Efficient polymeric reactor

A technology of polymerization reactors and reactors, which is applied in the field of pressure vessels, can solve the problems of large temperature changes, poor temperature control accuracy, and high energy consumption, and achieve the effects of avoiding segregation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

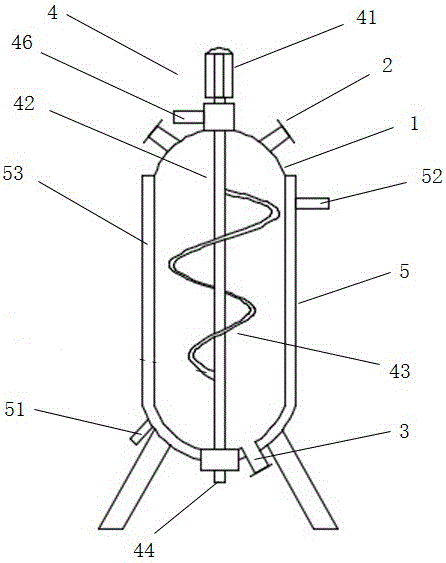

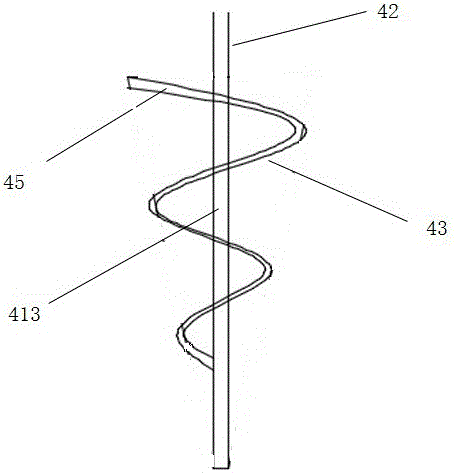

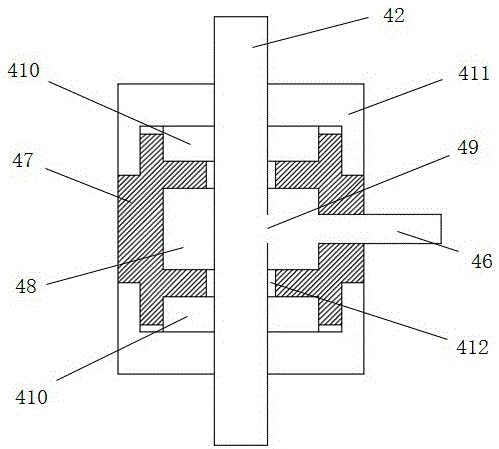

[0020] Embodiment 1: A high-efficiency polymerization reactor, including reactor body 1, feed port 2, discharge port 3, agitator 4, reactor jacket 5, reactor jacket 5 water inlet, reactor jacket 5 Water outlet, the top of the reactor body 1 is provided with several feed ports 2; the bottom of the reactor body 1 is provided with a discharge port 3; the reactor body 1 is provided with a reactor jacket 5; An external heating and cooling chamber 53 is formed between the reactor jacket 5 and the reactor body 1; the bottom of the reactor jacket 5 is provided with a reactor jacket 5 water inlet; the top of the reactor jacket 5 is provided with Reactor jacket 5 water outlet is arranged; Described reactor body 1 is provided with stirrer 4 along center line; Described stirrer 4 comprises servo motor 41, stirring shaft 42 and stirring paddle 43; Described servo motor 41 is arranged on The top of the reactor body 1; the stirring shaft 42 is connected with the servo motor 41; the stirring ...

Embodiment 2

[0021] Embodiment 2: A high-efficiency polymerization reactor, including reactor body 1, feed port 2, discharge port 3, agitator 4, reactor jacket 5, reactor jacket 5 water inlet, reactor jacket 5 Water outlet, the top of the reactor body 1 is provided with several feed ports 2; the bottom of the reactor body 1 is provided with a discharge port 3; the reactor body 1 is provided with a reactor jacket 5; An external heating and cooling chamber 53 is formed between the reactor jacket 5 and the reactor body 1; the bottom of the reactor jacket 5 is provided with a reactor jacket 5 water inlet; the top of the reactor jacket 5 is provided with Reactor jacket 5 water outlet is arranged; Described reactor body 1 is provided with stirrer 4 along center line; Described stirrer 4 comprises servo motor 41, stirring shaft 42 and stirring paddle 43; Described servo motor 41 is arranged on The top of the reactor body 1; the stirring shaft 42 is connected with the servo motor 41; the stirring ...

Embodiment 3

[0022] Embodiment 3: A high-efficiency polymerization reactor, including reactor body 1, feed port 2, discharge port 3, agitator 4, reactor jacket 5, reactor jacket 5 water inlet, reactor jacket 5 Water outlet, the top of the reactor body 1 is provided with several feed ports 2; the bottom of the reactor body 1 is provided with a discharge port 3; the reactor body 1 is provided with a reactor jacket 5; An external heating and cooling chamber 53 is formed between the reactor jacket 5 and the reactor body 1; the bottom of the reactor jacket 5 is provided with a reactor jacket 5 water inlet; the top of the reactor jacket 5 is provided with Reactor jacket 5 water outlet is arranged; Described reactor body 1 is provided with stirrer 4 along center line; Described stirrer 4 comprises servo motor 41, stirring shaft 42 and stirring paddle 43; Described servo motor 41 is arranged on The top of the reactor body 1; the stirring shaft 42 is connected with the servo motor 41; the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com