Pouring furnace arch for industrial boiler

A technology for industrial boilers and pouring furnaces, applied in the field of boilers, can solve the problems of poor coal combustion radiation heat accumulation, difficult re-use of refractory materials, and short service life, so as to be beneficial to environmental protection, reduce internal stress, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

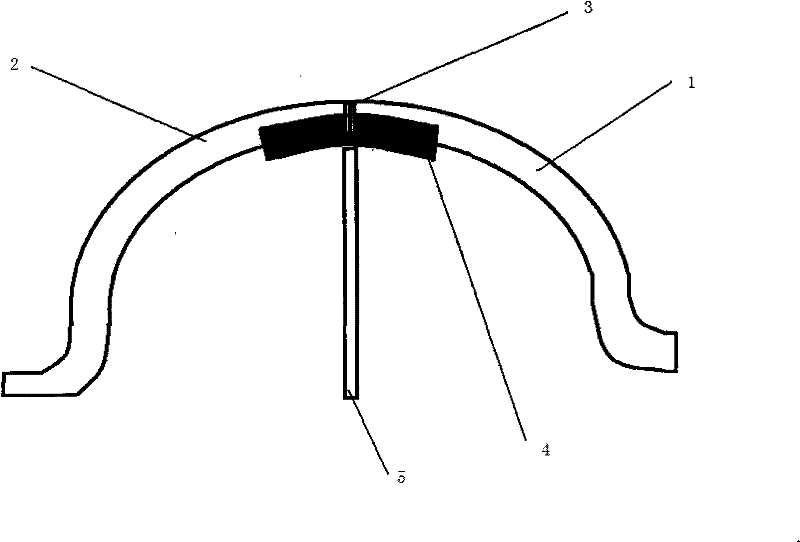

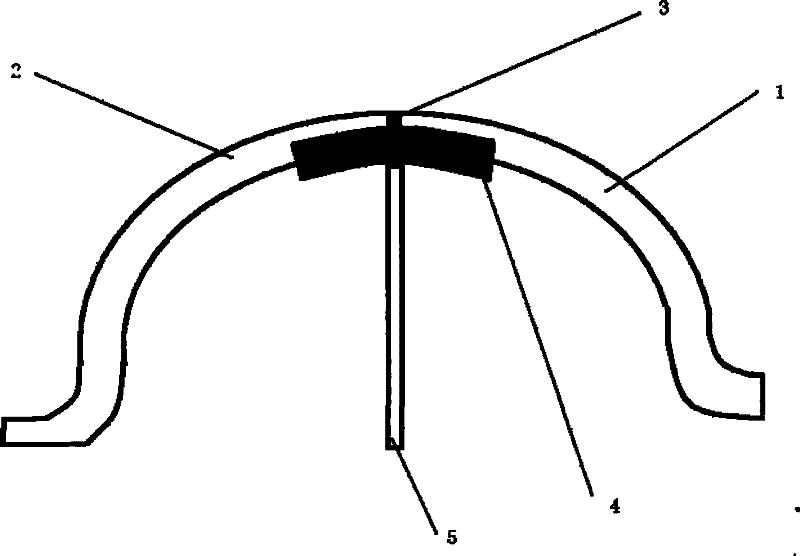

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] As shown in the figure, a casting furnace arch of an industrial boiler includes a front arch 1 and a rear arch 2. The furnace arch is a cast-type structure. The height of the outlet of the front arch 1 is higher than the height of the front port of the rear arch 2, and the front arch 1 is a hyperbolic paraboloid. , The rear arch 2 is flat, inclined, and reverse-inclined from the back to the front. There is an expansion joint 3 on the furnace arch, and the arch bar 4 is separated from the arch foot 5.

[0010] In the accompanying drawings: 1 is the front arch; 2 is the rear arch; 3 is the expansion joint; 4 is the arch bar; 5 is the arch foot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com