Building sealing glue and preparation method thereof

A sealant and construction technology, applied in the field of building gap filling, can solve the problems of easy cracking, cracking, and building waterproofing problems of filling materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

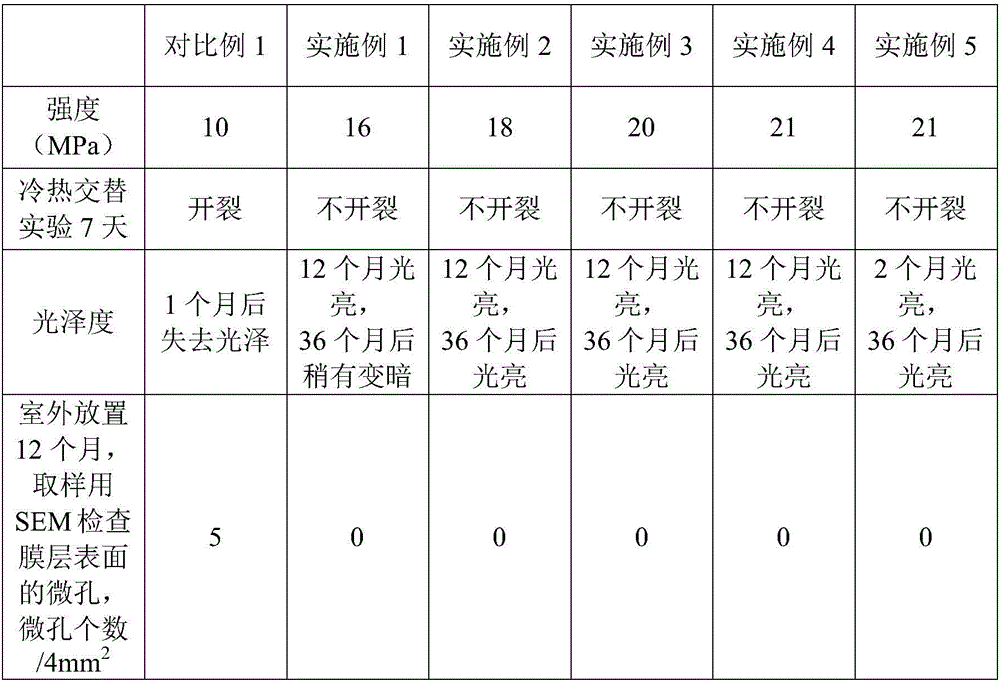

Examples

preparation example 1

[0093] The preparation of modified curing agent I (a):

[0094] Add 30 parts by weight of E-51 epoxy resin (epoxy equivalent of 185-190g / eq) dropwise to 20 parts by weight of 650 polyamide within 1.5h, control the reaction temperature at 50°C, and react for 2h to obtain the improved Sexual curing agent I(a).

preparation example 2

[0096] The preparation of modified curing agent I (b):

[0097] Add 35 parts by weight of E-51 epoxy resin dropwise to 23 parts by weight of V115 type polyamide within 1.5 hours, control the reaction temperature at 50°C, and react for 2 hours to obtain modified curing agent I(b).

preparation example 3

[0099] The preparation of modified curing agent I (c):

[0100] Add 30 parts by weight of E-51 epoxy resin dropwise to 18 parts by weight of 203 type polyamide within 1.5 hours, control the reaction temperature at 50°C, and react for 2 hours to obtain modified curing agent I(c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com