Method for manufacturing integrated color luminous vycor glass

A high-silica glass and manufacturing method technology, applied in the field of colored luminous glass, can solve the problems of high cost, long cycle, cumbersome process, etc., and achieve the effect of suppressing concentration quenching and enhancing luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

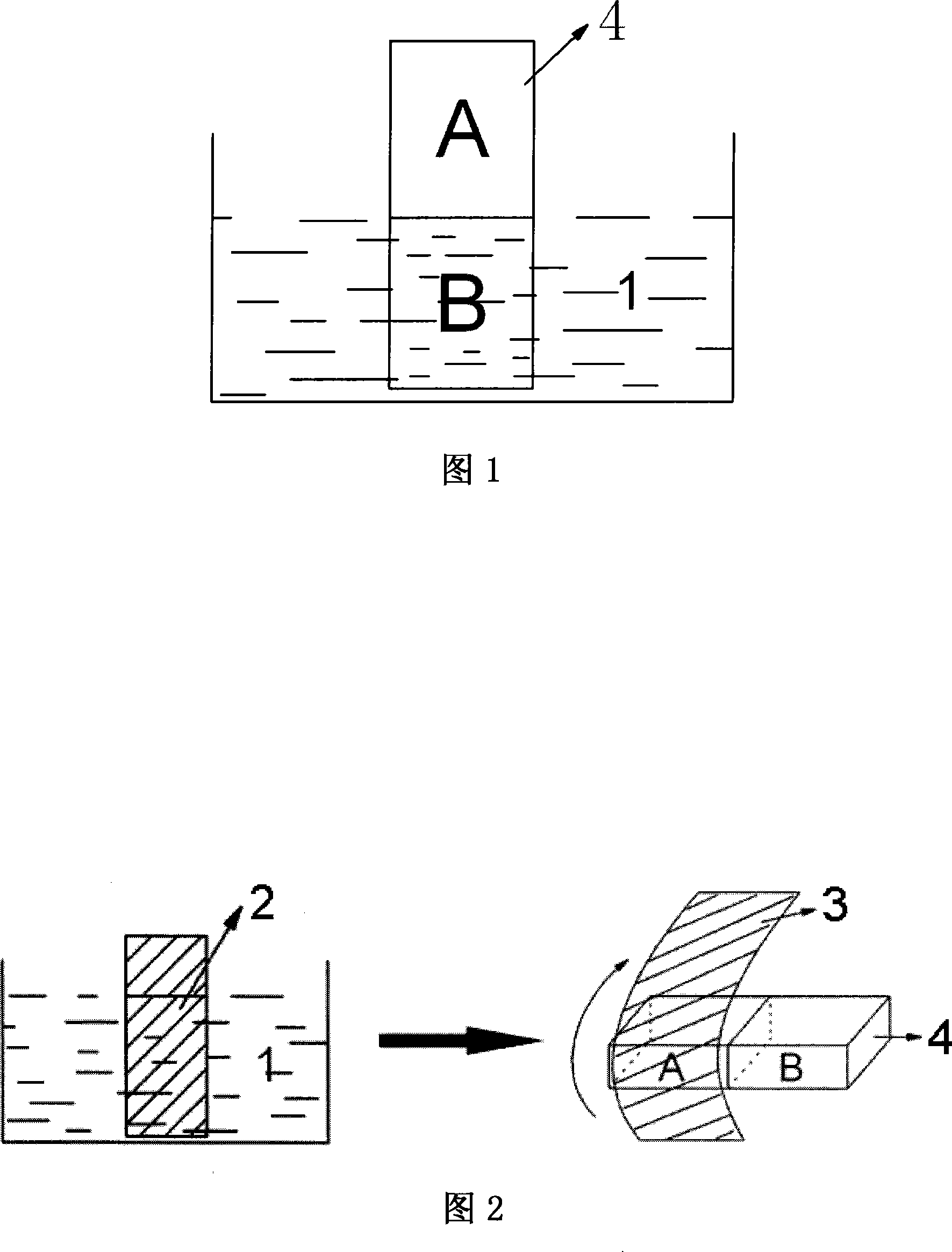

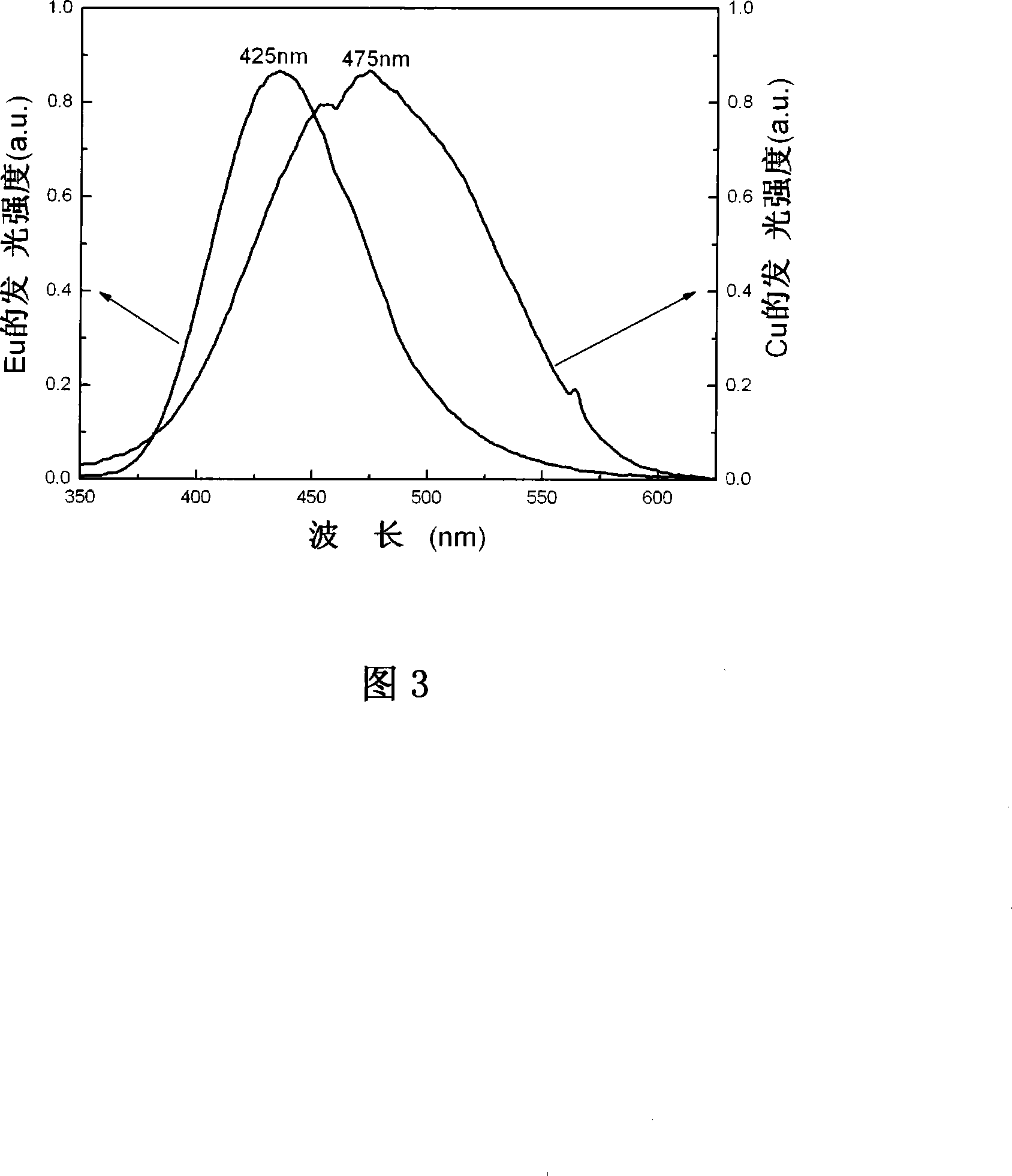

[0035] 0.50g analytically pure europium nitrate (Eu(NO 3 ) 3 9H 2 O) be completely dissolved in the distilled water of 20ml and be mixed with the Eu of 0.05mol / L 3+ solution; 0.135g of analytically pure copper chloride (CuCl 2 ) was completely dissolved in 20ml of distilled water to prepare 0.05mol / L of Cu 2+ solution. Divide the selected porous glass strip into two sections, A and B, and immerse Eu 3+ solution, and then immerse Cu in section B 2+ solution. The porous glass impregnated with luminescent ions is fully dried in air at 200°C and put into a corundum crucible with a cover, and 10g of graphite or carbon powder is placed around the glass, and then put into a high-temperature furnace for sintering. During the sintering process, the temperature rises from room temperature to 900°C at a rate of 10°C / min, and then from 900 to 1150°C at a rate of 5°C / min, and is kept at 1150°C for 30 minutes, and then the glass is cooled to room temperature with the high-temperature...

Embodiment 2

[0037] 0.10g analytically pure Eu(NO 3 ) 3 9H 2 O, 0.70g analytically pure yttrium nitrate (Y(NO 3 ) 3 9H 2 O) and 0.27g of 97% (vanadyl sulfate) VOSO 4 Completely dissolved in 20ml of distilled water to prepare a mixed solution, the solution of Eu 3+ The concentration is 0.01mol / L, Y 3+ The concentration is 0.08mol / L, V 4+ The concentration is 0.08mol / L, and this solution is recorded as solution 1; 0.43g analytically pure cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) be completely dissolved in the distilled water of 20ml, be mixed with the Ce of 0.05mol / L 3+ Solution, denoted as solution 2; 0.30g analytically pure terbium nitrate (Tb(NO 3 ) 3 9H 2 O) be completely dissolved in the distilled water of 20ml and be mixed with the Tb of 0.30mol / L 3+solution, denoted as solution 3. Divide the selected porous glass strip into three sections A, B, and C, and use the segmental coating and doping method to immerse solution 1 into section A, immerse solution 2 into section B, and ...

Embodiment 3

[0039] 0.17g of analytically pure silver nitrate (Ag(NO 3 ) 3 ) is completely dissolved in 20ml of 1mol / L dilute nitric acid to prepare 0.05mol / L Ag + Solution, denoted as solution 1; 0.17g content 97% vanadyl sulfate (VOSO 4 ) was completely dissolved in 20ml of distilled water to prepare 0.05mol / L of V 4+ Solution, denoted as solution 2; 0.26g analytically pure tin chloride (SnCl 4 ) was completely dissolved in 20ml of ethanol to prepare 0.05mol / L of Sn 4+ solution, denoted as solution 3. Divide the selected porous glass strip into three sections A, B, and C, and use the segmental coating and doping method to immerse solution 1 into section A, immerse solution 2 into section B, and immerse solution 3 into section C. The porous glass impregnated with luminescent ions is fully dried in air at 400°C and put into a corundum crucible with a cover, and 15g of graphite or carbon powder is placed around the glass, and then put into a high-temperature furnace for sintering. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com