Extraction tank and preparation method thereof

A technology of extraction tank and phenolic epoxy vinyl ester, which is applied in the field of extraction tank and its preparation, can solve the problems of sudden increase and decrease of temperature of mixed liquid and equipment, and achieves reduction of curing shrinkage and internal stress, high strength, and improvement of stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

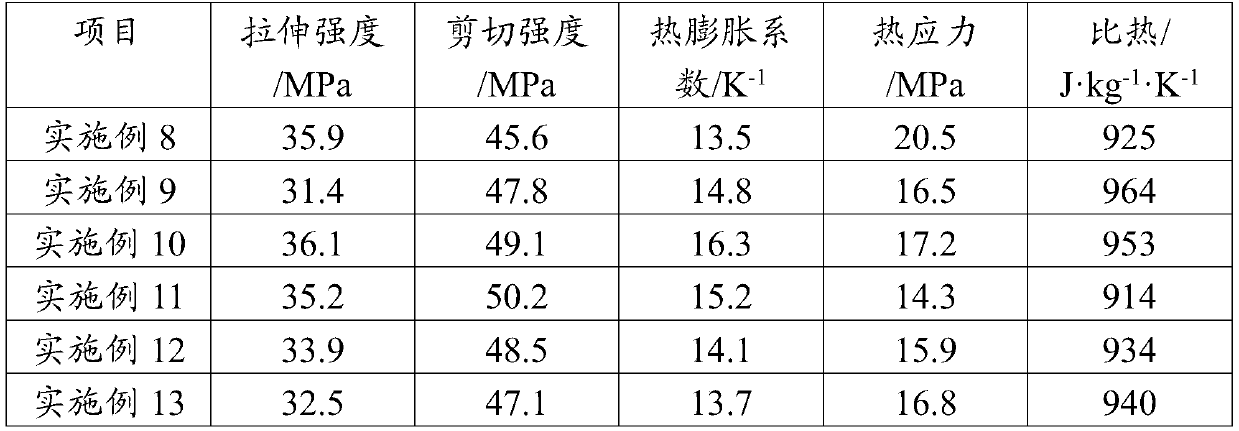

Examples

Embodiment 1

[0022] The quartz sand is prepared according to the ratio of 20 parts of 10-20 mesh, 25 parts of 20-40 mesh, 25 parts of 40-80 mesh, and 15 parts of 80-200 mesh before use.

Embodiment 2

[0024] Put 80 parts of novolac epoxy vinyl ester resin, 20 parts of filler, 5 parts of additives, 1 part of surfactant, and 1 part of defoamer into the reaction kettle in proportion and stir evenly to obtain the combination of novolac epoxy vinyl ester resin Things to spare.

Embodiment 3

[0026] Put 80 parts of novolac epoxy vinyl ester resin, 25 parts of filler, 5 parts of additives, 1 part of surfactant, and 1 part of defoamer into the reaction kettle in proportion and stir evenly to obtain the combination of novolac epoxy vinyl ester resin Things to spare.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com