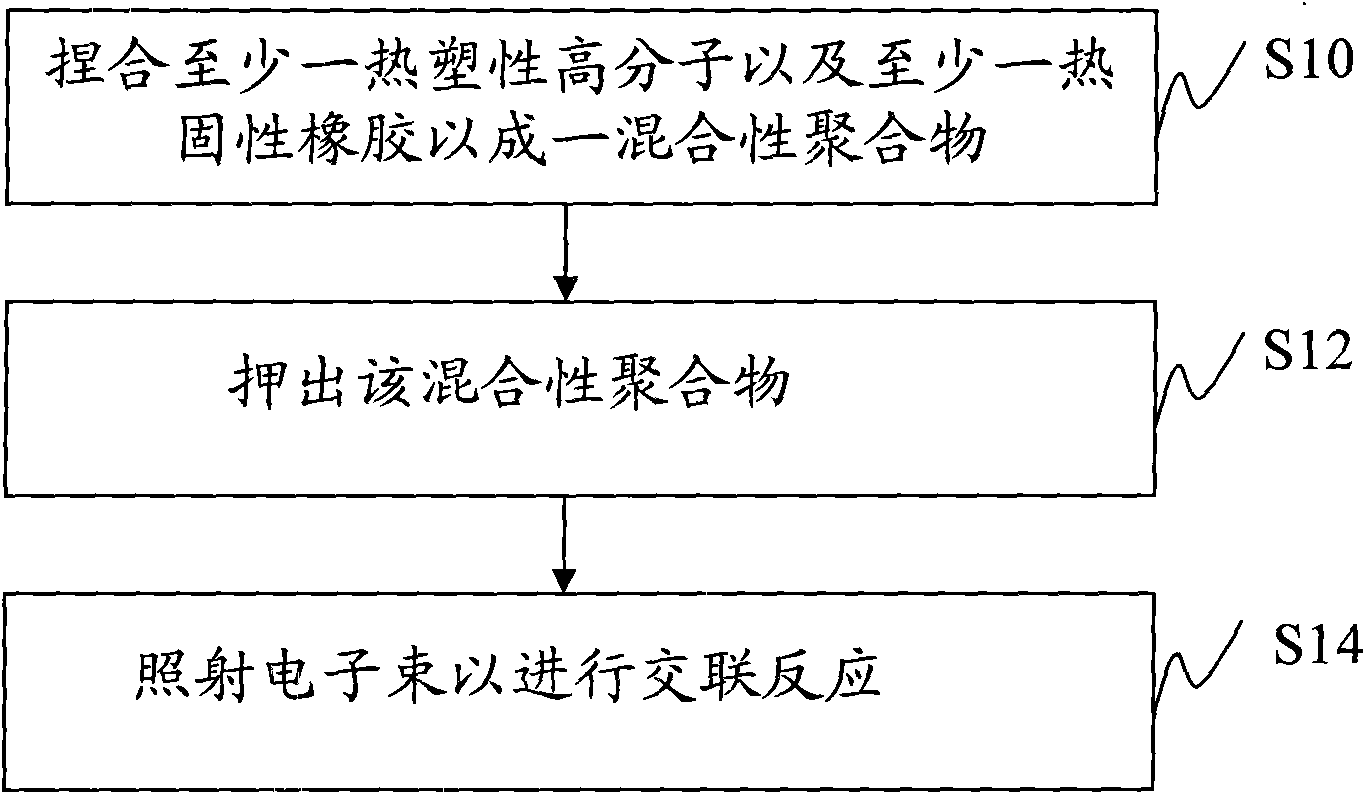

[0036] First, please refer to figure 1 , is a manufacturing flow chart of one of the preferred embodiments of the present invention; as shown in the figure, the main steps of the electronic cross-linking polymer manufacturing method of the present invention include:

[0037] Step S10, kneading at least one thermoplastic polymer and at least one thermosetting rubber to form a hybrid polymer;

[0038] Step S12, extruding the hybrid polymer; and

[0039] Step S14, irradiating electron beams to carry out cross-linking reaction.

[0040] Wherein, the thermoplastic polymer is a thermoplastic elastomer (Thermoplasticlastomer; TPE), for example: low-density polyethylene, the thermosetting rubber is ethylene-propylene rubber,

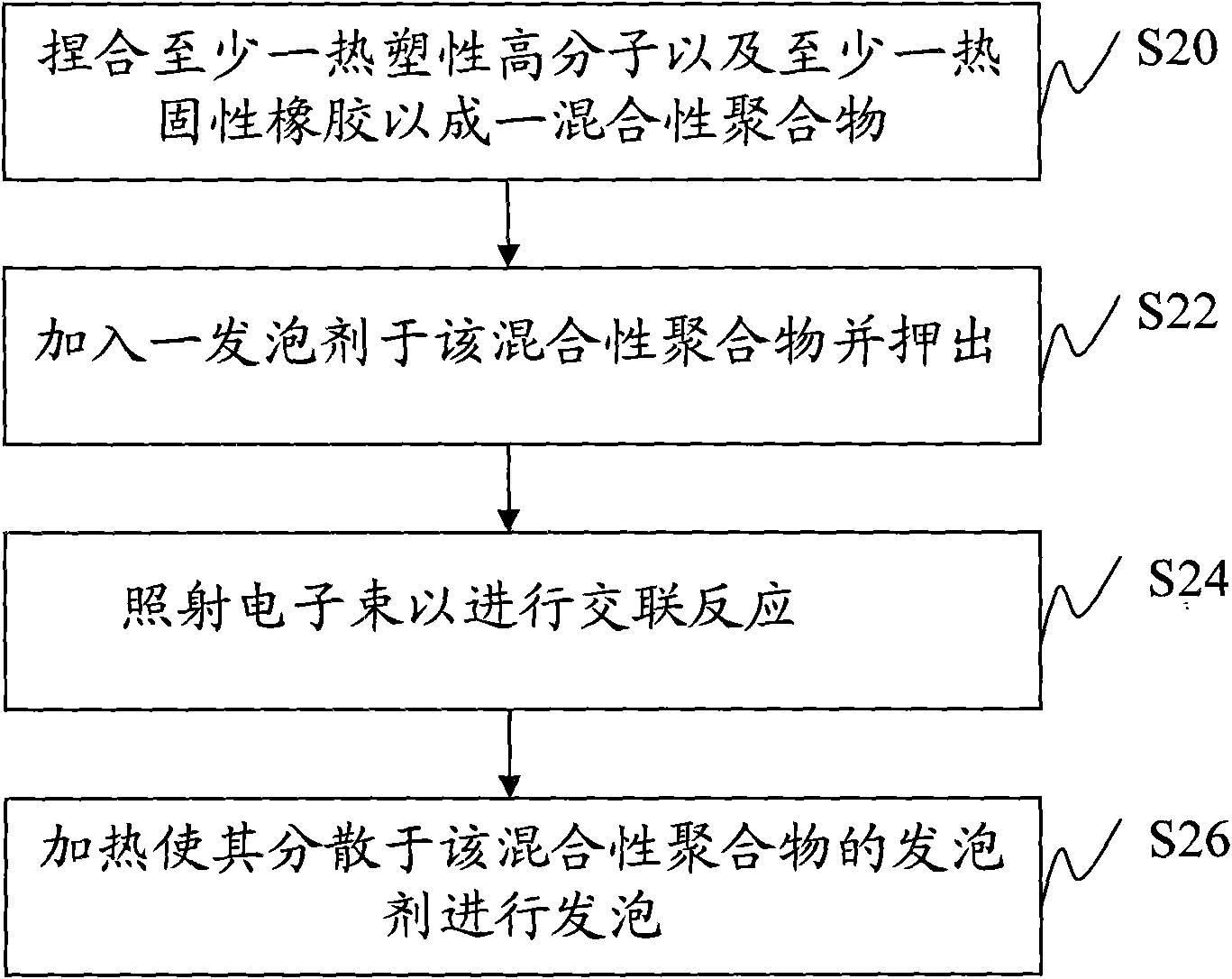

[0041] Please refer to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com