Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

A cathode active material, lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as poor battery discharge performance at high currents, and achieve improved electrical conductivity, high current discharge performance, and improved The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

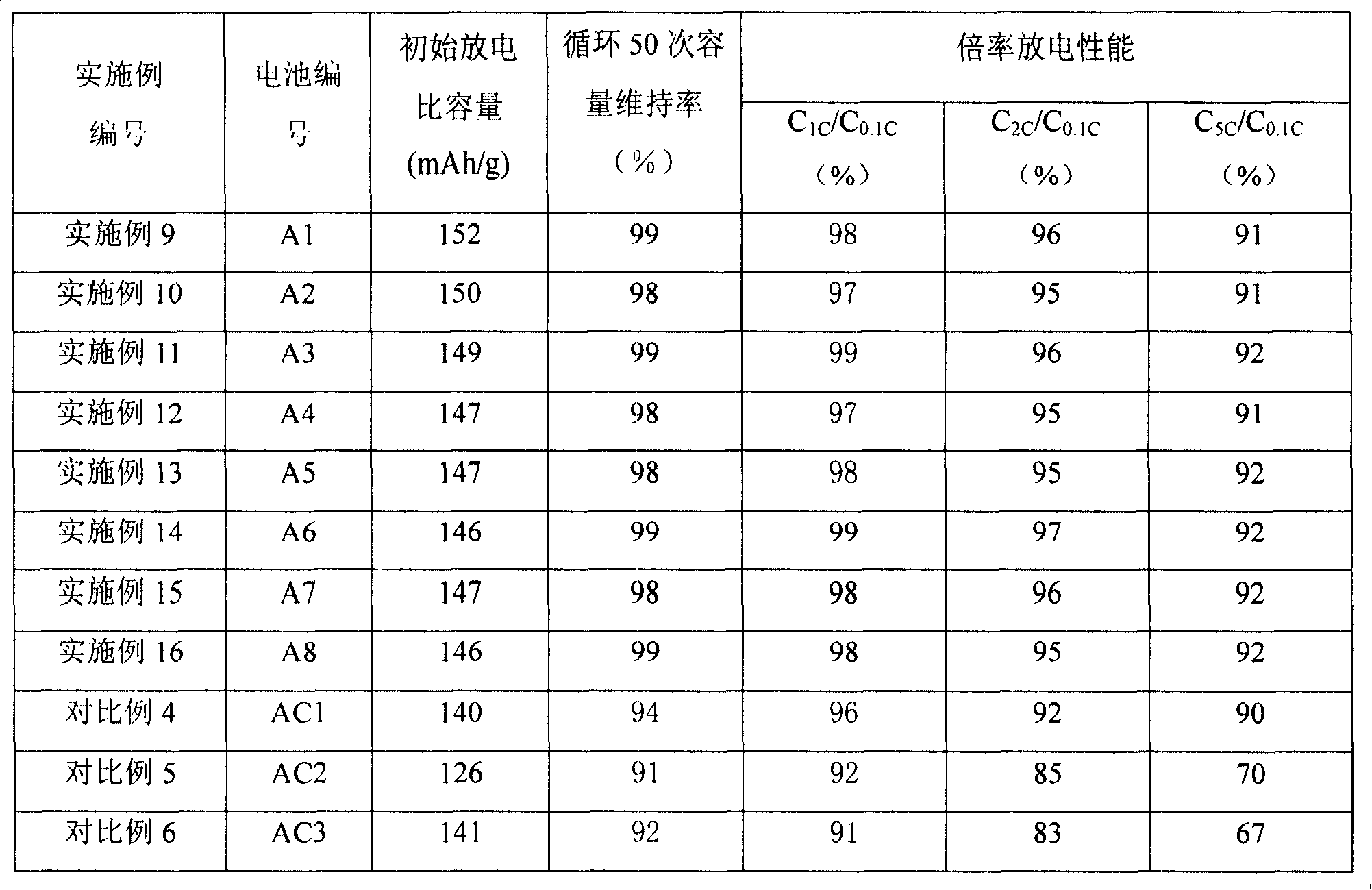

Examples

Embodiment 1

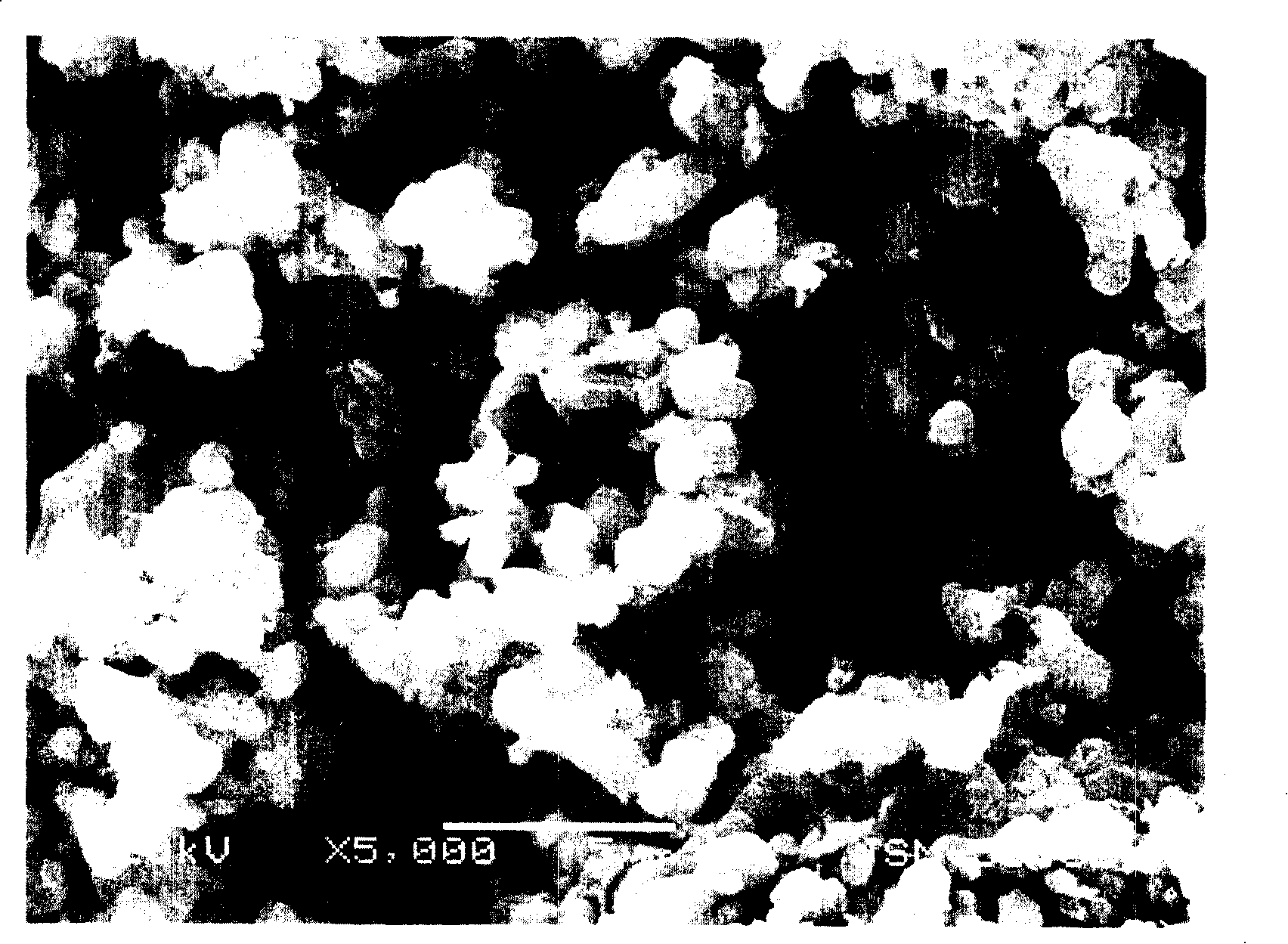

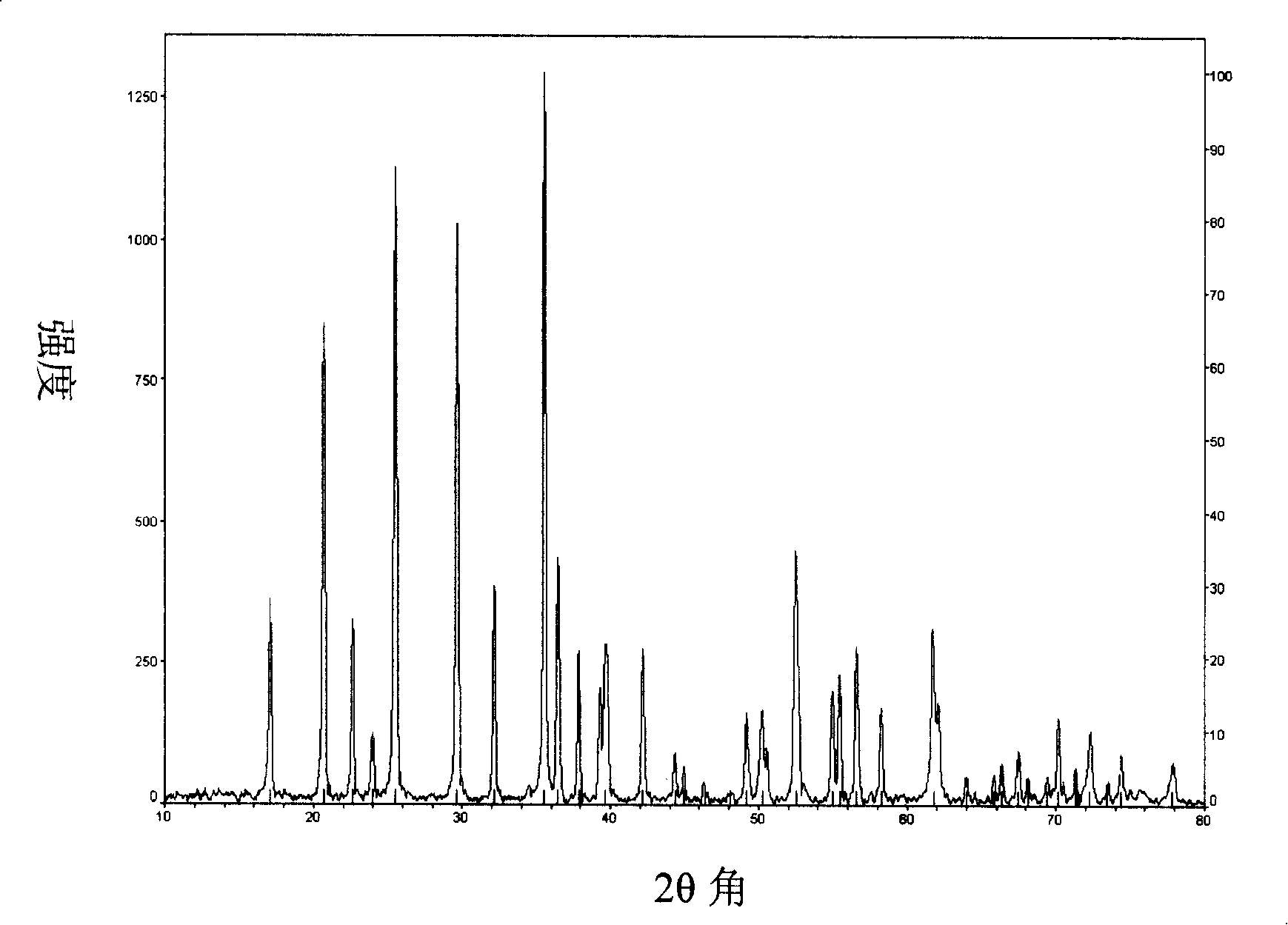

[0036] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the invention

[0037] (1) Add 0.1 mole of Li 2 CO 3 , 0.2 mol FeC 2 o 4 2H 2 O, 0.2 mole NH 4 h 2 PO 4 Mix with glucose and 250 ml of absolute ethanol (Li:Fe:P molar ratio is 1:1:1), ball mill in a ball mill jar at a speed of 300 rpm for 12 hours, take it out, and dry it at 70°C;

[0038] (2) Under the protection of argon gas with a flow rate of 10 liters / minute, the mixture in step (1) was heated to 450° C. for sintering at a constant temperature at a rate of 2° C. / minute for 6 hours, cooled naturally to room temperature, then added sucrose, and Mix with 100 milliliters of absolute ethanol, ball mill for 1 hour at a speed of 150 rpm in a ball mill jar, take out, and dry at 70°C; the weight of the glucose in the step (1) and the sucrose in the step (2) The ratio is 2.5:1;

[0039] (3) Under the protection of argon gas with a flow rate of 10 ...

Embodiment 2

[0043] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the invention

[0044] Lithium ferrous phosphate was prepared according to the method of Example 1, except that in step (2), the mixture in step (1) was heated to 450°C for sintering at a constant temperature of 6 hours at a heating rate of 2°C / min, and then naturally cooled to room temperature, then add sucrose, and stir and mix evenly, under the protection of argon with a flow rate of 10 liters / min, heat the above-mentioned sintered product to 700°C at a heating rate of 10°C / min and sinter at a constant temperature for 10 hours, then naturally cool to room temperature , jet milling to obtain LiFePO doped and coated with carbon 4 Composite material, other steps, each substance dosage ratio and condition are the same as embodiment 1.

[0045] The lithium ferrous phosphate composite material obtained above is passed through a 200 mesh sieve, and its m...

Embodiment 3

[0047] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the invention

[0048] (1) 0.21 moles of LiOH, 0.2 moles of FeC 2 o 4 2H 2 O, 0.2 moles (NH 4 ) 2 HPO 4 Mix with sucrose and 250 ml of absolute ethanol (Li:Fe:P molar ratio is 1:1:1), ball mill in a ball mill jar at a speed of 300 rpm for 12 hours, take it out, and dry it at 70°C;

[0049] (2) Under the protection of argon gas with a flow rate of 10 liters / min, the mixture in step (1) was heated to 450°C at a constant temperature for 6 hours at a rate of 2°C / min and sintered at a constant temperature, then naturally cooled to room temperature, and then polyacrylamide was added , and mixed with 100 milliliters of absolute ethanol, ball milled for 0.5 hour at a speed of 200 rev / min in a ball mill jar, taken out, and dried at 70°C; the sucrose in the step (1) and the polypropylene in the step (2) The weight ratio of dilute amides is 3.2:1;

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com