High-sulfur-capacity low-cost desulfurizing agent and preparation method thereof

The technology of desulfurizer and auxiliary agent is applied in the field of high sulfur capacity and low cost desulfurizer and its preparation, which can solve the problems of poor water resistance, low sulfur capacity and low strength of desulfurizer, achieve good synergistic effect, reduce preparation cost, Best water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1) Put 1000g of iron oxyhydroxide, 100g of volcanic ash, 100g of fly ash, and 100g of calcium hydroxide into a mixing mill and stop mixing for 30 minutes to obtain a mixture;

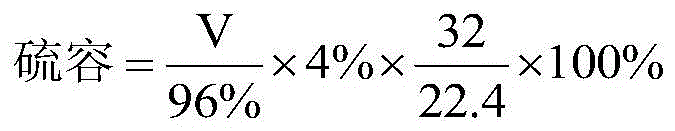

[0055] 2) Add 400g of water to the above mixture, and mix and mill for 10 minutes; the mixed and milled strips to be extruded are extruded into a screw extruder to obtain strips with a diameter of 3.8mm-4.2mm, and the strips are placed at 60 Dry at ℃ for 8 hours to obtain high sulfur capacity and low cost desulfurizer A. The measured sulfur capacity of desulfurizer A is 45%, and the radial crush resistance is 89N / cm.

Embodiment 2

[0057] 1) Put 1500g iron oxyhydroxide, 50g volcanic ash, 200g fly ash, and 200g calcium sulfate into a mixer mill and stop mixing milling for 10 minutes to obtain a mixture;

[0058] 2) Add 550g of water to the above mixture, and mix and mill for 15 minutes; the mixed and milled strips to be extruded are extruded into a hydraulic extrusion machine to obtain strips with a diameter of 3.8mm-4.2mm, and the strips are placed at 110 Dry at ℃ for 2 hours to obtain desulfurizer B with high sulfur capacity and low cost. The measured sulfur capacity of desulfurizer B is 42%, and the radial crush resistance is 135N / cm.

Embodiment 3

[0060] 1) Put 1000g ferric oxyhydroxide, 300g fly ash, and 100g calcium sulfate hemihydrate into a mixer and grind for 35 minutes and then stop mixing to obtain a mixture;

[0061] 2) Add 350g of water to the above materials, and mix and mill for 20 minutes; the mixed and milled strips to be extruded are extruded into a screw extruder to obtain strips with a diameter of 3.8mm-4.2mm, and the strips are placed at 10°C Under drying, the drying time is 24 hours to obtain a high-sulfur capacity and low-cost desulfurizer C. The measured sulfur capacity of the desulfurizer C is 36%, and the radial crushing resistance is 125N / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com