Thin plate covering part reinforcing rib forming die and method

A technology for forming molds and reinforcing ribs, which is applied to forming molds and forming fields of reinforcing ribs of thin plate covering parts, to achieve the effects of increasing the friction coefficient, increasing the clamping effect, and increasing the frictional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

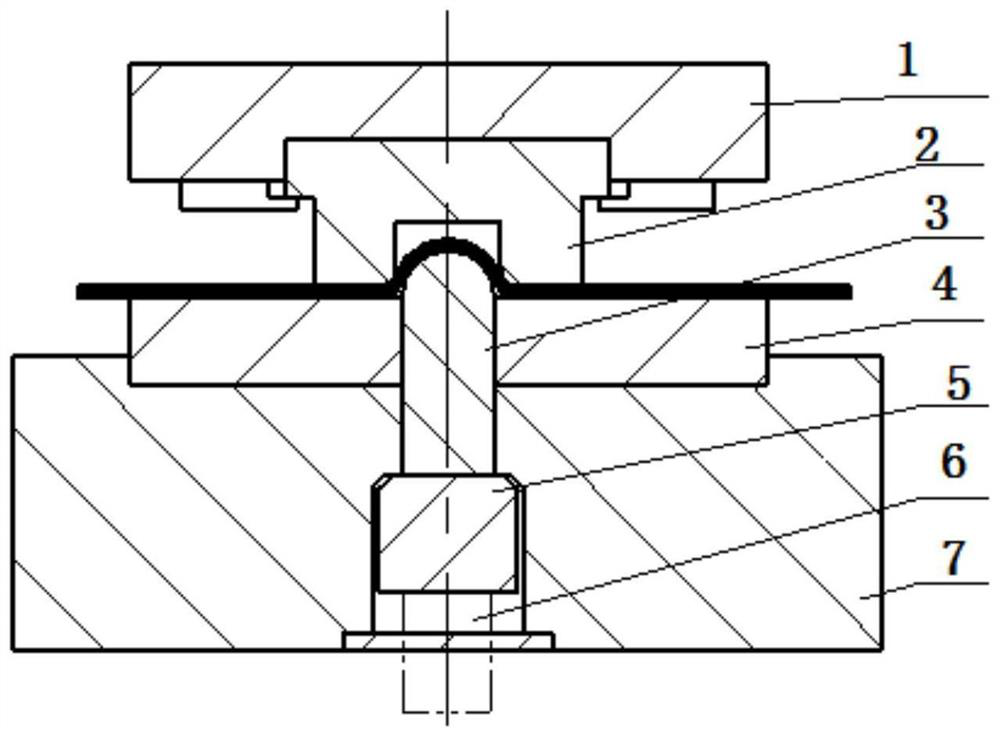

[0014] A mold for forming stiffeners of a thin plate cover part proposed by the present invention includes an upper mold base 1, a die 2, a punch 3, a binder plate 4, an air cushion plate 5, an air cushion rod 6, and a lower mold base 7;

[0015] Among them, the die 2 is connected with the upper slider of the press through the upper die base 1, the pressing plate 4 is fixed on the lower die base 7 and connected with the base of the press, and the punch 3 is installed in the middle of the pressing plate 4 and the lower die base 7. hole, the lower end is supported by a hoverboard 5 and an air cushion rod 6.

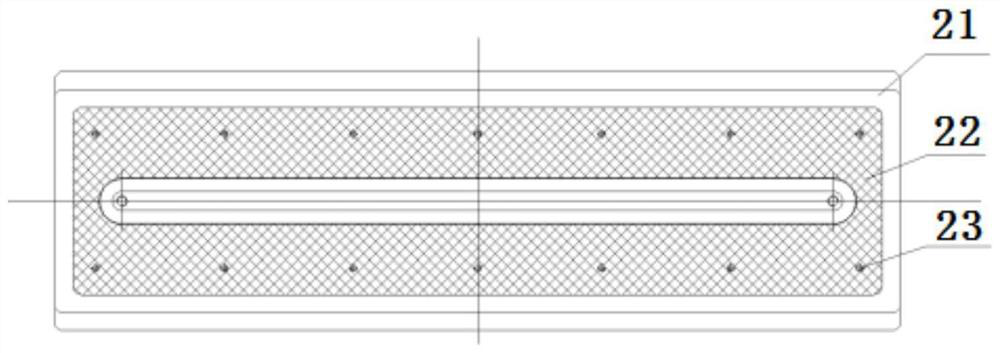

[0016] The structure of the die 2 adopts the planar part of the die body 21 to embed the polyurethane 22, the polyurethane material is 2-3 mm higher than the die, and there is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com